Manufacturing method of multi-pipe tubular joint

A technology of intersecting nodes and production methods, applied in the direction of buildings and building structures, can solve the problems of increased cost input, complex stress distribution, difficulty in ensuring uniformity, etc., and achieve the effect of ensuring bearing capacity and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

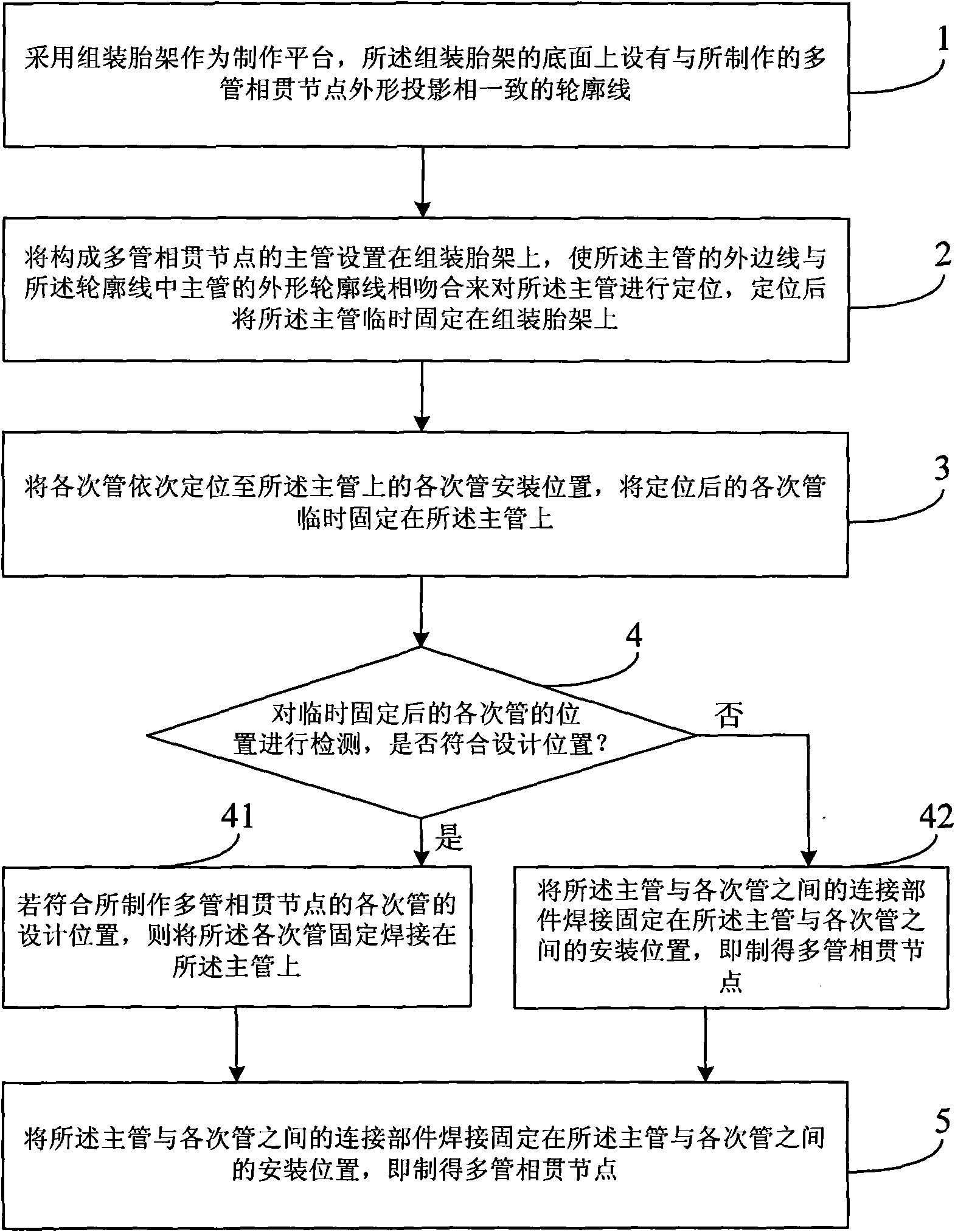

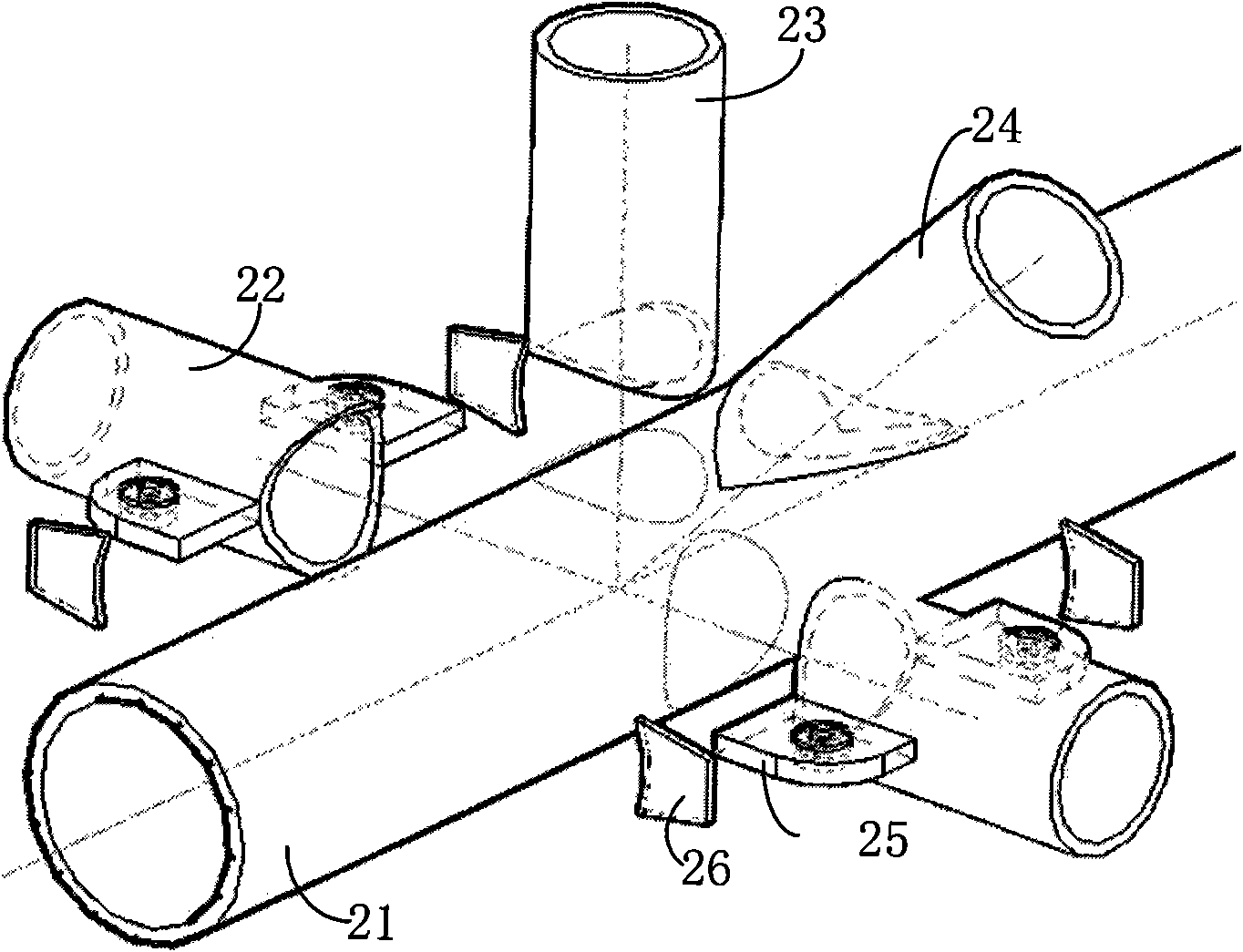

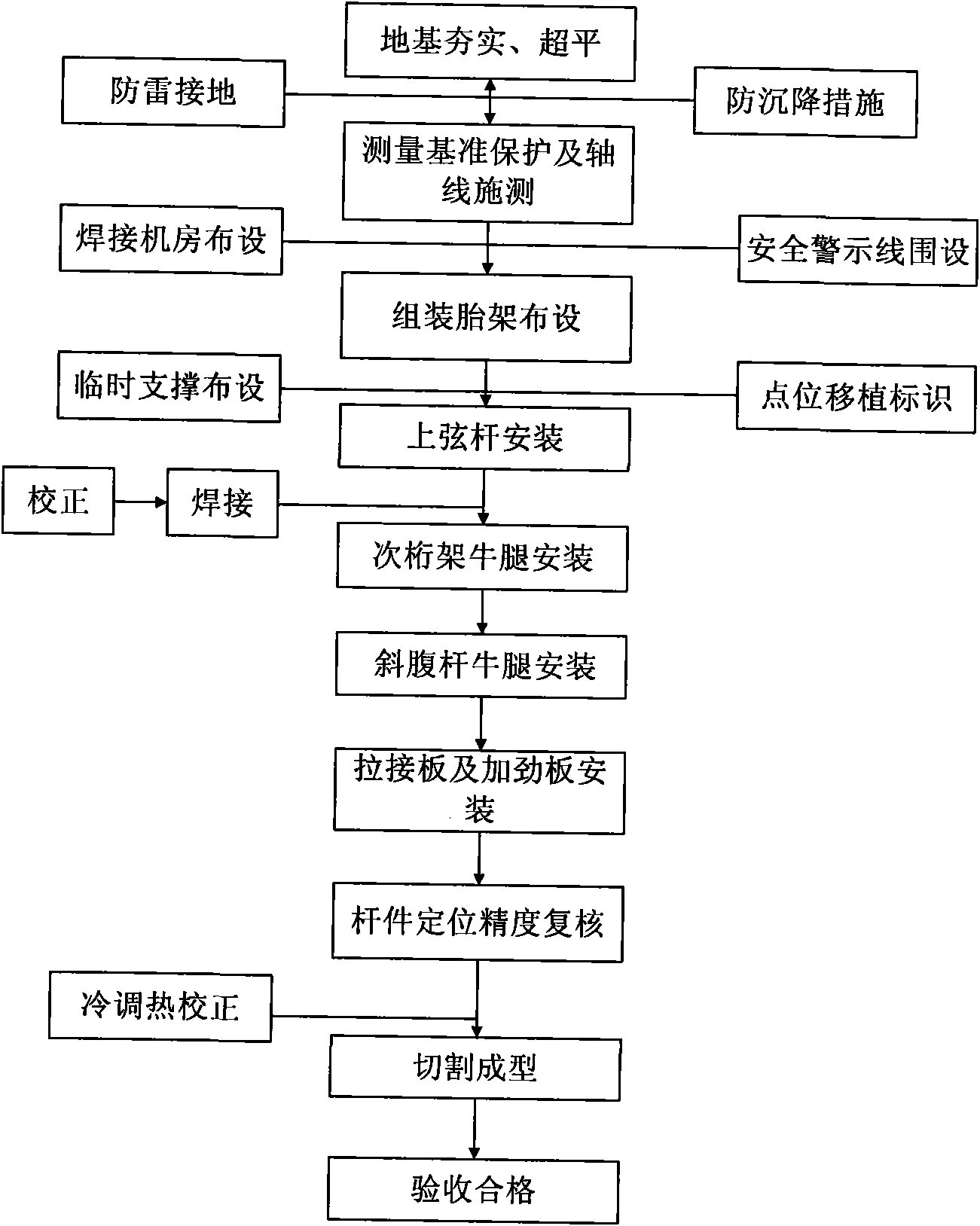

[0036] This embodiment provides a method for manufacturing multi-pipe intersecting nodes, which can manufacture multi-pipe intersecting nodes that meet the requirements in precision and bearing capacity, and solve the problem that the existing technology cannot guarantee the accuracy and accuracy of multi-pipe intersecting nodes. Bearing capacity, but in steel structure engineering, cast steel joints are used to replace multi-pipe intersecting joints, resulting in high cost and low engineering quality; for example figure 1 As shown, the manufacturing method of the multi-pipe intersecting node includes the following steps:

[0037] Step 1, using the assembled tire frame as a production platform, the bottom surface of the assembled tire frame is provided with contour lines consistent with the shape projection of the fabricated multi-pipe intersecting nodes;

[0038] In the above step 1, on the bottom surface of the assembled tire frame, there is a contour line consistent with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com