Method for measuring deep rock-sample initial damage distribution

A technology of initial damage and measurement method, which is applied in material analysis using sonic emission technology, solid analysis using sonic/ultrasonic/infrasonic waves, and testing of material strength by applying repetitive force/pulse force, etc. Serious problems, to achieve the effect of ensuring rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

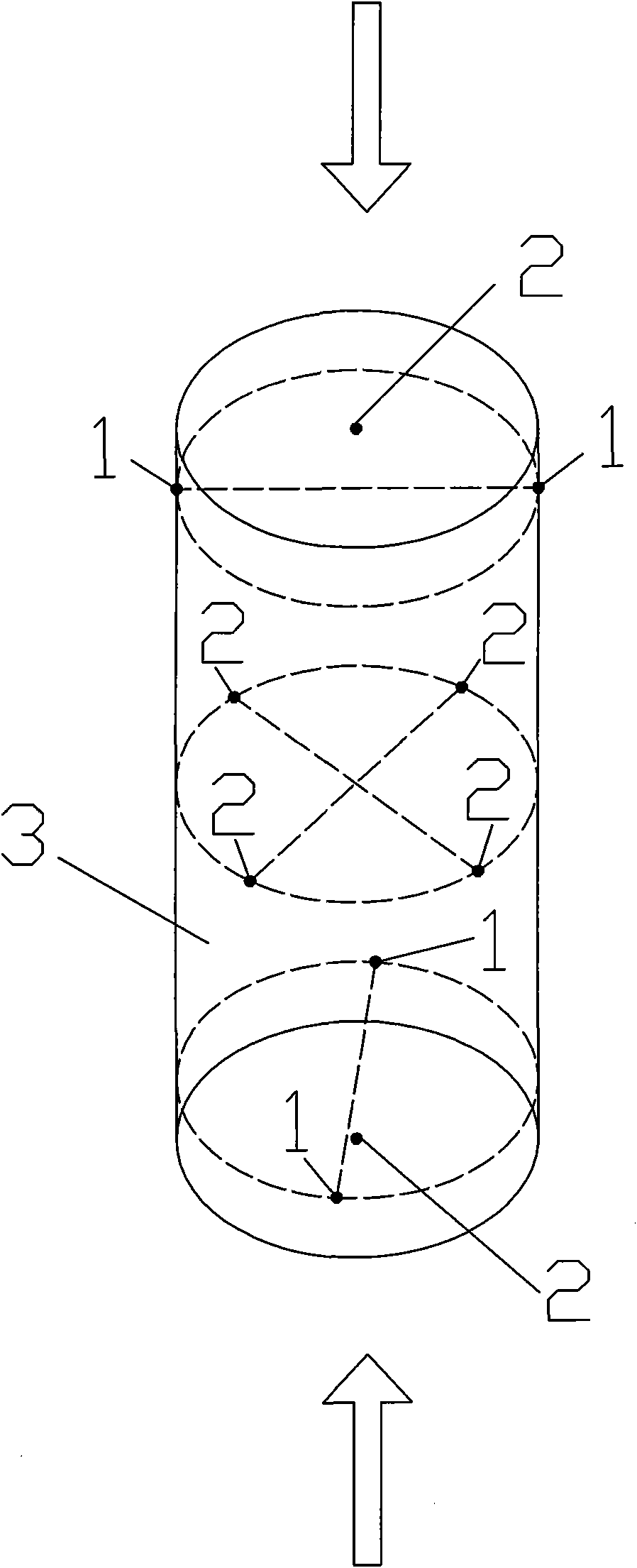

[0017] Such as figure 1 As shown, in this example, the distribution of the initial damage of deep rock samples is determined, and the specific steps are as follows:

[0018] a. Process rock sample 3. In order to more accurately test the distribution of initial damage in the rock sample and to facilitate the arrangement of acoustic waves and acoustic emission probes, a cylindrical rock sample with a diameter of 80-100 mm is generally selected. The diameter of the rock sample used in this example is 80 mm , Aspect ratio of 2:1 (160mm high).

[0019] b. Grind a small platform at the position where the probe is to be placed on the rock sample to ensure that the probe and the rock sample are fully coupled (the acoustic wave detection probe 2 and the acoustic emission probe 1 selected in this example are both flat-bottomed probes). Arrange a pair of acoustic detection probes 2 on the top and bottom of the rock sample (this pair of probes should be coupled with the indenter of the t...

