Patents

Literature

39 results about "Compressor map" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

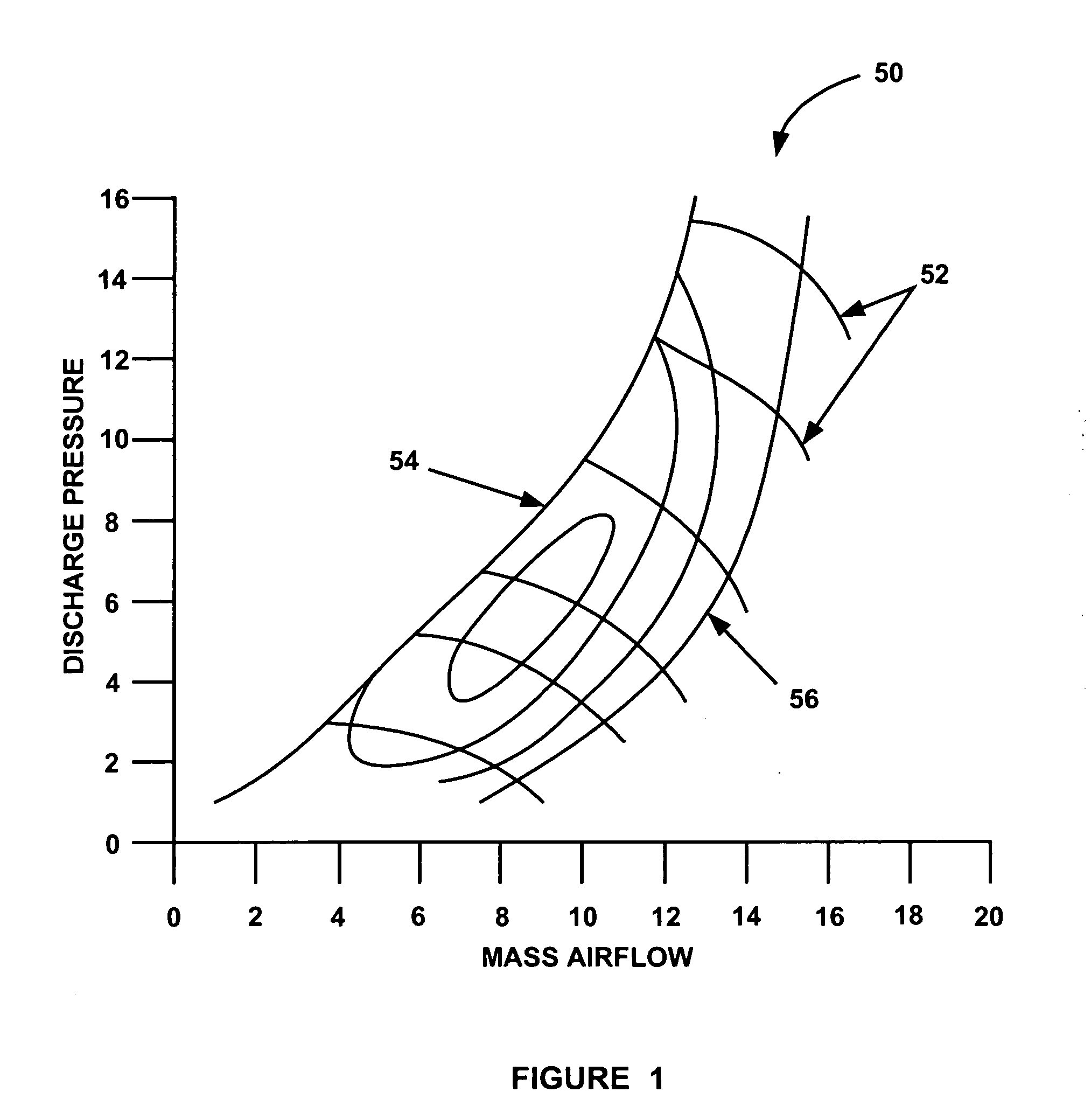

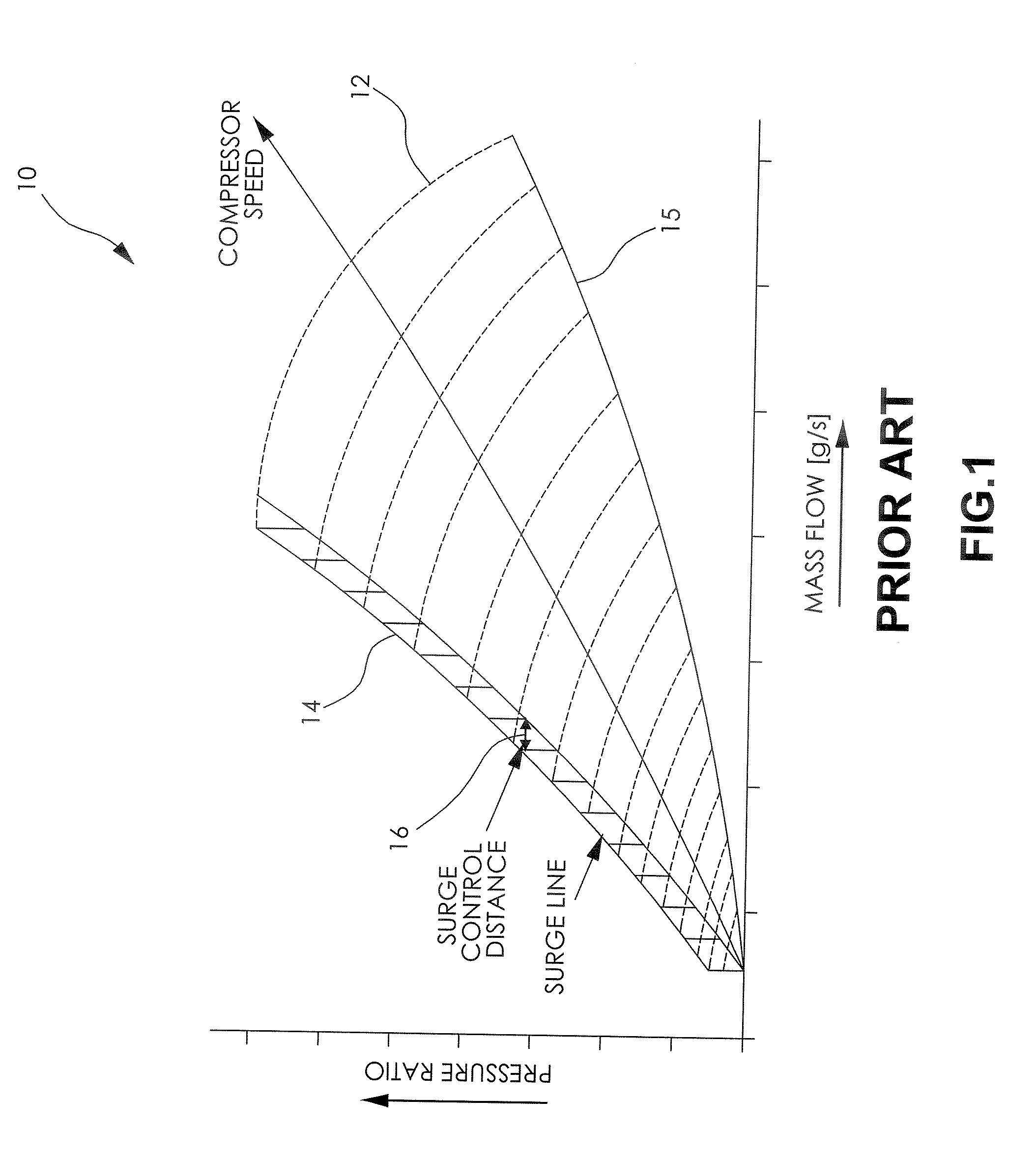

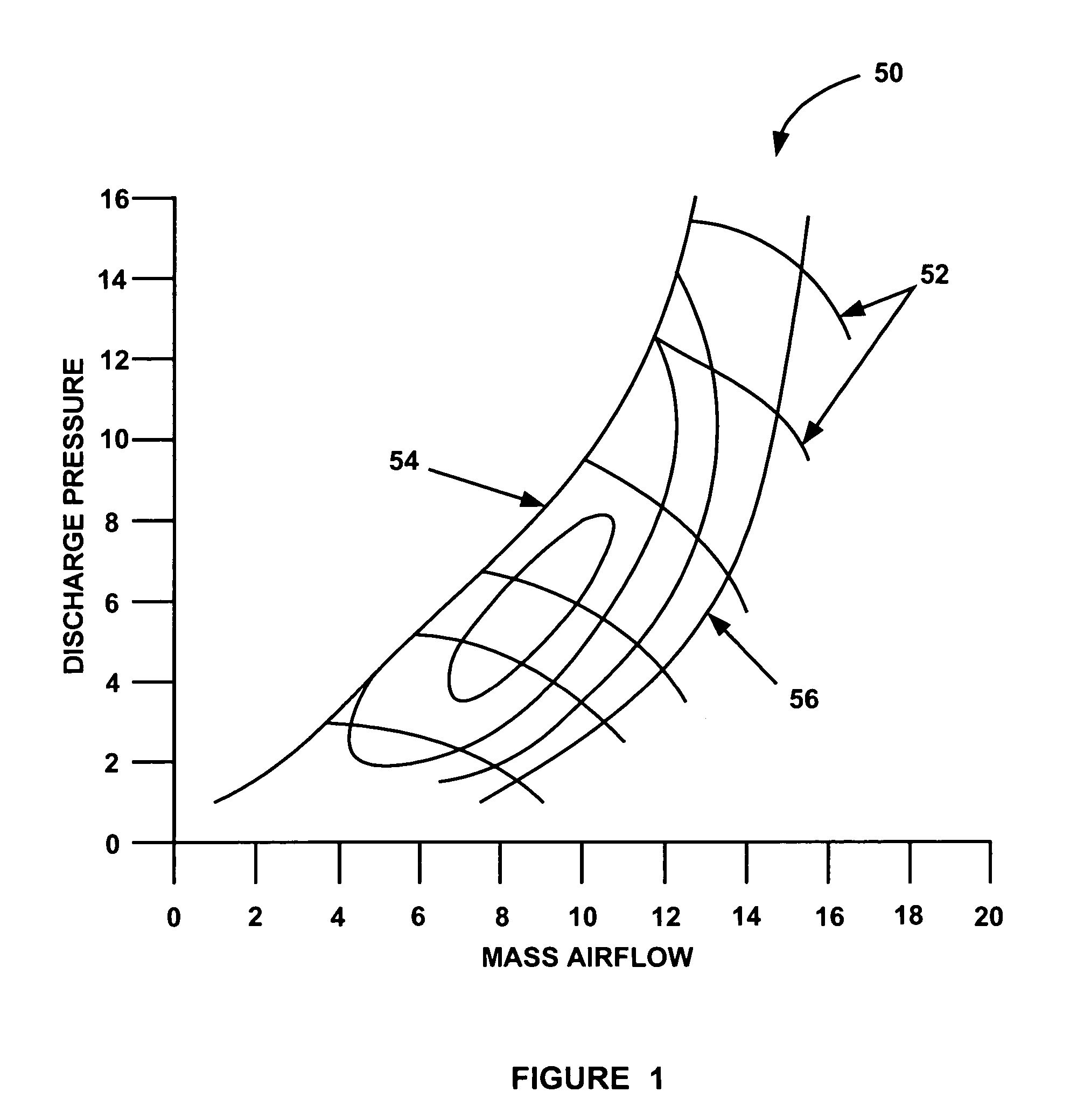

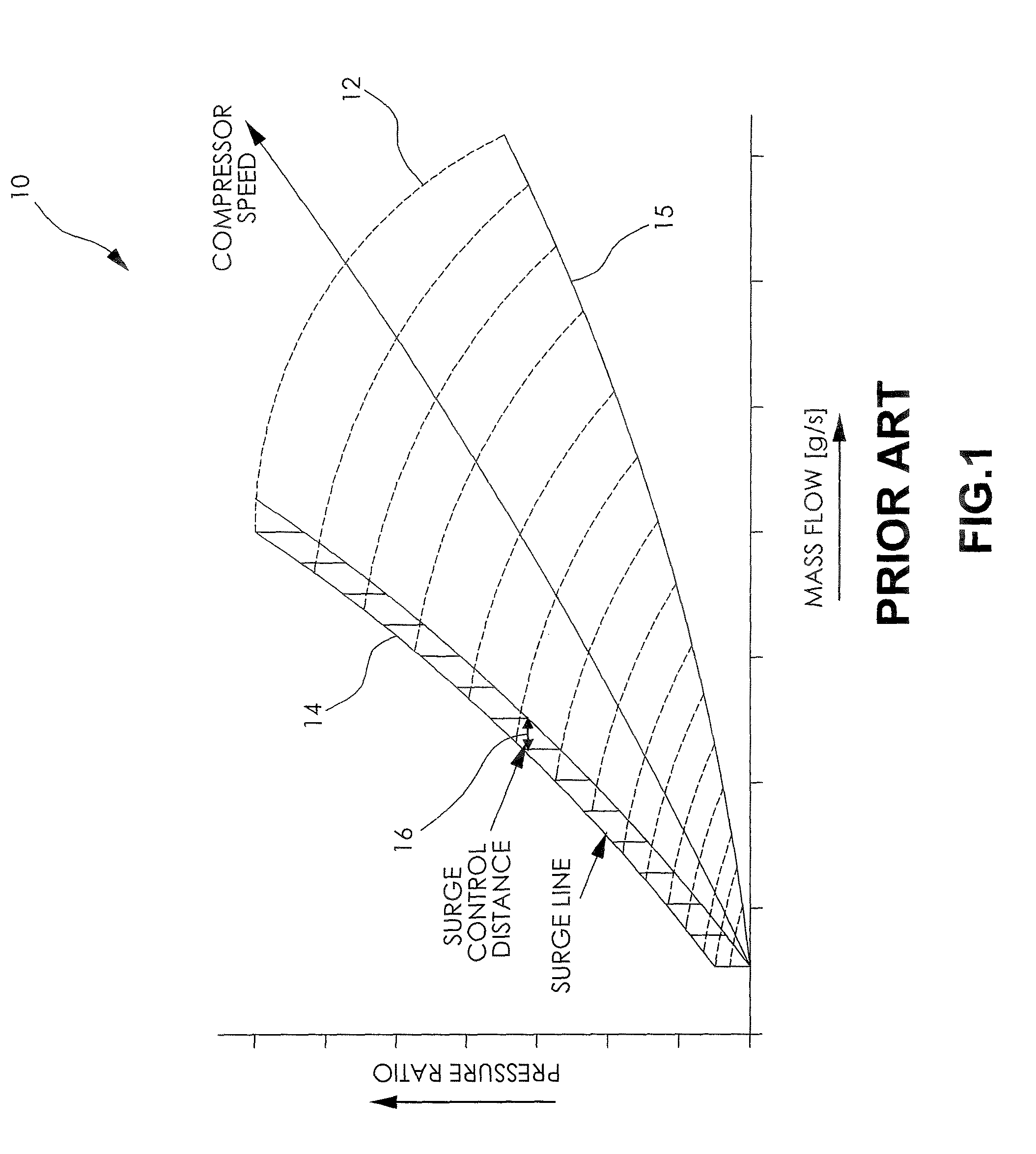

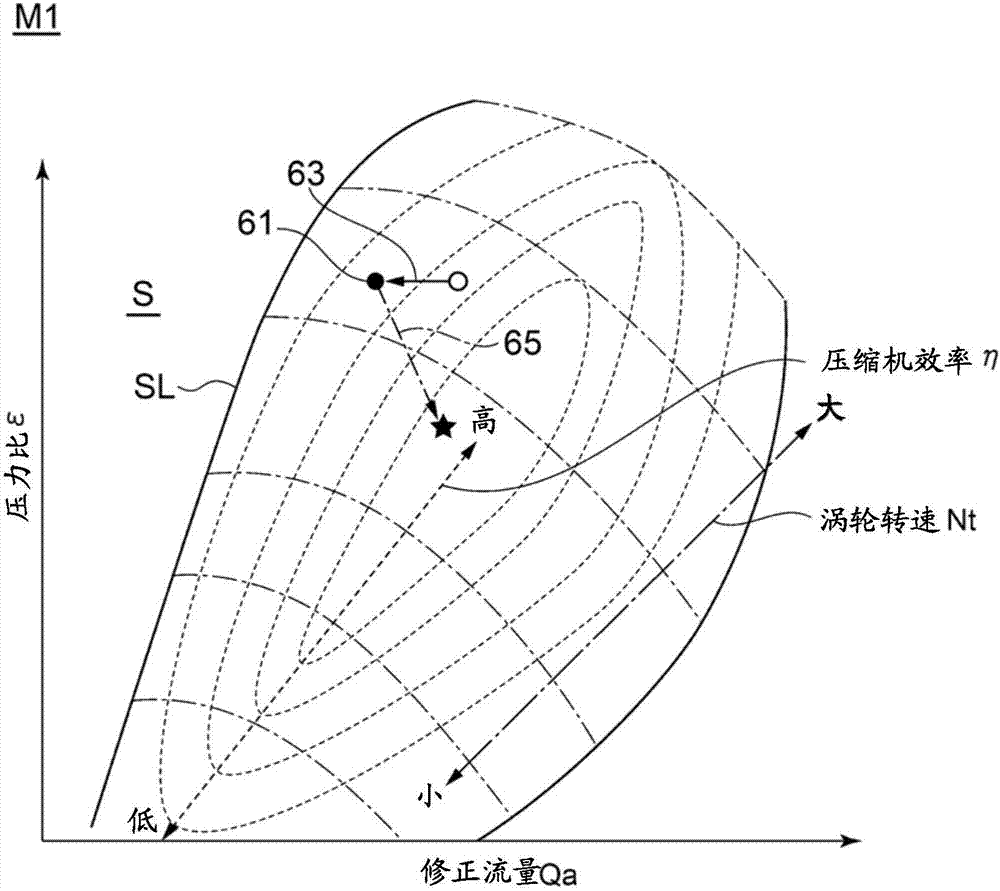

A compressor map is a chart created for a compressor in a gas turbine engine. Complete maps are based on compressor rig test results or predicted by a special computer program. Alternatively the map of a similar compressor can be suitably scaled.

