Volatile gas treatment and recycling system and method thereof

A volatile gas, treatment cycle technology, applied in the direction of separation methods, chemical instruments and methods, combined devices, etc., can solve the problems that the bonding cannot work continuously, there is no effective treatment method, and the treatment cost is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

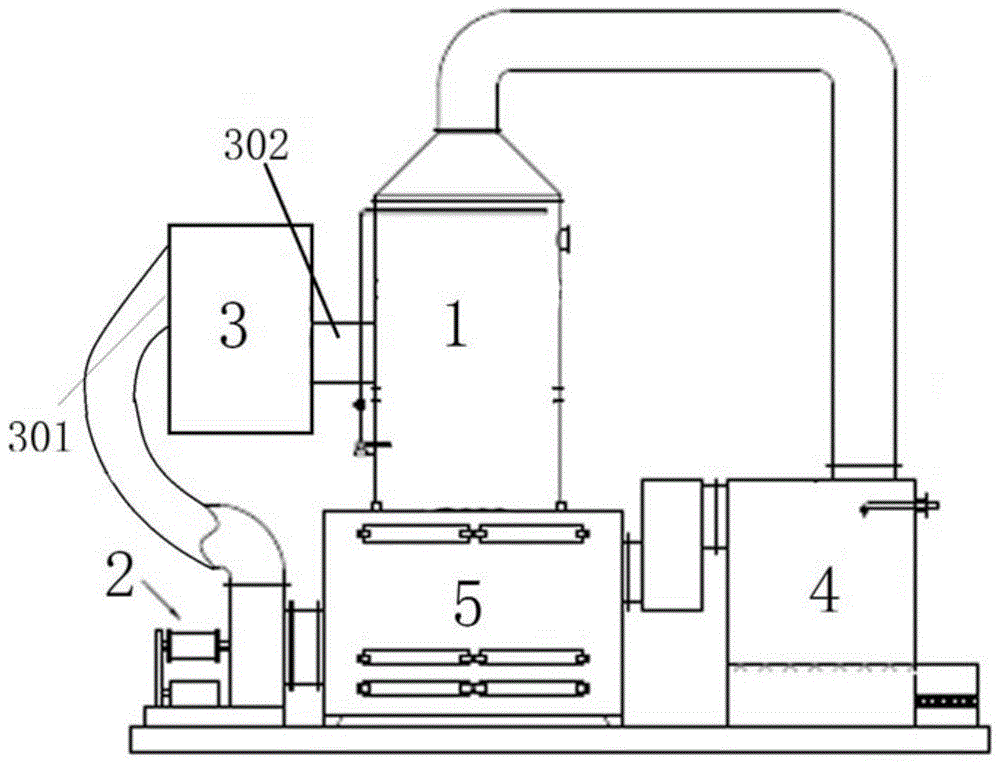

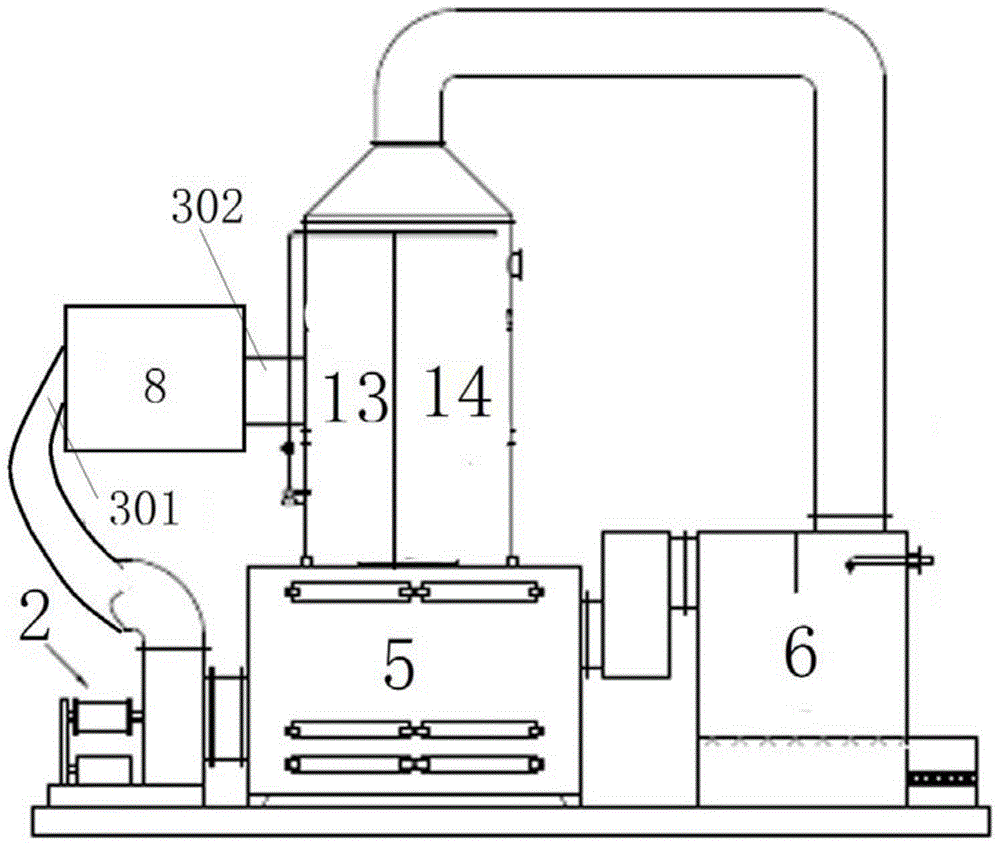

[0092] Such as figure 1 and figure 2 As shown, a volatile gas treatment recycling system, the volatile gas treatment recycling system includes a volatile gas treatment device 1 and a fan 2; the volatile gas treatment device is connected to the fan 2 through a pipeline;

[0093] The volatile gas treatment and recycling system also includes a closed volatile gas generation area 3;

[0094] The volatile gas generating area 3 is provided with an air inlet and an air outlet, the volatile gas processing device 1 is provided with an air inlet and an air outlet, and the fan 2 is provided with an air inlet and an air outlet;

[0095] The gas outlet of the volatile gas generating area 3 is connected to the air inlet of the volatile gas processing device 1; the air inlet of the volatile gas processing device 1 is provided with a particle filter 18; the volatile gas The gas outlet of the volatile gas treatment device 1 is connected to the air inlet of the fan 2 through a pipeline, and ...

Embodiment 2

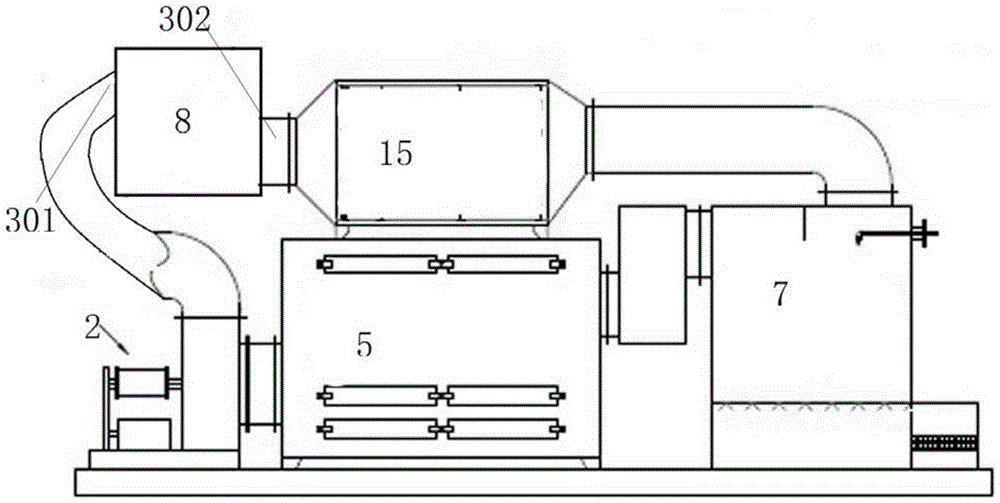

[0133] Such as image 3 As shown, a volatile gas treatment and recycling system is characterized in that: the volatile gas treatment and recycling system includes an activated carbon adsorption device 15 and a fan 2; the activated carbon adsorption device 15 is connected to the fan 2 through a pipeline;

