Outrigger locking device and concrete pump truck

An outrigger locking and locking technology, applied in the direction of the unloading device, etc., can solve the problems of increasing the friction between the lock tongue and the inner wall of the cylindrical shell, the locking device is laborious to use, and inconvenient to process, and achieves flexible and convenient layout. Safe and reliable locking, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

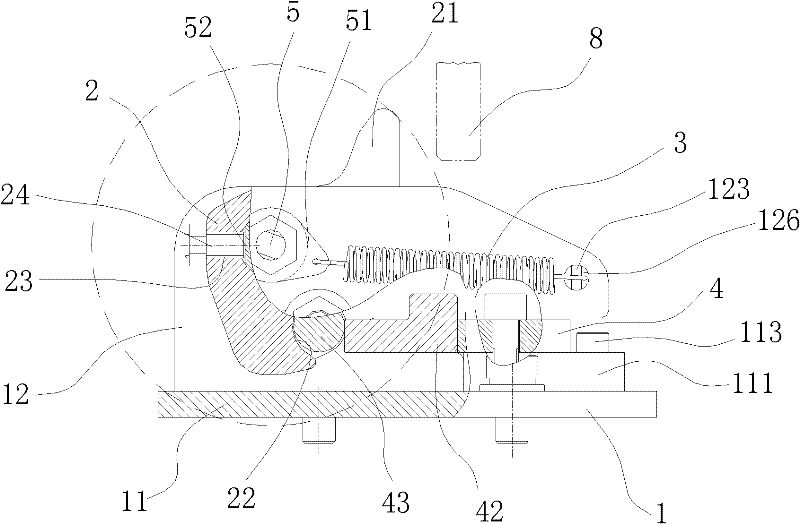

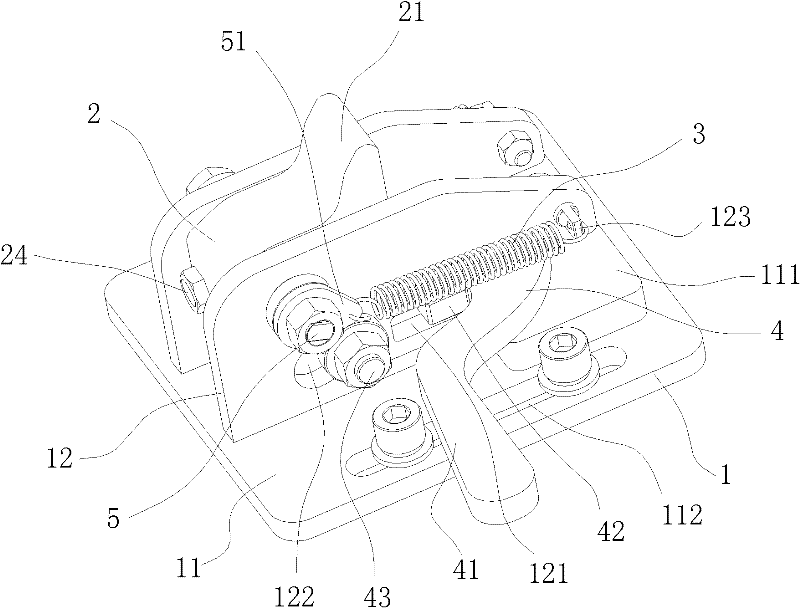

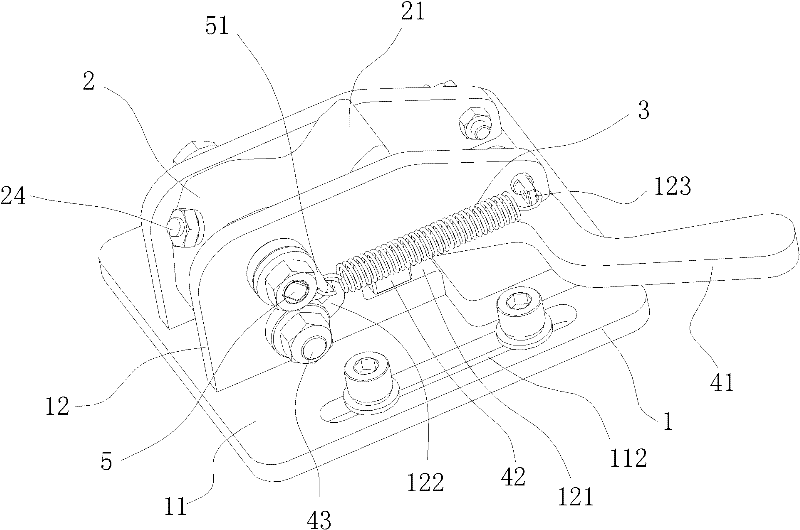

[0034] Figure 1 to Figure 10 It shows an embodiment of an outrigger locking device of the present invention, including a mounting base 1, a lock core 2 and an operating mechanism 4, the lock core 2 includes a locked state and an unlocked state, the lock core 2 is hinged to the mounting base 1, and the lock The core 2 can deflect around the hinge shaft. The operating mechanism 4 is used to drive the lock core 2 to swing around the hinge shaft and switch between the locked state and the unlocked state. A lock core return spring 3 is provided between the mounting base 1 and the lock core 2. Through the lock core return spring 3, the lock core 2 is always subjected to the return driving force that drives the lock tongue 21 to protrude from the mounting seat 1, so as to keep the lock core 2 reset between the locked state and the unlocked state. This deflection structure greatly reduces the requirement for installation space, saves space, and makes the arrangement of the outrigger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com