Method for selecting eccentric distance of rotational valve plate and double eccentric butterfly valve

A technology of eccentricity and rotary valves, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of inconvenient installation of valve plates, and achieve the effects of improving sealing performance, good sealing performance, and increasing torque pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

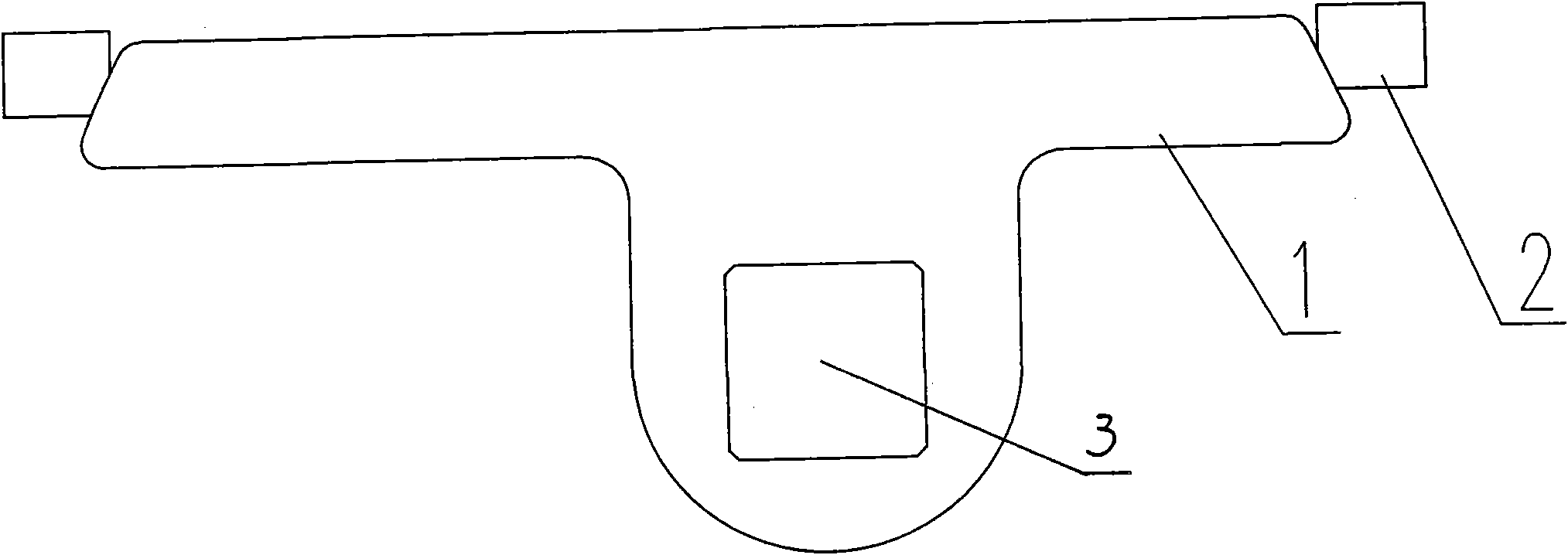

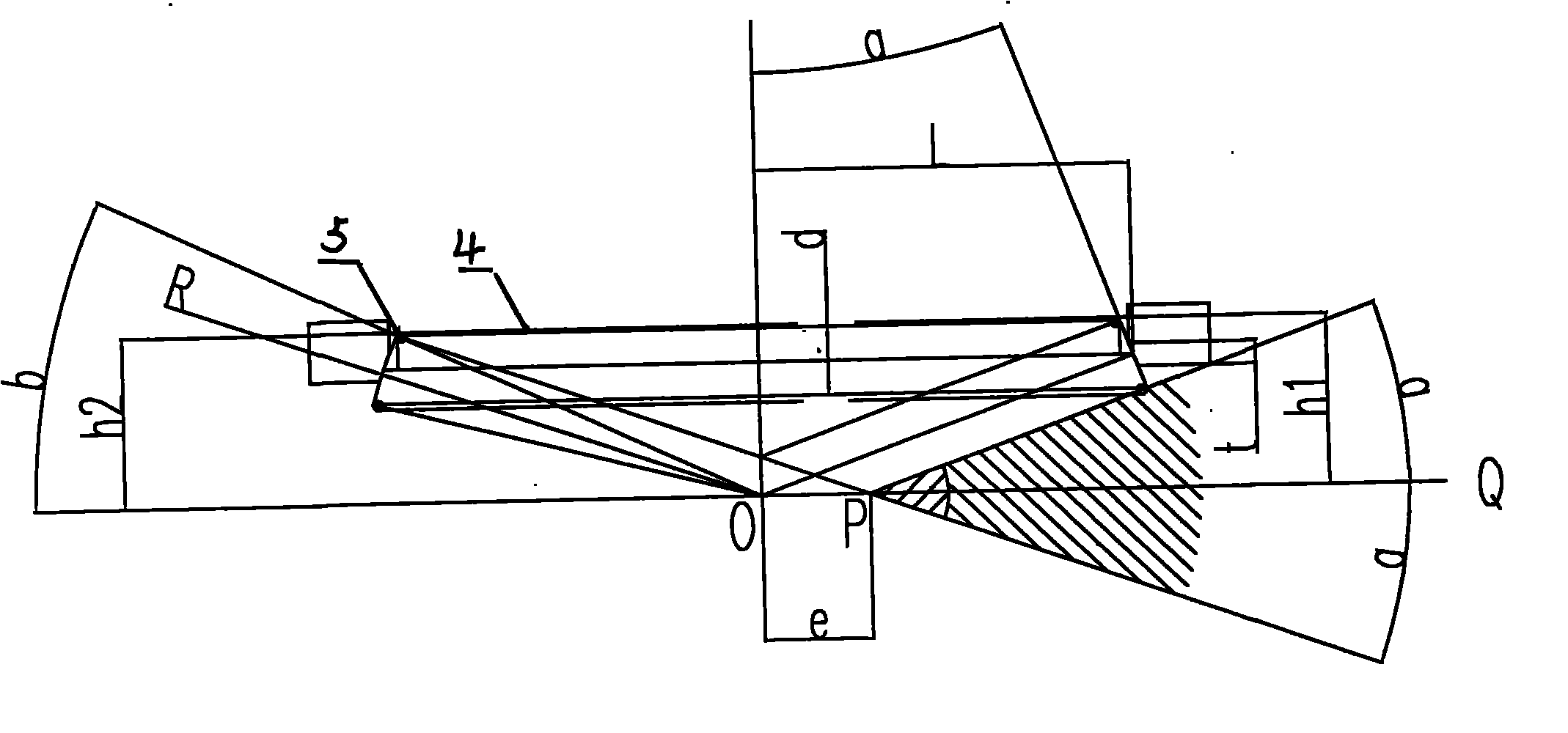

[0028] Example 1 (Determining the eccentricity by mapping method): see figure 1 , 2 , The basic structure of butterfly valve is composed of valve plate 1, valve seat 2 and rotating shaft 3. The valve plate rotation valve eccentric distance selection area of the present invention: take the diameter of the circular valve plate 1 perpendicular to the rotating shaft 3 to obtain the valve plate section 4, and the four vertices 5 on the left and right ends of the section 4 form an isosceles trapezoid , From the diagonal of the trapezoid as the vertical line of the waist to obtain the intersection point P, the intersection of the area above the vertical line of the upper angle and the area below the vertical line of the lower angle of the section-the shaded part (within the 2a angle), which is the rotation The range of the selected point of the axis eccentricity. The intersection point P of the two vertical lines is the minimum eccentricity e. Point O in the figure is the intersect...

Embodiment 2

[0031] Example 2 (determining the eccentricity by formula method): Set the butterfly valve diameter to be 3 inches (φ80mm), and the cone surface is sealed, then L=40mm, the thickness d of the valve plate sealing surface is 5.5mm, and the four vertices of the trapezoid are rounded to 1.5 mm (rounding can prevent the valve plate from scratching the valve ring), the trapezoid half-cone angle a is 25°. Calculated according to the aforementioned formula: left and right eccentricity e=5.5 / sin50=7.18mm (consistent with the drawing method): front and rear eccentricity h 1 =40*tga25+5.5 / 2+1.5*(1-sin25)=22.27mm.

