Marine low-speed diesel engine common-rail fuel injection system with external pressurization piston

A technology of fuel injection system and pressurized piston, which is applied to fuel injection device, charging system, mechanical equipment, etc., can solve the problems of poor high-pressure sealing, difficulty in quick reset of pressurized piston, rising processing cost, etc., so as to reduce the sealing performance. requirements, improve reliability and safety, reduce the effect of overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, in order to understand the structure and application process of the present invention more clearly, but this should not limit the protection scope of the present invention.

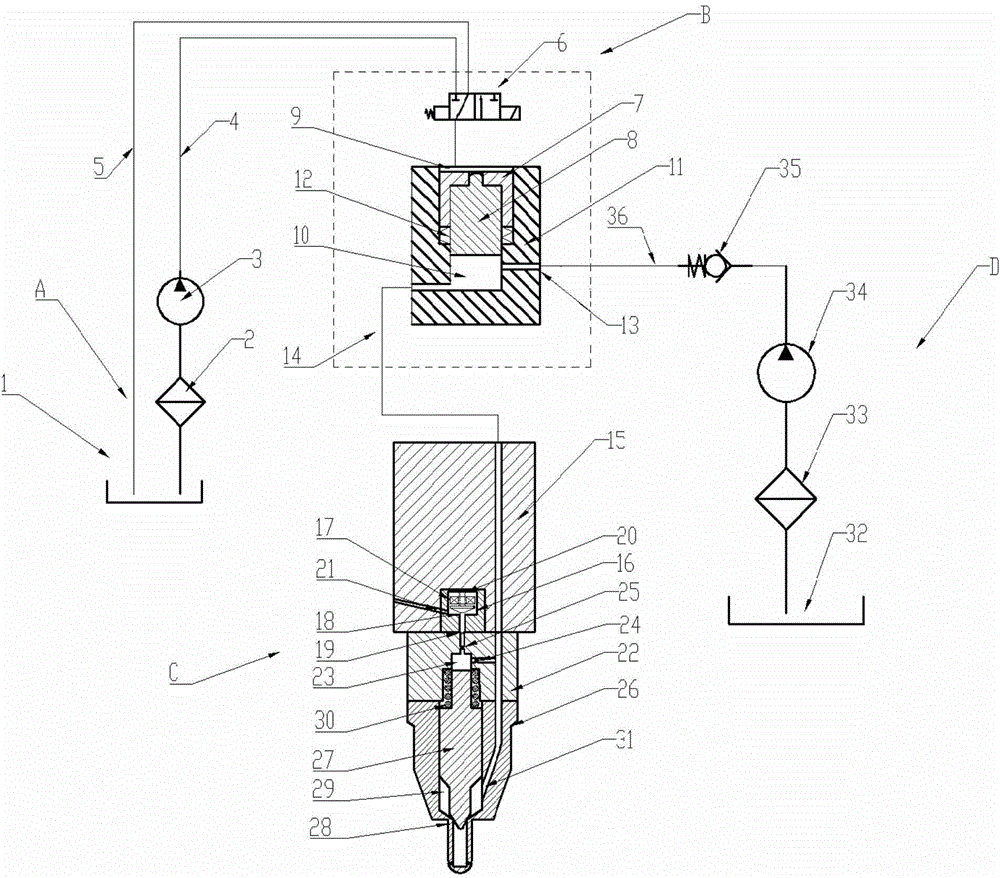

[0035] see figure 1 , The common rail fuel injection system for marine low-speed diesel engines with external booster pistons according to the present invention includes a servo oil supply part A, a hydraulic booster part B, a common rail injector C and a fuel supply part D.

[0036]The servo oil supply part A includes a servo oil tank 1, a servo oil filter 2, a servo oil delivery pump 3, a servo oil inlet pipe 4 and a servo oil return pipe 5; the servo oil filter 2 is located in the servo oil tank 1 One end of the servo oil delivery pump 3 is connected to the servo oil filter 2 , the other end is connected to the servo oil inlet pipe 4 , and the servo oil return pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com