Horizontal type turbulent ball packing filter device

A technology of filter device and ball filler, which is applied in the fields of filtration of dispersed particles, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as inability to install, and achieve the effect of improving dust removal efficiency, high working reliability and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

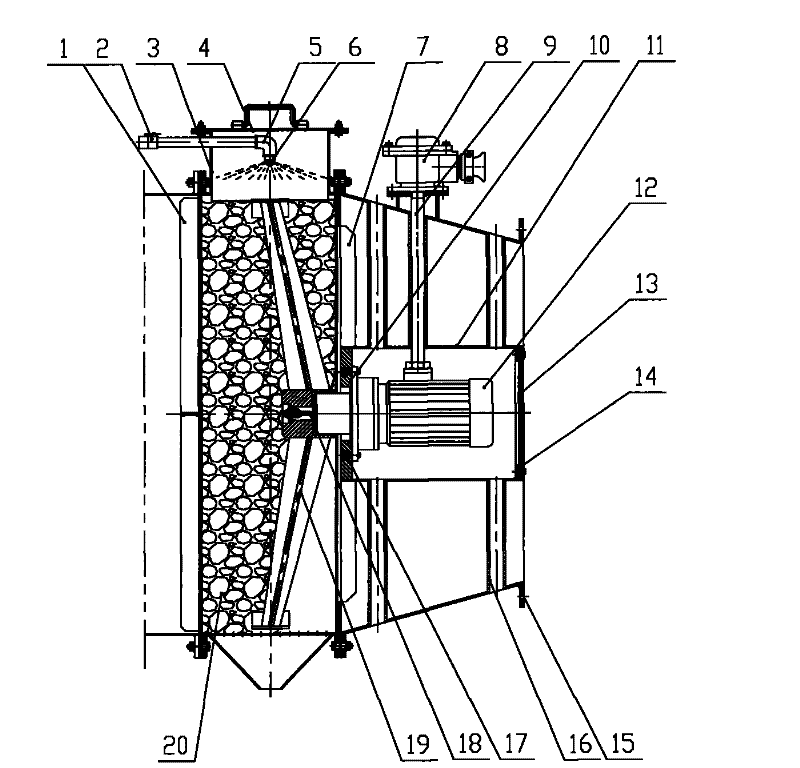

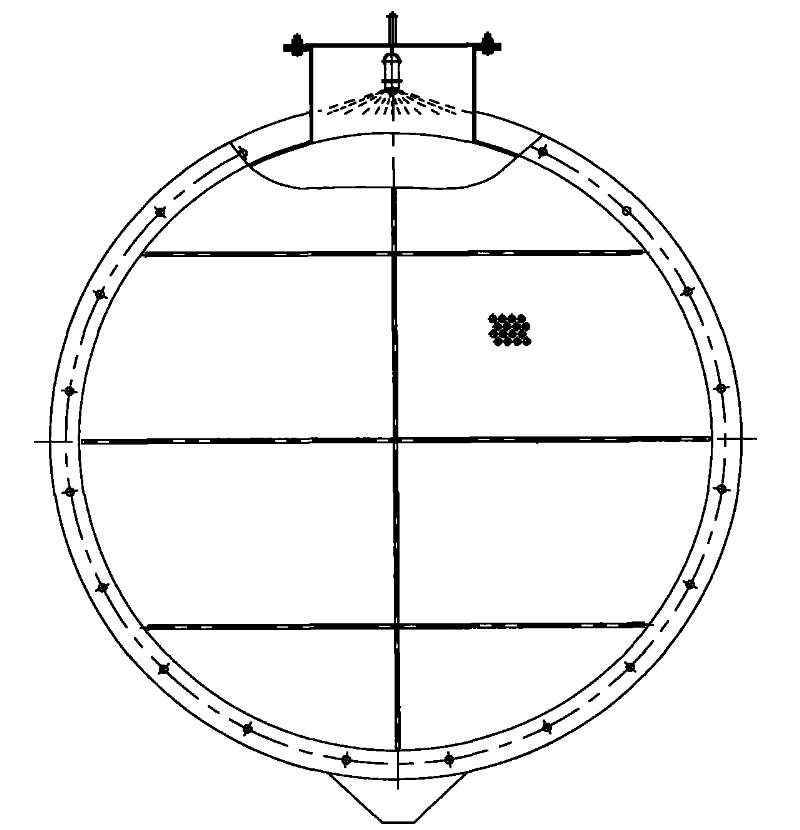

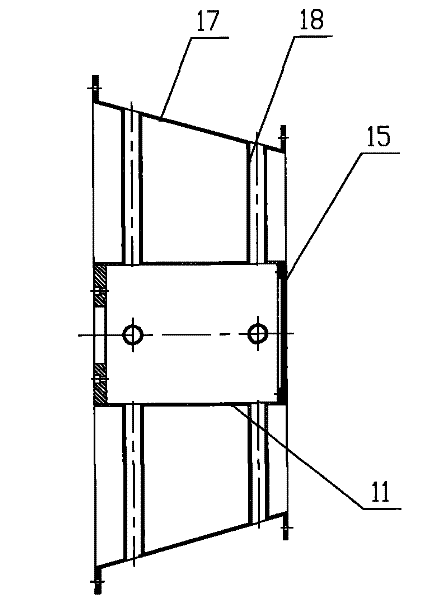

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0021] In the present invention, the turbulent ball packing filter device is designed as a horizontal cylinder structure, which is mainly composed of a filter, a water supply device, a stirring device and the like. The filter is composed of a cylinder body 3, a cover plate 1 and a bottom plate 7 to form a stuffing chamber, that is, a porous or seam-structured cover plate 1 and a bottom plate 7 are respectively arranged on both sides of the cylinder body 3, and filler balls 20 are filled in the stuffing chamber. The filler ball 20 can be a hollow sphere made of non-metallic material. The cover plate 1 and the bottom plate 7 are porous or slit structures that facilitate the passage of air, such as a grid plate, or a louver plate, or a flat plate with slits. The cylindrical outer periphery of the filter cylinder body 3 is a sealing structure. The top of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com