Control system of frequency conversion-controlled centrifugal machine

A control system and frequency conversion control technology, which is applied to electromechanical devices, electrical components, AC commutators, etc., can solve the problems of obvious running vibration, large running noise, and high starting noise, and achieves large control range, small control error, Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

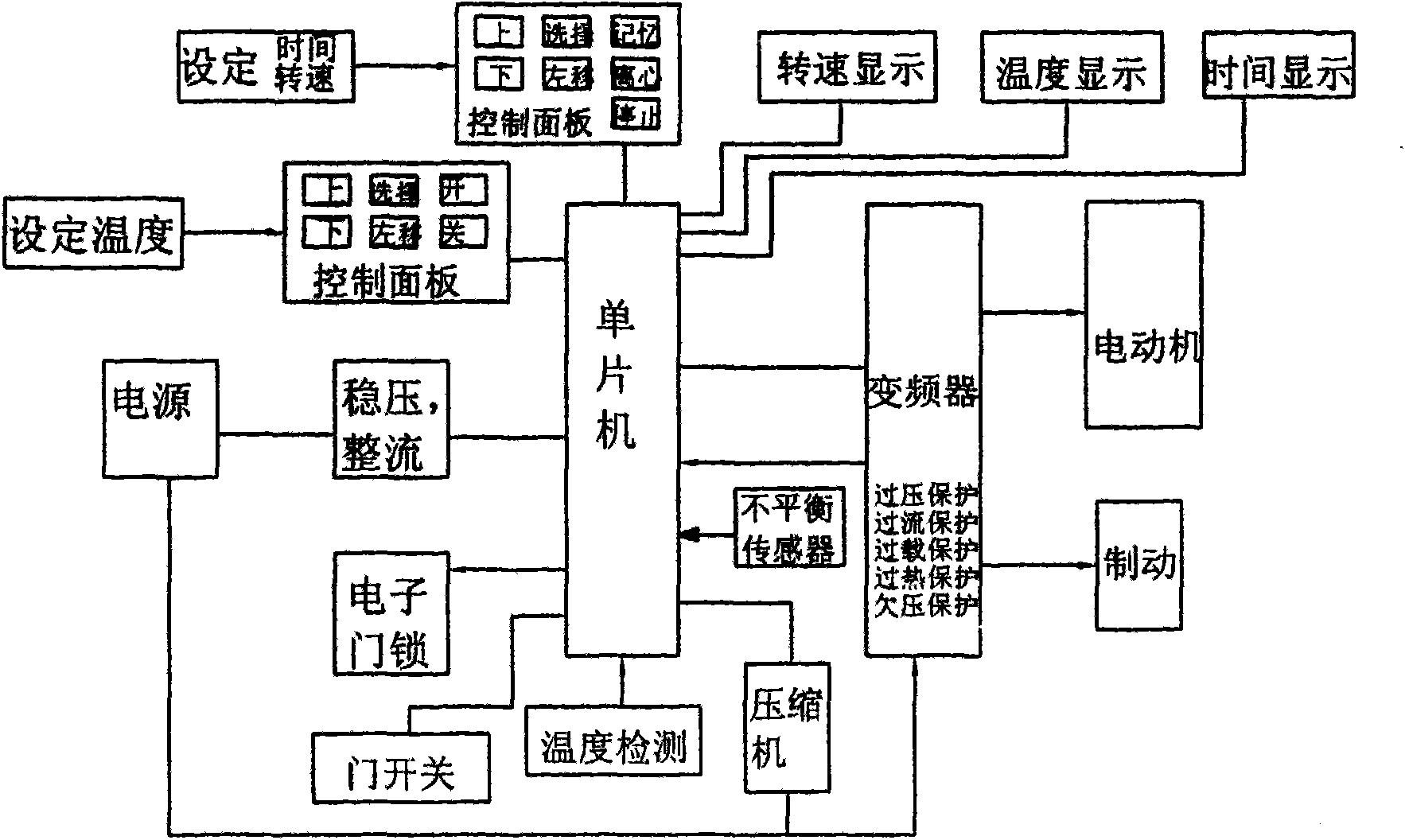

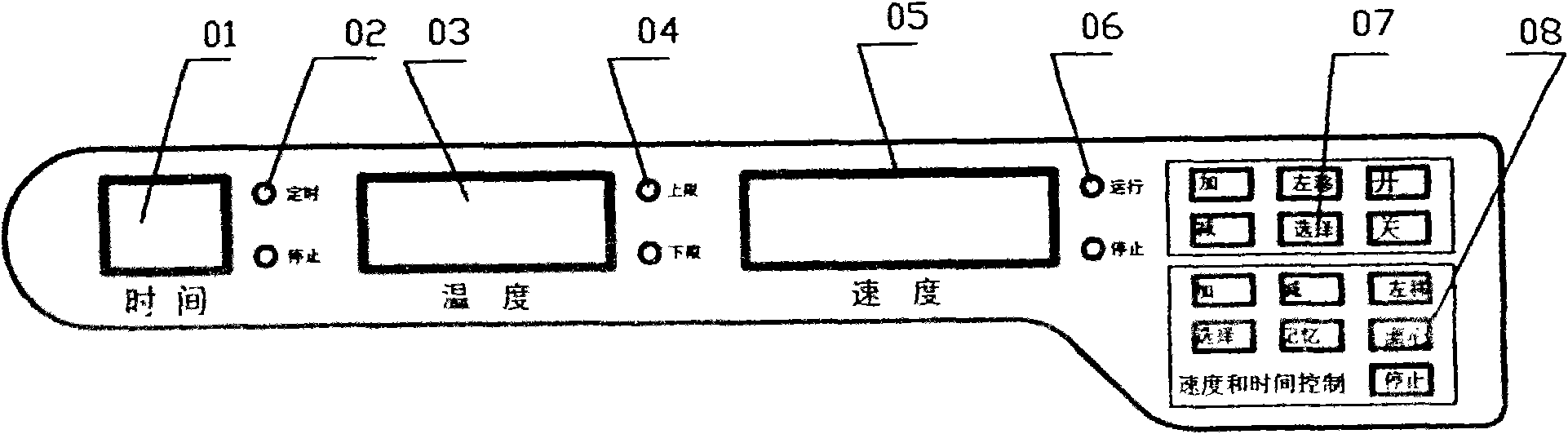

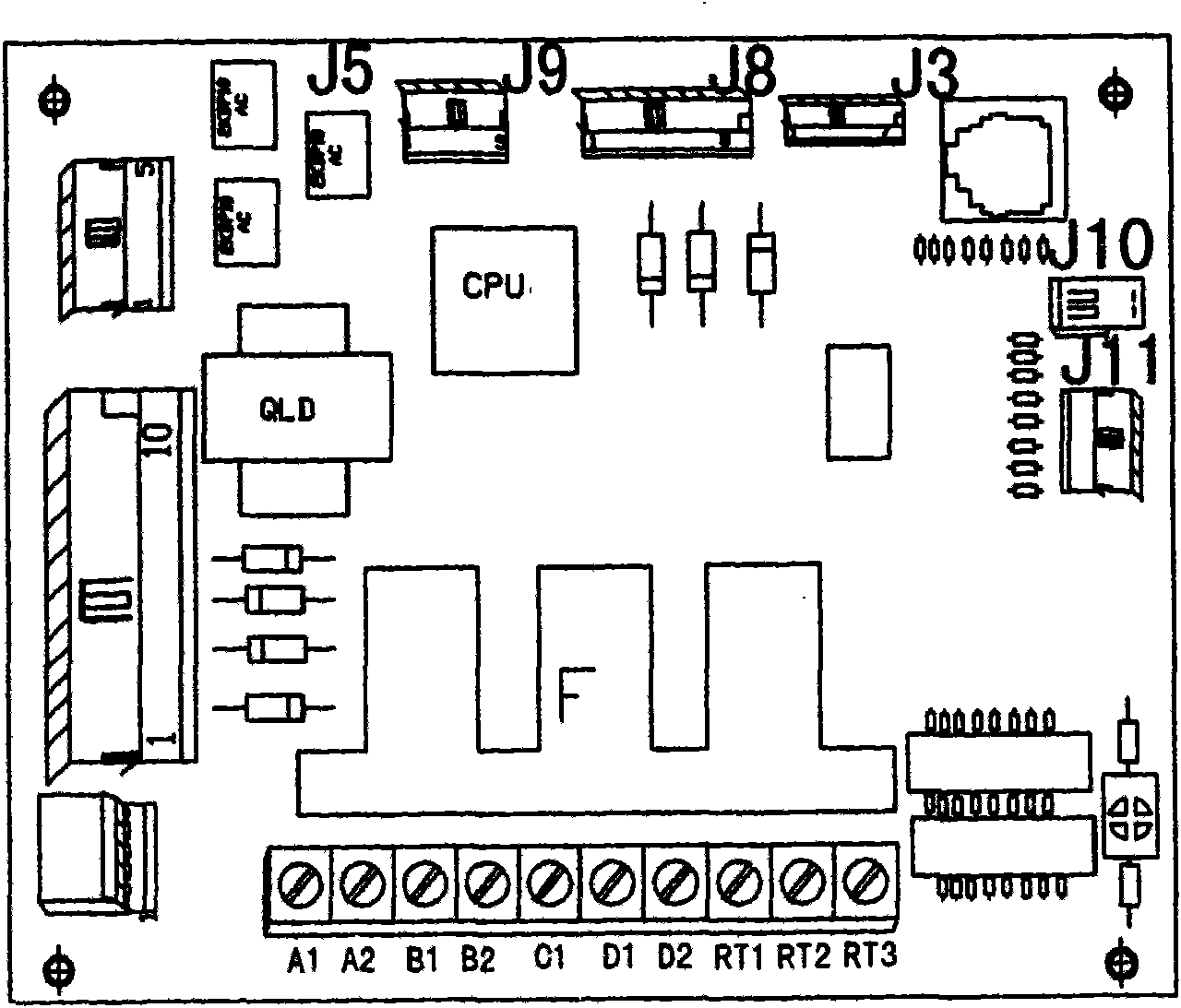

[0034] Attached below figure 1 , 2 , 3 and embodiment further illustrate the present invention:

[0035] This embodiment is a control system applied to a DL-6000B frequency conversion controlled centrifuge. The centrifuge motor used for control is an asynchronous motor. The outer diameter of the motor is 130mm, the total length is 229mm, the diameter of the rotating shaft is 16mm, and the It is 750W. Control block diagram such as figure 1 shown.

[0036] The control system of this embodiment is attached with figure 1 A block diagram for the principle of operation is attached figure 2 The control panels given are samples and are attached image 3 The control system of the DL-6000B frequency conversion control centrifuge made by the main control board interface and connecting lines, wherein; the control block diagram (see attached figure 1), which is the working principle diagram of the centrifuge control system controlled by frequency conversion. Its control process is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com