Impact testing machine of pneumatic piston type automobile parts

A technology for auto parts and crash testing, applied in the field of simulated crash testing machines, can solve the problems of difficulty in product testing, waste of cost, low efficiency, etc., and achieve the effects of convenient and fast speed control, cost reduction, and short acceleration stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

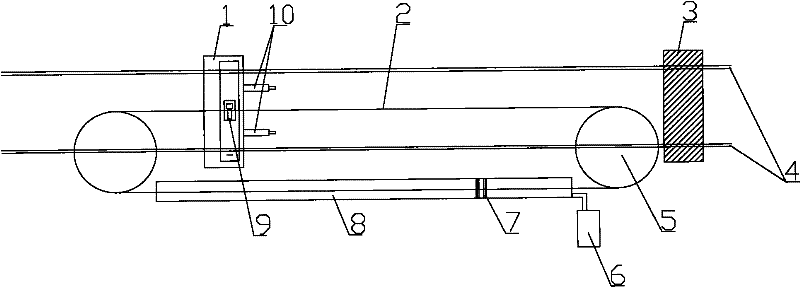

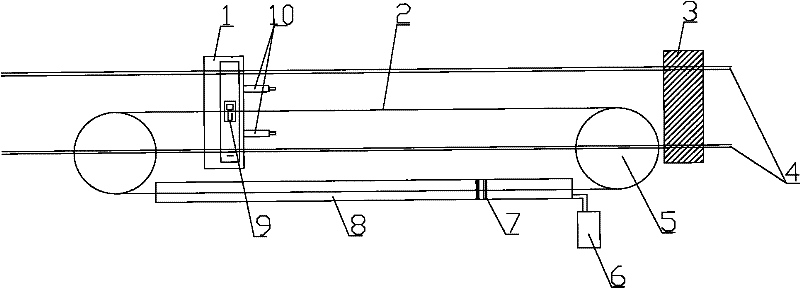

[0020] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0021] As shown in Fig. 1, the present invention discloses a crash test machine for auto parts, including a model car 1 for the crash test, the model car 1 is equipped with an automatic tightening and disengaging device 9, a model man and a buffer device 10, etc. basic equipment. Various auto parts products can be installed on the model car 1, and a collision test is carried out to test the anti-collision strength of the auto parts products.

[0022] The model car 1 slides freely within the travel range of the running track 4 , and a collision barrier 3 is arranged at the end of the running track 4 . The model car 1 will hit the collision barrier 3 at a certain speed.

[0023] The movement of the model car 1 is realized by a traction guide mechanism, and the traction guide mechanism includes a cylinder 8 as a driving device, and the cylinder 8 includes an air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com