Hollow fiber ultra-filtration film component with crisscross separating film

A separator and cross-shaped technology, which is applied in the field of hollow fiber ultrafiltration membrane modules, can solve the problems of affecting the flow rate of water passing through the ultrafiltration membrane and slow water outlet, and achieve the effect of easy cleaning and increased water flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

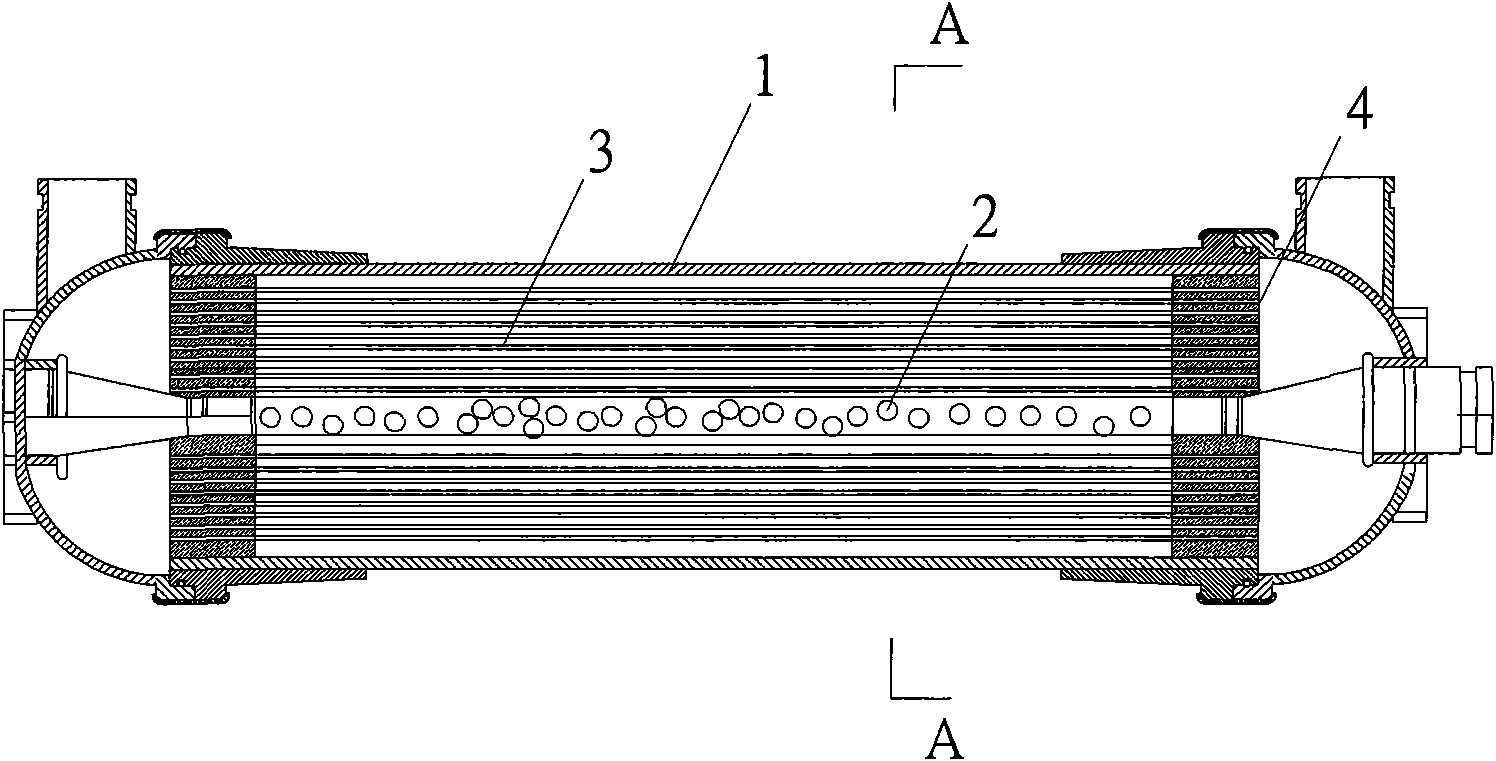

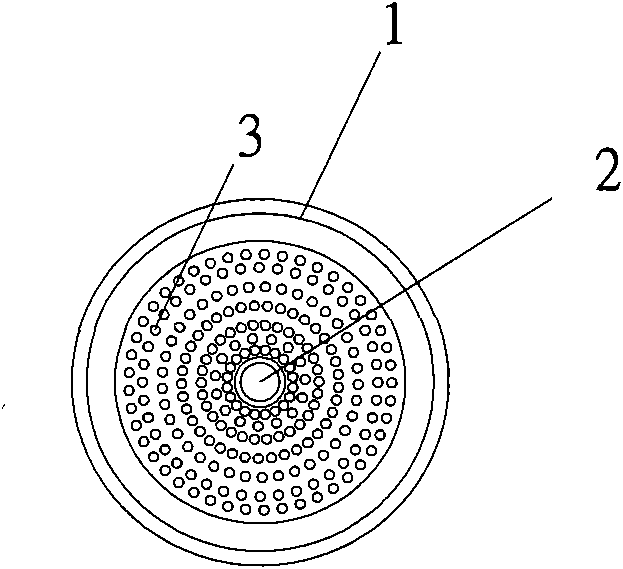

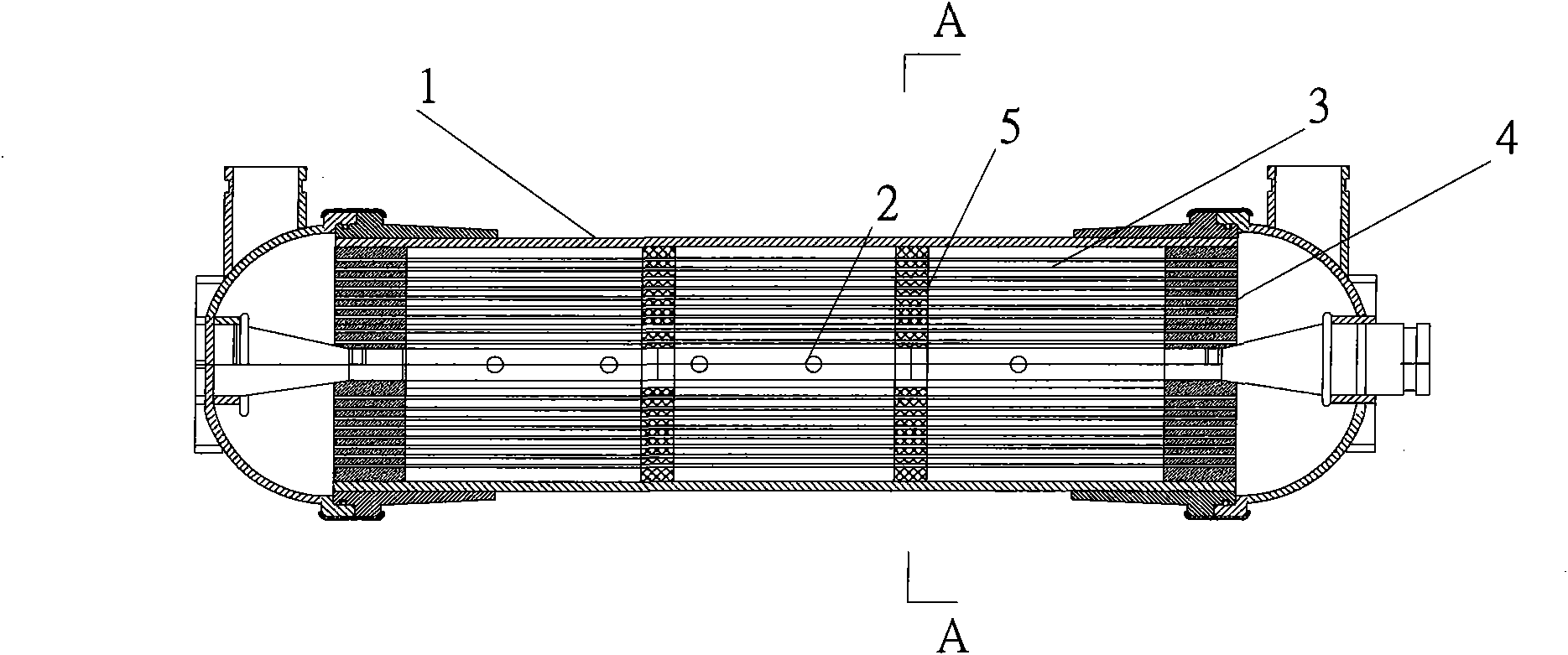

[0013] Such as image 3 Shown is a schematic diagram of a hollow fiber ultrafiltration membrane module with a cross-shaped separator, Figure 4 for image 3 In the sectional view of A-A, the hollow fiber ultrafiltration membrane module with a cross-shaped separator includes a pressure-bearing shell 1, a central conduit 2 is provided at the center of the pressure-bearing shell 1, and a central conduit 2 is provided between the inner wall of the pressure-bearing shell 1 and the central conduit 2 The ultrafiltration membrane 3 is provided with a sealant 4 at both ends of the pressure-bearing shell 1, and at least one cross-shaped separator 5 is arranged in the pressure-bearing shell 1 along the radial direction. Each blade of the cross-shaped separator 5 has a corrugated structure.

[0014] When assembling, put each selected equal portion of ultrafiltration membrane tow into the pressure-bearing housing 1, and then install two cross-shaped separators 5 from both ends of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com