Gearbox with 16+8 gears

A gearbox and gear technology, applied in the field of gearboxes, can solve problems such as affecting the normal operation of the tractor, unreasonable internal structure layout, restricting the use of the tractor, etc., to achieve the effects of improving the comfort of operation, easy shifting, and reducing the failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

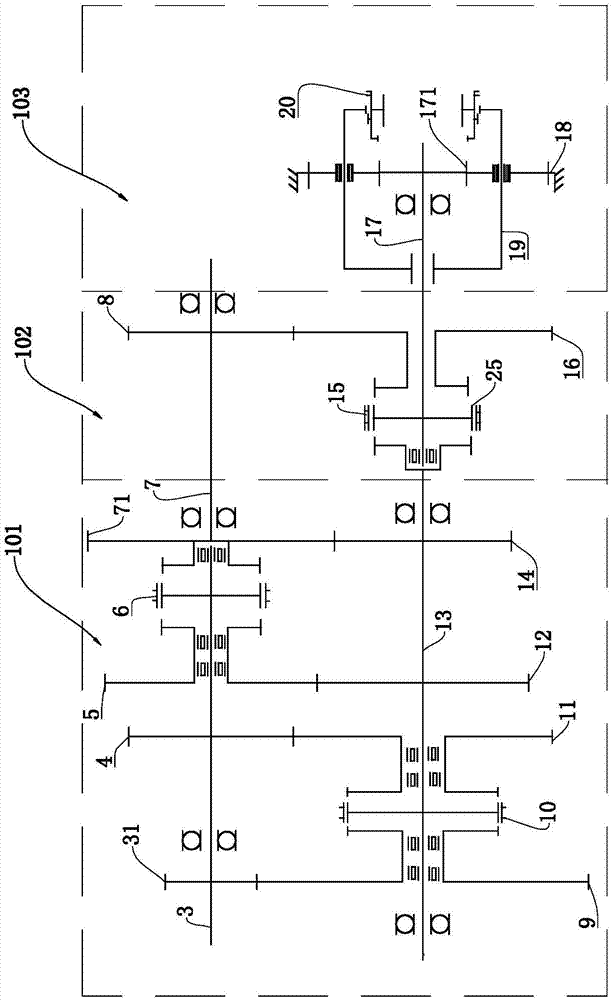

[0016] Such as figure 1 As shown, a gearbox with 16+8 gears, including a case (not shown in the figure),

