Service mannequin pressure test system

A clothing man table, pressure testing technology, applied in the direction of measuring fluid pressure, simultaneous measurement of multiple hydraulic valves, measuring devices, etc., can solve the problems of high cost, clothing deformation, time-consuming testing, etc., and achieves convenient operation, simple mechanism, and economical Effects of cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

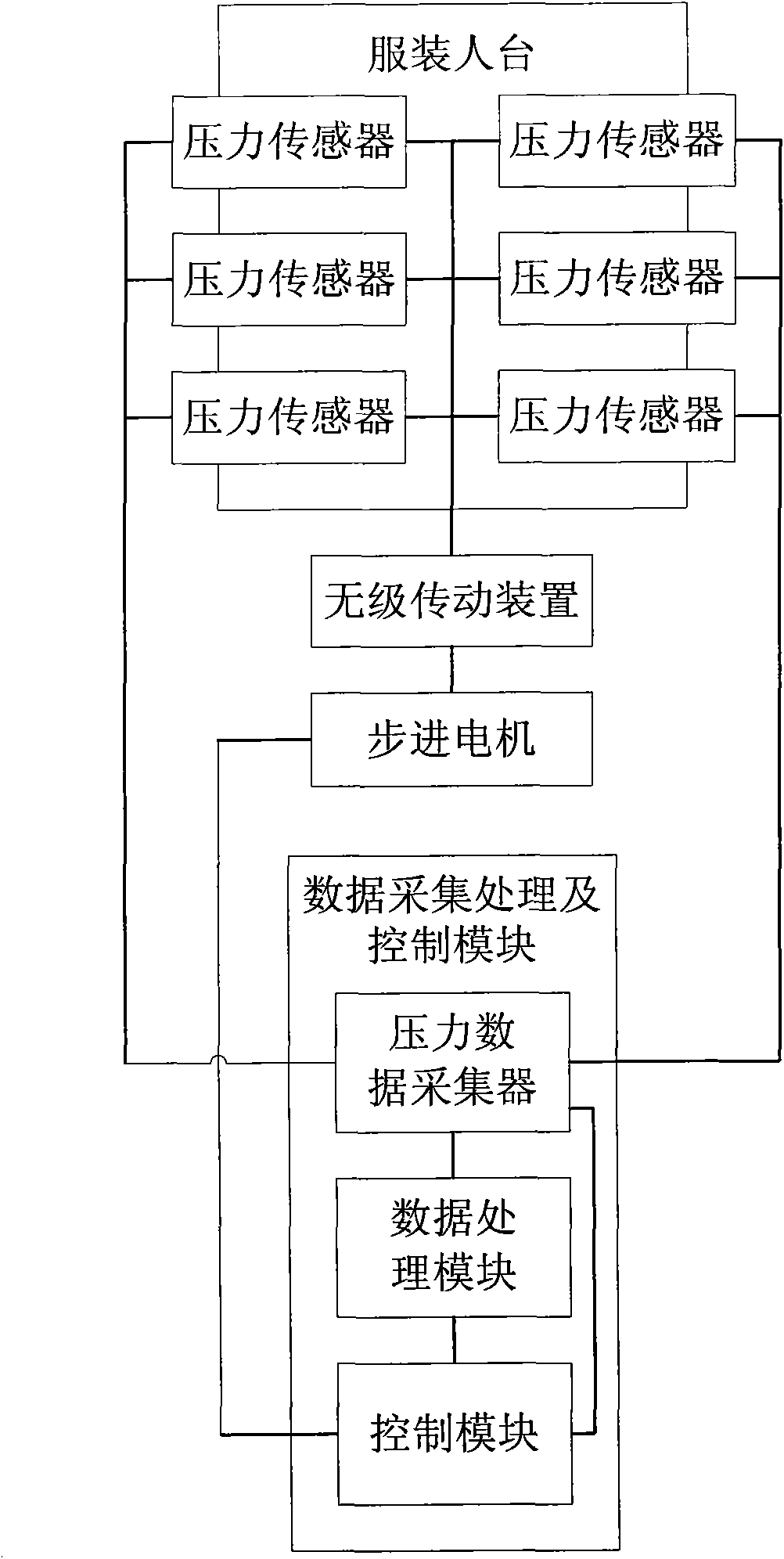

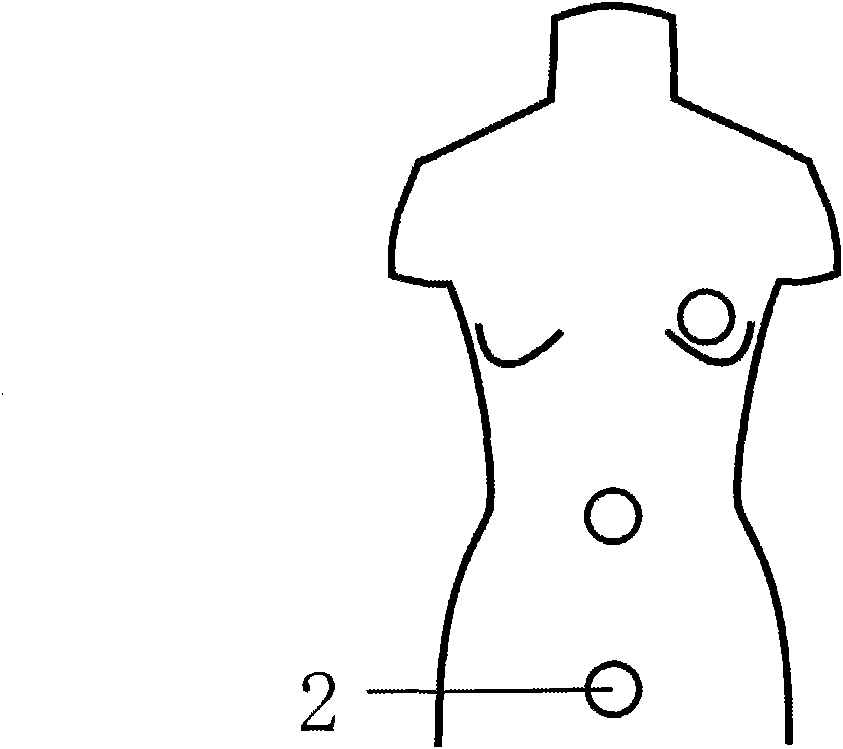

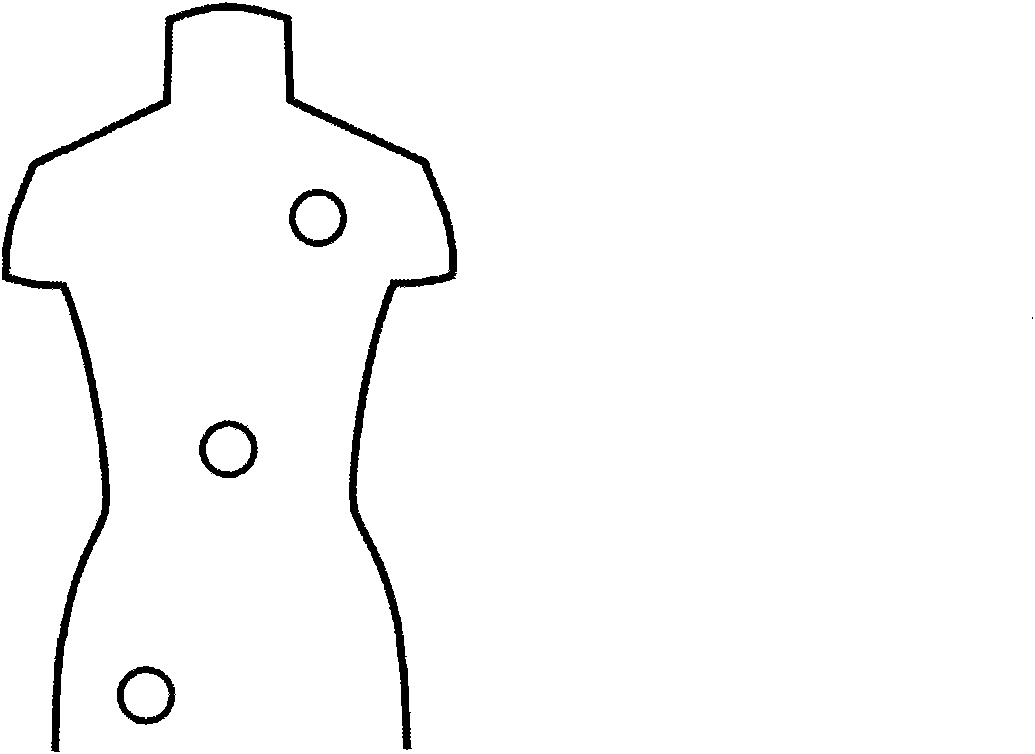

[0021] The invention relates to a clothing mannequin pressure testing system, which is a testing system capable of simultaneously testing the pressure of multiple different parts of clothing distributed on the mannequin, and is used for measuring and evaluating the pressure performance of clothing. High-precision pressure sensors are pre-embedded in multiple parts of the mannequin. The height and speed of the pressure sensor protruding from the human body surface can be adjusted through a stepless transmission device. The pressure data collector is connected with the pressure sensor, which is processed by the corresponding program in the computer. The module displays, records and stores pressure values.

[0022] Pre-buried high-precision pressure sensors in multiple parts of the mannequin, the pressure data collector is connected with the pressure sensors, and the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com