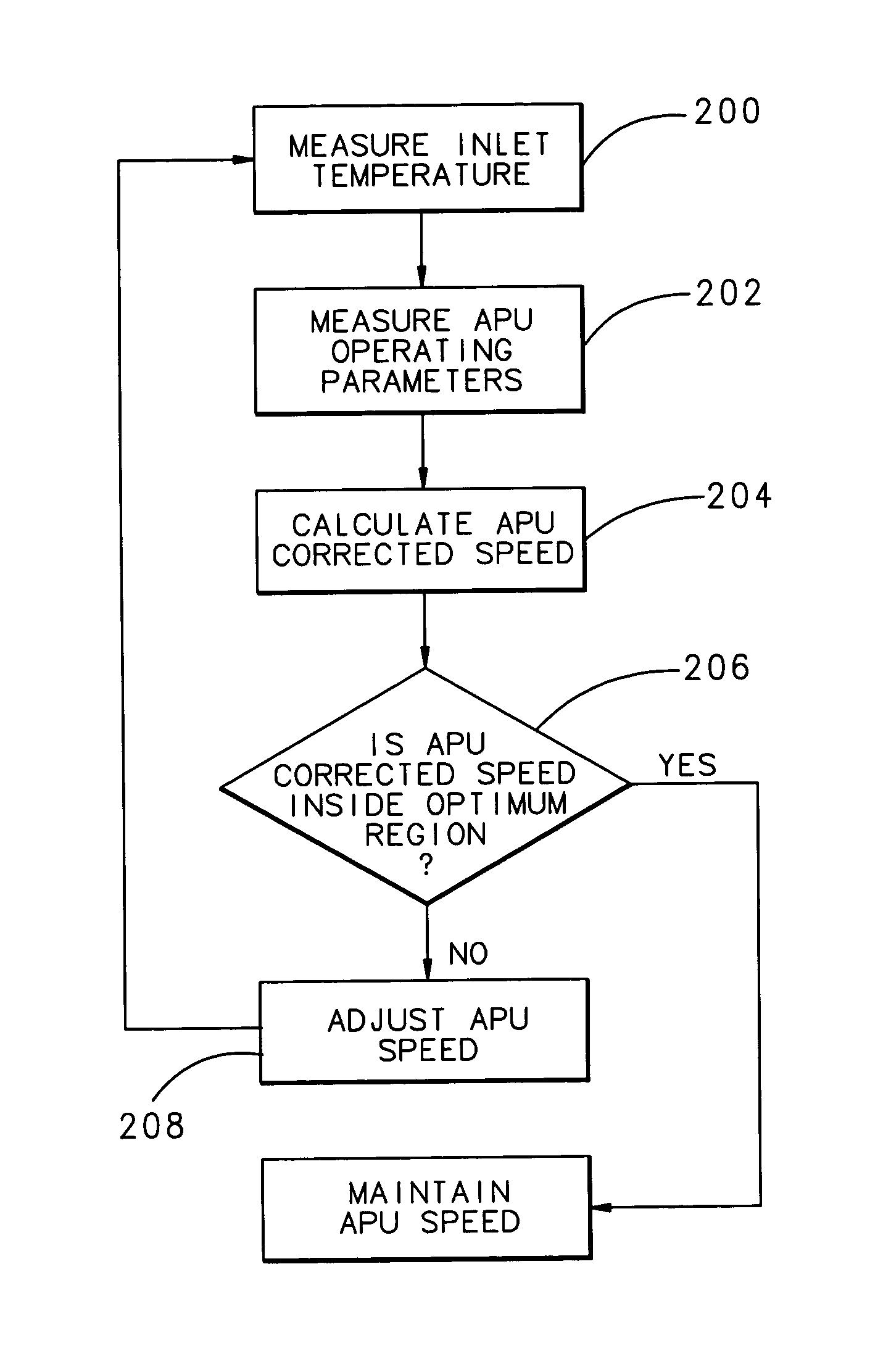

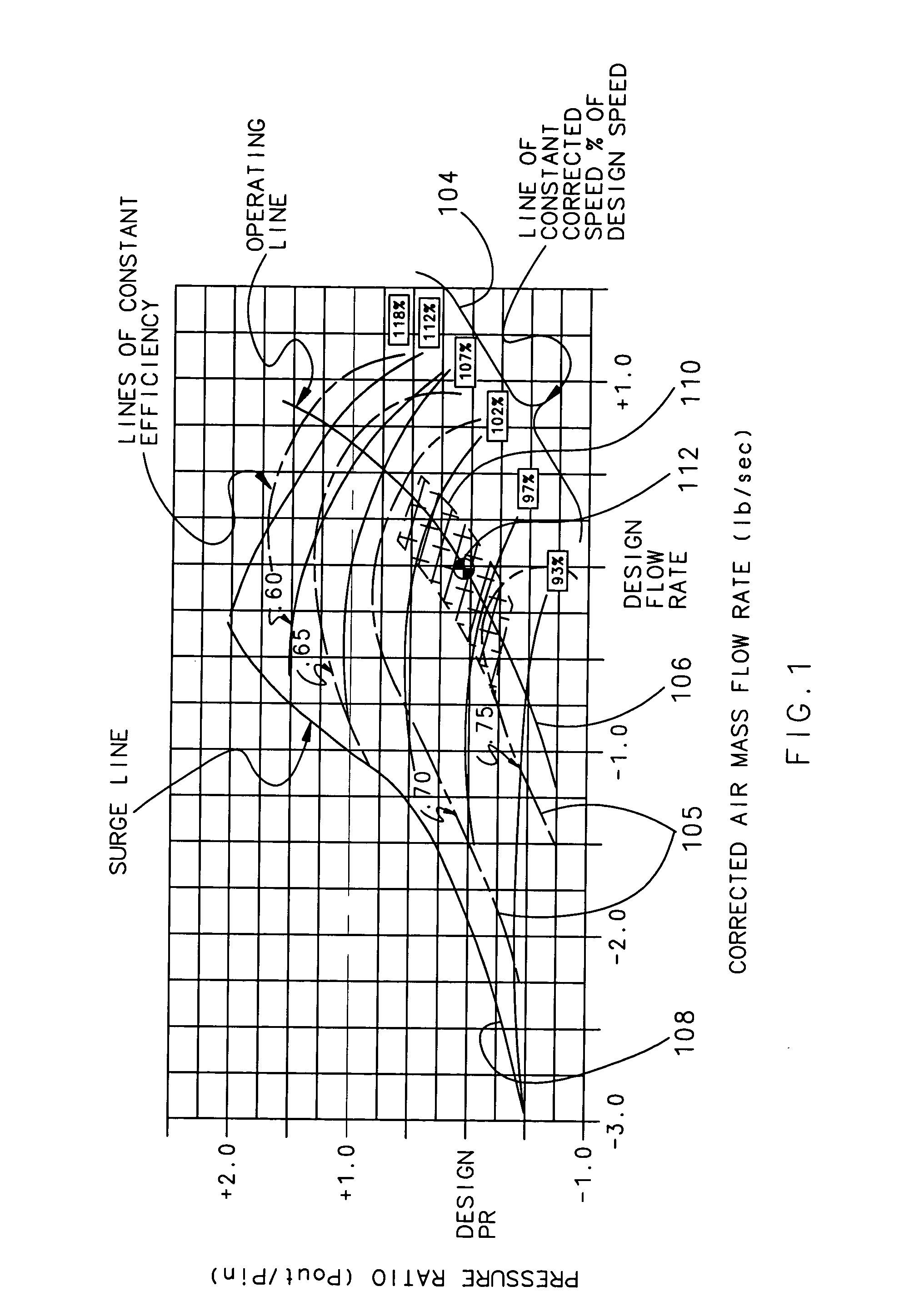

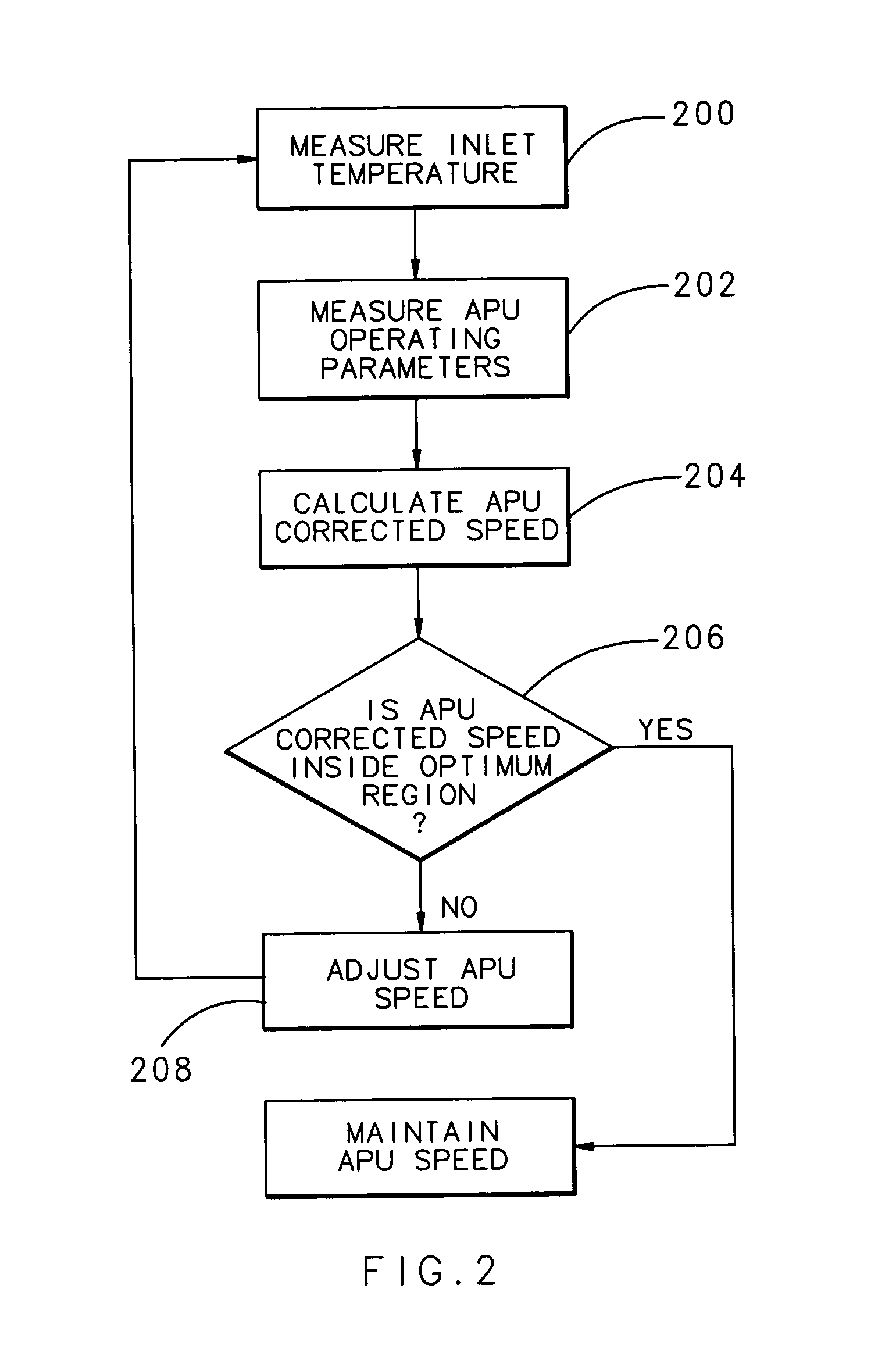

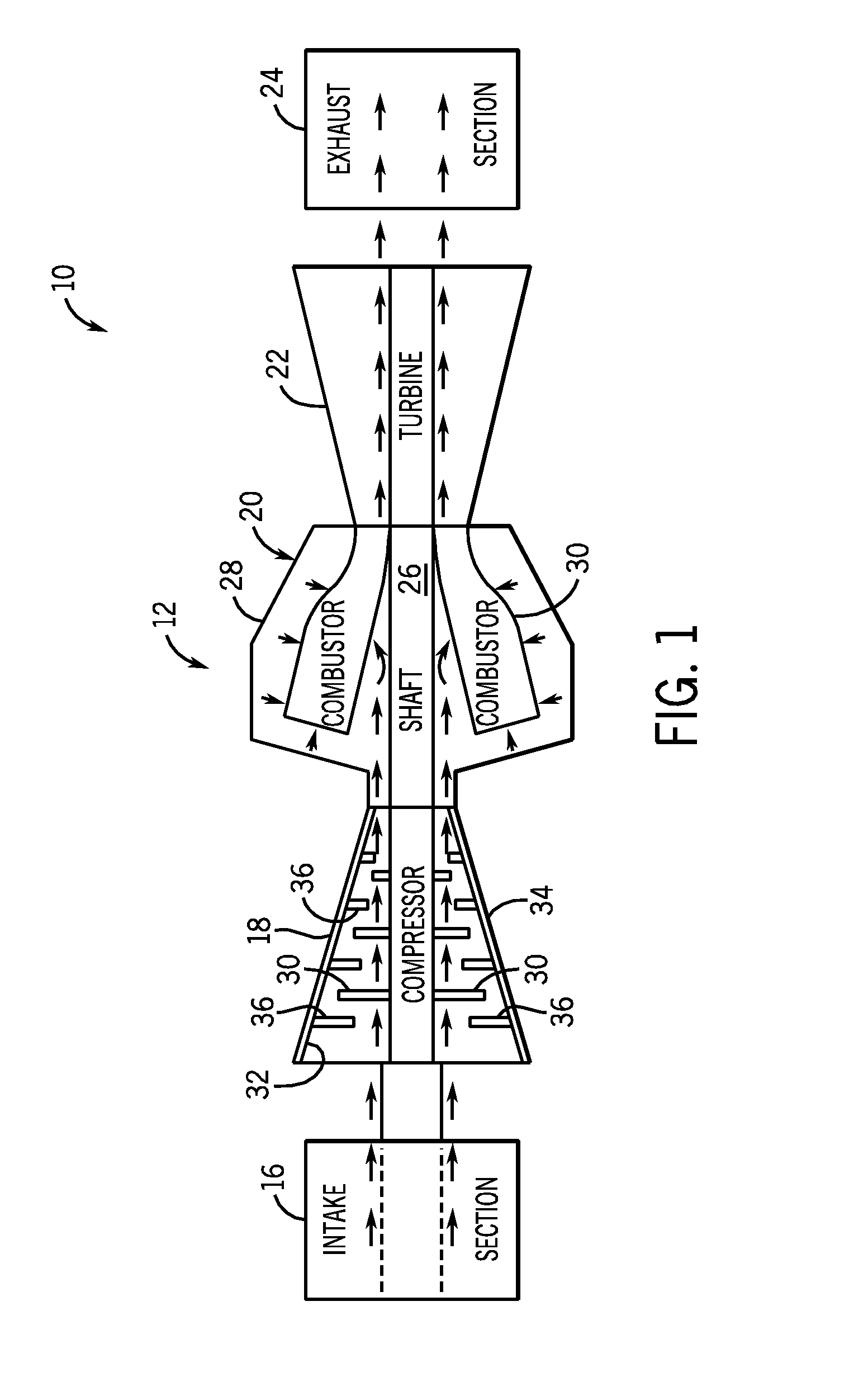

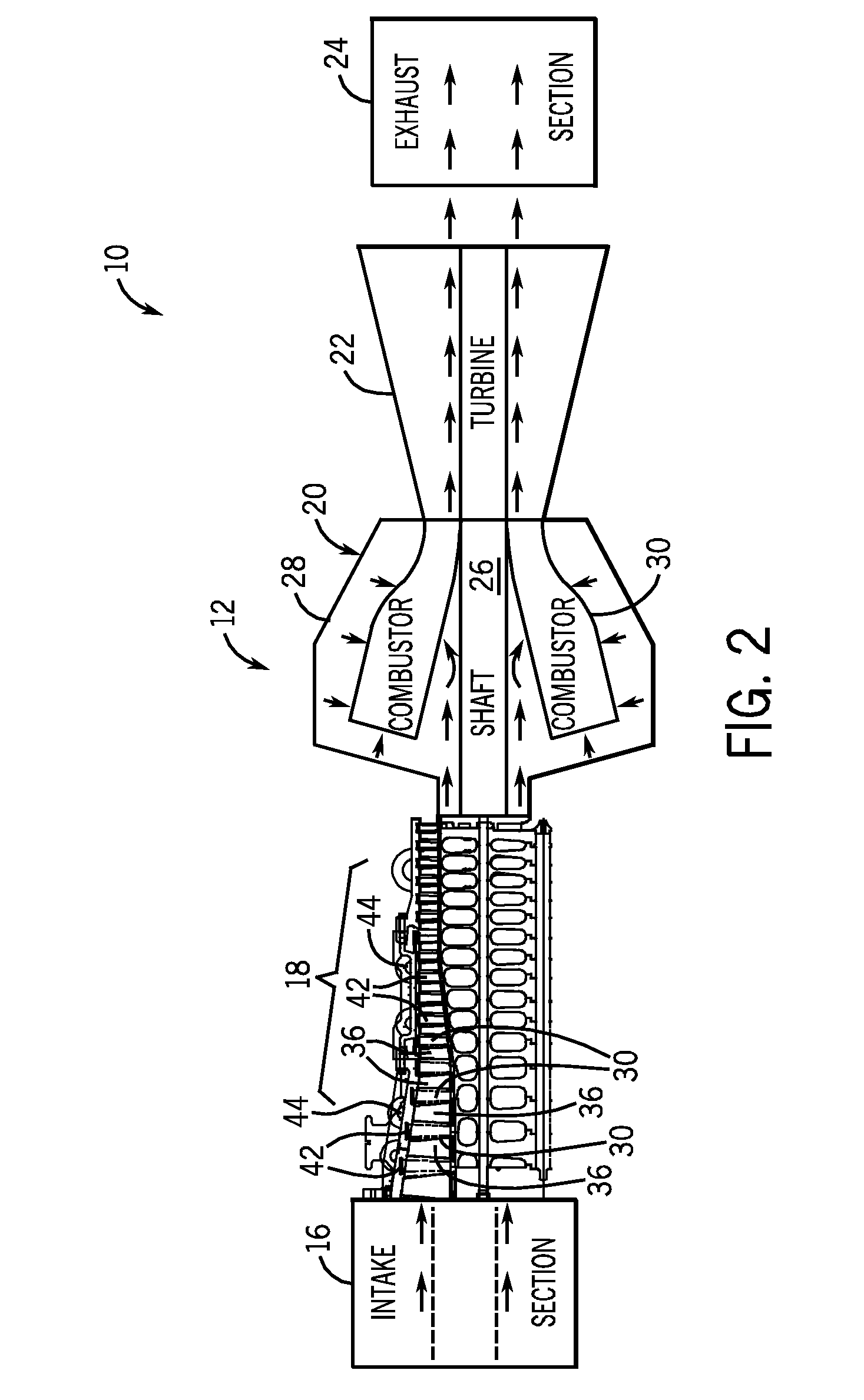

Auxiliary power unit control method and system

ActiveUS7367193B1Smoother transfer of powerSmooth transferExhaust apparatusSilencing apparatusEngineeringAuxiliary power unit

