Sheet processing apparatus

A paper processing device and stapler technology, which is applied in the direction of binding, can solve the problems of time-consuming, inconsistent folding position and binding position of paper stacks, etc., and achieve the effect of easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

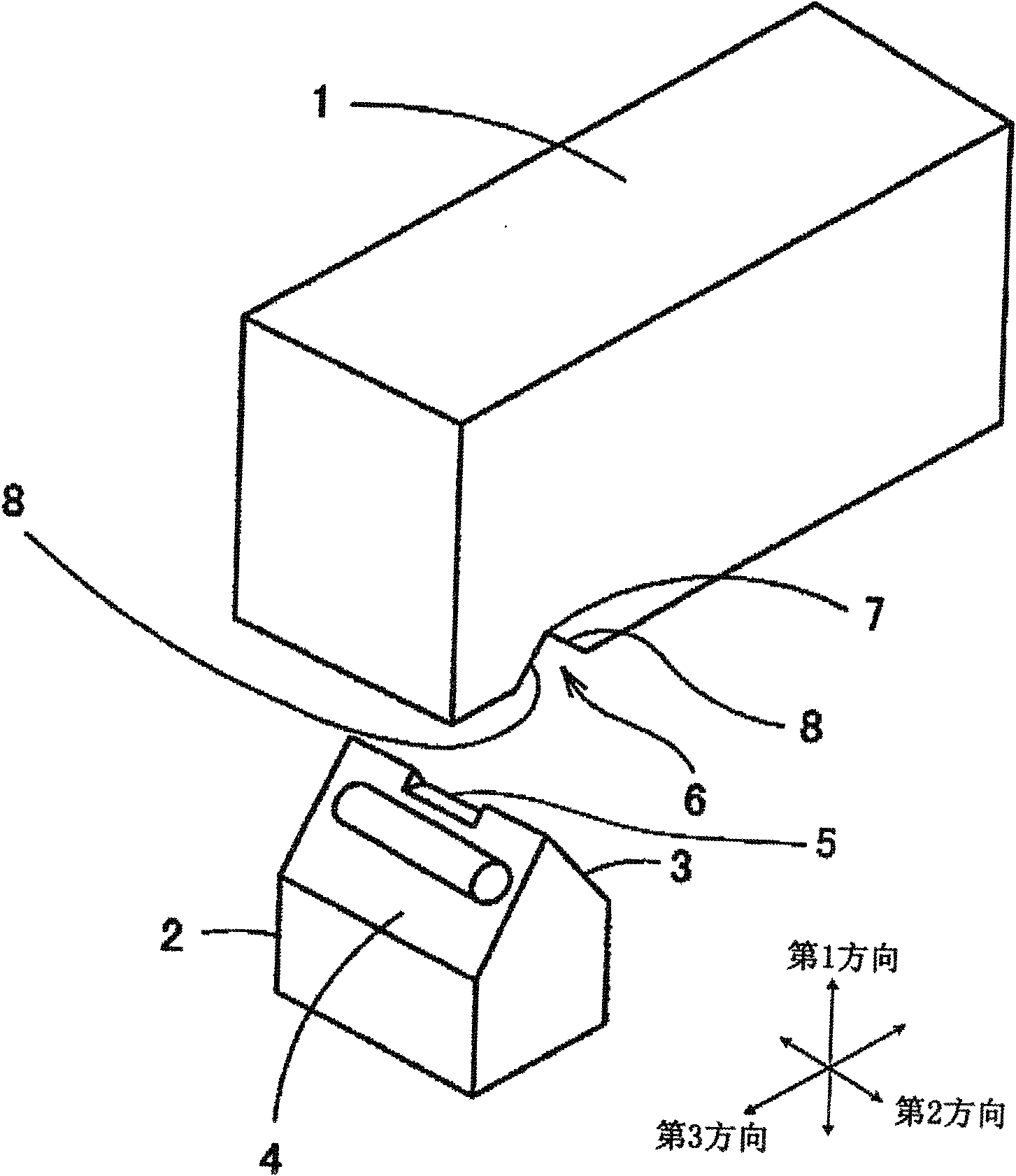

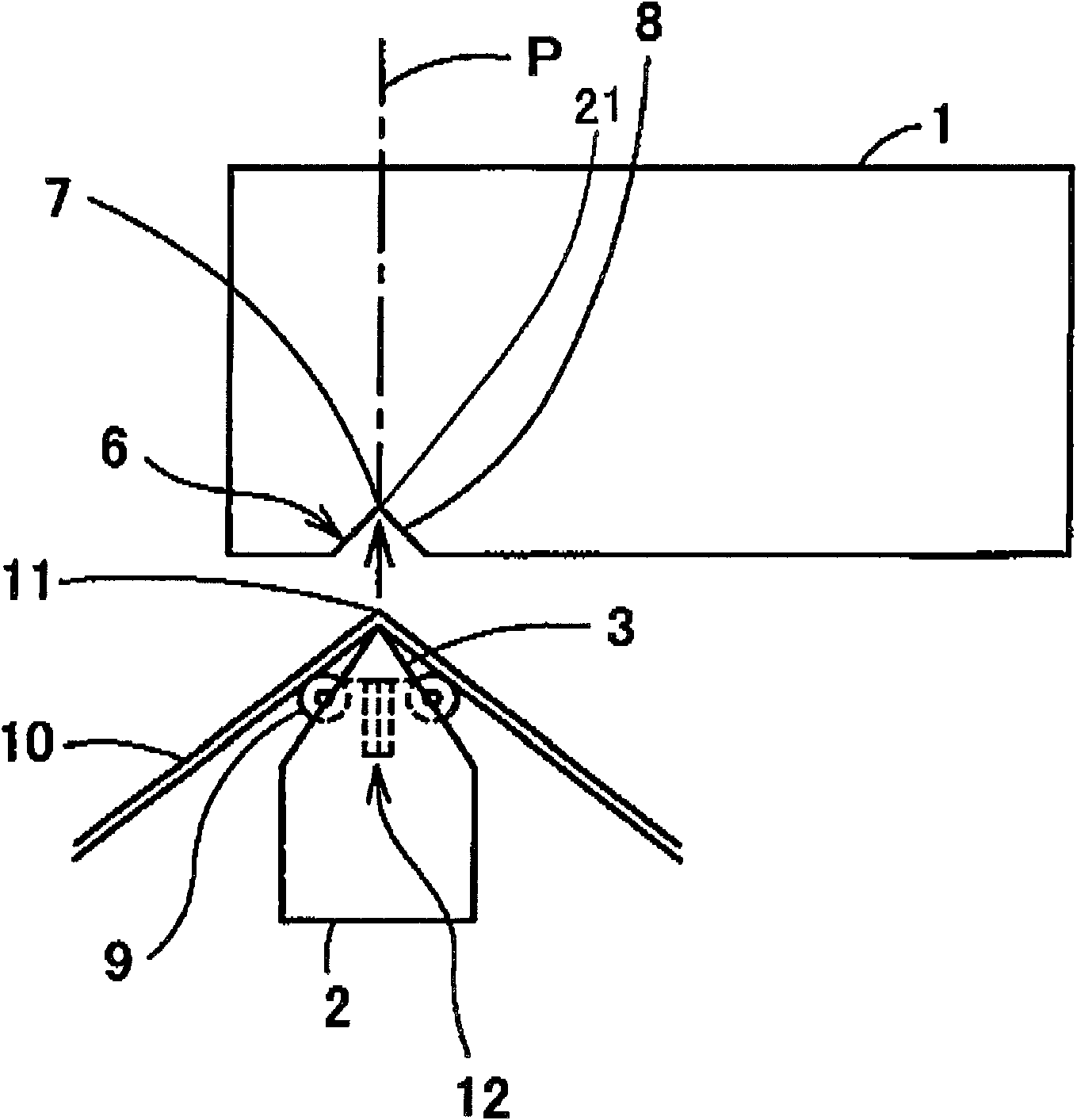

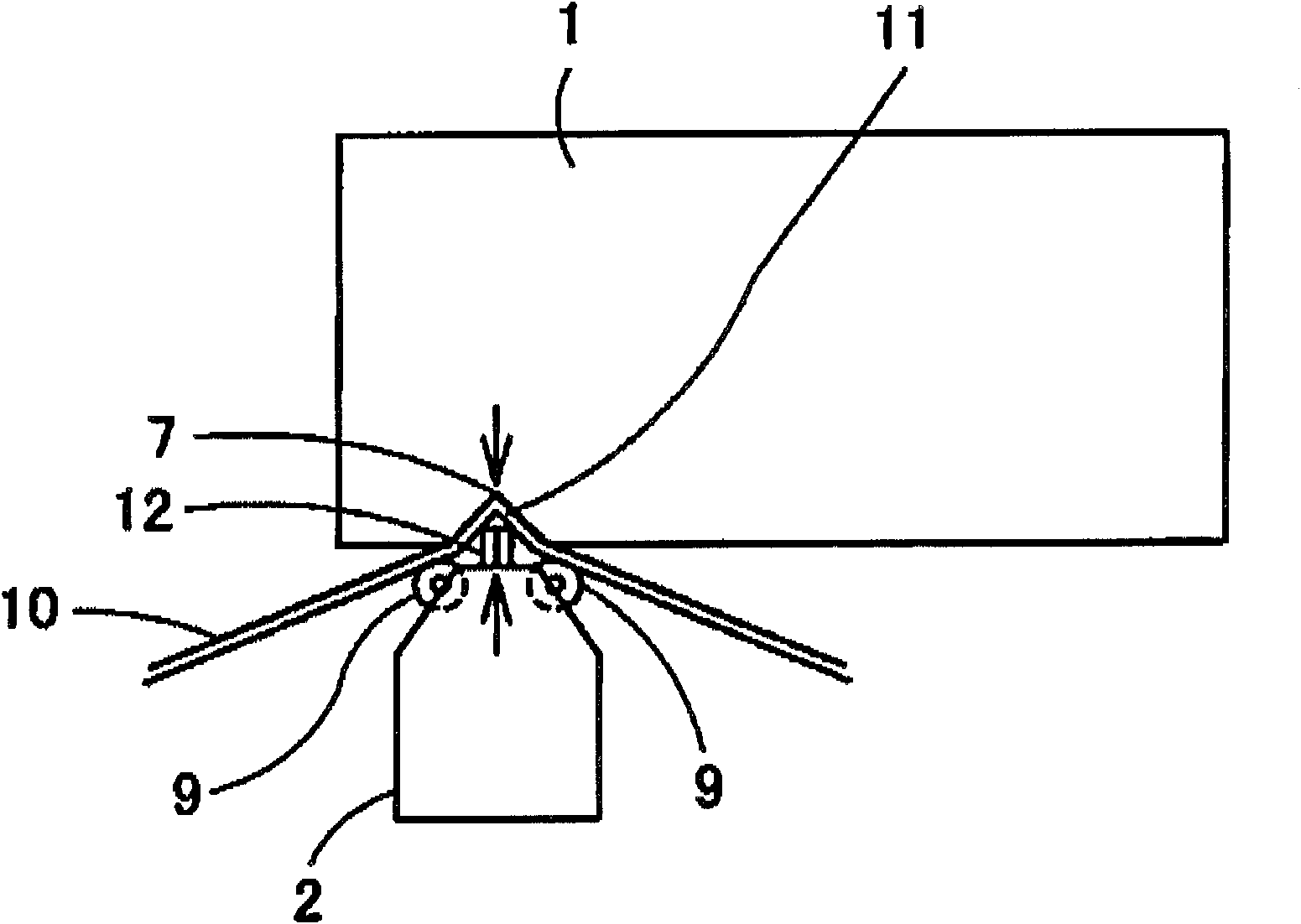

[0018] figure 1 A sheet processing apparatus equipped with a saddle stitcher in a typical embodiment is shown. Reference numeral 1 denotes a driving unit, and 2 denotes a clincher unit.

[0019] The driving unit 1 includes a driving unit 21 that guides the driver 20 in a slidable manner, a magazine unit (not shown) that stores staples, and a supply unit that supplies staples from the magazine unit to the driving unit. (not shown), a driving drive mechanism (not shown) that drives the driver 20 downward (first direction = clincher unit side) to drive the staples supplied to the driving unit 21 . In addition, the staple driven by the driver 20 has a crown extending in the second direction and two legs bent from both ends of the crown.

[0020] The clincher unit 2 has a built-in clincher 12 that supports and bends the legs of the staples driven out from the driving unit, and a saddle 3 for placing the folded paper stack at the center is integrally formed at the upper end. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com