Secondary wiring method in power engineering

A technology of secondary wiring and power engineering, applied in circuits, connections, electrical components, etc., can solve the problems of difficult to achieve uniform secondary wiring, high work intensity, difficult to uniform, etc., to achieve strong perception and easy operation. , clear texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

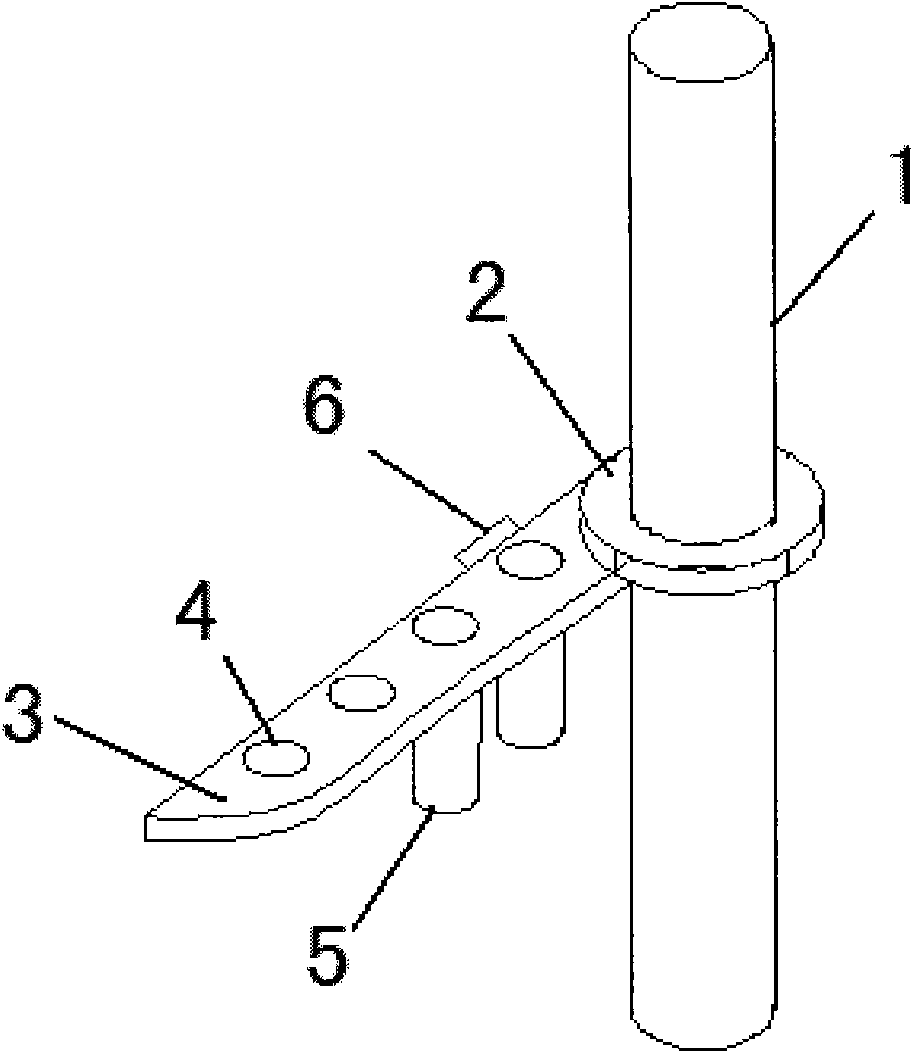

[0011] Such as figure 1 As shown, one end of the arc bender 2 is inserted into the distribution frame 1, and the other end of the arc bender 2 is a handle 3, and there are several holes 4 on the handle 3, and the screws 5 pass through the holes and are connected with the nuts. , the screw 5 close to the distribution frame 1 is connected with the hanging card 6, and the distribution frame 1 is formed by connecting end to end of several poles. Before wiring, divide and bind the wires, measure the length of the terminal and the total length of the bending arc (with a margin), straighten the divided wires, and cut them vertically from top to bottom according to the measured length cut.

[0012] The specific operation method is:

[0013] 1. Upper cable

[0014] In order to make the wiring process reasonable and beautiful, the wiring procedure should be completed after all the cables are laid, and the cables should be neatly and orderly inserted into the panel cabinet or terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com