Innercurve multiple-action radial plunger type hydraulic motor

A hydraulic motor and multi-function technology, applied in the field of hydraulic motors, can solve problems such as heavy workload, troublesome parts processing, and assembly, and achieve the effects of prolonging service life, simplifying processing difficulty and cost, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

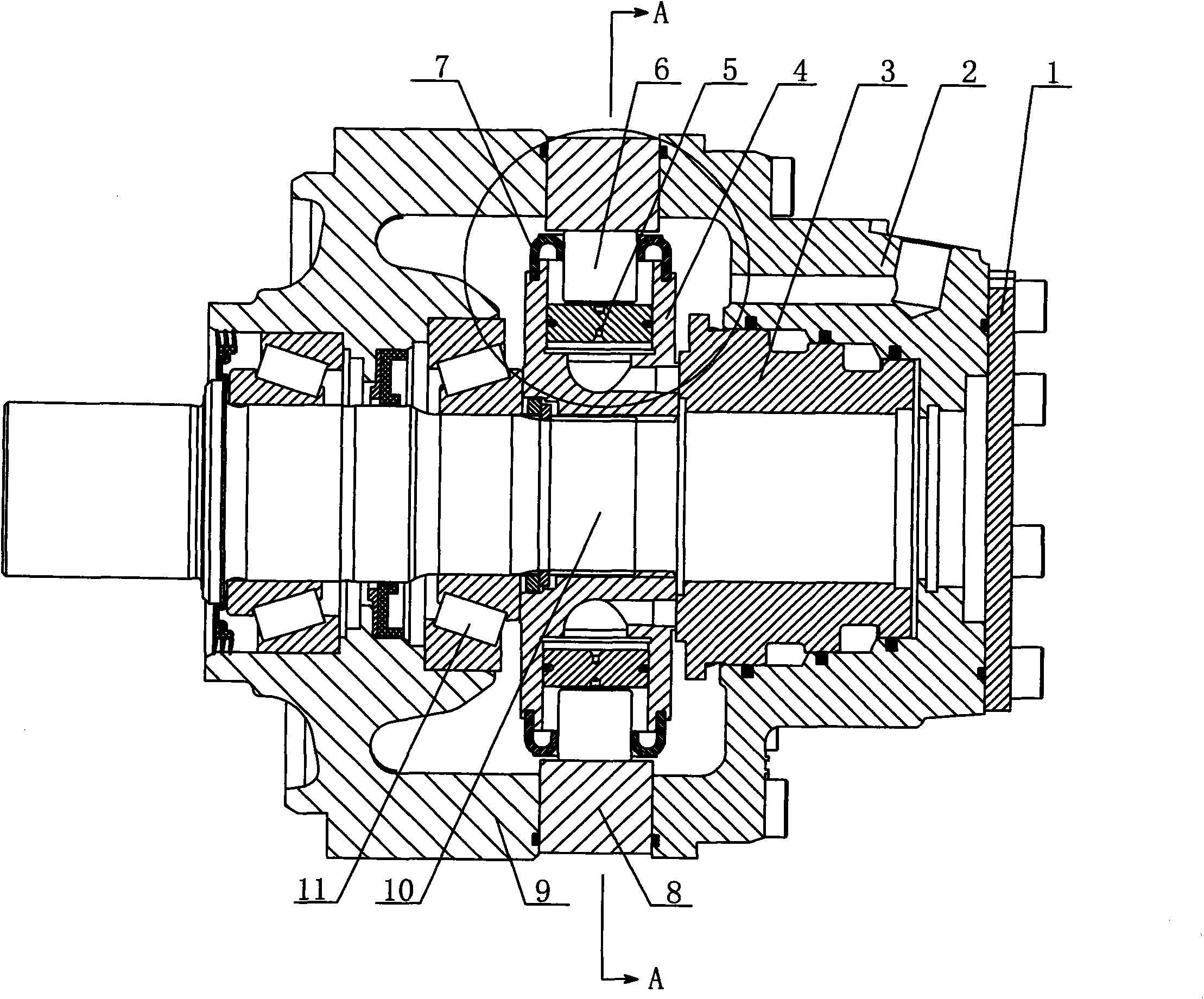

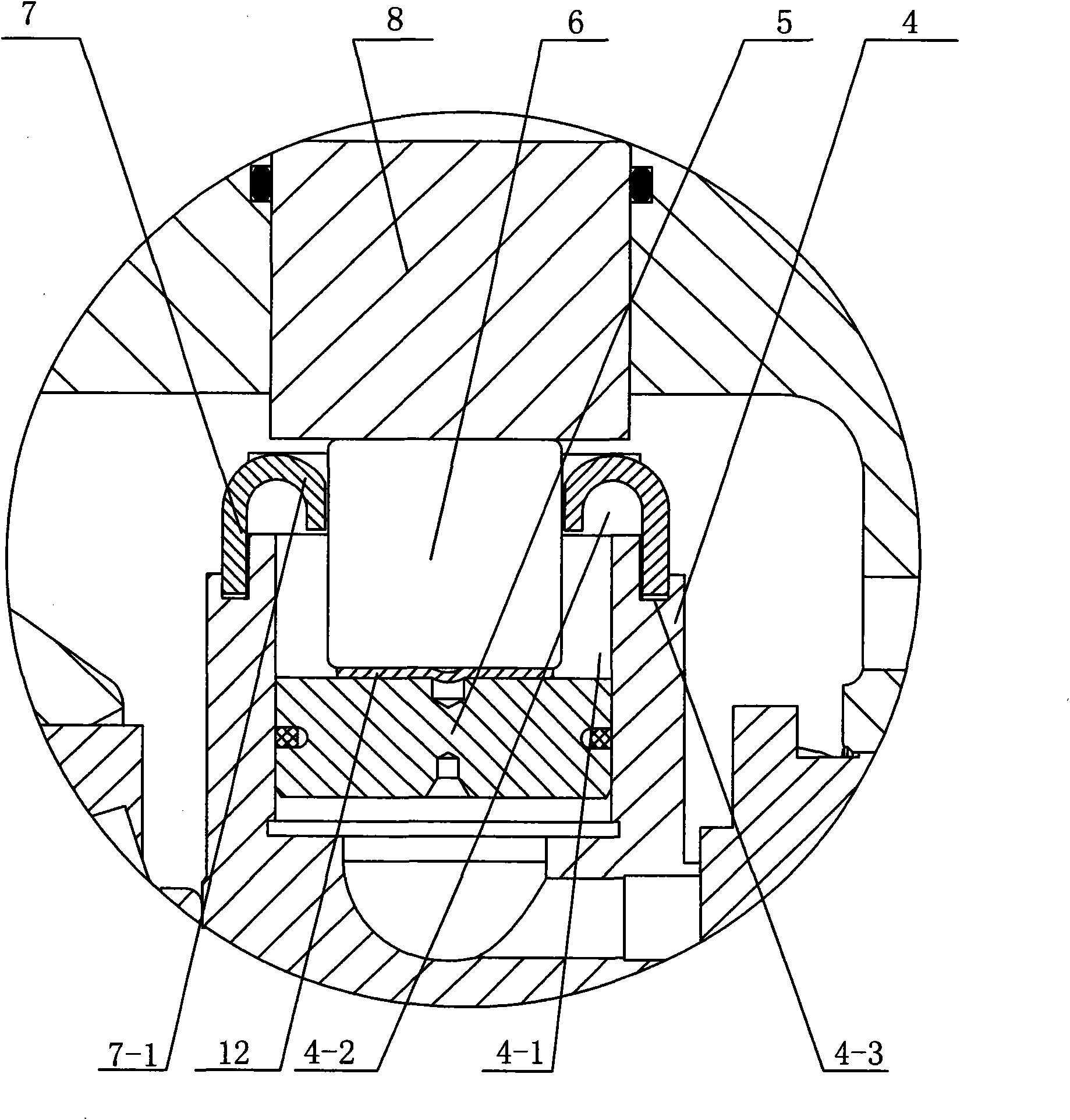