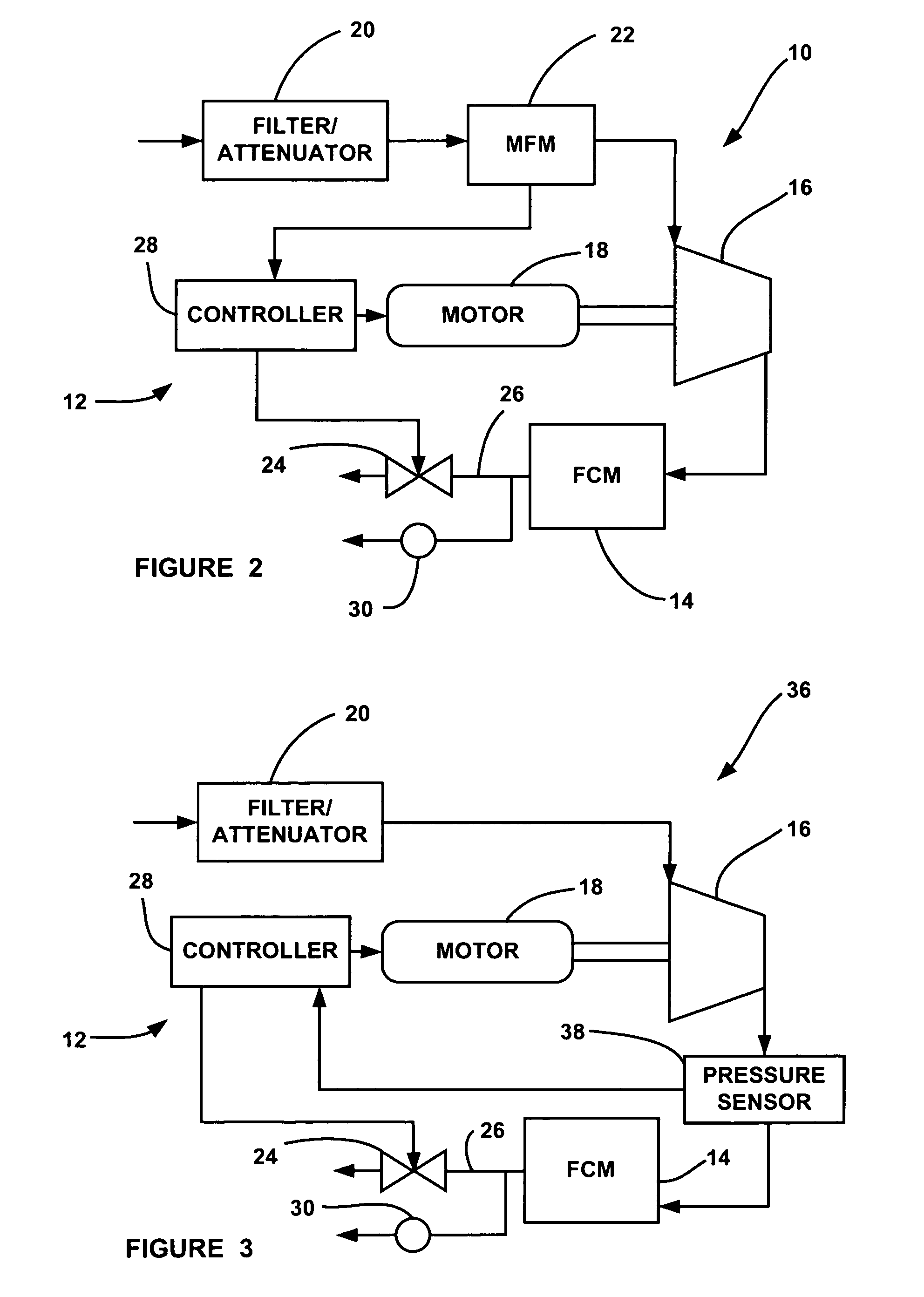

An adjustment method and system for an auxiliary power unit (APU) allows the APU speed to vary based on the inlet air temperature to the APU compressor. The APU is controlled by a control law that allows the APU speed to float within a selected range based on speed and electric power generators phase matching criteria that provides smooth power transfer between the APU and a main engine generator. The specific APU mechanical speed for a given temperature may be determined from a compressor map that identifies the optimum combination of pressure ratio, flow rate and efficiency for a given inlet temperature, and avoids running the APU near mechanical resonant vibration conditions.