[0134] The volatile gas treatment and recycling system also includes a closed painting room 8; the air inlet of the activated carbon adsorption device 15 is provided with a particle filter 18;

[0135] The painting room 8 is provided with an air inlet and an air outlet, the activated carbon adsorption device 15 is provided with an air inlet and an air outlet, and the fan 2 is provided with an air inlet and an air outlet;

[0136] The air outlet of the painting room 8 is connected with the air inlet of the activated carbon adsorption device 15; the air outlet of the activated carbon adsorption device 15 is connected with the air inlet of the fan 2 through a pipeline, The air po...

Embodiment 3

[0161] Such as Figure 4 and Figure 14 As shown, a volatile gas treatment and recycling system is characterized in that: the volatile gas treatment and recycling system includes a gas phase oxidation treatment device 16 and a fan 2; the gas phase oxidation treatment device 16 passes through the pipeline and the fan 2 connected;

[0162] The volatile gas treatment and recycling system also includes a closed painting room 8; a particle filter 18 is provided at the air inlet of the gas phase oxidation treatment device 16;

[0163] The volatile gas generating area 3 is provided with an air inlet and an air outlet, the gas phase oxidation treatment device 16 is provided with an air inlet and an air outlet, and the fan 2 is provided with an air inlet and an air outlet;

[0164] The gas outlet of the volatile gas generating area 3 is connected to the gas inlet of the gas phase oxidation treatment device 16; the gas outlet of the gas phase oxidation treatment device 16 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com