Method for accurately controlling residue alkalinity of tundish in continuous-casting steel pouring process

A precise control, tundish technology, applied in the field of steelmaking, can solve the problem of reducing the ability to absorb inclusions, affecting the composition and quality of molten steel, and reducing the number of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution is to add a certain amount of small-grained white ash to the tundish steel surface at the same time as the covering agent is put into the molten steel pouring process in the continuous casting process, so as to achieve the purpose of accurately controlling the alkalinity of the tundish slag.

[0013] Take the process of producing ultra-low carbon steel in a 180-ton steel ladle and a 50-ton tundish as an example:

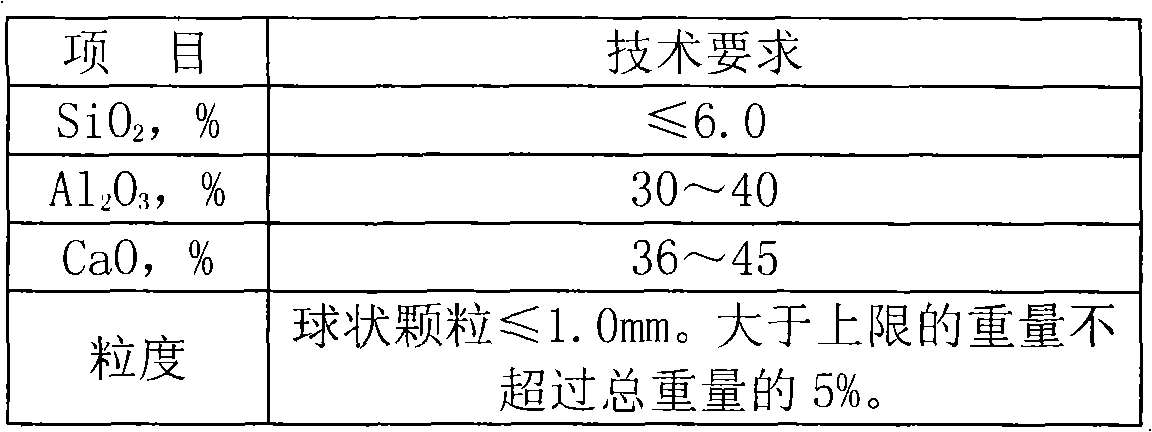

[0014] Small-grain white ash technical conditions:

[0015] project

skills requirement

SiO 2 ,%

≤2.0

CaO, %

≥85.0

Granularity, mm

8~20

[0016] Covering agent technical conditions:

[0017]

[0018] 1) By sampling and analyzing the tundish slag, the changes of ultra-low carbon steel tundish slag are obtained as follows:

[0019] Can times

Adding amount of covering agent, t

first can

2.43

600

second can

2.35

200

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com