Planet carrier of the cage type

A planet carrier and planet shaft technology, applied in the field of cage-type planet carrier, can solve the problem of unsuitable helical gears, etc., and achieve the effects of simplified assembly, compact design and better load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

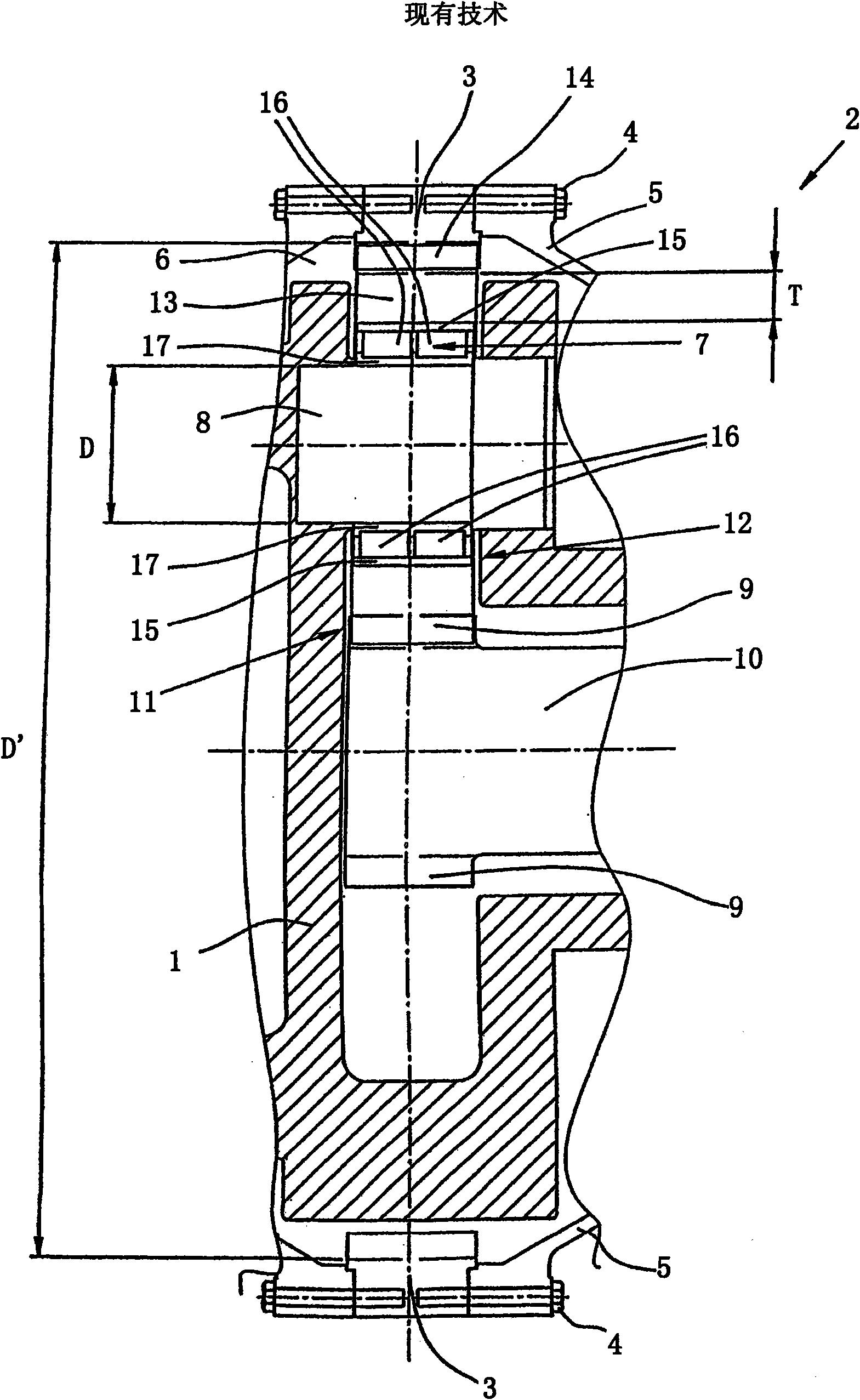

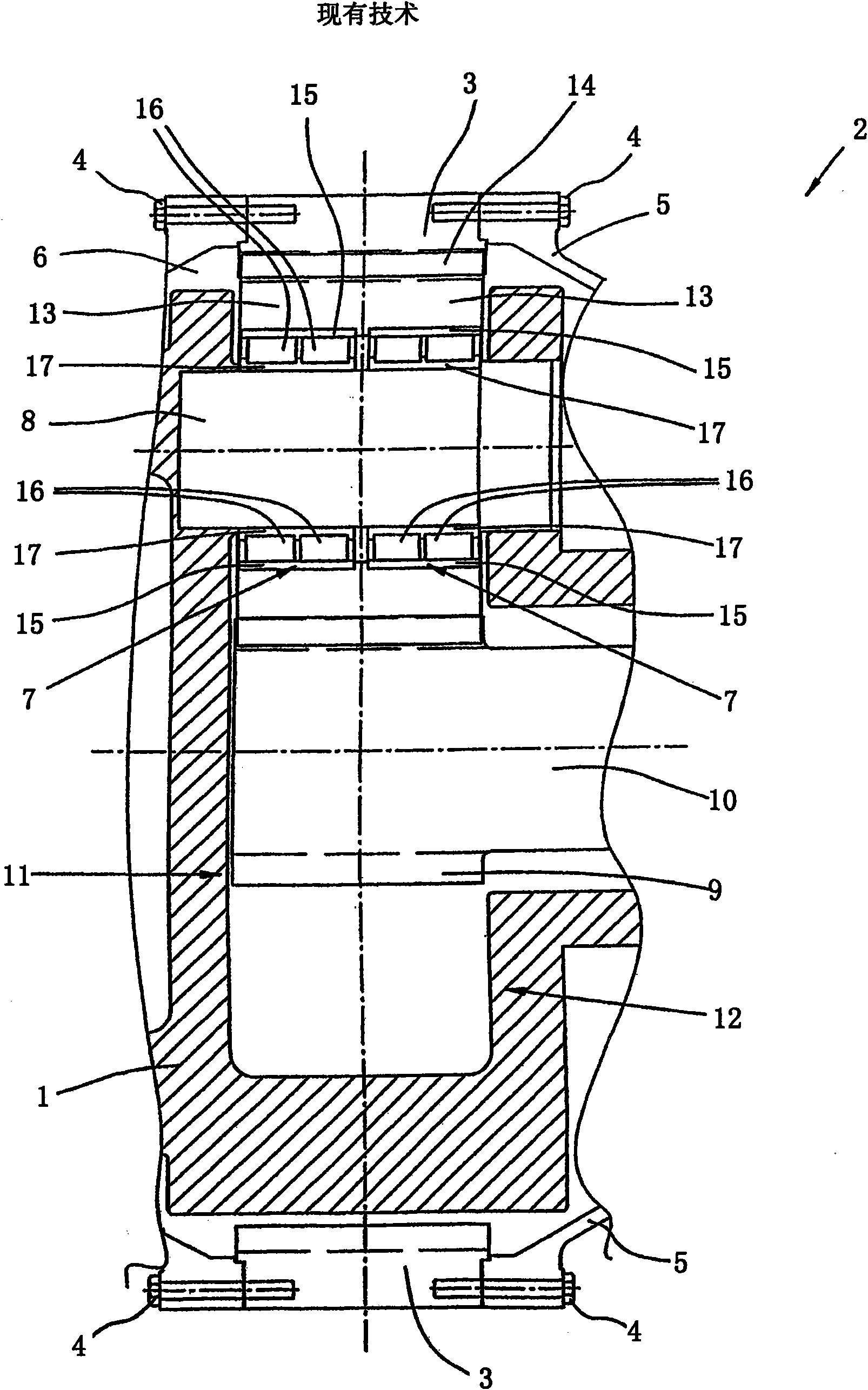

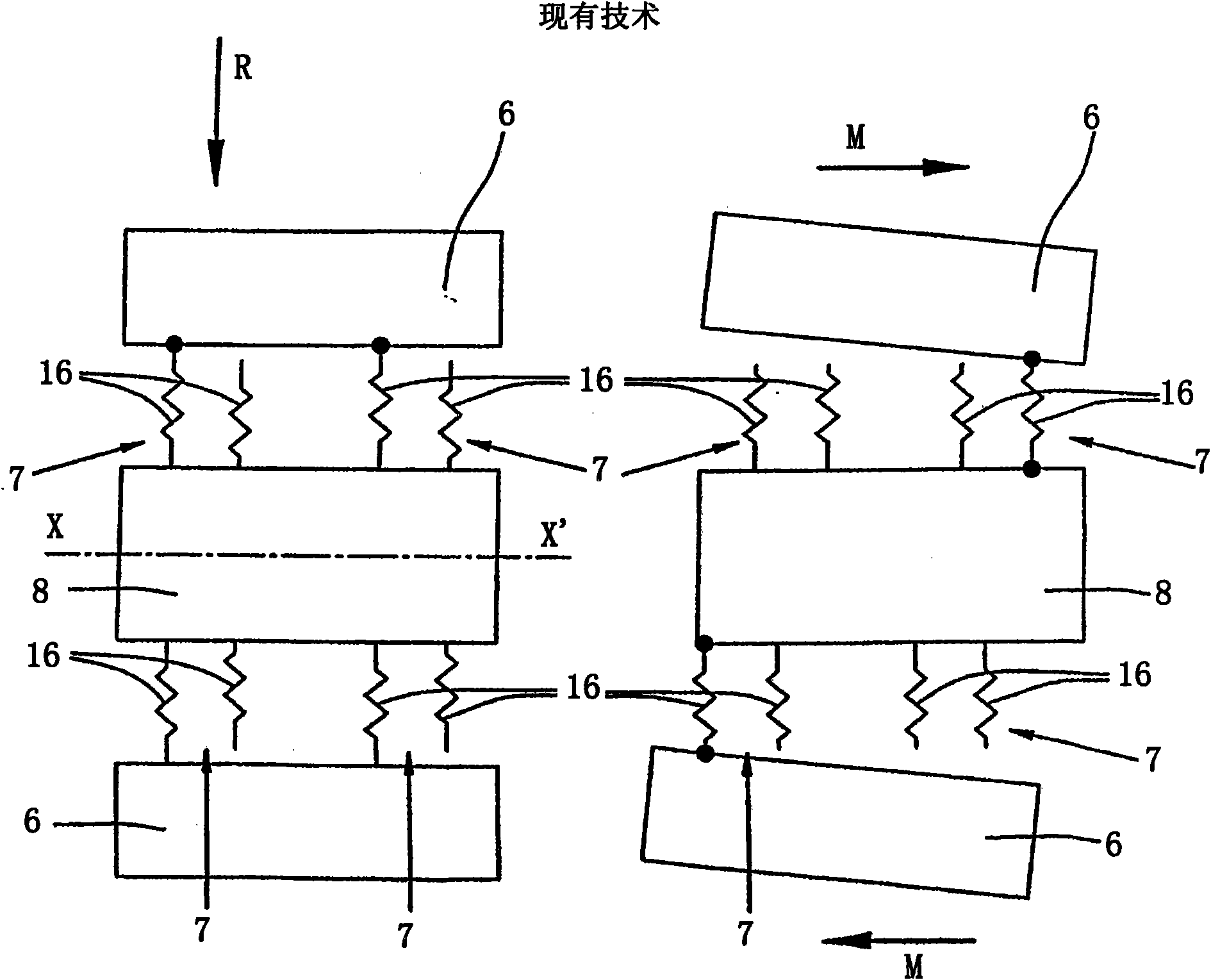

[0089] figure 1 The planet carrier 1 shown in is a cage-type planet carrier and is part of an epicyclic gear system 2 .

[0090] Furthermore, the epicyclic gear system consists of the following: ring gear 3, which is connected to housing 5 by bolts 4; planetary gears 6, in figure 1 Only one of the planetary gears 6 is shown in , and the planetary gear 6 is rotatably mounted on the planetary shaft 8 of the planetary carrier 1 ; and the sun gear 9 is mounted to the output shaft 10 .

[0091] The planet carrier 1 of the known epicyclic gear system 2 can be used to convert the slow rotation of the planet carrier 1 to the output shaft 10 through the interaction between the planet wheels 6 and the sun gear 9 on this planet carrier 1 with the ring gear 3 fast rotation.

[0092] In this known cage planet carrier 1 , the planet wheels 6 are arranged between two walls 11 and 12 of the planet carrier 1 .

[0093] In addition, the walls 11 and 12 support the planet shafts 8 on either s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com