Large air-cooled turbo-generator with circumferential mixed ventilation cooling structure

A turbo-generator, ventilation and cooling technology, which is applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problem that the single-unit capacity of the turbo-generator cooling technology cannot be taken into account at the same time, so as to improve the cooling effect and reduce the power. , the effect of large heat dissipation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

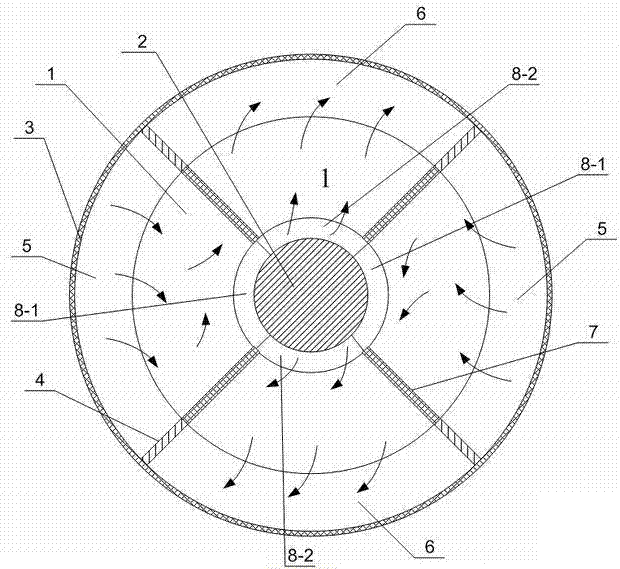

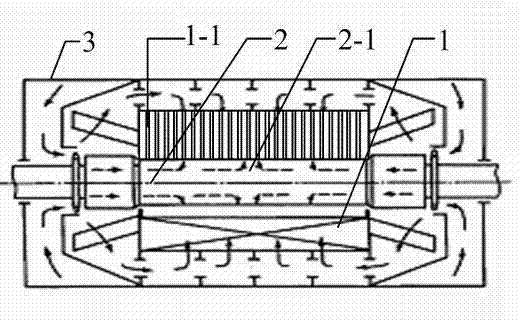

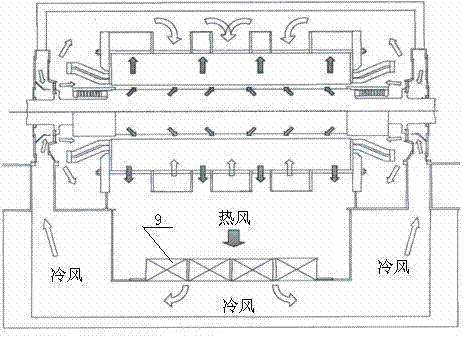

[0011] Specific implementation mode one: the following combination figure 1 , figure 2 and image 3 Describe this embodiment, this embodiment includes a stator 1, a rotor 2 and a casing 3, an air gap is formed between the outer surface of the rotor 2 and the inner surface of the stator 1, and the stator 1 is housed inside the casing 3, It also includes four axial rubber partitions 4 and a cooler 9, the four axial rubber partitions 4 are evenly arranged between the inner circular surface of the casing 3 and the outer circular surface of the stator 1 along the circumferential direction, forming Two opposite cold wind areas 5 and two opposite hot air areas 6 , the two opposite hot air areas 6 communicate with the inlet of the cooler 9 .

[0012] In this embodiment, a special oil-resistant and electric-resistant synthetic rubber strip partition is used between the inner circular surface of the casing 3 and the outer circular surface of the stator 1 to divide it into four parts ...

specific Embodiment approach 2

[0013] Specific implementation mode two: the following combination figure 1 and figure 2 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that it also includes four air gap baffles, and the air gap segment corresponding to the stator arc segment corresponding to the cold wind area 5 is the air gap arc segment 8 in the cold wind area -1, there are two air gap arc sections 8-1 in the cold wind zone, and an air gap baffle plate is respectively arranged on the two end faces of the air gap arc section 8-1 in the cold wind zone. Other components and connections are the same as those in Embodiment 1.

[0014] The setting of the air gap baffle can prevent the air volume at the entrance of the air gap from affecting the cold wind area, and even cause the effect of air recharge. The mixing of the air volume at the outlet of the cold air area can reduce the temperature of the air entering the hot air area.

[0015] working principle:

[0016] The ...

specific Embodiment approach 3

[0017] Specific implementation mode three: the following combination figure 1 Describe this embodiment, the difference between this embodiment and Embodiment 1 or 2 is that it also includes four ventilation channel steels 7, the four ventilation channel steels 7 are evenly arranged along the circumferential direction of the stator 1, and the four ventilation channel steels The channel steel 7 divides the stator 1 into four regions, and the arc segments of the outer wall of the stator 1 corresponding to the four regions correspond to the arc segments where the cold wind zone 5 and the hot wind zone 6 are respectively located. Other compositions and connections are the same as those in the first or second embodiment.

[0018] In this embodiment, four ventilation channel steels 7 are used in the area of the stator 1 to divide the stator 1 into the same four areas on the circumference, and the stator 1 is formed into a petal layout. This petal-type layout structure separates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com