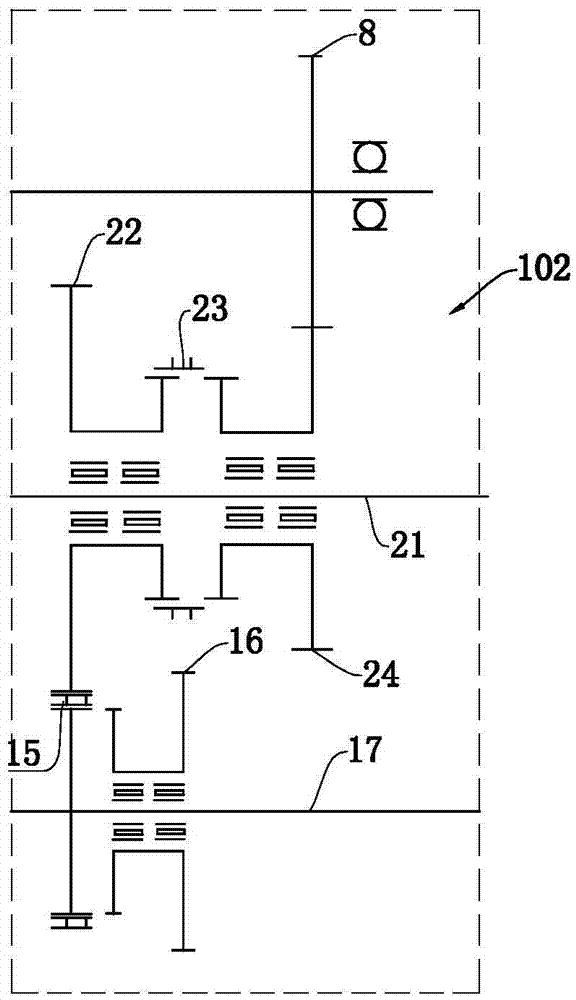

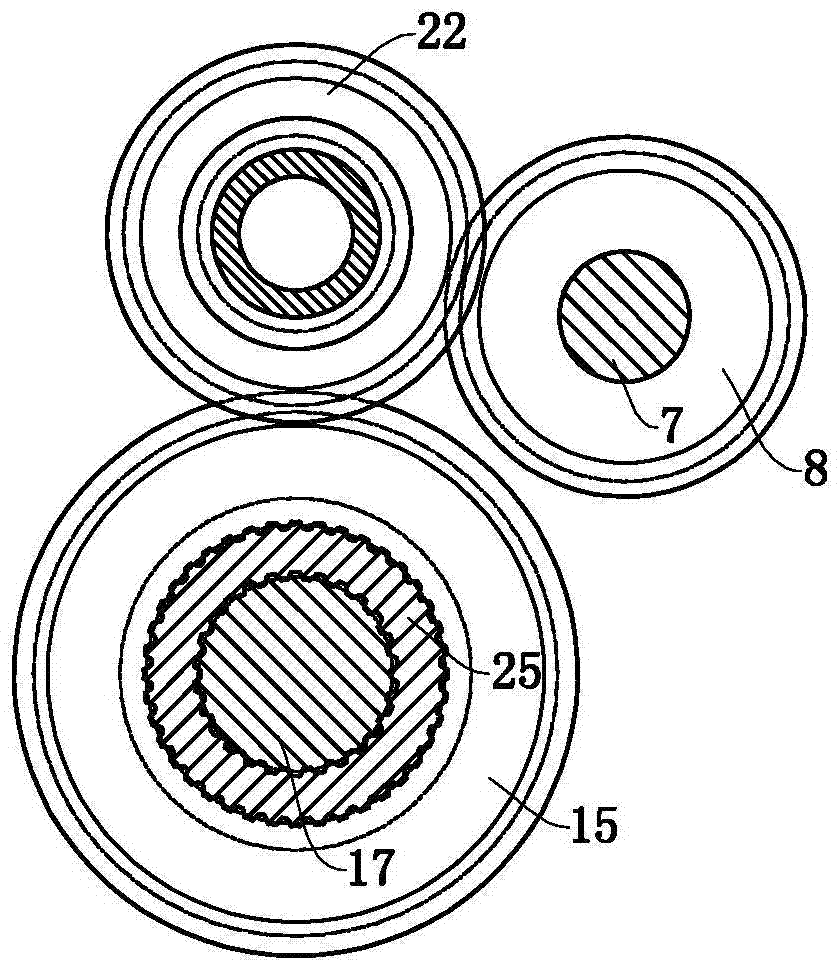

[0017] A parallel and correspondingly arranged input shaft 3 and an intermediate shaft 13, as well as a parallel and correspondingly arranged auxiliary transmission driving shaft 7, an idler shaft 21 and an output shaft 17 are installed in the box, and the input shaft 3 and the auxiliary transmission driving shaft 7 are arranged coaxially. The intermediate shaft 13 is arranged coaxially with the output shaft 17, and the main transmission mechanism 101, the auxiliary transmission mechanism 102, and the fast and slow gear transmission mechanism 103 are sequentially installed on these shafts;

[0018] The main transmission mechanism 101 such as figure 1 shown in .

[0019] One end of the input shaft 3 is a power input end, and the other end of the input shaft 3 is rotationally connected with the auxiliary transmission driving shaft 7 through a bearing. The input shaft 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com