Gear-driven assembly of transmission gear shifting

A technology of transmission gears and shifting devices, which is applied in the direction of wheel transmissions, vehicle gearboxes, rotary transmissions, etc., can solve the problem that gear shifting will not be easily performed, and achieve the effect of easy gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, a gear driven assembly of a transmission gear shifting device according to various embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0047] figure 2 and 3 is a view showing an example to which the gear follower assembly of the present invention can be applied.

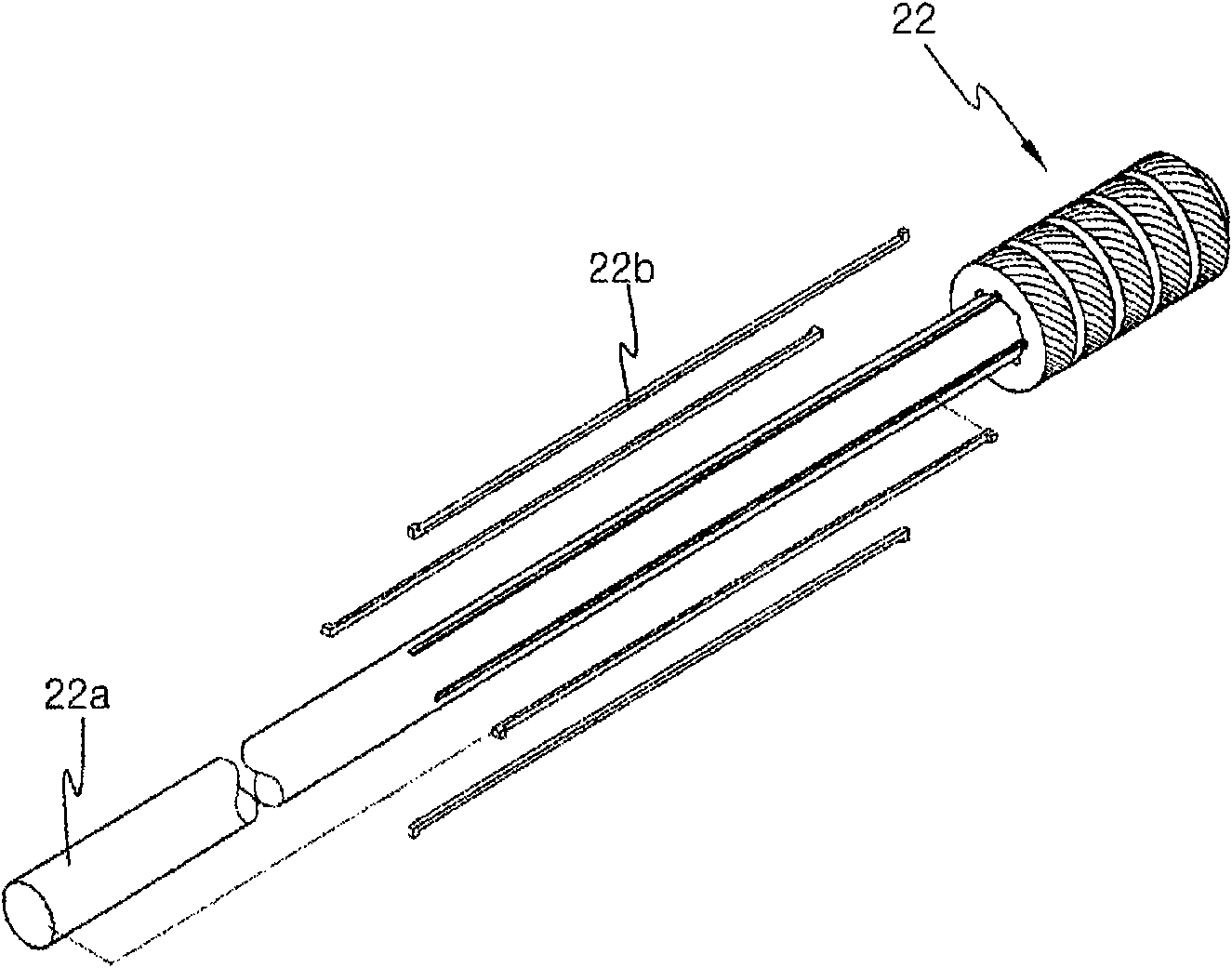

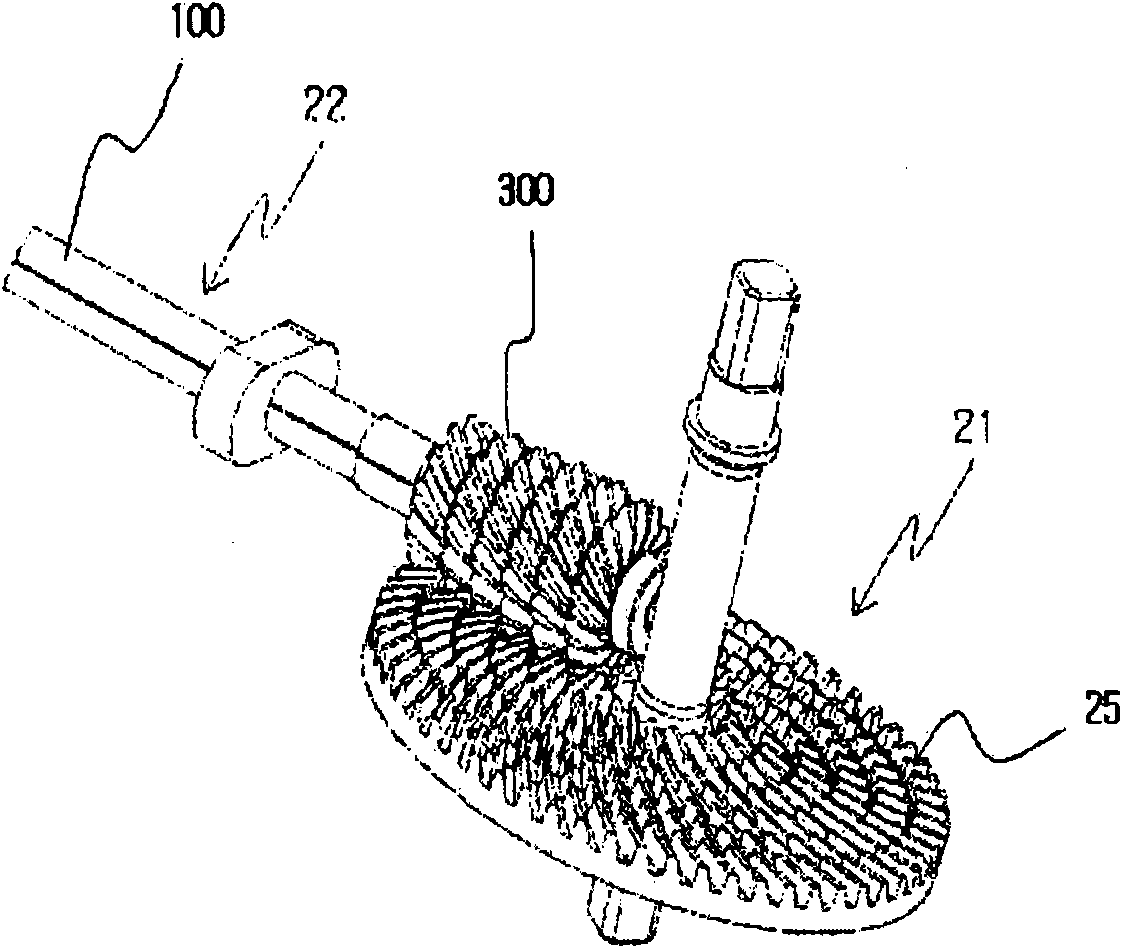

[0048] refer to figure 2 and 3 , the pedal 11 of the bicycle 10 is connected to the crank 12 , the crank 12 is connected to the gear drive assembly 21 , and a plurality of driving bevel gears 25 are concentrically arranged in the gear drive assembly 21 . In addition, the gear driving assembly 21 is connected with the gear driven assembly 22, wherein a plurality of driven bevel gears 300 are installed at the driven shaft 100 so that the driving bevel gears 25 engage with the driven bevel gears 300, respectively.

[0049] As disclosed in Korean Patent Registration No. 2008-0688611 entitled "Transmission Gear Shifting Device for Automobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com