Repair of heating walls in a refractory furnace

A technology for heating walls and refractory bricks, used in lighting and heating equipment, furnaces, lining repair, etc., can solve labor-intensive, expensive, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

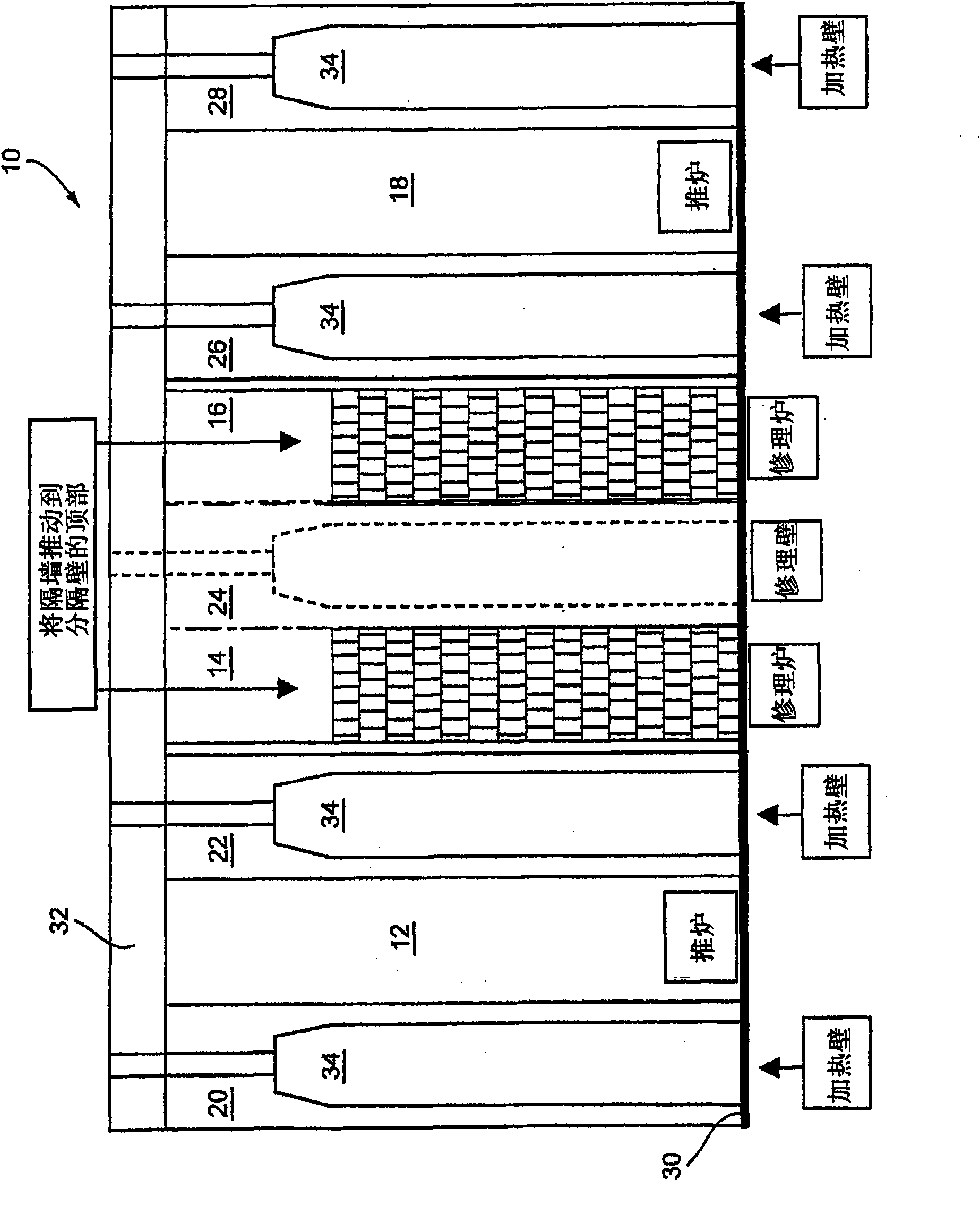

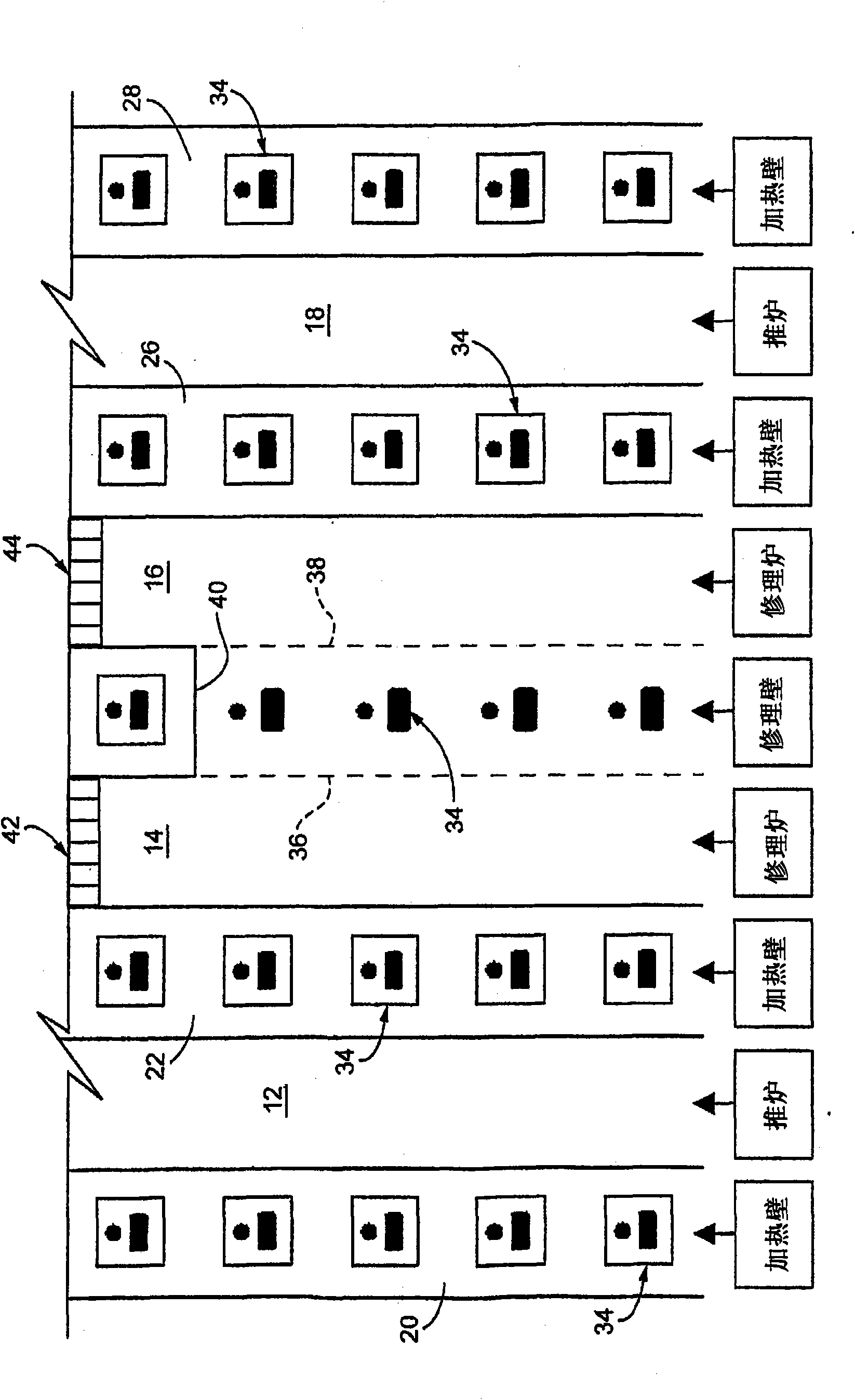

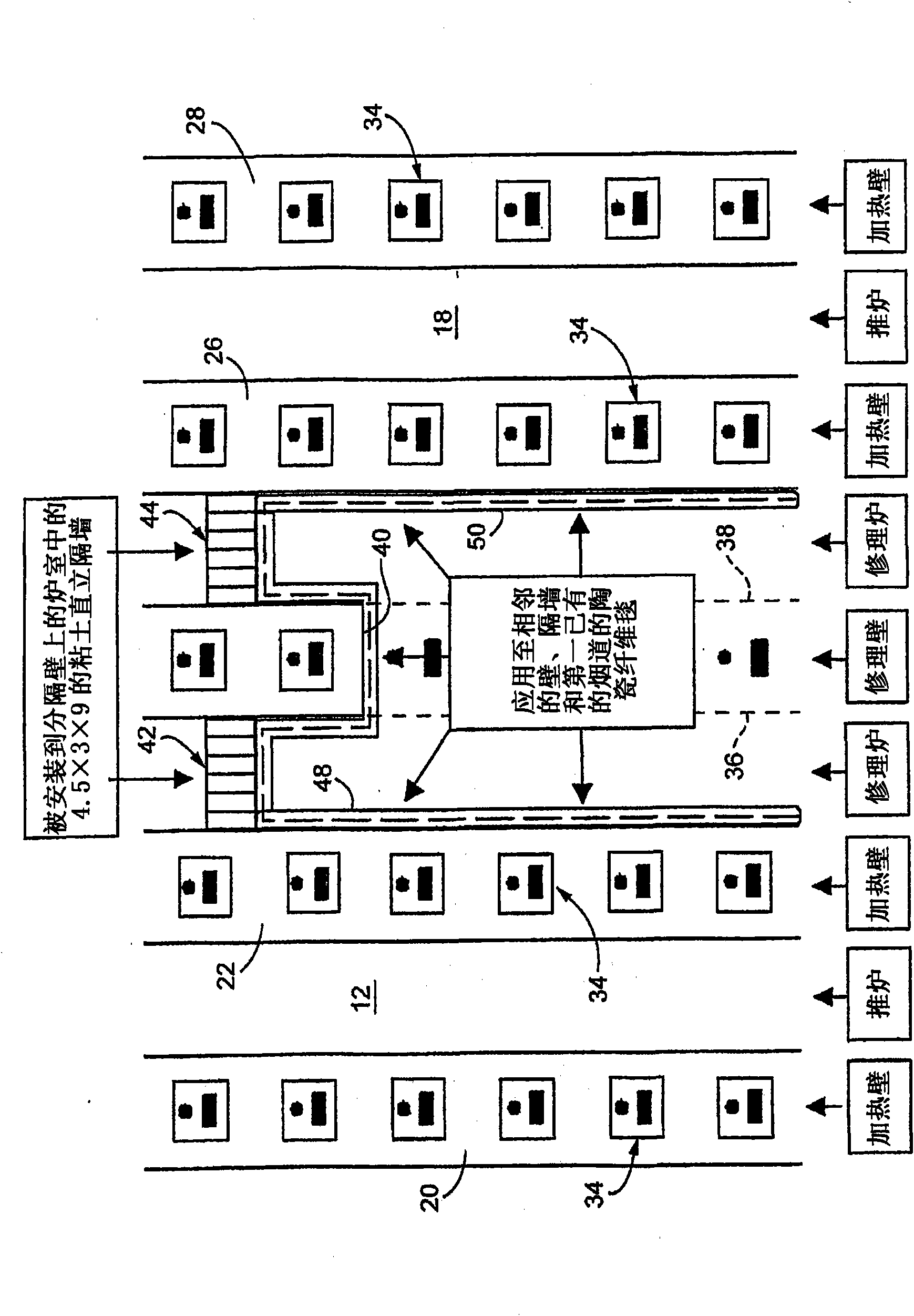

[0040] first reference figure 1 and 2 , showing a section 10 of a larger coke oven comprising a series or more substantially parallel side-by-side heating chambers or coke ovens 12, 14, 16 and 18, which are heated by walls 20, 22, 24, 26 and 28 apart. The base or bracket area is indicated by reference numeral 30, it being understood that the construction of the base is more complex than shown here. A top plate 32 extends across the top of the heating wall. It should also be understood that only a small portion of a coke oven is shown in the drawings for ease of understanding of the present disclosure, and only in a somewhat simplified manner.

[0041] exist figure 1 and 2 , each heating wall is shown to include a plurality of vertically oriented flues 34 in the interior of the wall. There may also be additional passages formed in the heating wall (eg horizontal flue sections, horizontal or vertical ducts, etc.), all covered by the term "flue", "vent" or "other passage". ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com