Owner:HAMILTON SUNDSTRAND CORP

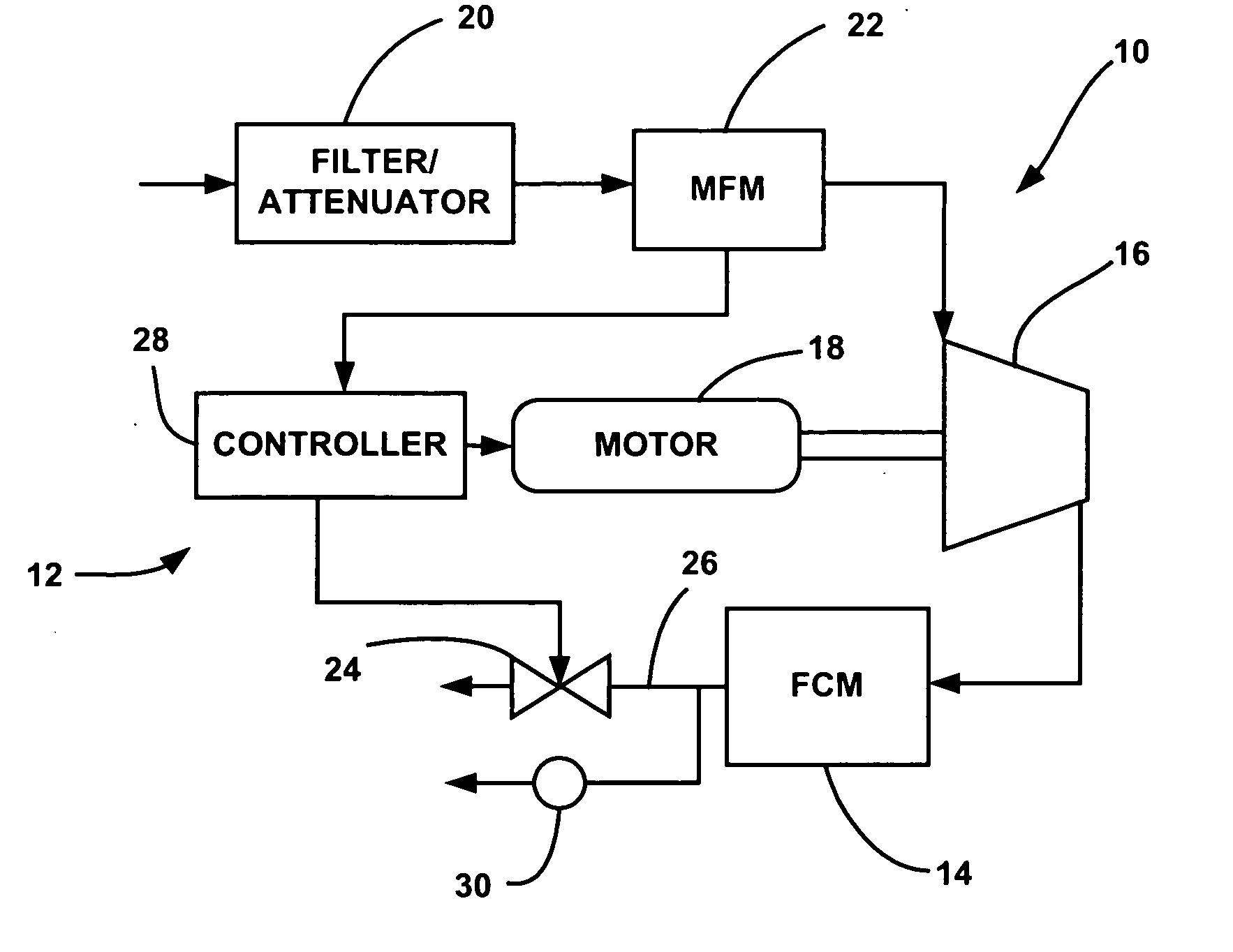

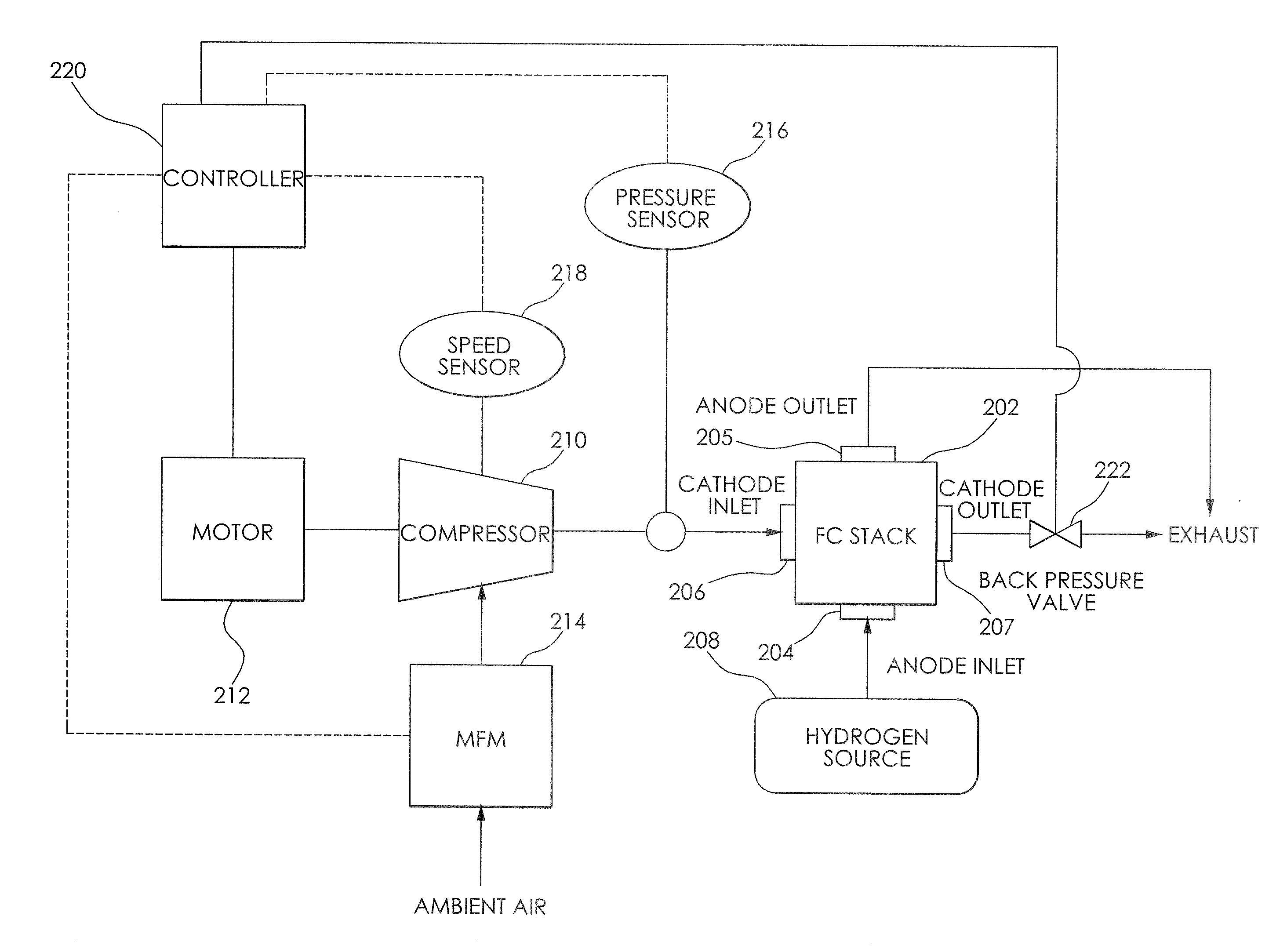

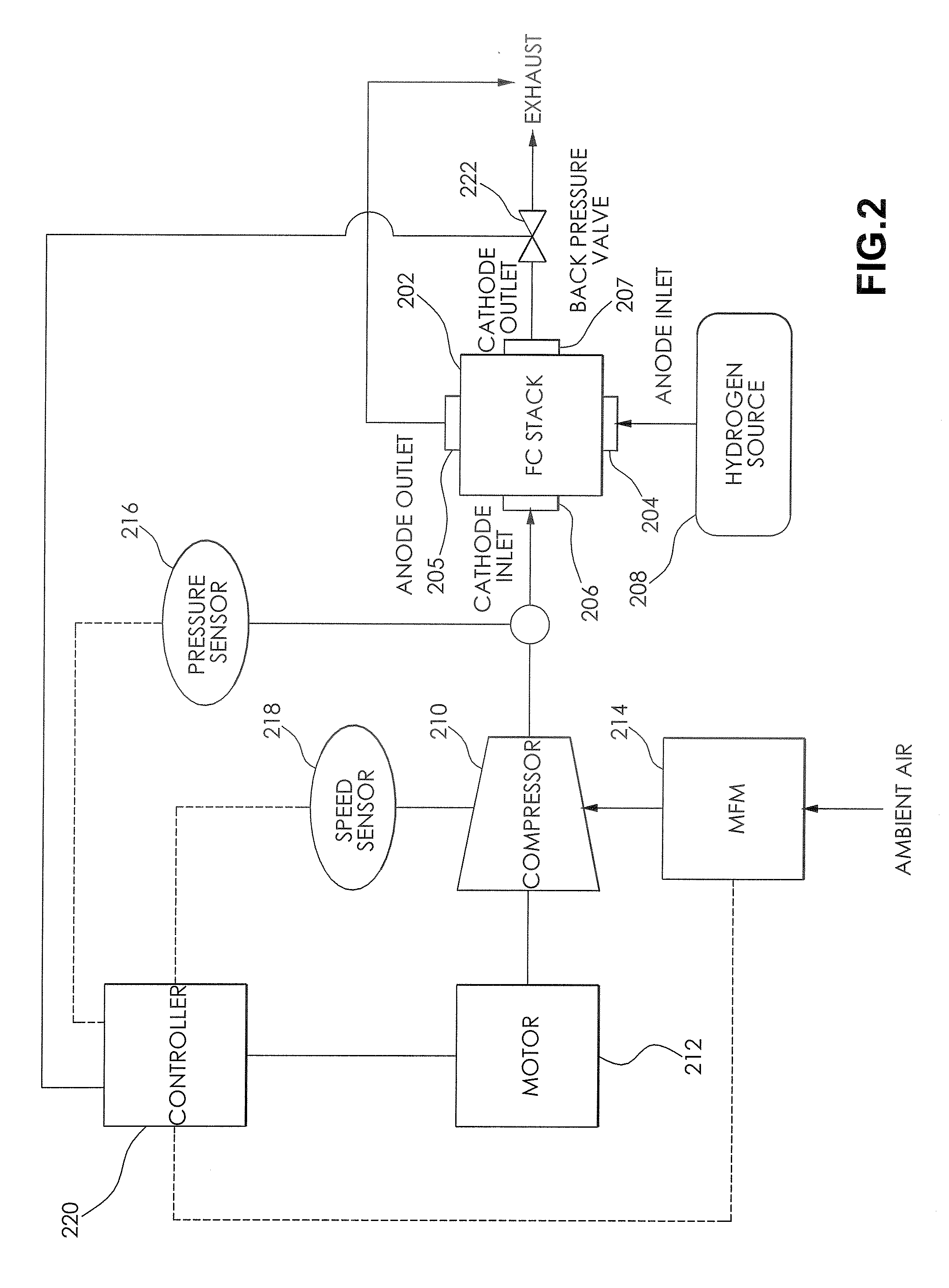

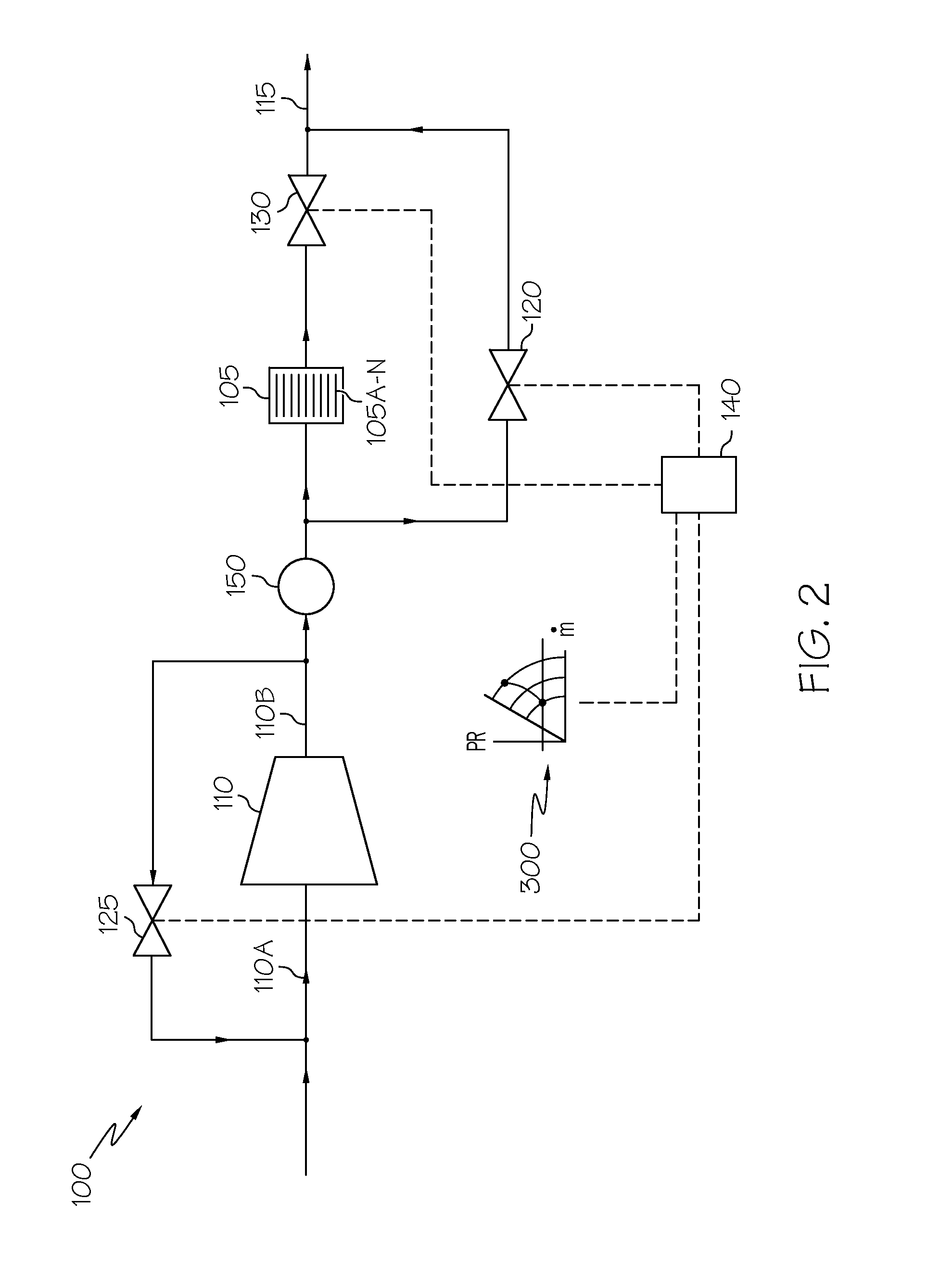

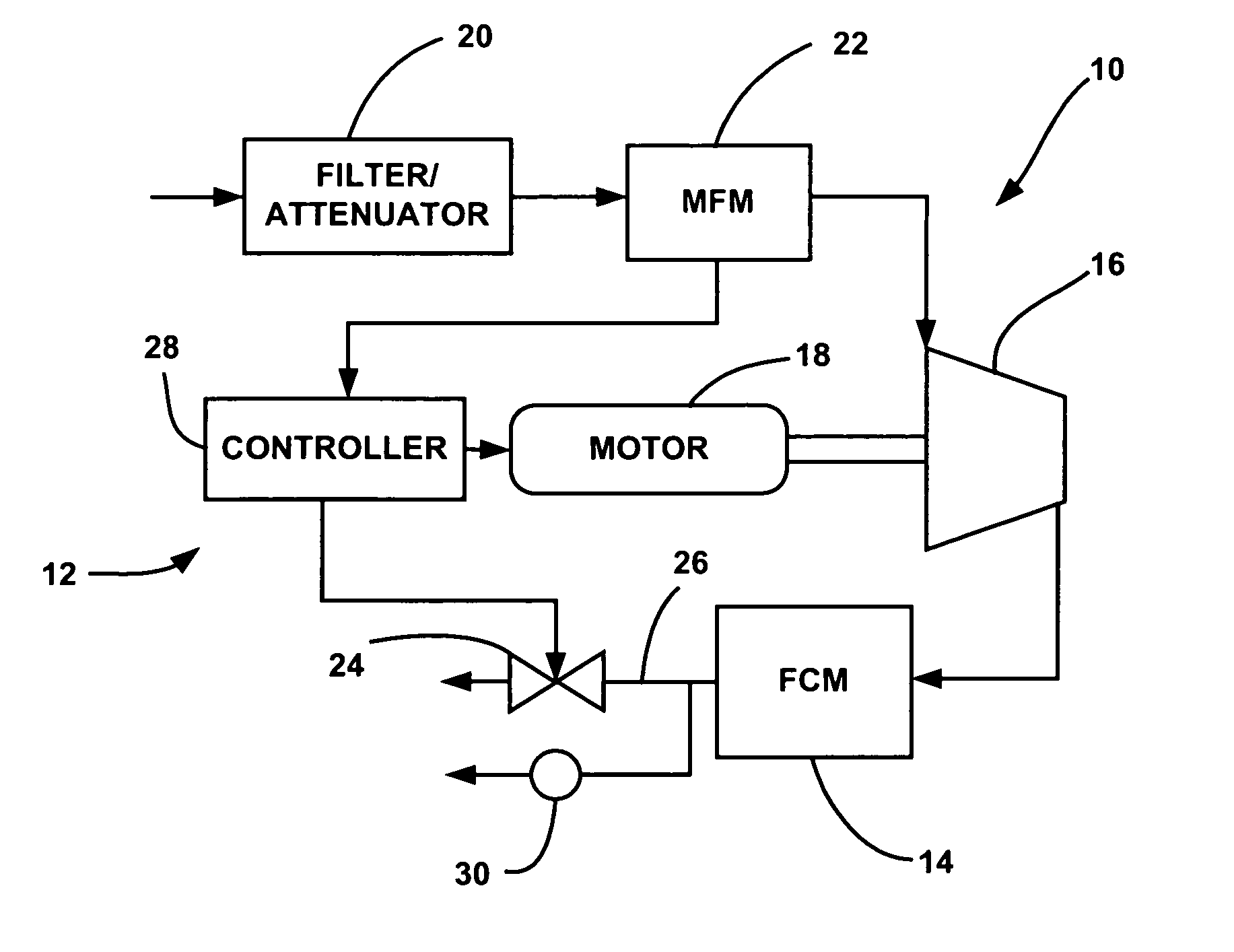

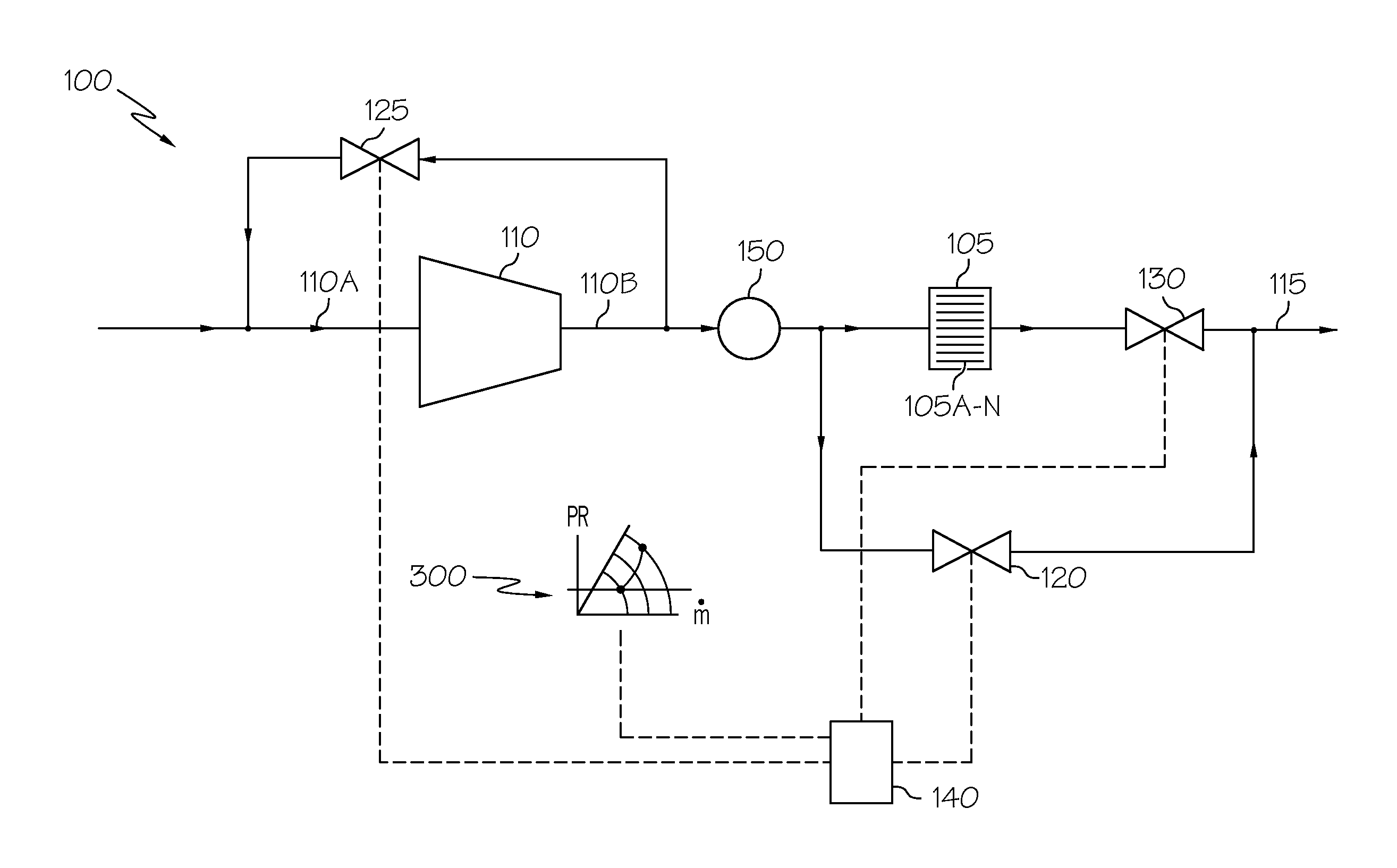

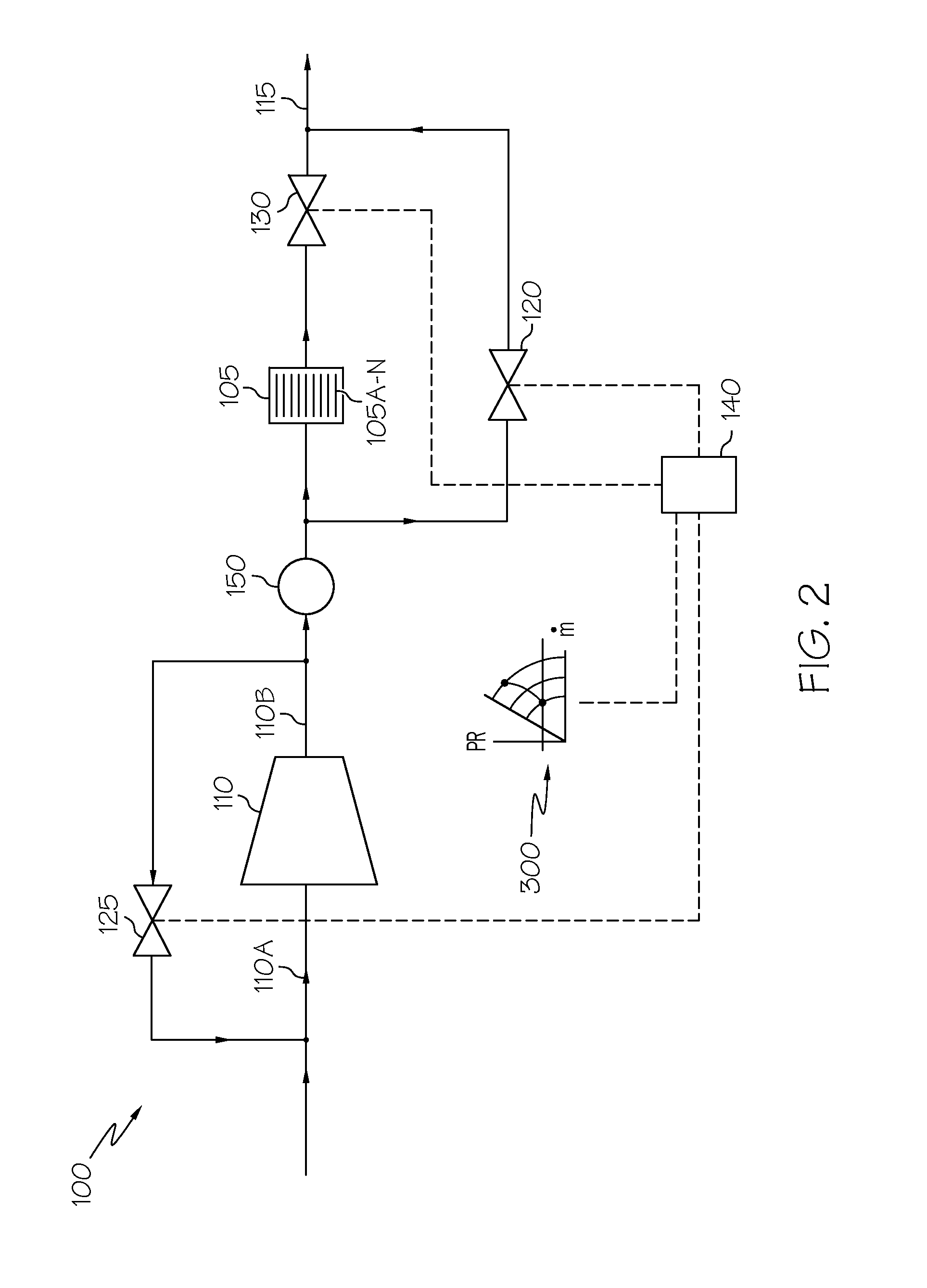

Virtual compressor operational parameter measurement and surge detection in a fuel cell system

ActiveUS20050164057A1Lowering system back pressureIncrease compressor speedFuel cell auxillariesFuel cellsDischarge pressure

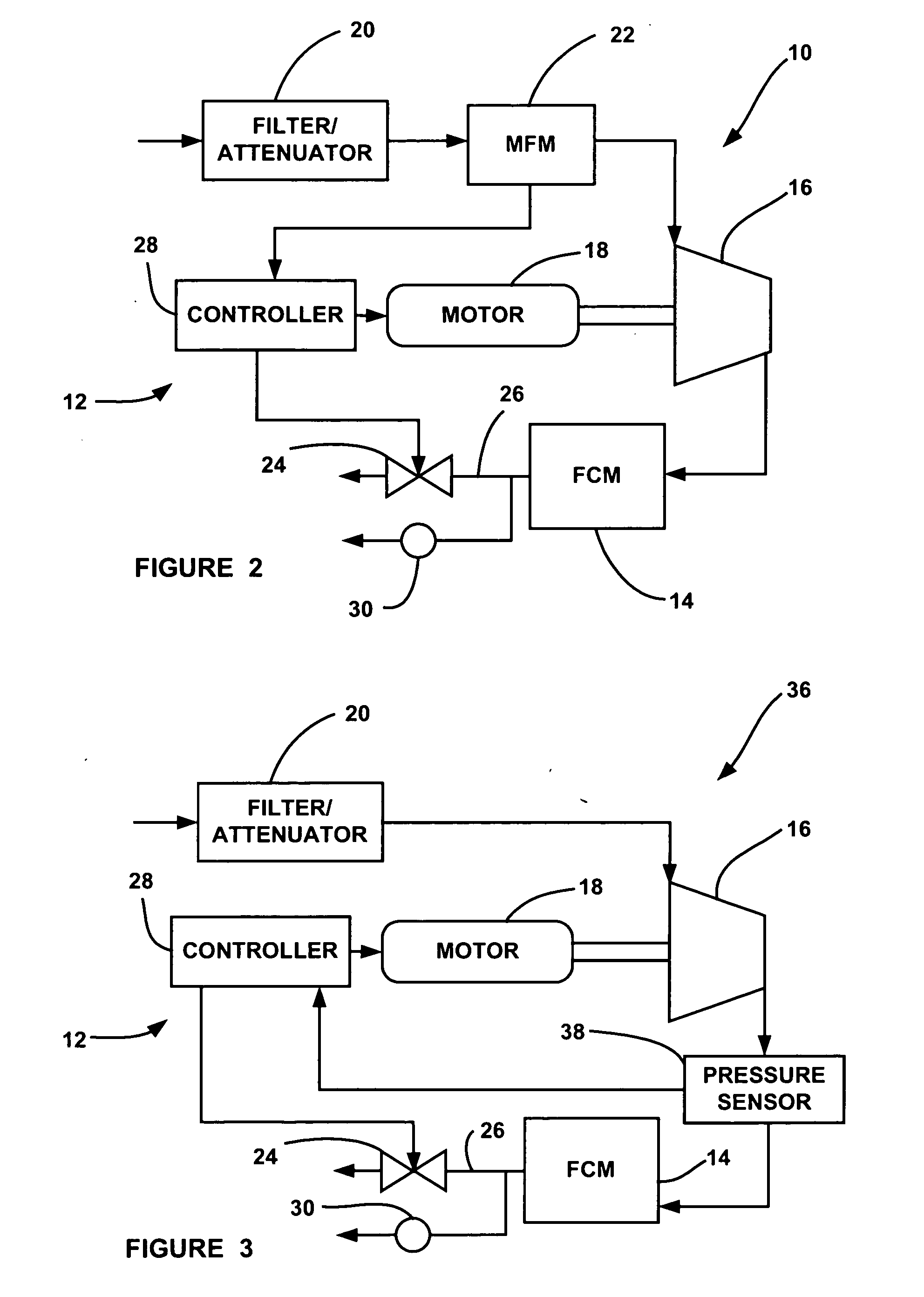

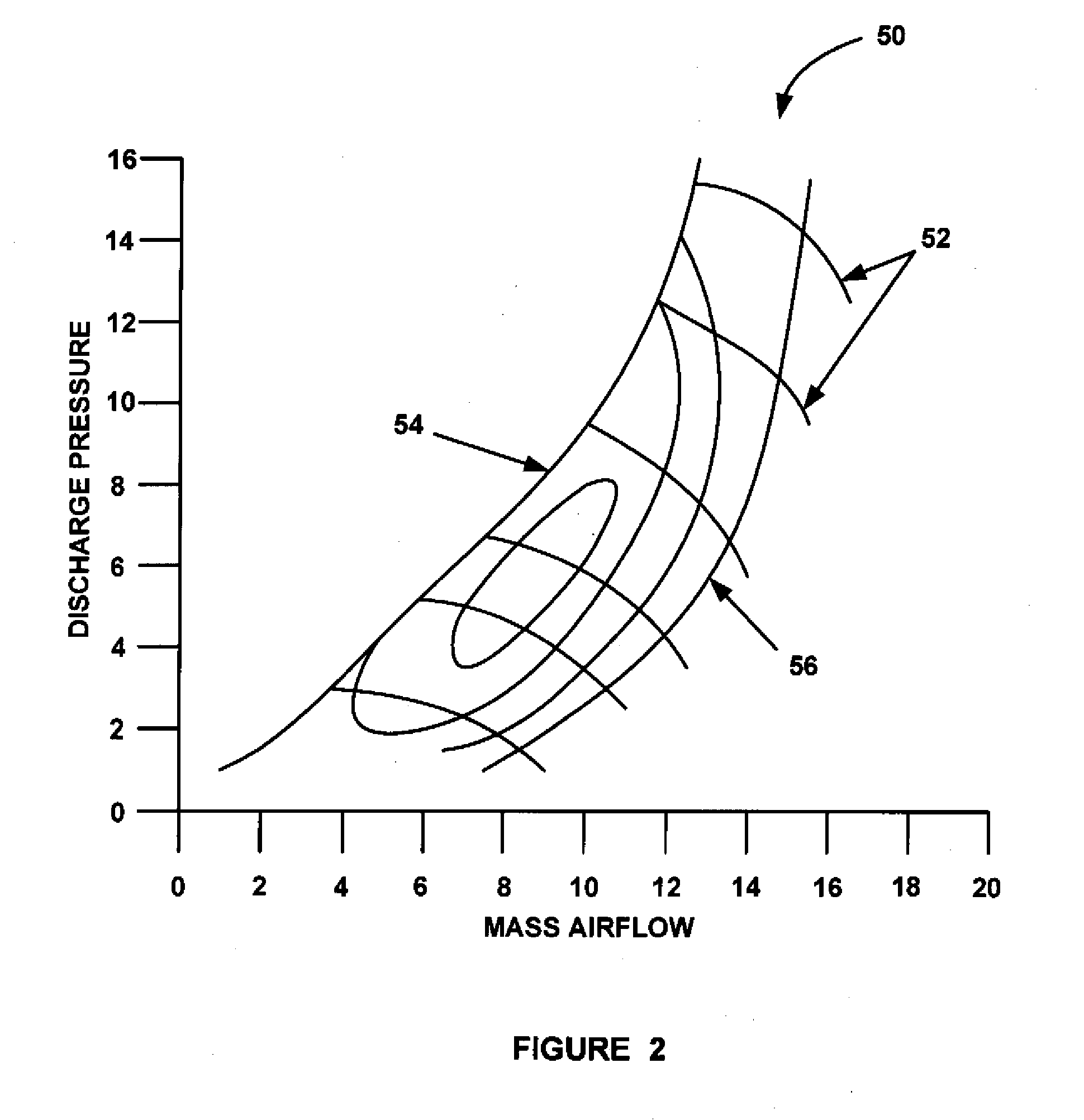

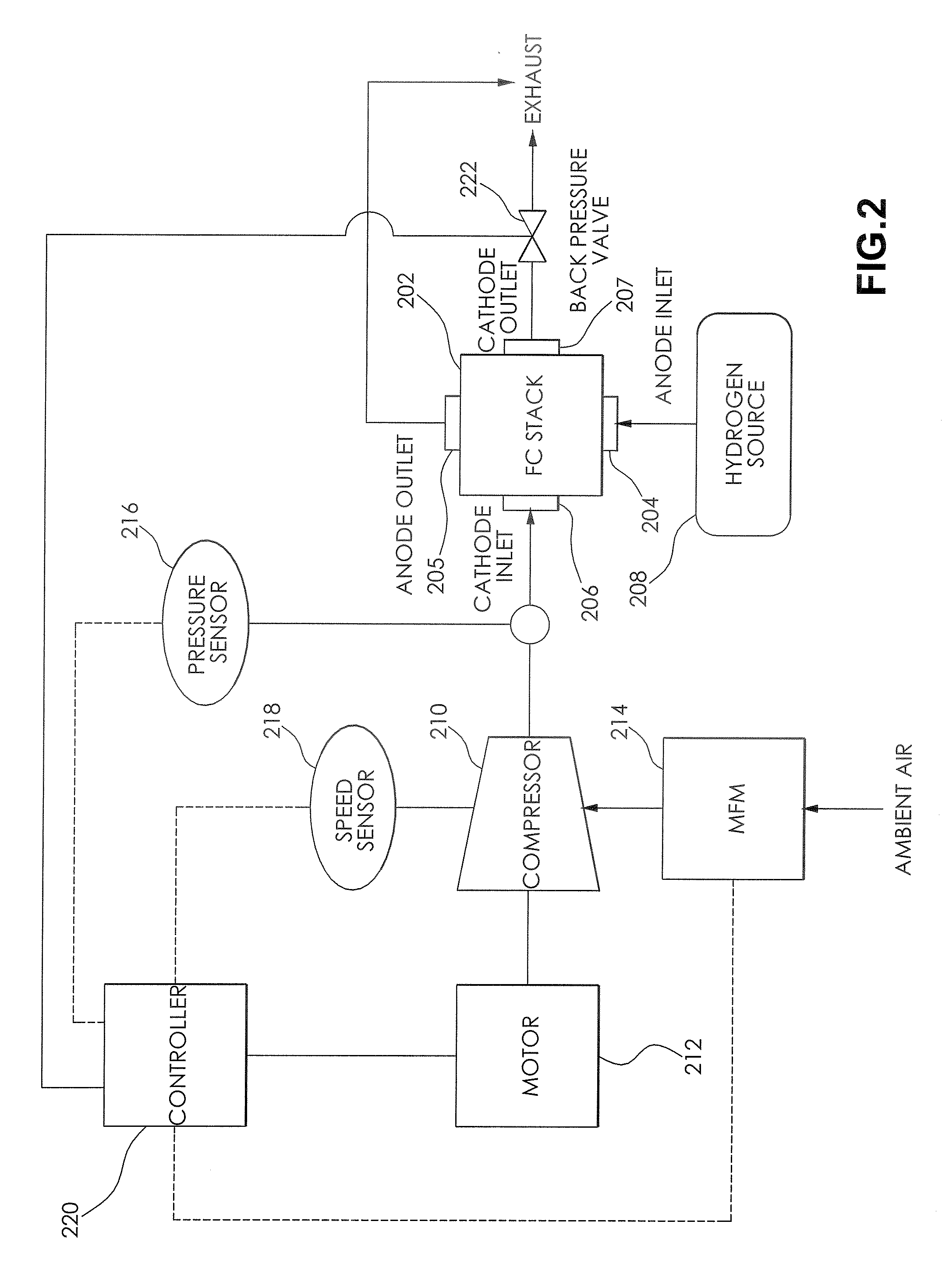

A fuel cell system that employs surge prevention by electronically mapping the compressor for discharge pressure versus mass airflow. In one embodiment, the fuel cell system employs a mass flow meter that measures the airflow to the compressor. A controller receives a signal from the mass flow meter indicative of the flow rate of the charge airflow to the compressor, and determines the outlet pressure and temperature of the compressor from the compressor speed and the measured airflow. This gives the compressor map location at which the compressor is operating. In another embodiment, the fuel cell system employs a pressure sensor that measures the output pressure of the compressor, and provides a pressure signal to the controller. The controller determines the mass airflow to the compressor to determine the compressor map location.

Owner:GM GLOBAL TECH OPERATIONS LLC

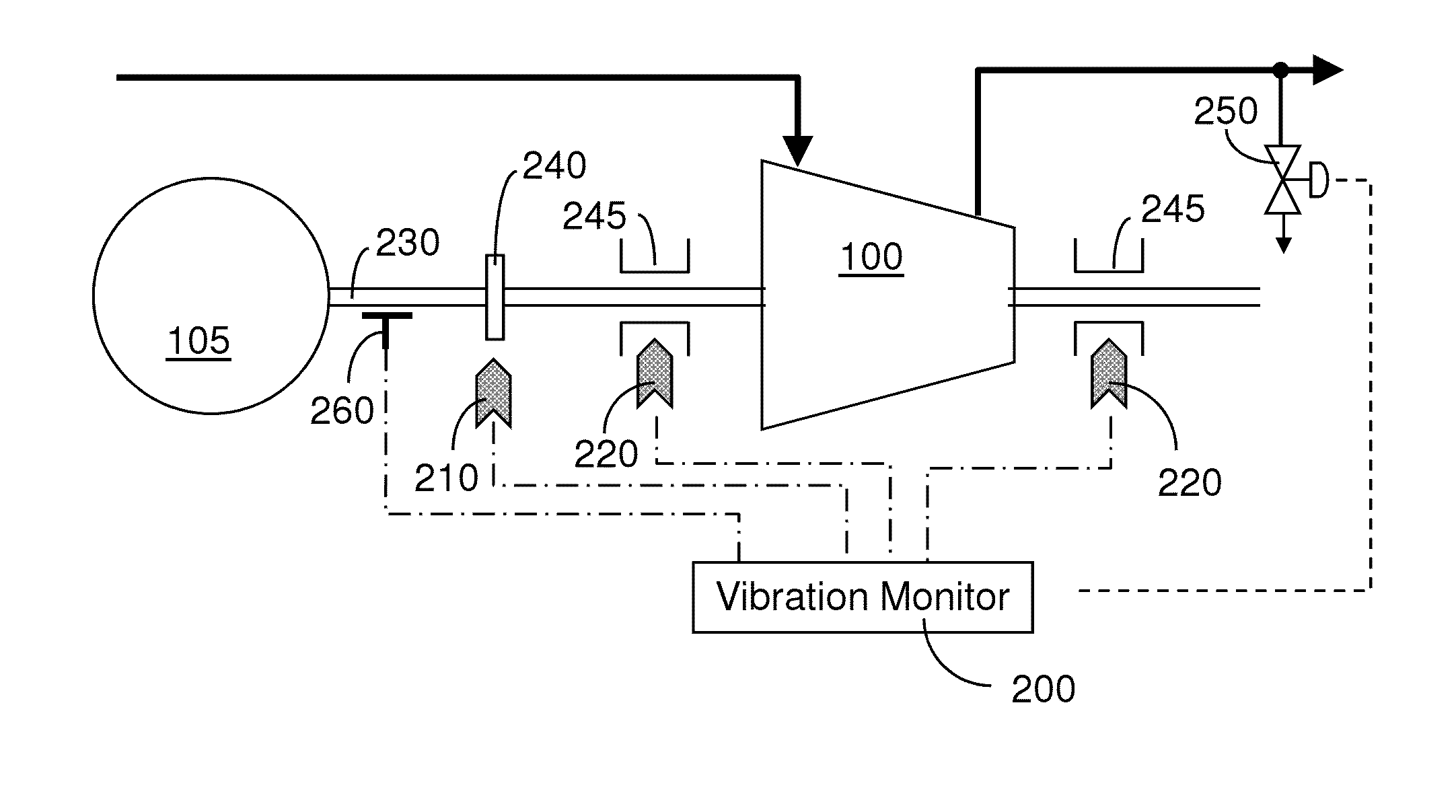

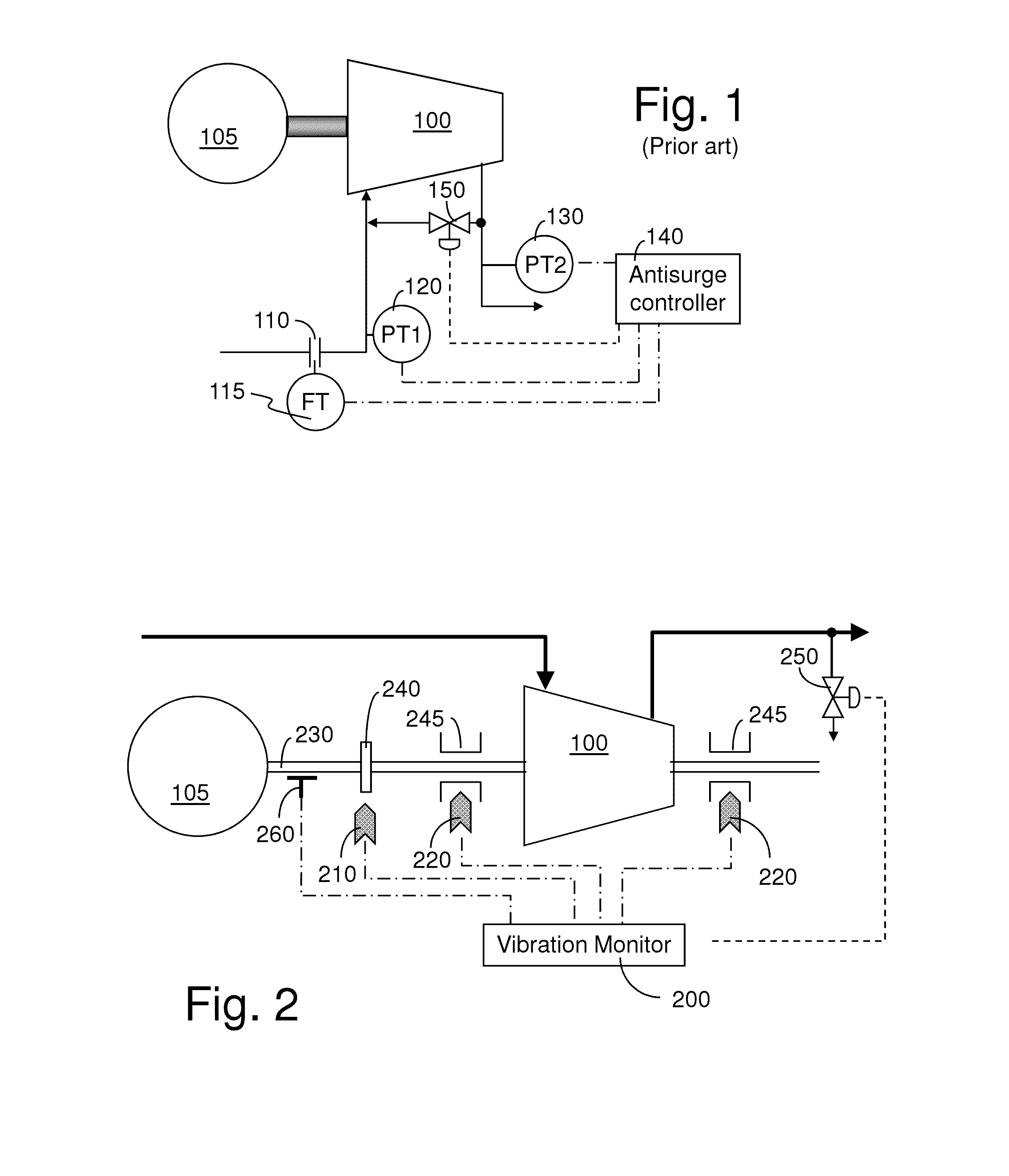

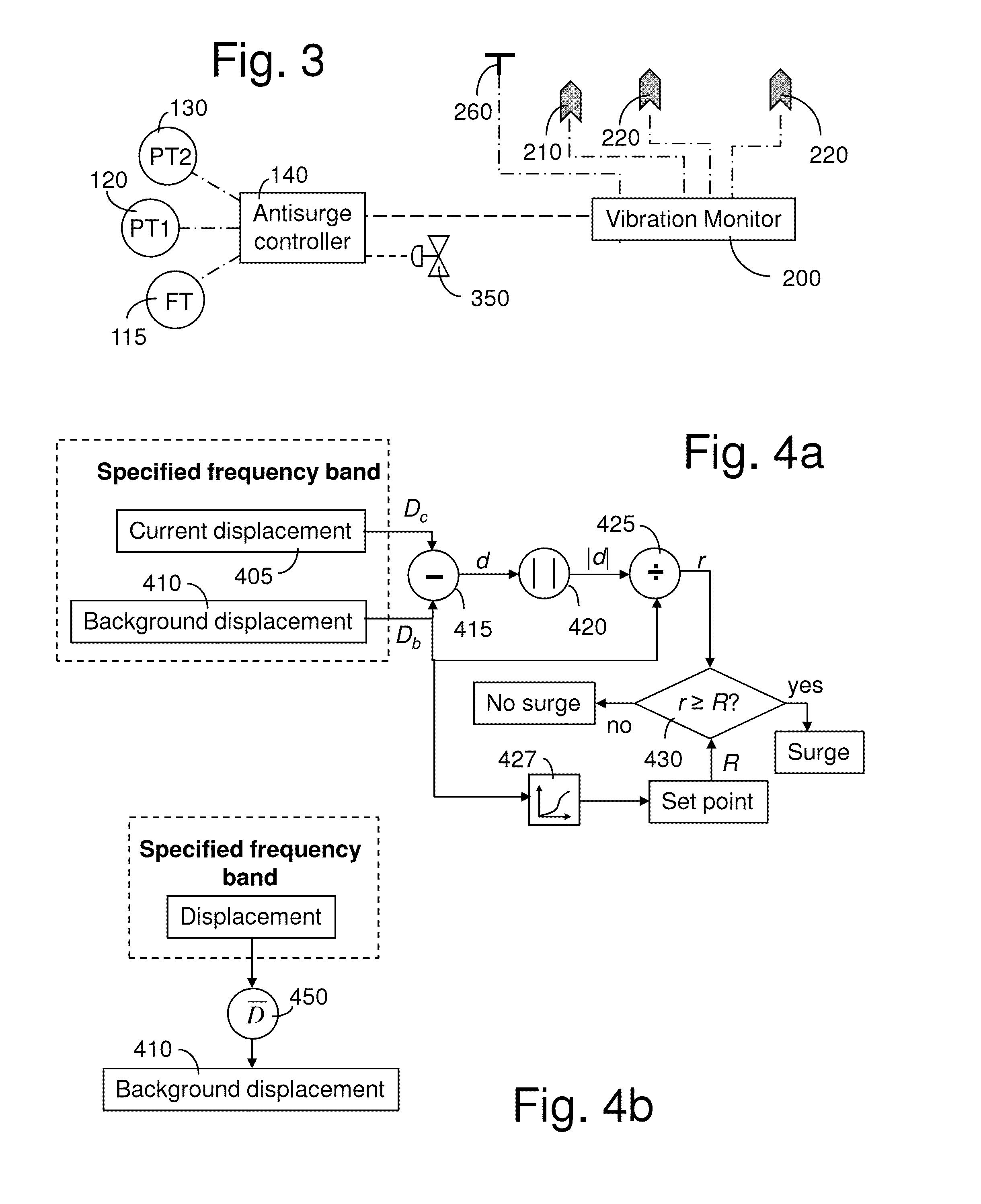