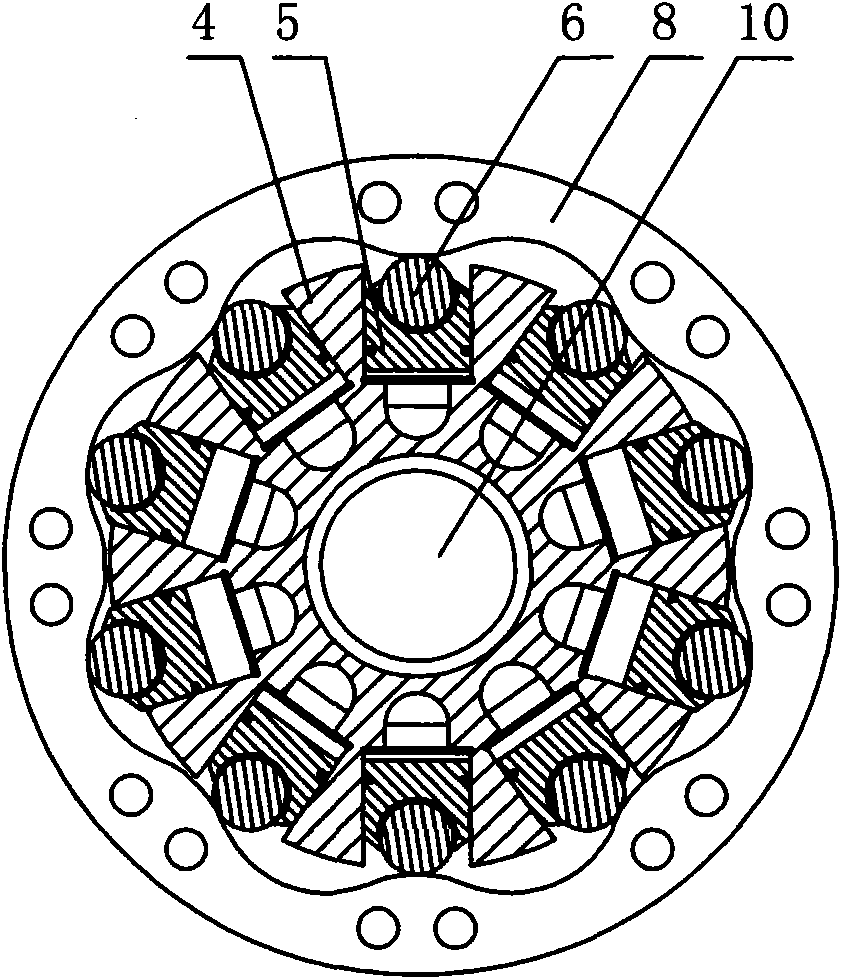

[0016] An inner curve multi-action radial plunger hydraulic motor, including a cover plate 1, a rear cover 2, a distribution shaft 3, a rotor 4, a plunger 5, a roller 6, a retaining ring 7, a stator 8, a front cover 9, The transmission shaft 10, the rolling bearing 11 and the sliding bearing 12, the cover plate 1 is fixed on the rear cover 2, the distribution shaft 3 is arranged in the rear cover 2, the rear cover 2 and the front cover 9 are fixed on the stator 8, and the transmission shaft 10 passes through the rolling bearing 11 It is supported, and the clearance is fixed and adjusted by bearing gaskets and retaining rings. The transmission shaft 10 and the rotor 4 are connected by splines to realize synchronous rotation, and the rotor 4 cooperates with the flow distribution shaft 3, such as figure 1 , figure 2 shown.

[0017] The plunger 5 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com