Embodiment 2

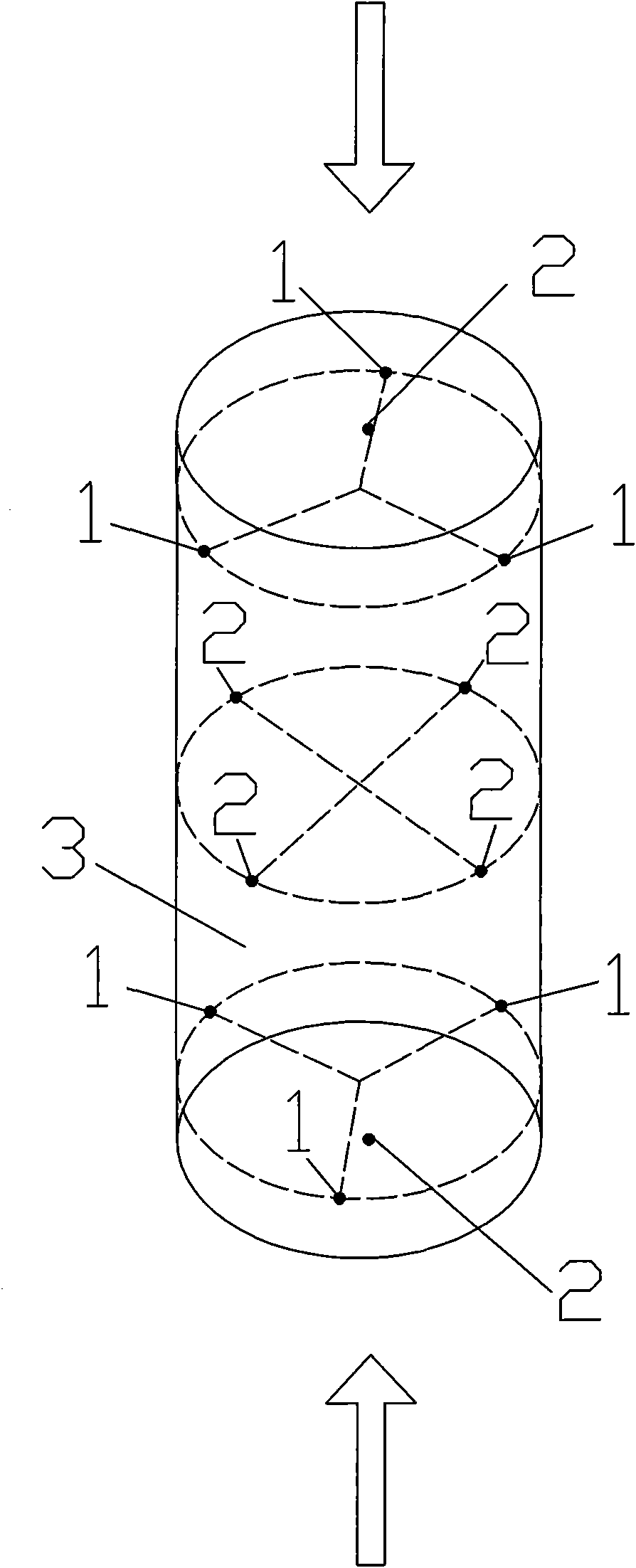

[0025] Such as figure 2 As shown, in this example, the distribution of the initial damage of deep rock samples is determined, and the specific steps are as follows:

[0026] a. To process rock sample 3, select a cylindrical rock sample with a height of 200 mm and a diameter of 100 mm.

[0027] b. Grind a small platform at the position where the probe is to be placed on the rock sample to ensure that the probe and the rock sample are fully coupled (the acoustic wave detection probe 2 and the acoustic emission probe 1 selected in this example are flat-bottomed probes). Arrange a pair of acoustic wave detection probes 2 on the top and bottom of the rock sample, and arrange two pairs of acoustic wave detection probes 2 at the two ends of the two diameters perpendicular to each other in the axial middle of the rock sample. Each pair of acoustic wave detection probes includes a transmitting probe and a Receive probe.

[0028] c. Arrange a group of acoustic emission probes 1 near ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com