Elastic strand coating process

A stranded wire, elastic technology, applied in the field of adhesive injection system, can solve the problem of fabric uniform gathering effect, affecting fabric to form effective liquid seal, stranded wire bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

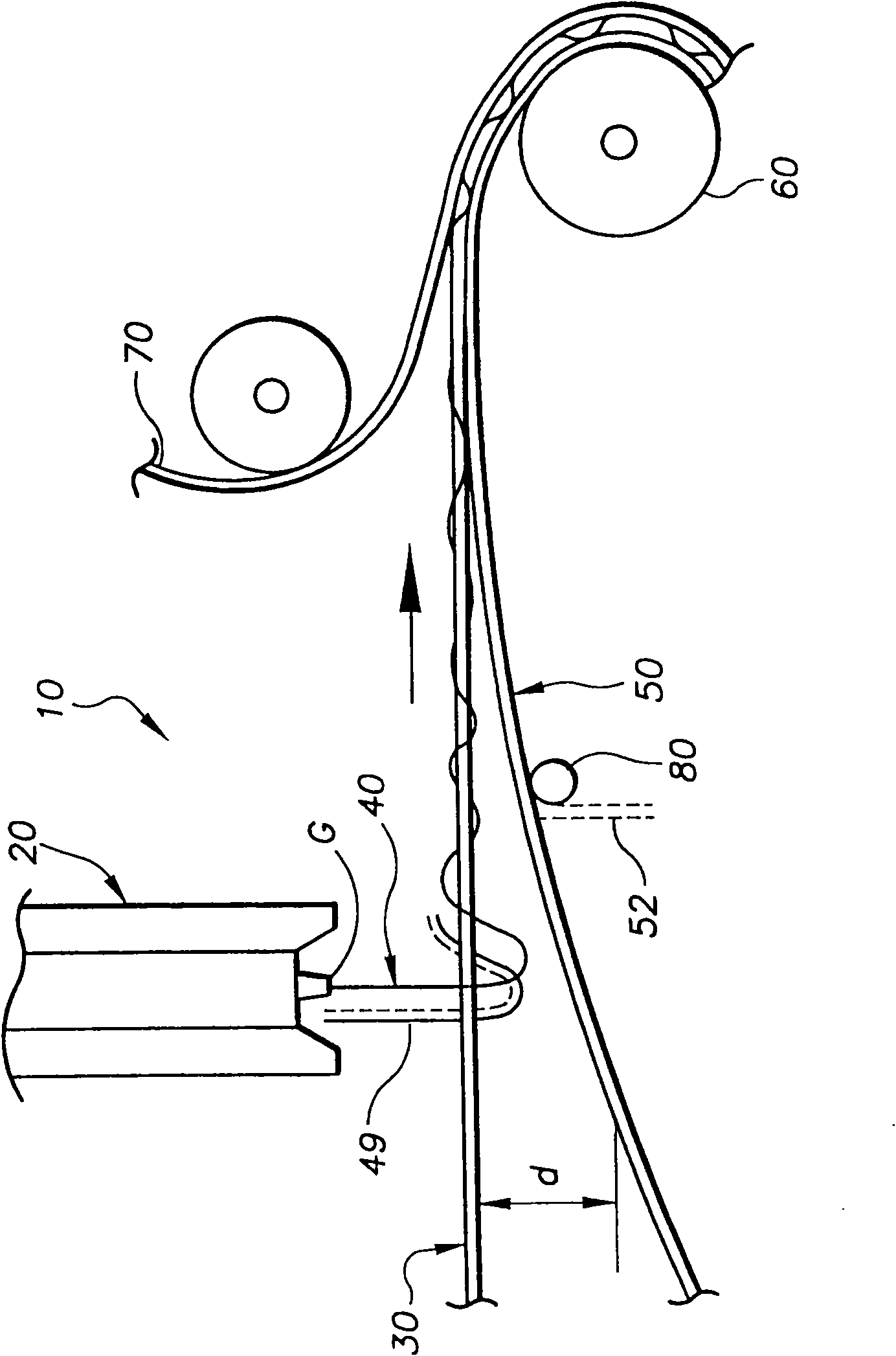

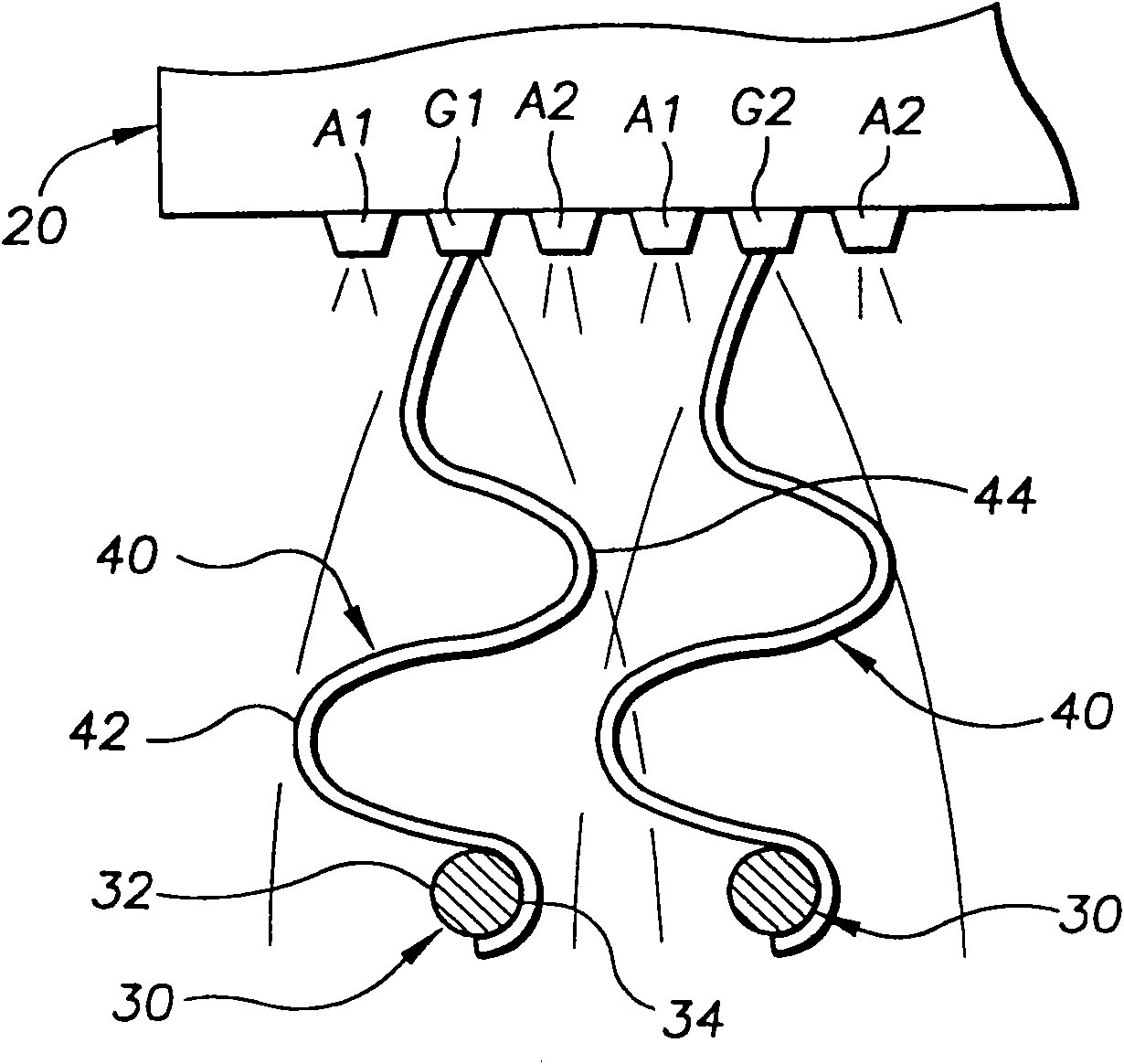

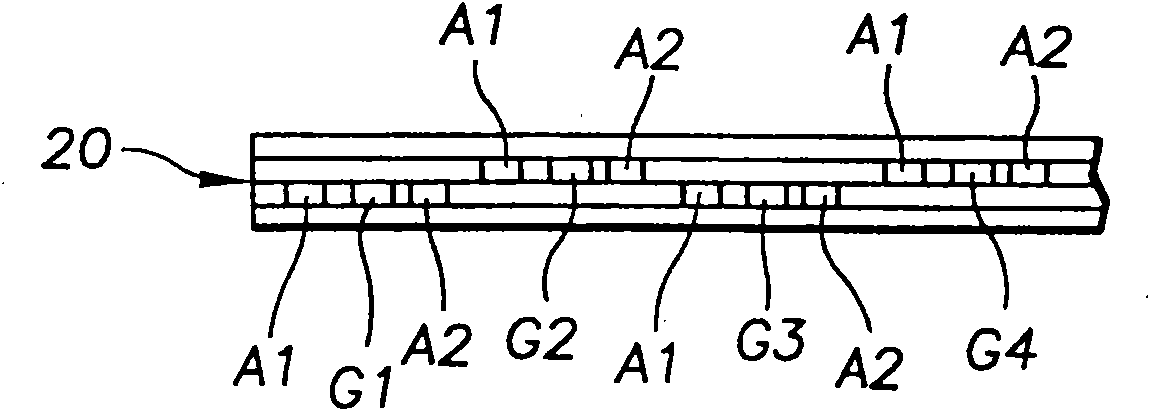

[0024] figure 1 is a system 10 of the present invention for applying a liquid, including an adhesive, to strands and, in some applications, bonding the adhesive-coated strands to a substrate. Exemplary system 10 ejects fibers of hot melt adhesive outwardly from one or more adhesive ejection nozzles, preferably having one or more adhesive orifices, and having first and second air opposite them. Meltblown nozzles with injection holes, such as Figure 2a and 2b , which will be discussed further below. Generally, the present invention is more suitable for spraying liquid to the strand 30, and the liquid sprayed from the nozzle 20 sticks substantially all on the strand 30, which prevents undesired spraying of the liquid on the underlying substrate or other area, thereby reducing fluid waste.

[0025] A typical application is the bonding of adhesive-coated extensible elastic strands 30 to a fabric substrate 50 in the manufacture of various body fluid-absorbent healthcare product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com