Top-close draft type range hood

The technology of a range hood and a case is applied in the direction of removing range hood, heating method, household heating, etc., which can solve the problems of incomplete smoking, easy to touch the head, easy to touch the operator's head, etc., so as to improve the smoking effect and have a simple structure. , The appearance of the product is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

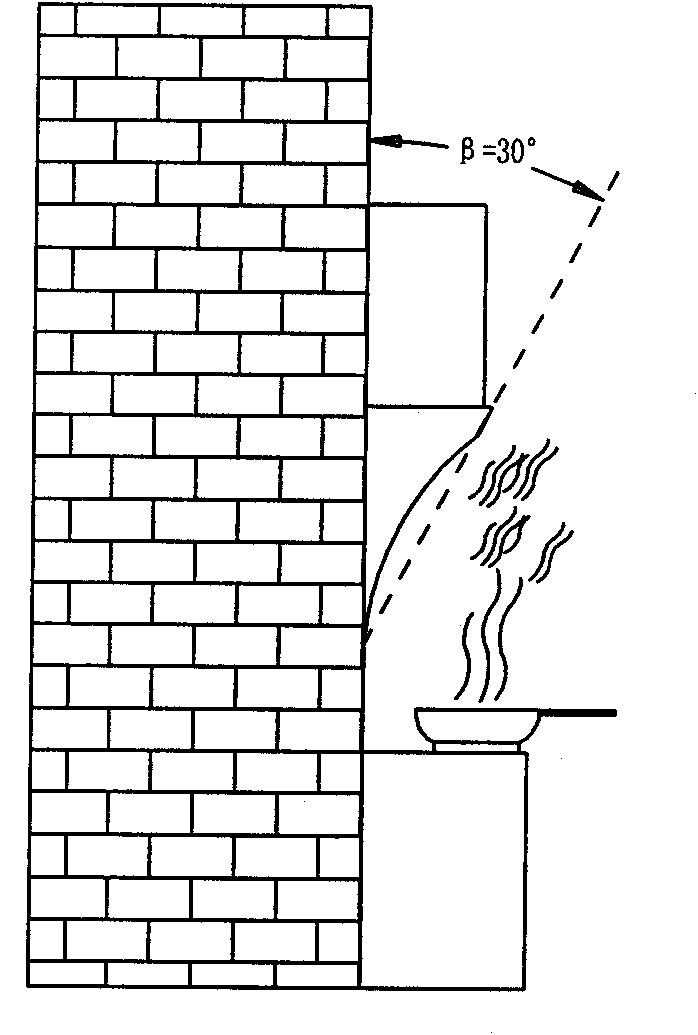

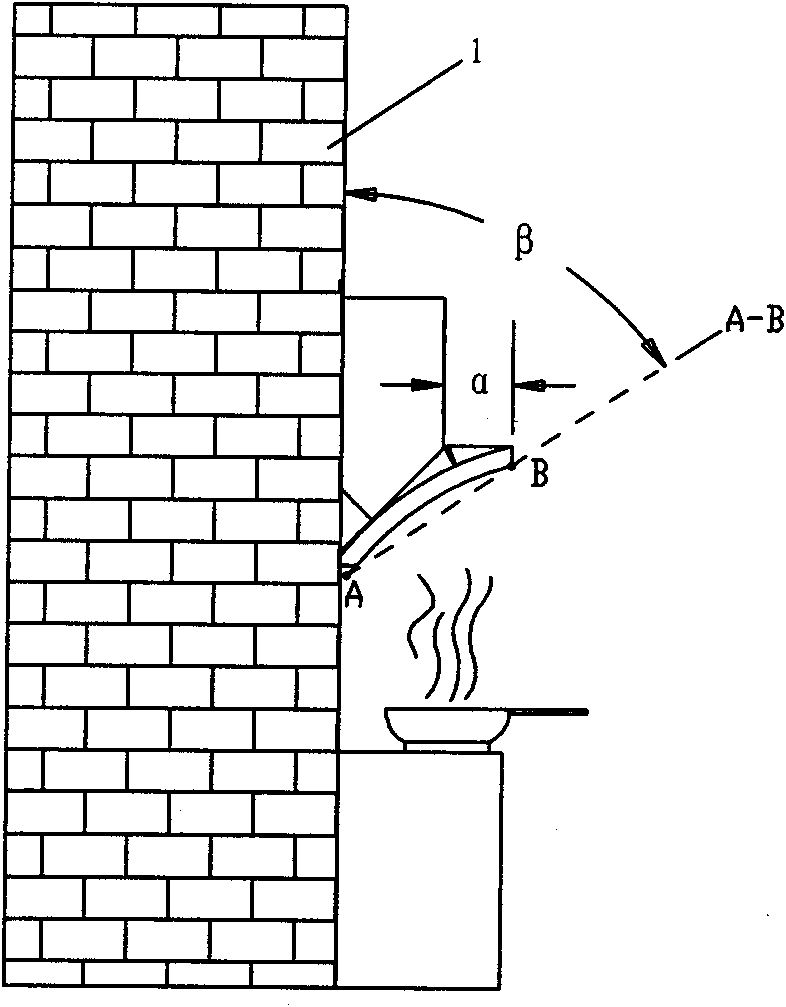

[0020] Such as Figure 3 to Figure 5 Shown is a top-close range hood, which includes a cabinet 2 installed on a wall 1 and a smoke collection hood 3 connected to the bottom of the cabinet 2 in an oblique shape. The cabinet 2 has front and rear end surfaces 201 and 202. The smoke hood 3 is provided with a smoke collection panel 4, and the smoke collection panel 4 is provided with a smoking port 401. The smoke collection panel 4 extends out of the chassis 2 along the bottom A of the rear end surface 202 of the chassis 2 from bottom to top in a concave arc shape. The front end face 201, the distance α between the extension end B of the arc-shaped smoke collecting panel 4 and the front end face 201 of the chassis 2 is about 170mm-180mm, and the starting and ending ends of the arc-shaped smoke collecting panel 4 are connected by a virtual straight line The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com