Compact injector device with two armatures

A technology of injection device and armature, which is applied in the directions of fuel injection device, charging system, condensed fuel collection/return, etc., can solve the problems of large structure space and complex structure, and achieve the effect of simple cost, compact structure and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

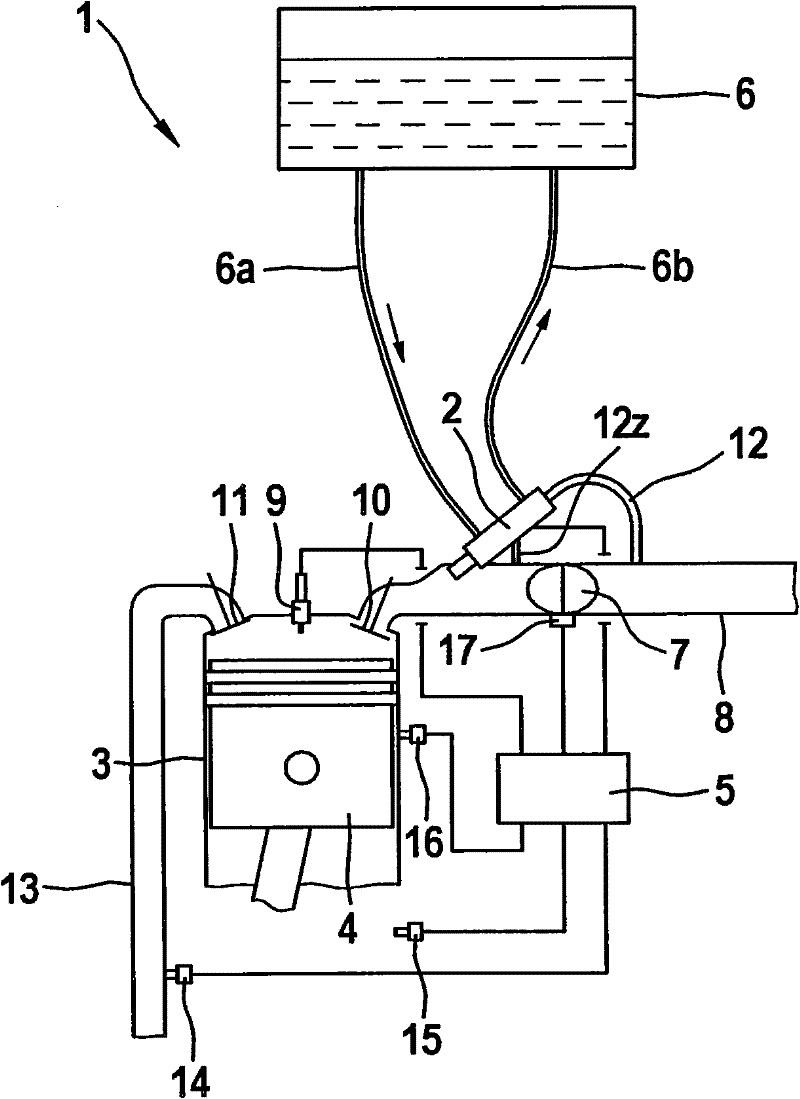

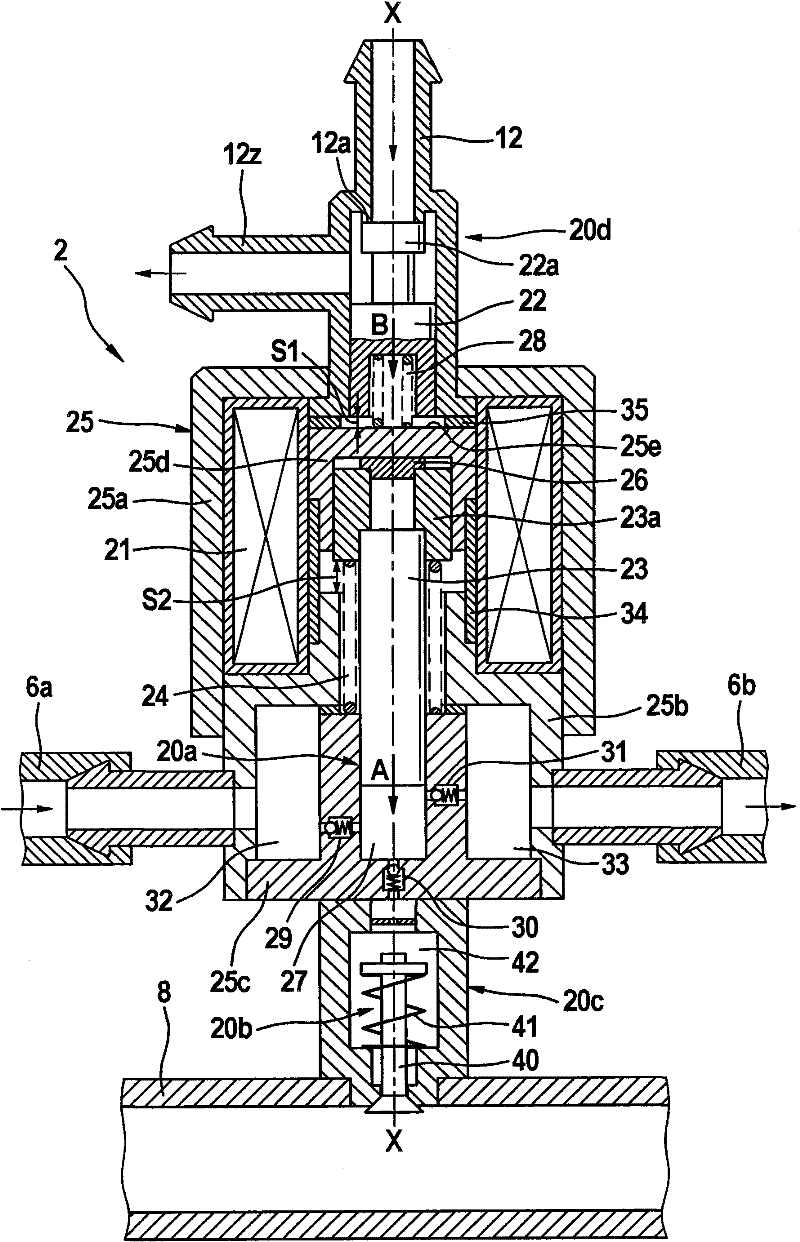

[0021] The following reference Figure 1 to 4 A small engine 1 having the injection device according to the first embodiment of the present invention will be described in detail.

[0022] figure 1 The structure of a small engine 1 configured as a single-cylinder engine is schematically shown. The small engine 1 includes a cylinder 3, a piston 4 capable of reciprocating inside it, a control unit 5 and an oil tank 6. The fuel tank 6 is connected to the injection assembly 2 through a fuel input line 6a. A fuel return line 6b returns to the fuel tank 6 from the injection assembly 2. As by figure 1 In a schematic representation, the fuel tank 6 is arranged above the injection assembly 2. As a result, fuel flows to the injection assembly 2 through the fuel supply line 6a based on gravity. The injection assembly 2 is represented very generally and includes a fuel pump, an injector with a combined pressure regulator and an air regulator, so that the injection assembly 2 is very compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com