Automatic adhesive tape machine

A tape machine, automatic technology, applied in the field of tape machines, can solve the problems of heavy weight, high manufacturing cost, complex structure, etc., and achieve the effect of stable performance, reasonable structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

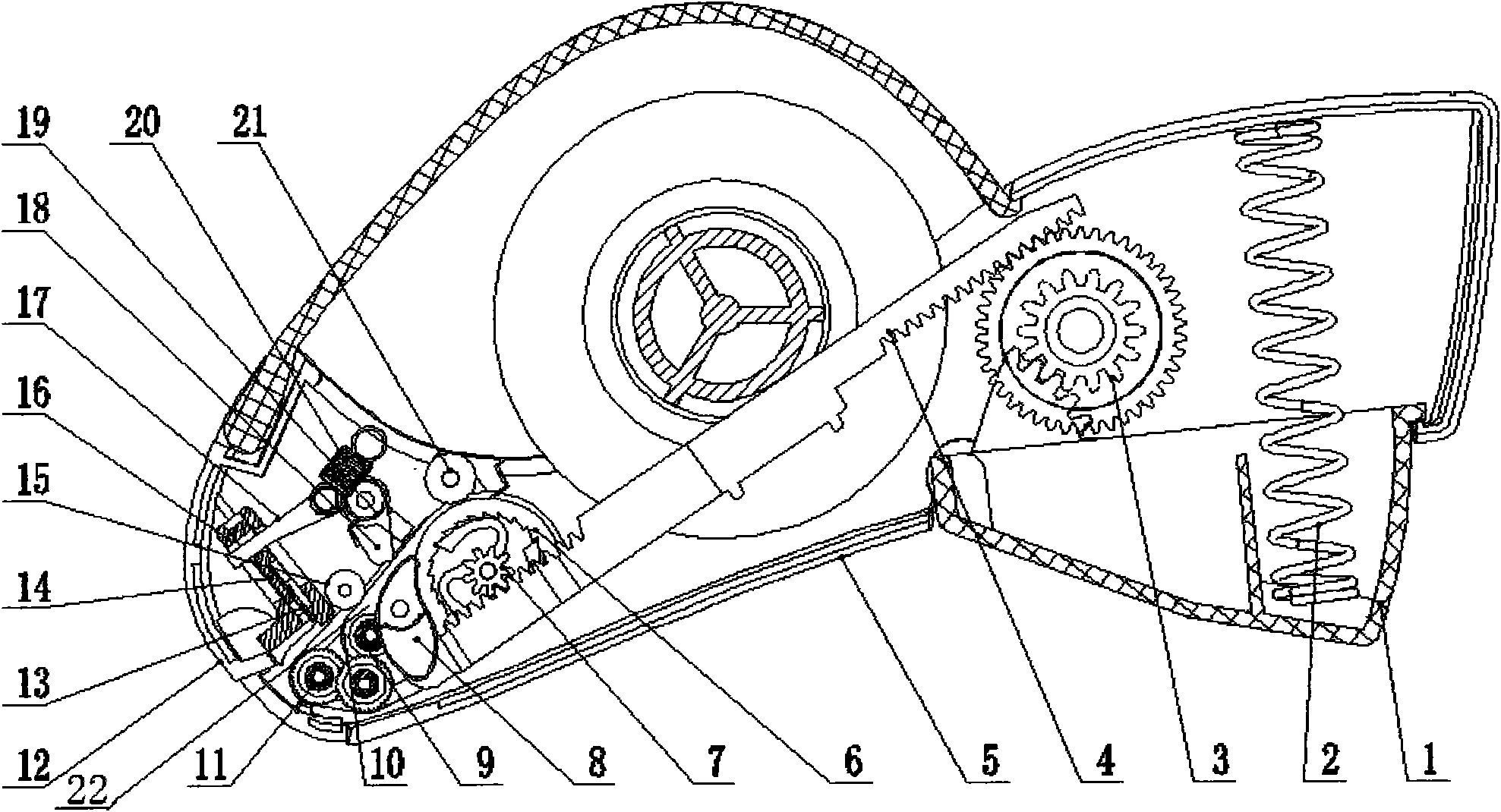

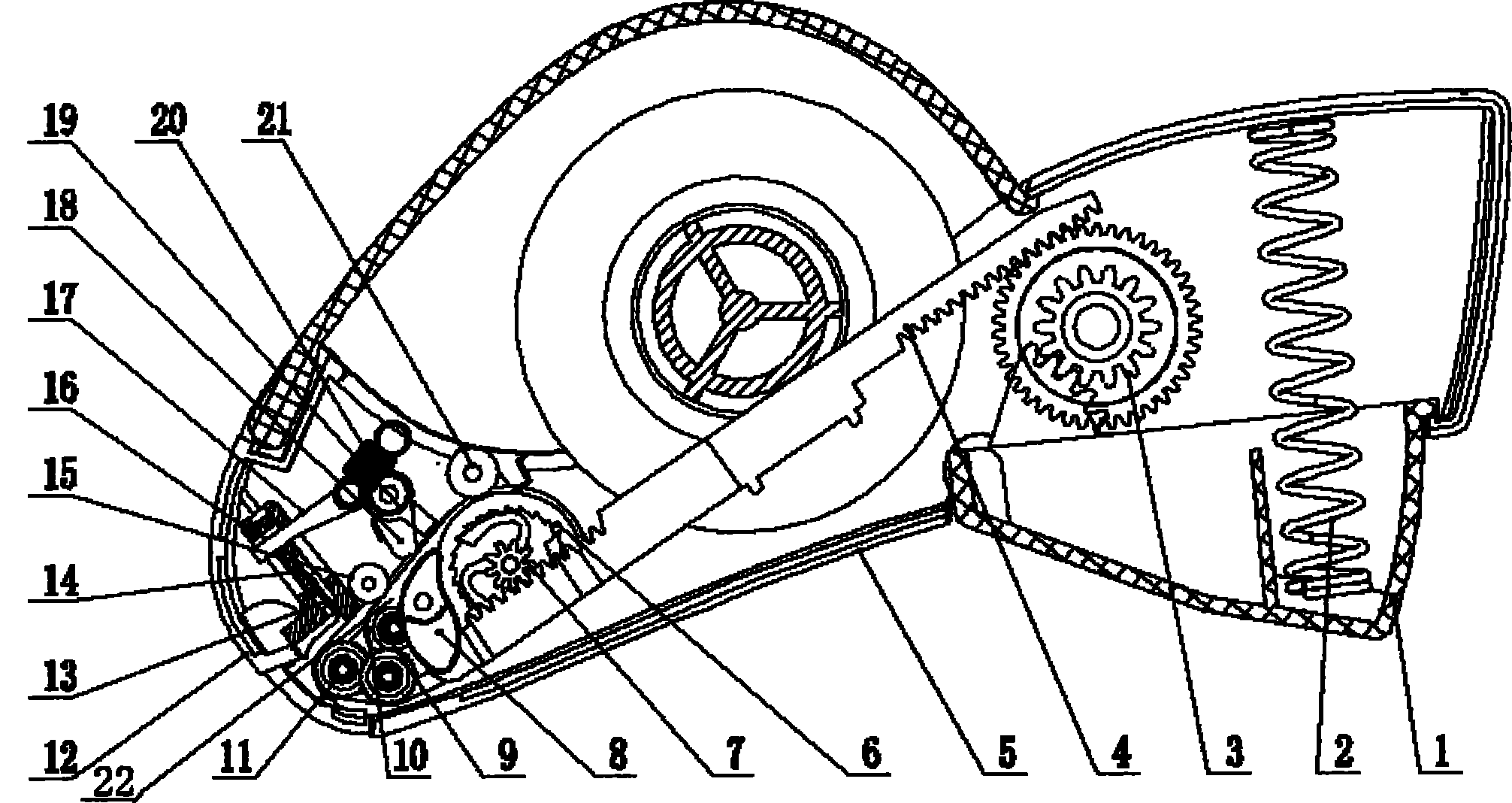

[0026] The automatic adhesive tape machine of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Automatic adhesive tape machine, such as figure 1 As shown, it includes a transmission conversion mechanism, a cutting mechanism, a transmission mechanism, a conveying mechanism and a cutting control mechanism. The transmission conversion mechanism and the cutting mechanism are arranged inside the upper shell 12, and the transmission mechanism, the conveying mechanism and the cutting control mechanism are arranged inside the lower casing 5; The transmission mechanism is composed of a key 1, a spring 2, a double tooth 3 and a rack 4. One end of the key 1 is connected to the lower casing 5 in a movable rotation, and the other end is supported by the spring 2. The fan-shaped teeth on the key 1 and the double tooth 3 The upper pinion meshes, the bull gear on the double teeth 3 meshes with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap