Preparation method of micro-arc oxidation film layer under effect of magnetic field

A technology of micro-arc oxidation and magnetic field, applied in the preparation of micro-arc oxidation film under the action of magnetic field, the field of preparation of oxide film, can solve the problem of increasing tolerance polarization, decreasing film growth rate, decreasing anion concentration, etc. problems, to achieve the effect of improving the performance of the film, improving the appearance, and increasing the growth rate of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the micro-arc oxidation film layer under the action of the magnetic field of the present invention is specifically implemented according to the following steps:

[0024] Step 1: decontaminate and degrease the surface of workpiece 3;

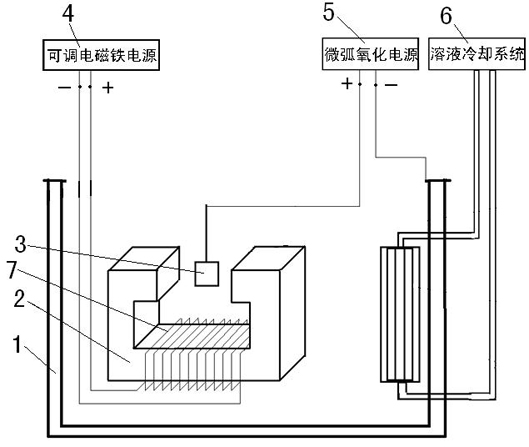

[0025] Step 2: using a magnetic field oxidation device, the structure of the magnetic field oxidation device is as follows figure 1 As shown, it includes an oxidation tank 1, an oxidation solution is placed in the oxidation tank 1, a micro-arc oxidation power supply 5 is connected to the oxidation tank 1, an iron core 2 is arranged in the oxidation tank 1, a coil 7 is wound on the iron core 2, and a coil 7 An adjustable electromagnet power supply 4 is connected to the top, and a solution cooling system 6 is arranged on one side of the oxidation tank 1. The processed workpiece 3 obtained in step 1 is placed between the two poles of the iron core 2, and the workpiece 3 and the micro-arc oxidation power supply 5 Con...

Embodiment 1

[0034] Step 1: Decontaminate and degrease the surface of ZM5100×60×5mm workpiece;

[0035] Step 2: using a magnetic field oxidation device, the structure of the magnetic field oxidation device is as follows figure 1 As shown, including the oxidation tank 1, the oxidation tank 1 is equipped with an oxidation solution, and its composition is 5g / lNa 2 SiO 3 , the oxidation tank 1 is connected with a micro-arc oxidation power supply 5, the oxidation tank 1 is provided with an iron core 2, the iron core 2 is wound with a coil 7, and the coil 7 is connected with an adjustable electromagnet power supply 4, one side of the oxidation tank 1 A solution cooling system 6 is provided, the processed workpiece 3 obtained in step 1 is placed between the two poles of the electromagnet, the workpiece is connected to the positive pole, and the oxidation tank is connected to the negative pole, the magnetic induction intensity is set to 2500Gs, the micro-arc oxidation frequency is 500Hz, and the ...

Embodiment 2

[0037] Step 1: Decontaminate and degrease the surface of LY1280×60×5mm workpiece;

[0038] Step 2: using a magnetic field oxidation device, the structure of the magnetic field oxidation device is as follows figure 1 As shown, including the oxidation tank 1, there is an oxidation solution in the oxidation tank 1, and its composition is: 3g / lNa 2 SiO 3 +2g / lNaAlO 2 +0.6g / lNa 2 B 4 o 7 +0.01g / lLaCl 3 , the oxidation tank 1 is connected with a micro-arc oxidation power supply 5, the oxidation tank 1 is provided with an iron core 2, the iron core 2 is wound with a coil 7, and the coil 7 is connected with an adjustable electromagnet power supply 4, one side of the oxidation tank 1 A solution cooling system 6 is provided, the processed workpiece 3 obtained in step 1 is placed between the two poles of the electromagnet, the workpiece is connected to the positive pole, the oxidation tank is connected to the negative pole, the magnetic induction intensity is set to 500Gs, the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com