Compressor

A technology for compressors and compressor impellers, which is applied in the field of compressors and can solve problems such as delayed surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

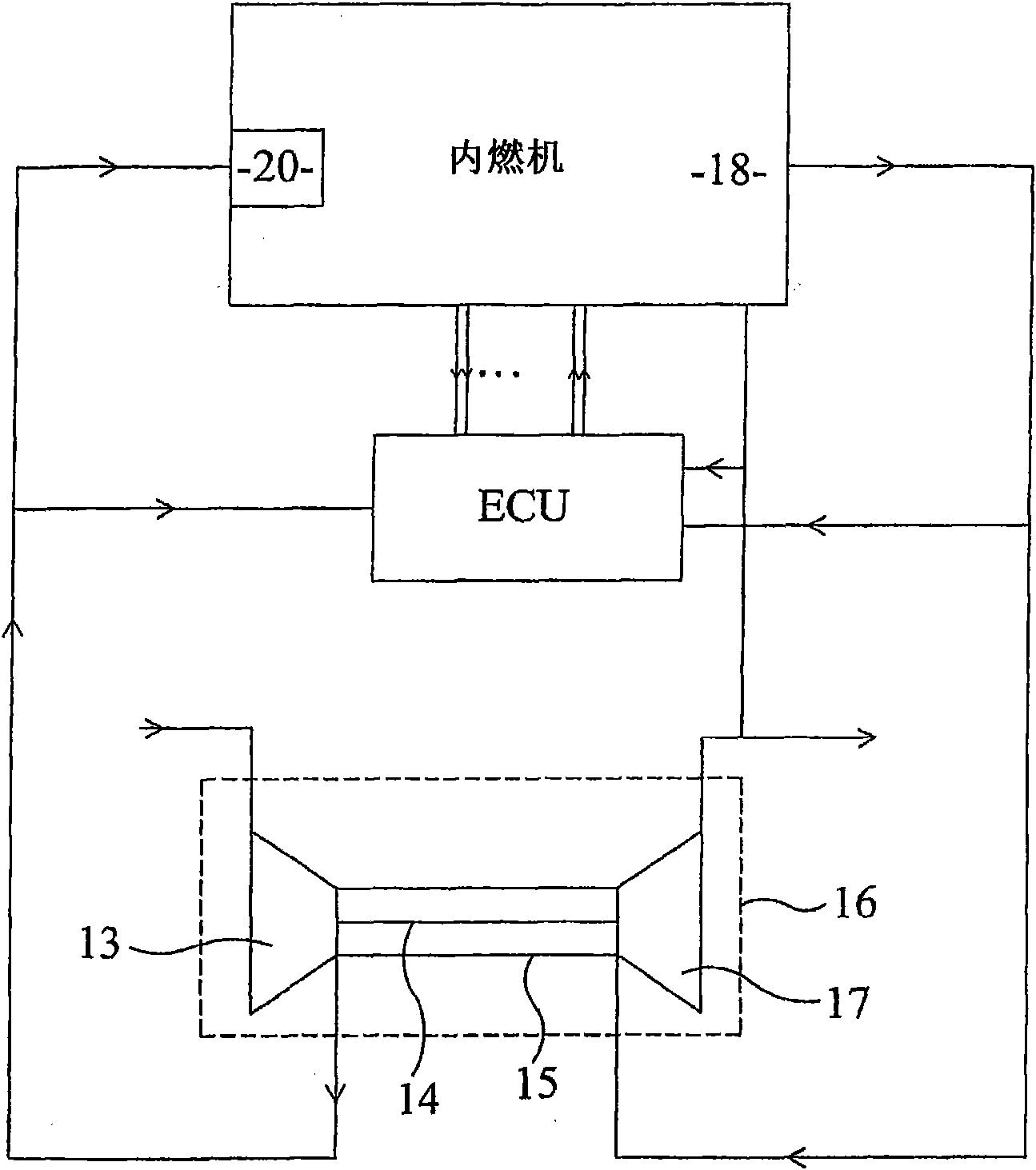

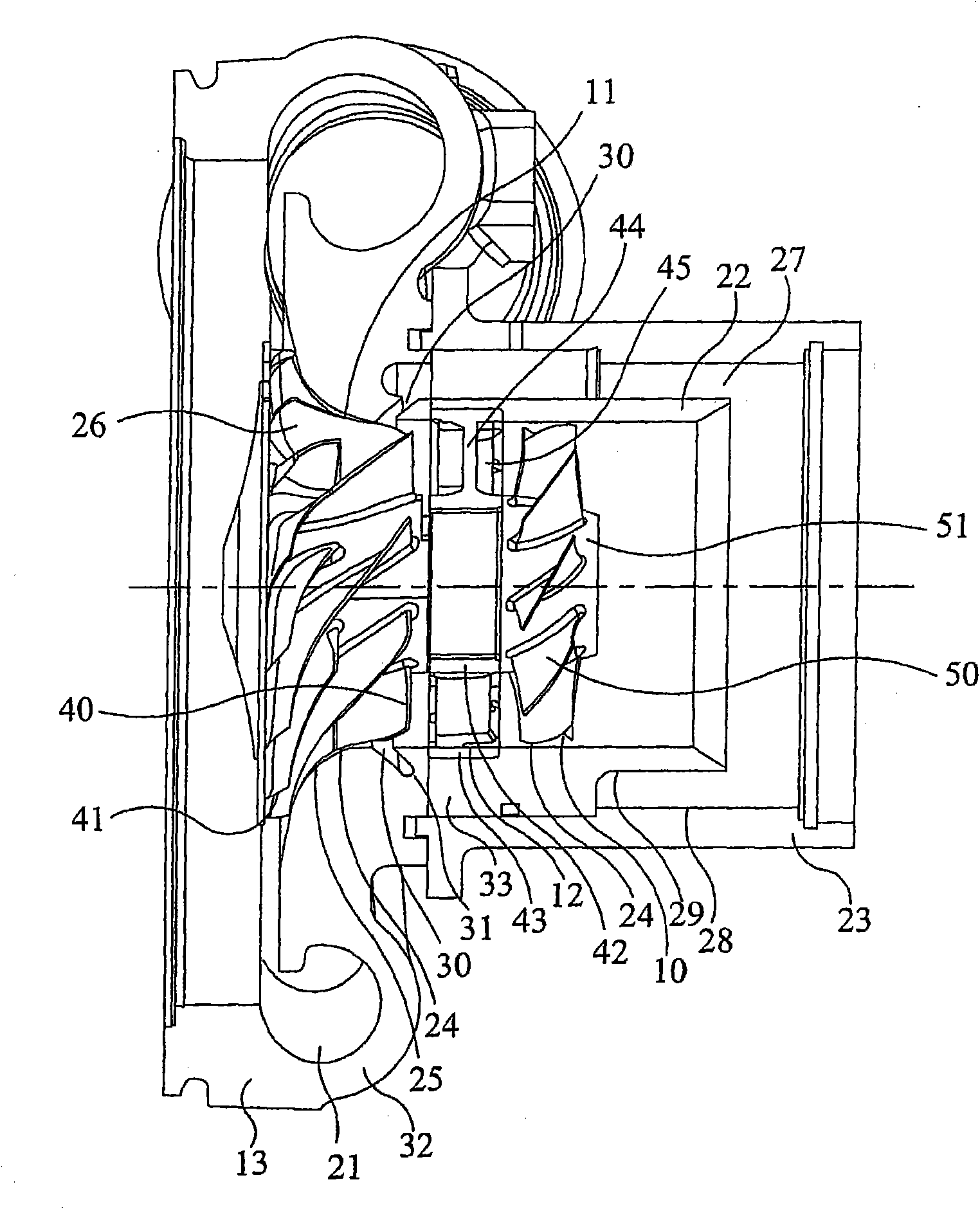

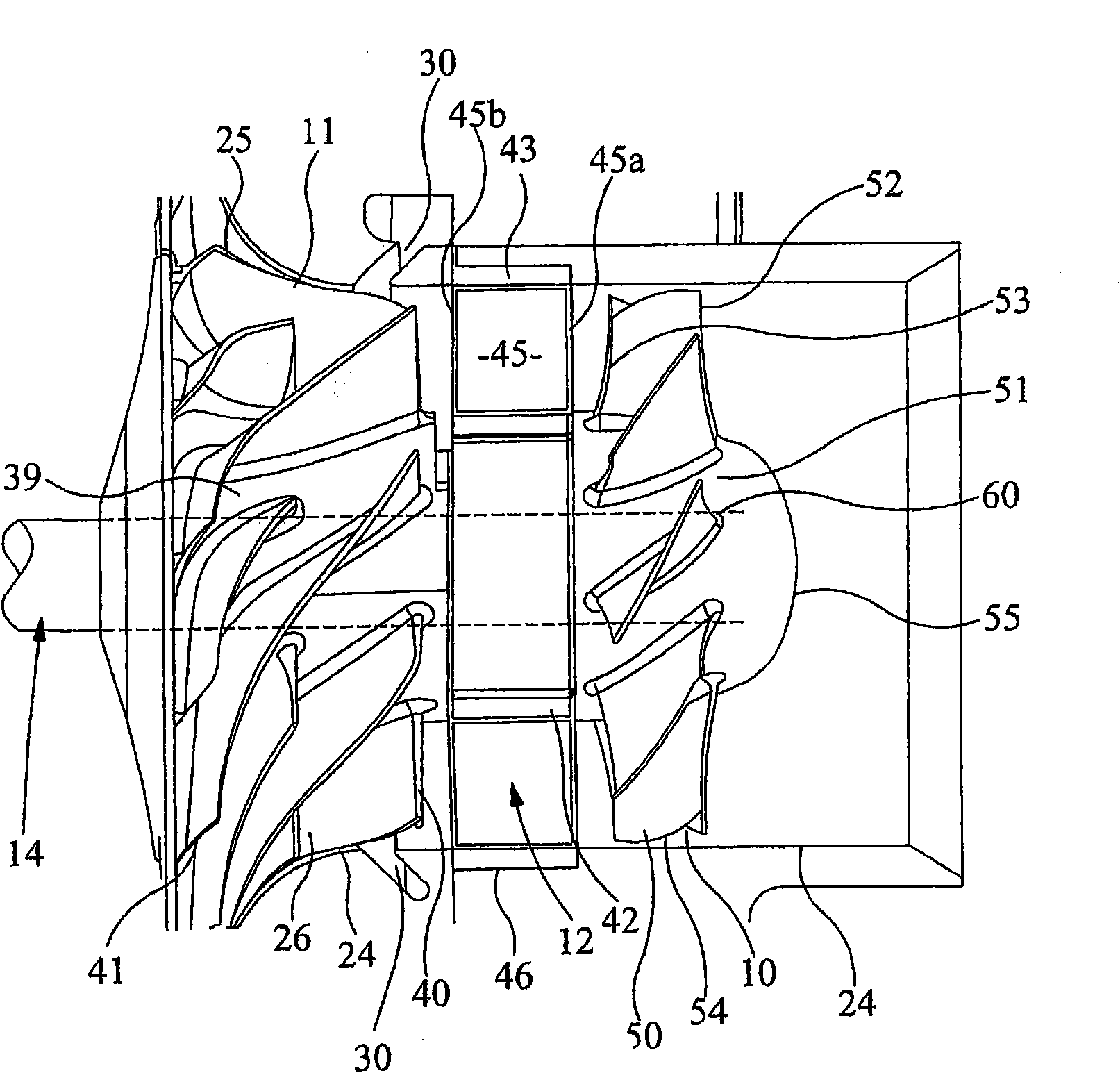

[0073] figure 1 Shows the compressor of the invention, belonging to the field of turbochargers fitted to internal combustion engines. figure 2 and image 3 A detailed enlarged exemplary embodiment showing compressor details. The compressor shown is a two-stage compressor for high compression ratios and includes an axial compressor wheel 10 upstream of a radial (centrifugal) compressor wheel 11 and passing through an intermediate axial The stator 12 is spaced apart from the radial compressor wheel 11 . The impellers 10, 11 are mounted on a common rotating shaft 14 (only image 3 shown), the common axis of rotation 14 revolves around figure 2 The compressor axis indicated by the dotted line rotates.

[0074] The compressor casing 13 is connected to a bearing housing 15 of the turbocharger 16 and the shaft 14 is designed to support an exhaust turbine 17 which is arranged on the other side of the bearing housing 15 . In operation, exhaust gas from the internal combustion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com