Scissor-type appliance elevator mechanism

A lifting mechanism, scissor-type technology, applied in the field of scissor-type equipment lifting mechanism, can solve the problems of time-consuming, many operators, and laborious, etc., and achieve the effect of simple structure and fast lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

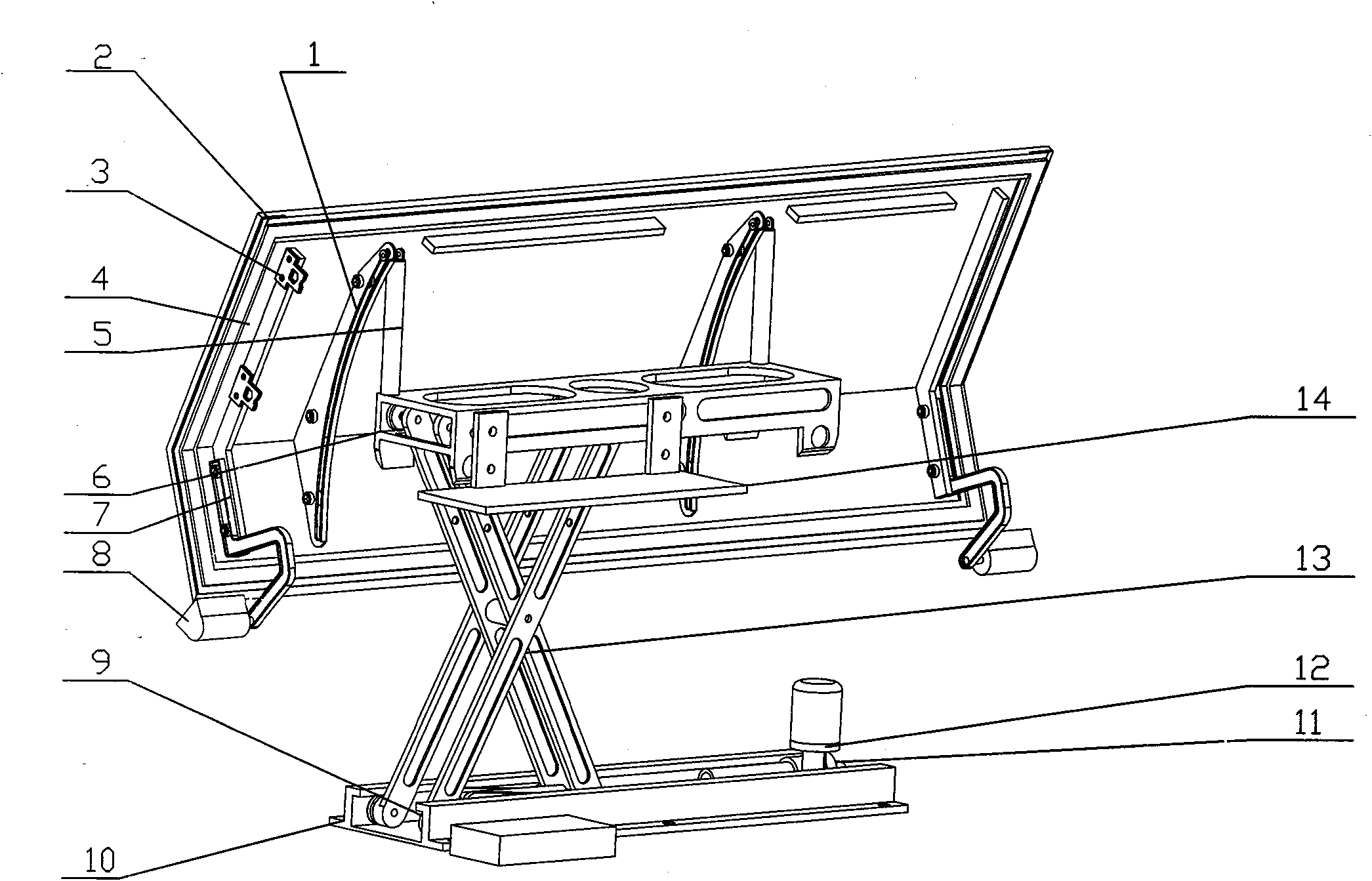

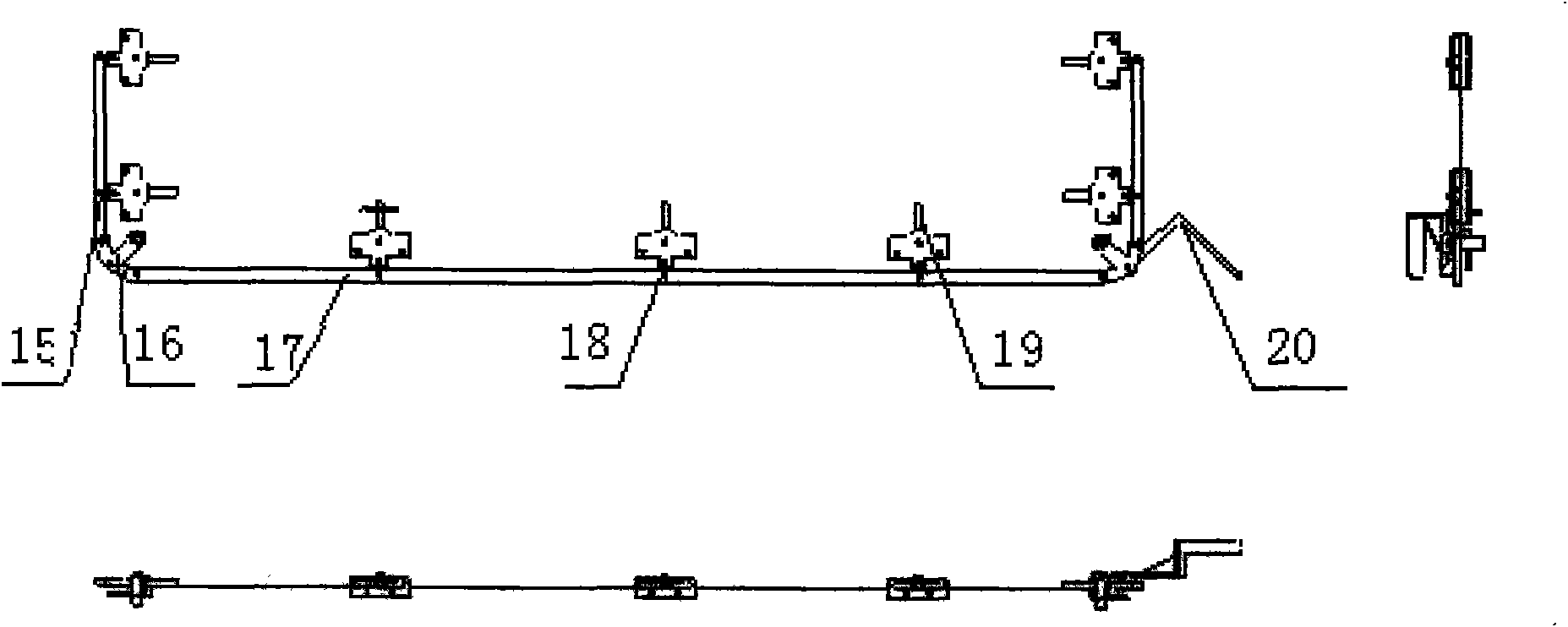

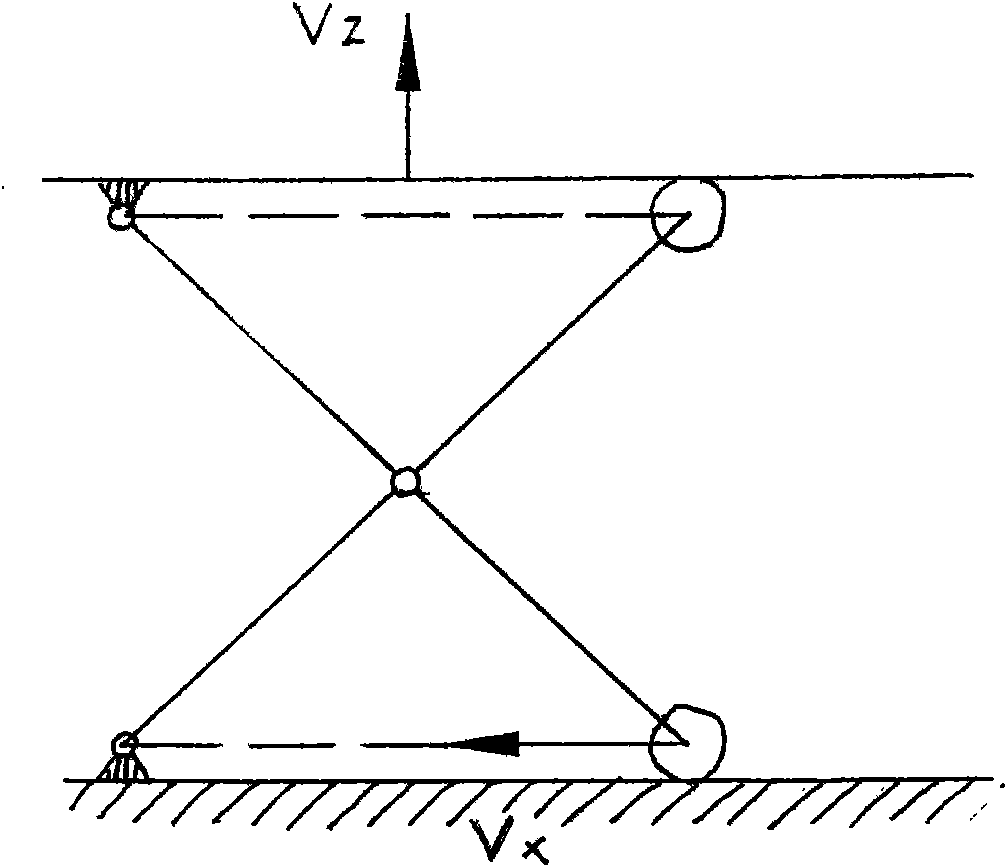

[0021] The scissor lifting mechanism provided by the present invention is realized through the following technical scheme: the scheme includes electric push rod, scissor rod group, bracket, block assembly, base, door bracket assembly, top frame, push rod support Seat, door shaft assembly, crank arm, door seal, hatch, door guide rail, door hook, short connecting rod, turntable, long connecting rod, lock body, dead bolt, handle, limit switch, etc.

[0022] The door mechanism includes the door shaft assembly, the crank arm, the door sealing strip, the door, the door guide rail and the door hook.

[0023] The hatch locking mechanism includes the short connecting rod, the rotating disk, the long connecting rod, the lock body, the dead bolt, the handle and the like.

[0024] The control mechanism includes the above-mentioned limit switch and the like.

[0025] When lifting, manually open the locking mechanism, control the electric push rod through the command of the control panel, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap