Dampening device of lithographic machine

A technology of printing presses and lithography, applied in the direction of lithographic rotary printing machines, printing machines, rotary printing machines, etc., can solve the problems of increasing the cost of printing enterprises, and achieve the effect of reducing the adhesion of paper powder and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

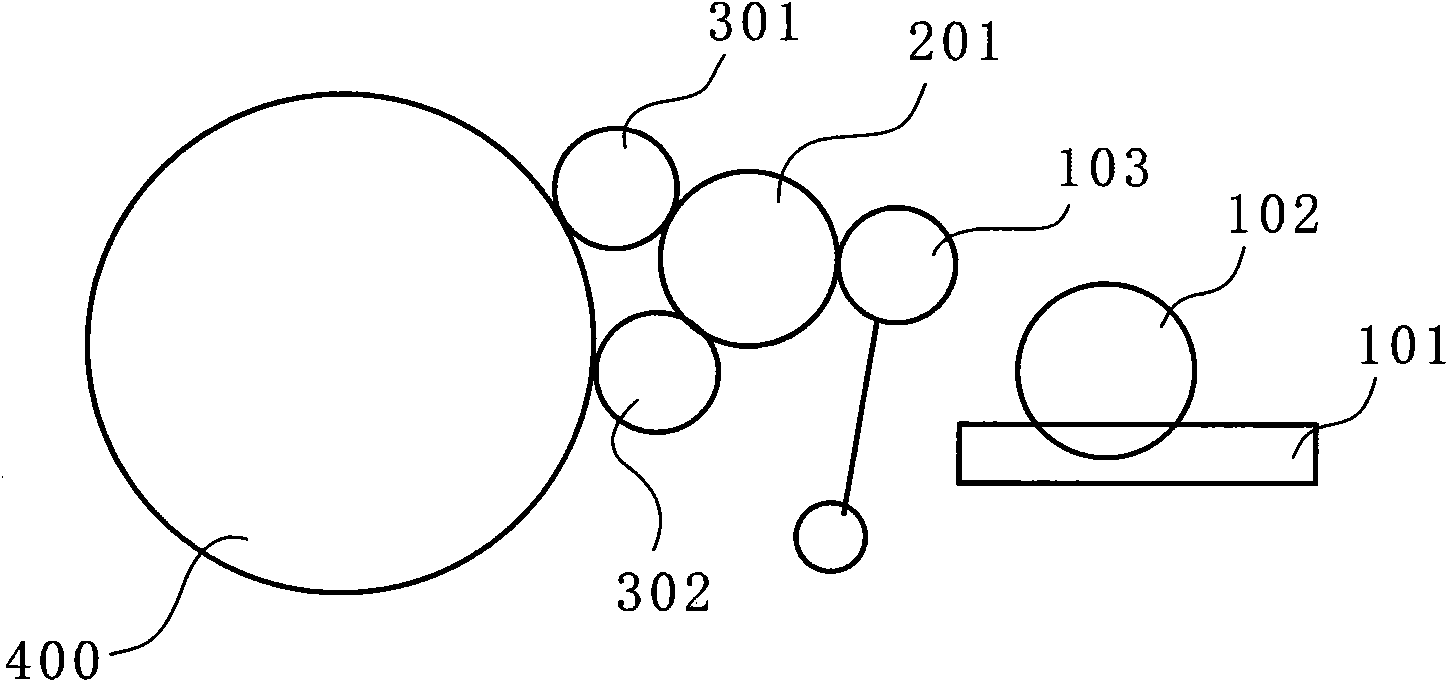

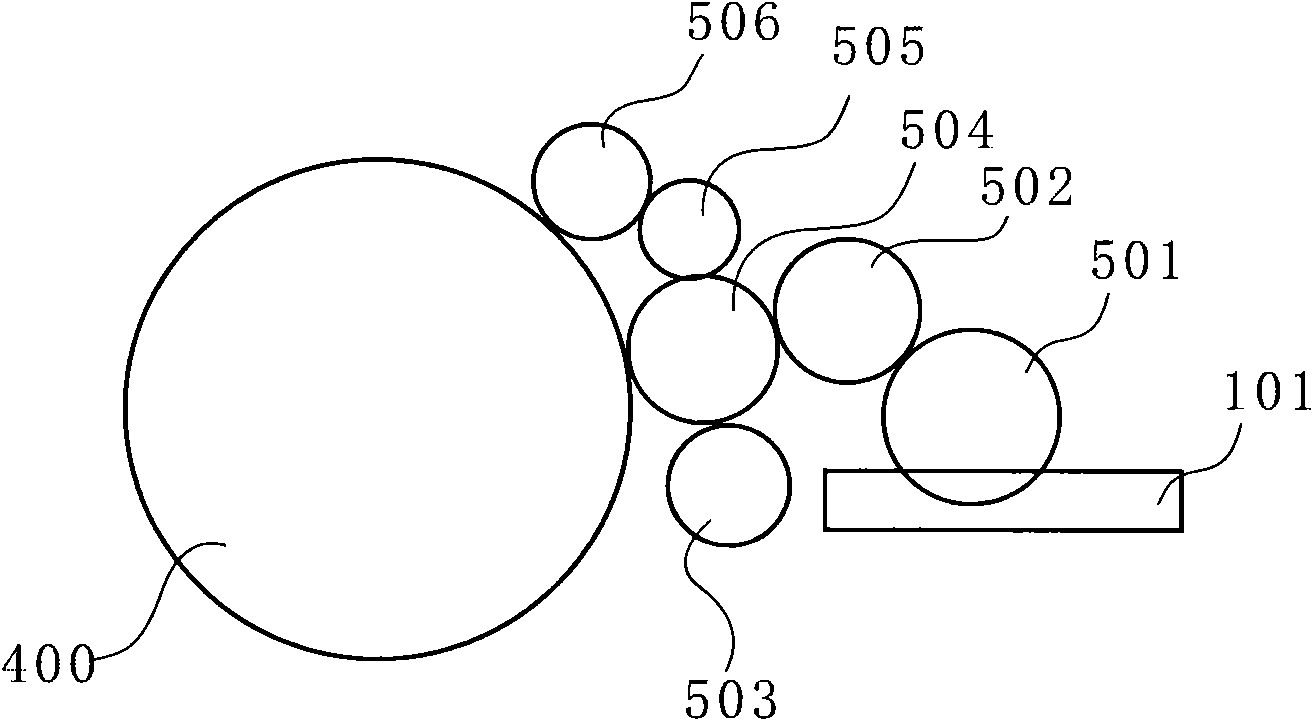

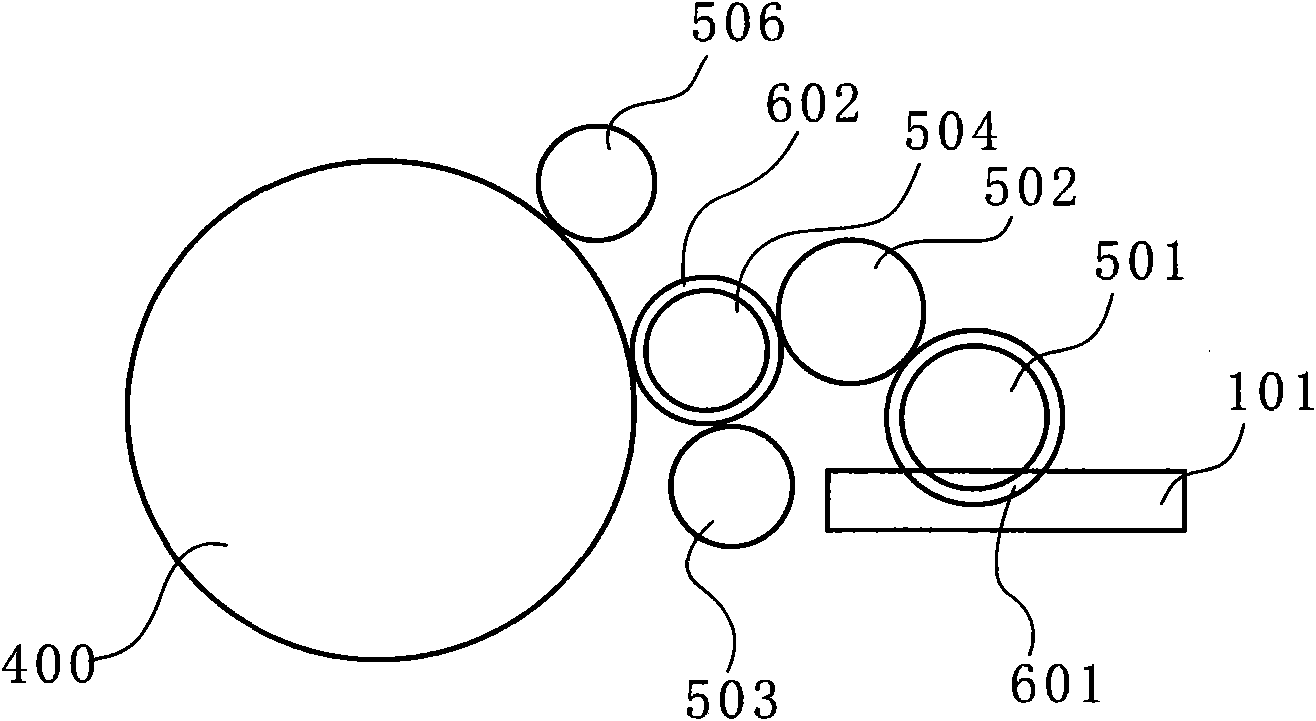

[0017] Such as figure 1 As shown, the dampening device of the lithographic printing machine of the present invention is an improvement on the alcohol dampening device, and the improvement is to remove the intermediate roller, and put the water wool cover 601 on the bucket roller 501 and the water roller 504 , 602. The specific method is to select a water bucket roll with a diameter 4.5mm smaller than that of the alcohol dampening device, and then put on a 140-pin water fleece sleeve 601, and select a water roll with a diameter smaller than that of the alcohol dampening device. The little 4.5mm impingement roller of diameter, and put on it the velvet cover 602 of 126 needles.

[0018] Putting the water fleece cover 601 on the water bucket roller 501 can make the water dampening solution pass from the water bucket 101 to the metering roller 502 smoothly, and putting the water fleece cover 602 on the water roll 504 can transfer the water on the printing plate The paper powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com