Novel press screw rod locking mechanism

A locking mechanism and press technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of uneven load distribution on the side of the thread, easy damage to the screw and connecting rod threads, poor interchangeability, etc. The effect of uniform force distribution, good interchangeability and uniform joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

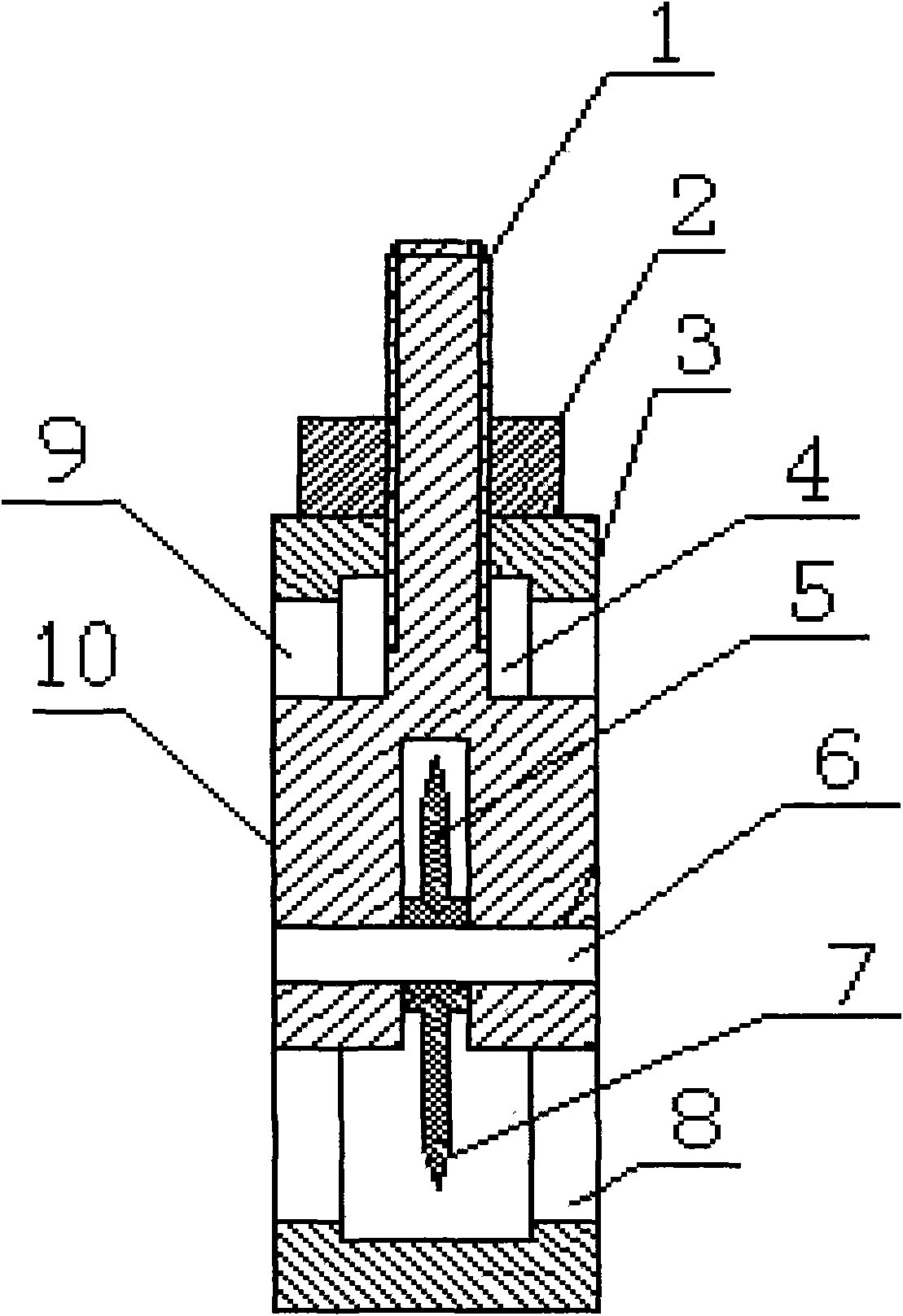

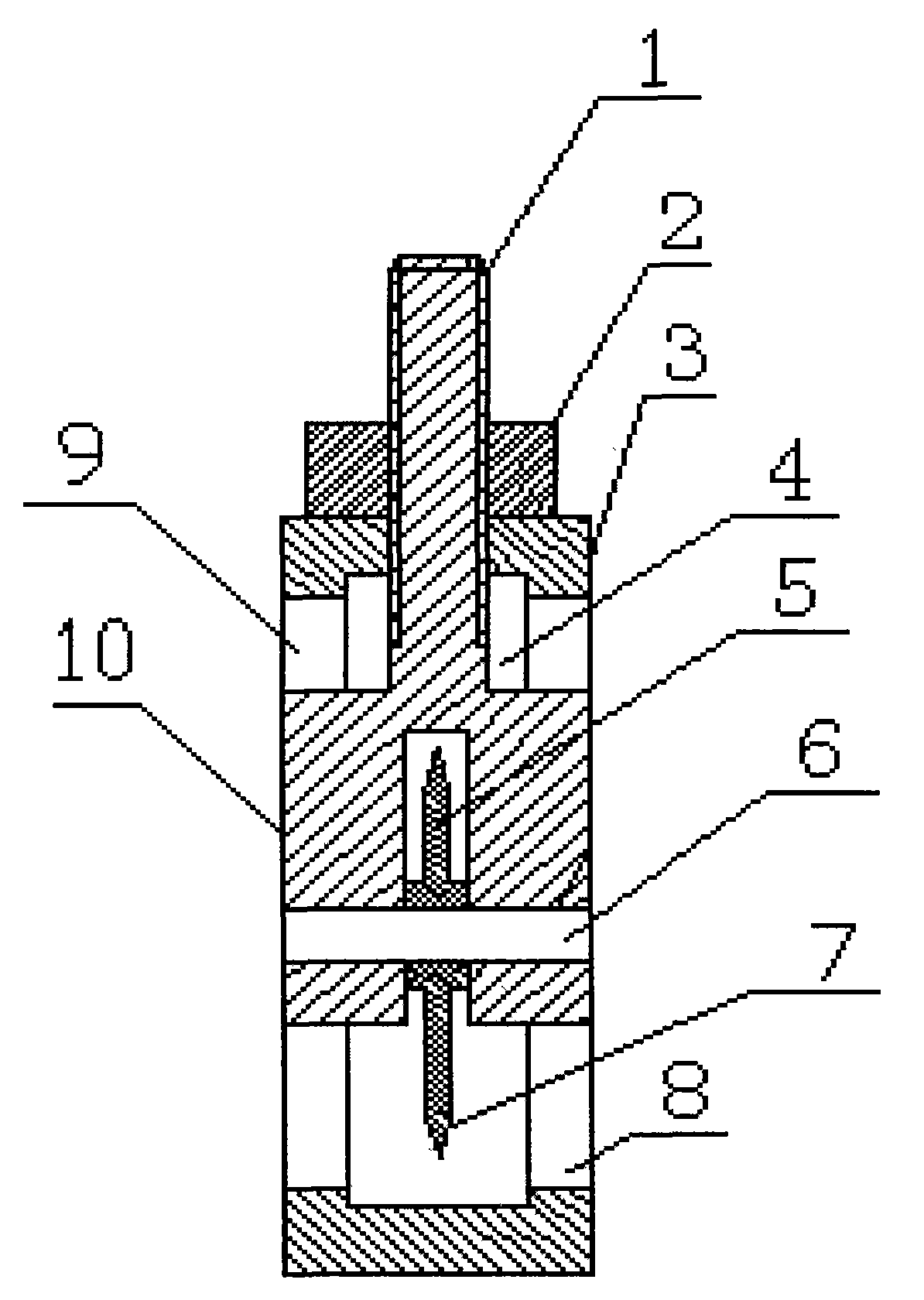

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

[0009] The outer locking device (3) and the connecting rod (1) are fixed to one end of the connecting rod (1) through the internal and external threads, and the middle part of the inner locking device (4) and the outer locking device (3) is processed with the connecting rod (1) ) in the middle part of the internal thread of the same specification is composed of a fixing plate (2), an upper screw mandrel (5), a lower screw mandrel (7) and a pressing plate (6) and is fixed with screws, combined with a lower screw mandrel fixing plate (8) and The upper screw fixing plate (9) forms an integral locking body (10), and the inner thread of the locking device (4) can be screwed into the inner thread of the connecting rod (1), so that the inner lock can be loosened. The tightening device (4) can adjust the upper screw mandrel (5) and the lower screw mandrel (7), and tightening t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap