Temperature control method for heating apparatus

A temperature control method and technology for heating equipment, which are used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as emission current runaway and failure, and achieve stable temperature control.

Active Publication Date: 2010-09-29

CANON ANELVA CORP

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0018] As described above, the temperature control method in Japanese Patent No. 3866685 suffers from failure in stably controlling the heater temperature due to runaway emission current at heater temperatures of 2000°C or higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

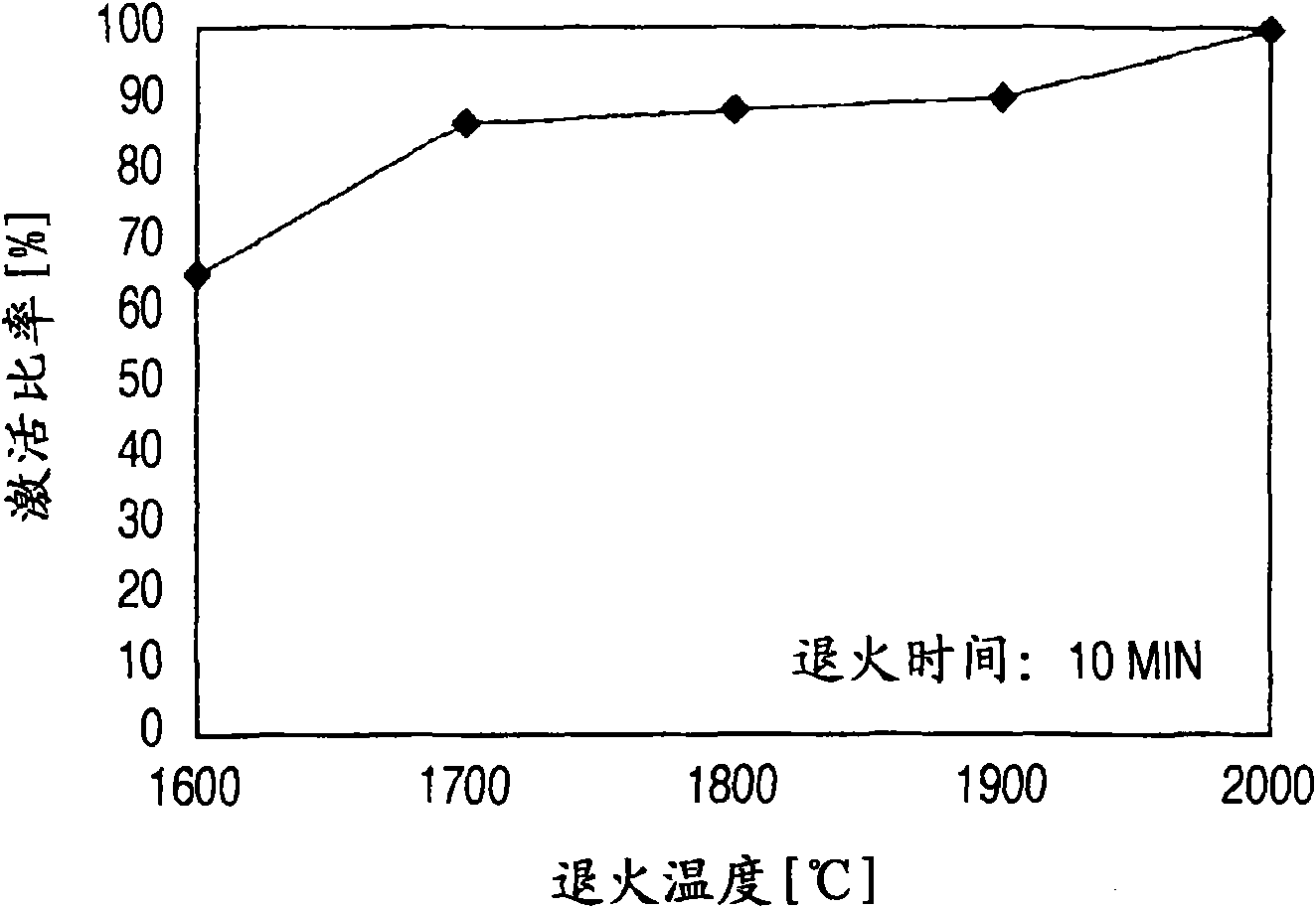

[0075] The present invention will be described in more detail below by giving examples. However, the present invention is not limited to the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

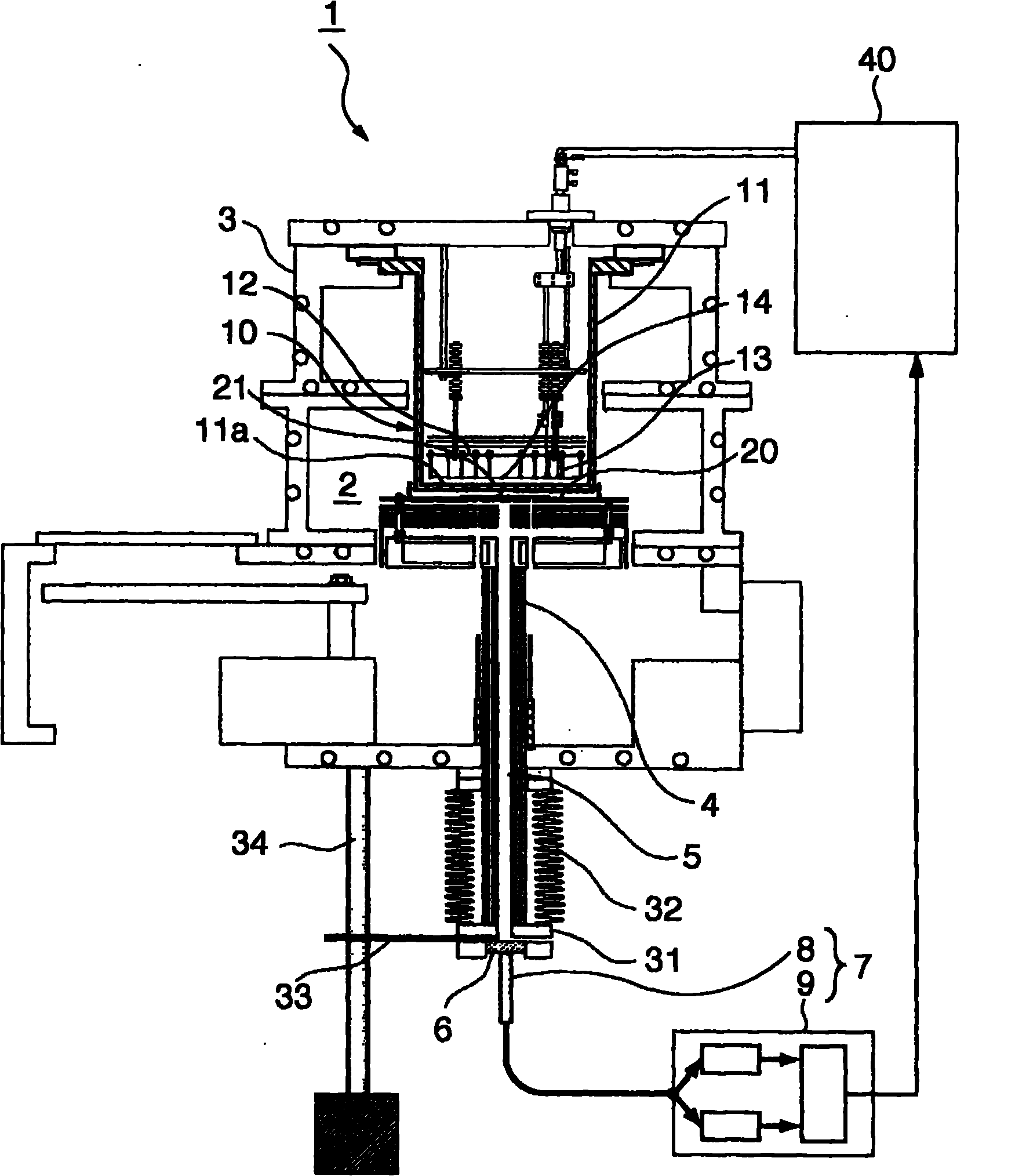

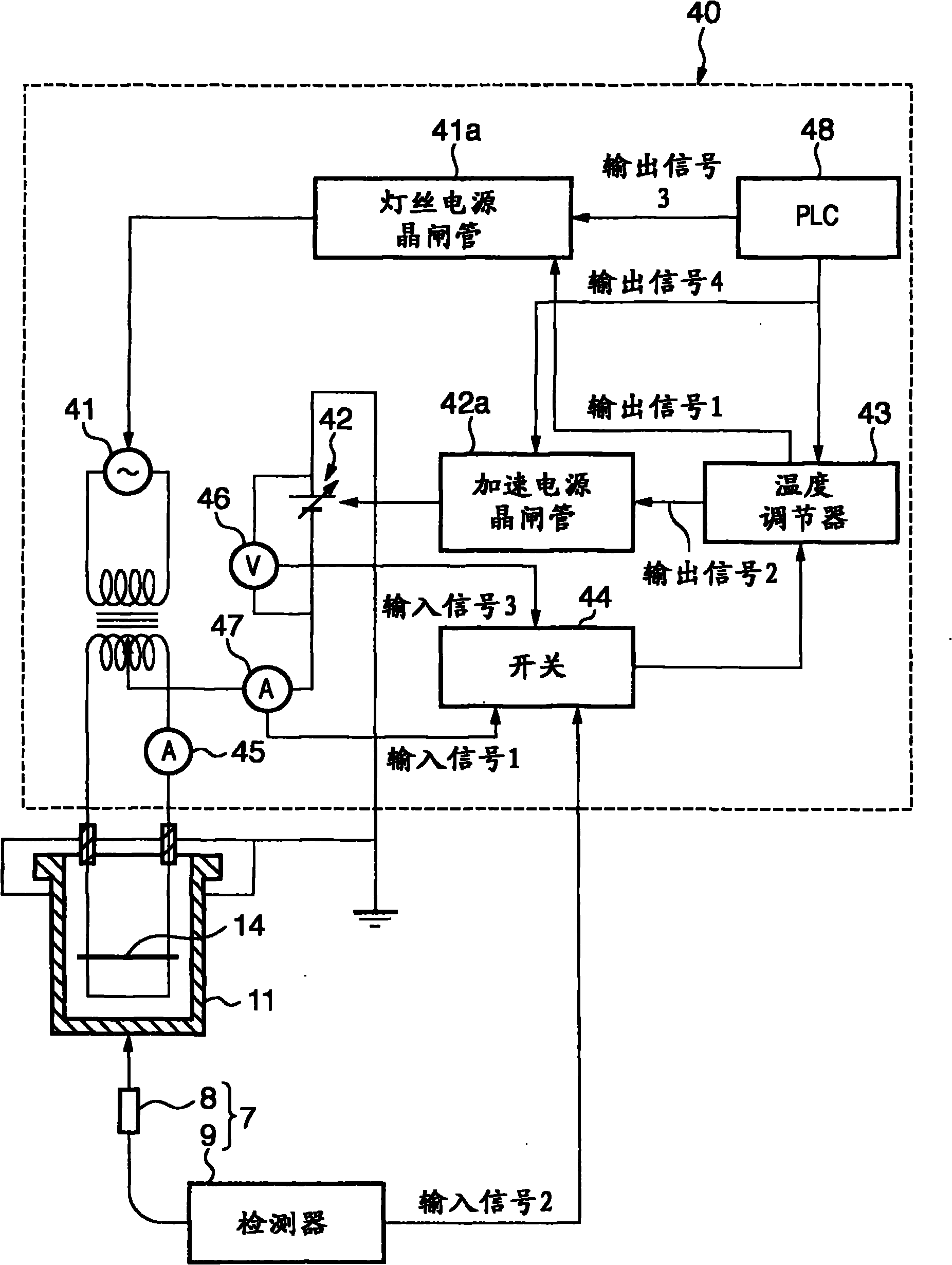

A temperature control method for a heating apparatus including a chamber which can be evacuated and has a conductive portion, a filament which is positioned in the chamber, a first power supply which supplies a current to the filament, a second power supply which applies, to the filament, a voltage for acceleration to the chamber, an ammeter which measures a current of the filament, and a voltmeter which measures the acceleration voltage, the method comprises a first step of evacuating an interior of the chamber; a second step of supplying the filament current from the first power supply to the filament after the first step; a third step of applying the acceleration voltage to the filament after the second step; and a fourth step of controlling the acceleration voltage to keep a surface temperature of the chamber to be lower than a temperature of the filament after the third step while keeping constant the filament current from the first power supply.

Description

technical field [0001] The present invention relates to a temperature control method for a heating device using an electron impact heating method that heats a semiconductor substrate to a high temperature in a vacuum in a manufacturing process of a semiconductor device. Background technique [0002] The manufacture of semiconductor devices requires a process of rapidly heating a semiconductor substrate. Generally, a temperature of 1600° C. or higher is especially necessary in the activation annealing treatment of wide bandgap semiconductors represented by silicon carbide (SiC) (see, reference 1: T.Kimoto, N.Inoue and H.Matsunami : Phys. Stat. Sol. (a) Vol. 162 (1997), p. 263). [0003] In the activation annealing process, in order to ensure high reliability of semiconductor devices, it is very important to electrically activate 100% of the doped impurities and restore a perfect crystal. In order for the activation annealing process to be usable for industry requirements, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/00H01L21/324

CPCH01L21/67248H01L21/67103H01L21/046

Inventor 柴垣真果真下香土井浩志

Owner CANON ANELVA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com