Backlight source

A backlight and light-emitting surface technology, applied in the field of backlight, can solve problems such as poor uniformity of LED backlight, and achieve the effects of avoiding overlapping of light and dark, increasing refraction angle, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

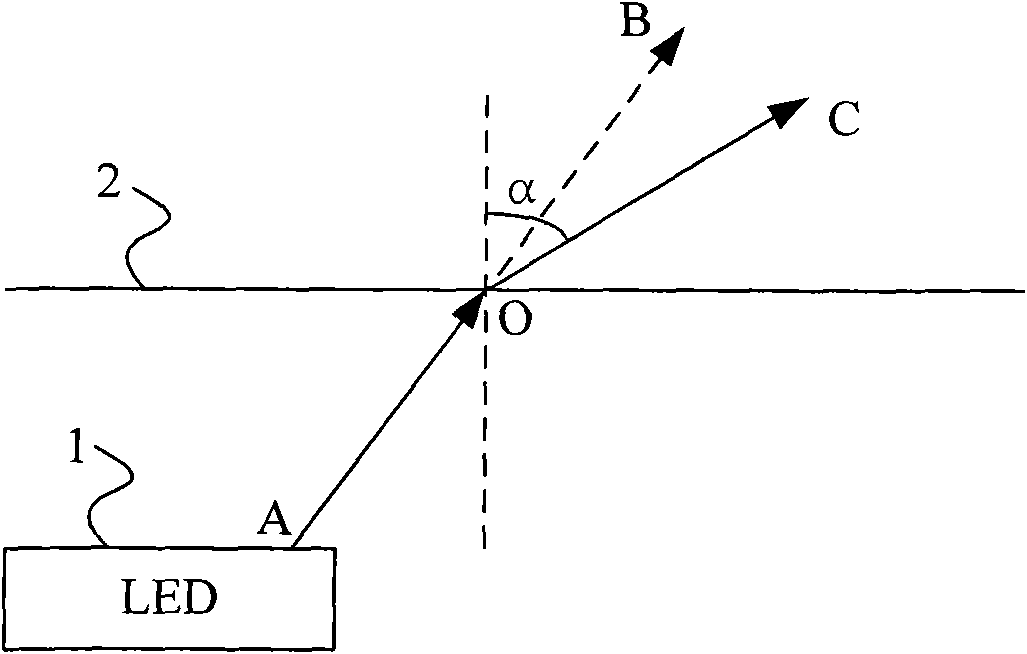

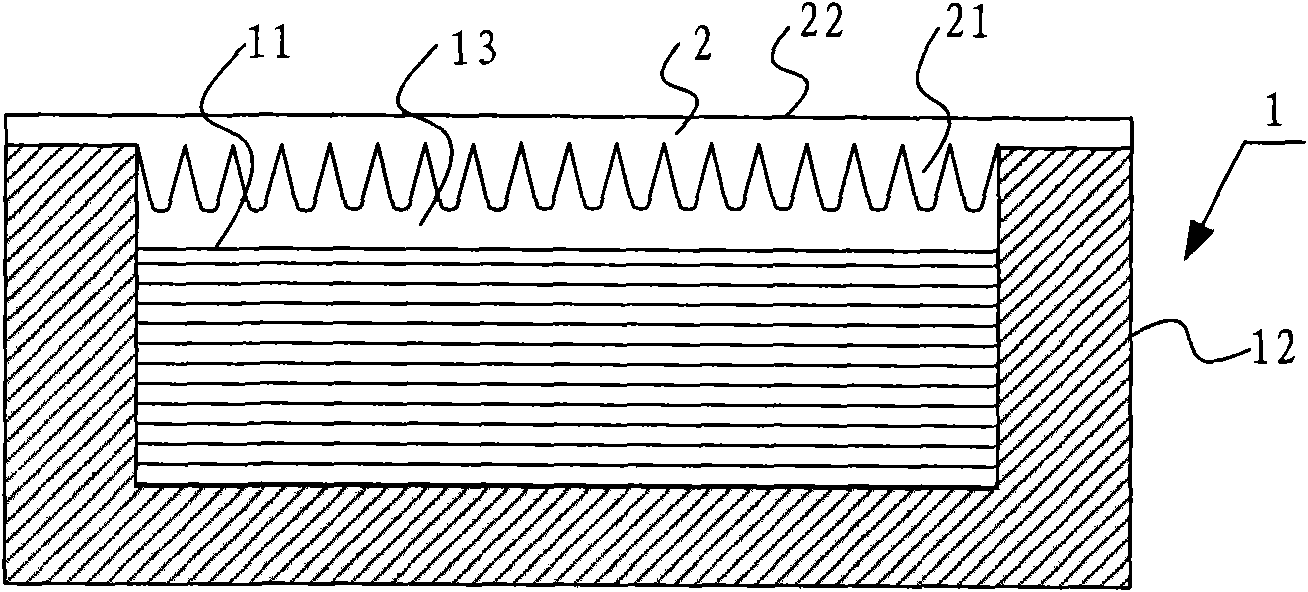

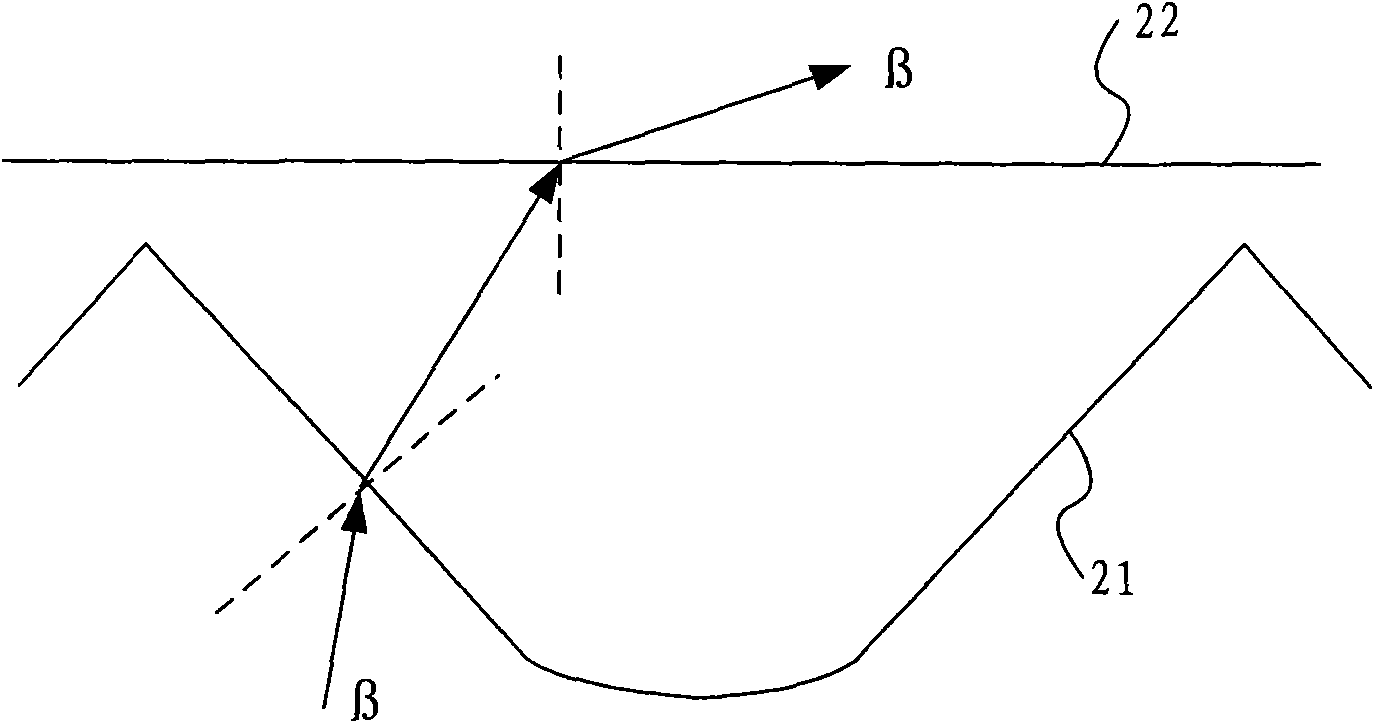

[0015] With the continuous development of LED technology, LED has gradually become the preferred light-emitting element in backlight due to its small size and high brightness. Therefore, the peripheral brightness is darker than the middle brightness, which will cause the overlapping phenomenon of light and dark among several LED illuminants, resulting in the defect of poor uniformity of LED backlight. The present invention provides a solution to the above defects The solution is that in the existing backlight using LED as the light source, in order to increase the brightness around the single LED illuminant, that is, to increase the intensity of light emitted to the periphery, a light-transmitting film is set on the light-emitting surface of each LED illuminant to play a role. It is not only transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com