Embodiment 3

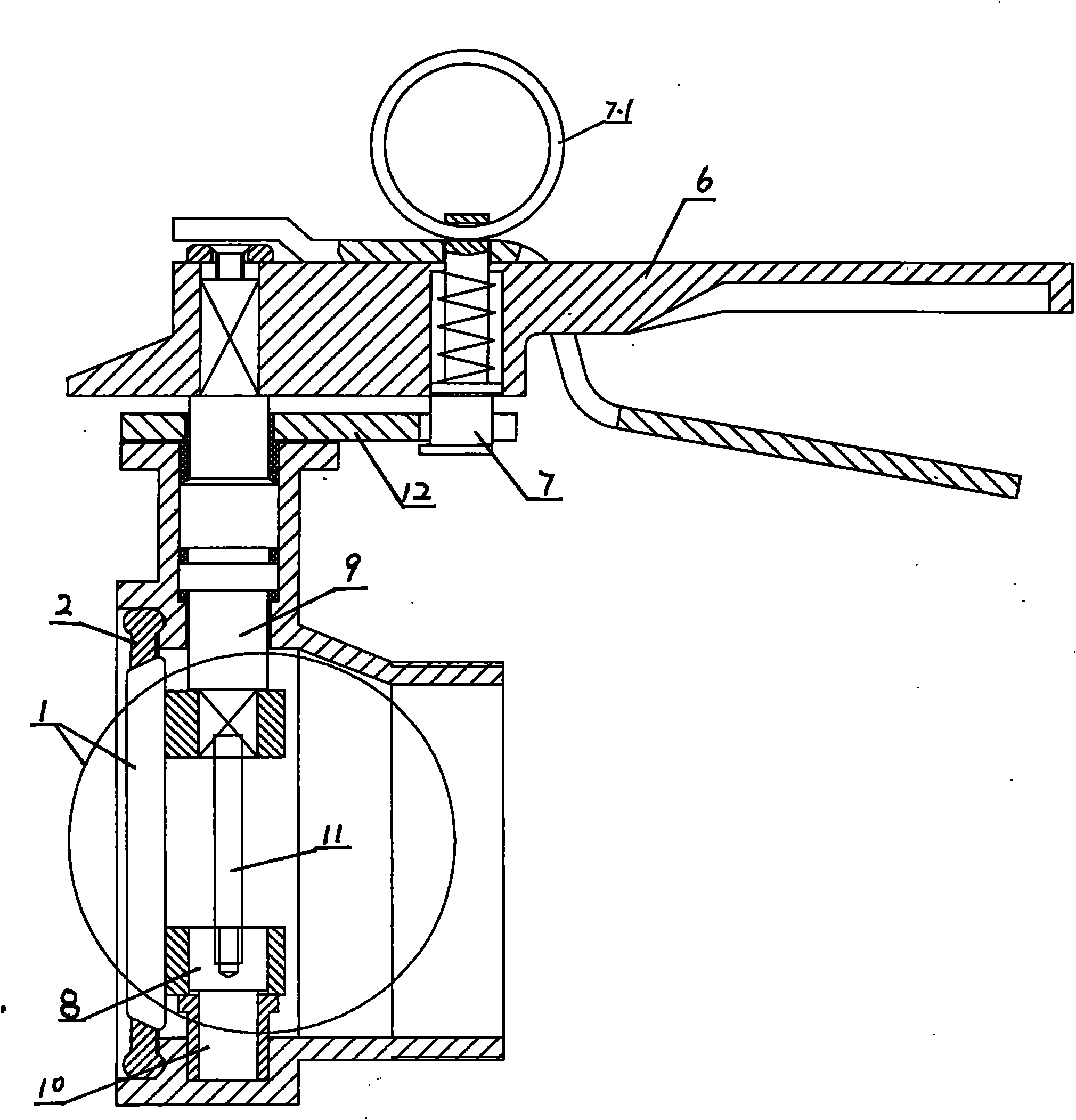

[0032] Example 3: See image 3 , As in Example 1, the valve plate rotating handle 6 closes the locking pin 7 to form an eccentric structure (which becomes an eccentric pin shaft), with a rotating / plugging ring 7.1 at the upper end. The valve plate is closed, the eccentric pin 7 is inserted and rotated, and the eccentric structure of the pin generates a torque thrust to push the handle, so that the valve plate is pressed against the valve ring, thereby preventing leakage.

[0033] For large-diameter butterfly valves, the rotating shaft can be driven by a motor-driven turbine / worm headstock. The self-locking effect of the turbine / worm rod ensures that the valve plate is tightly closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com