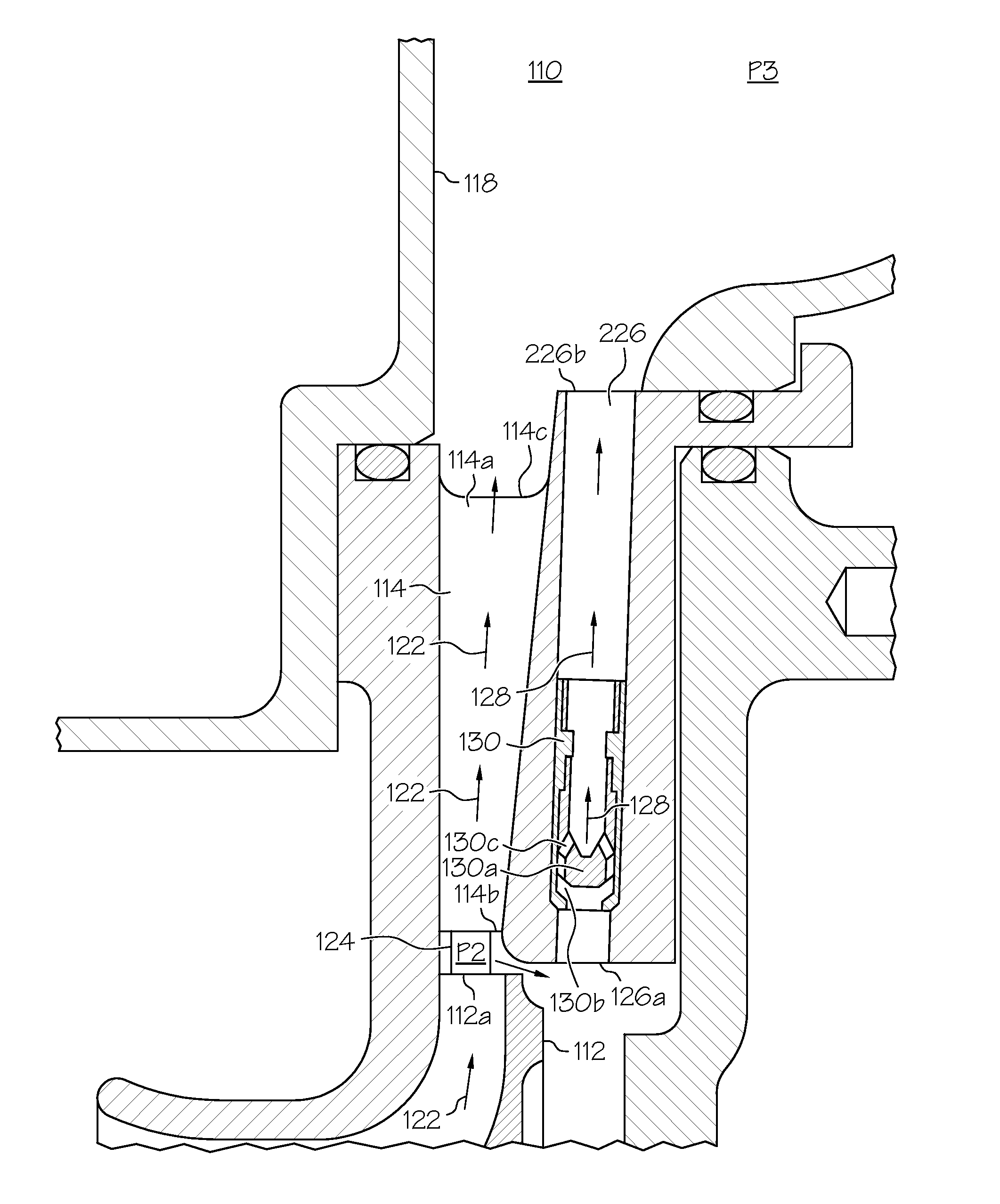

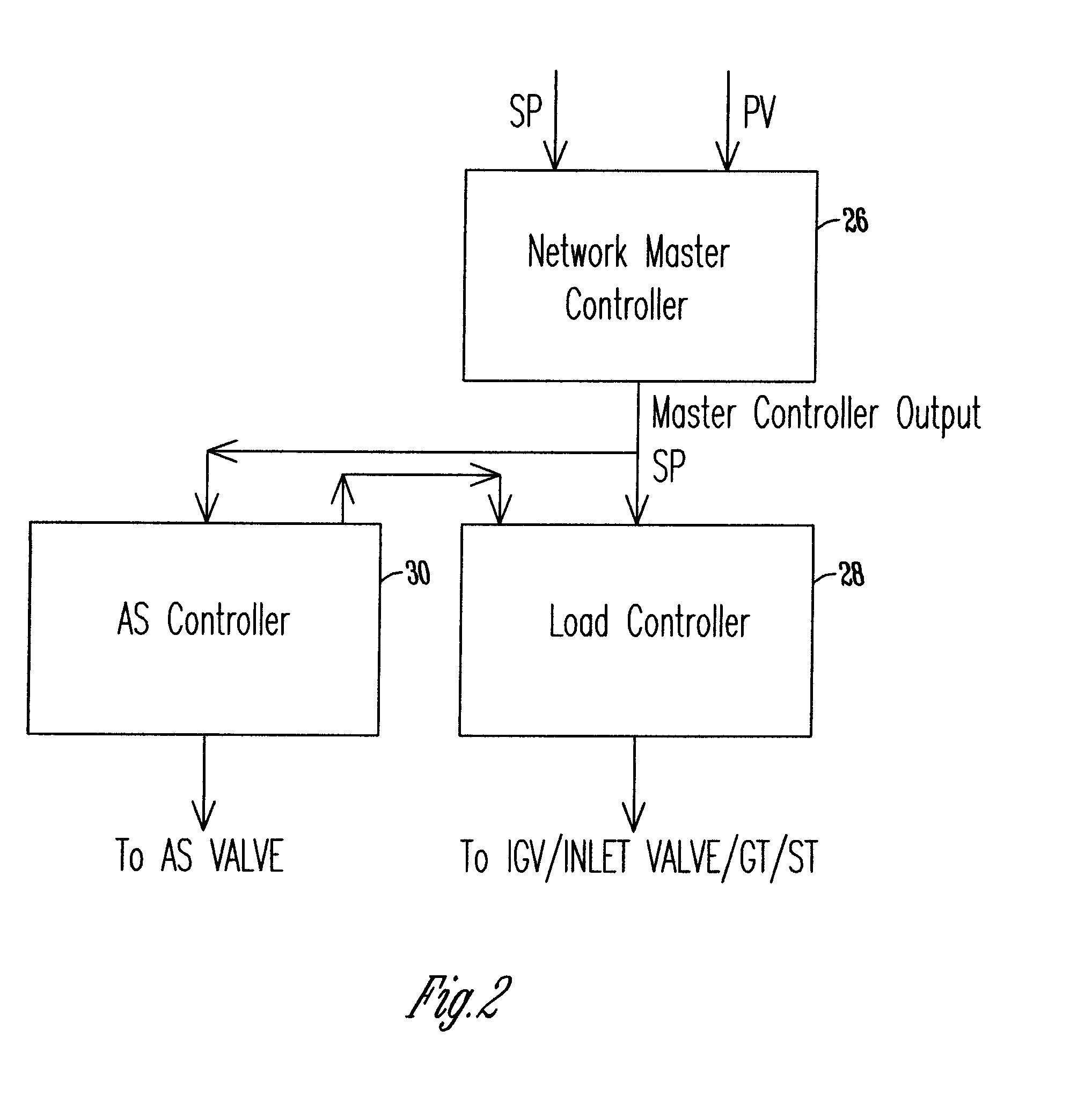

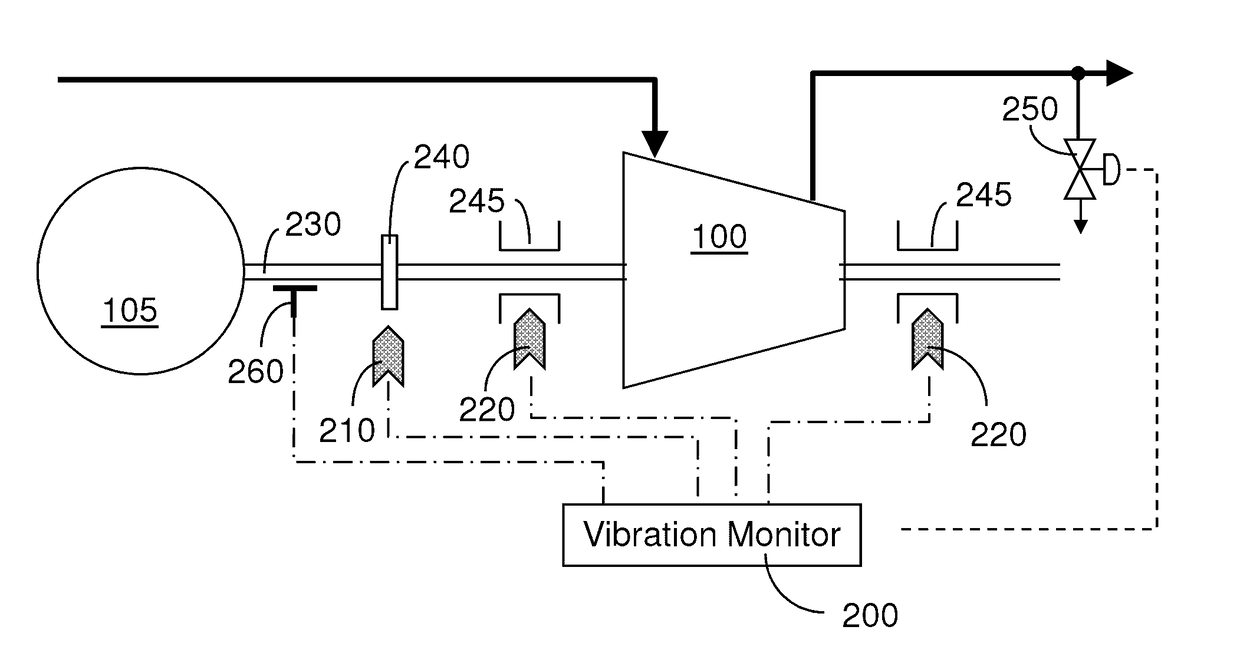

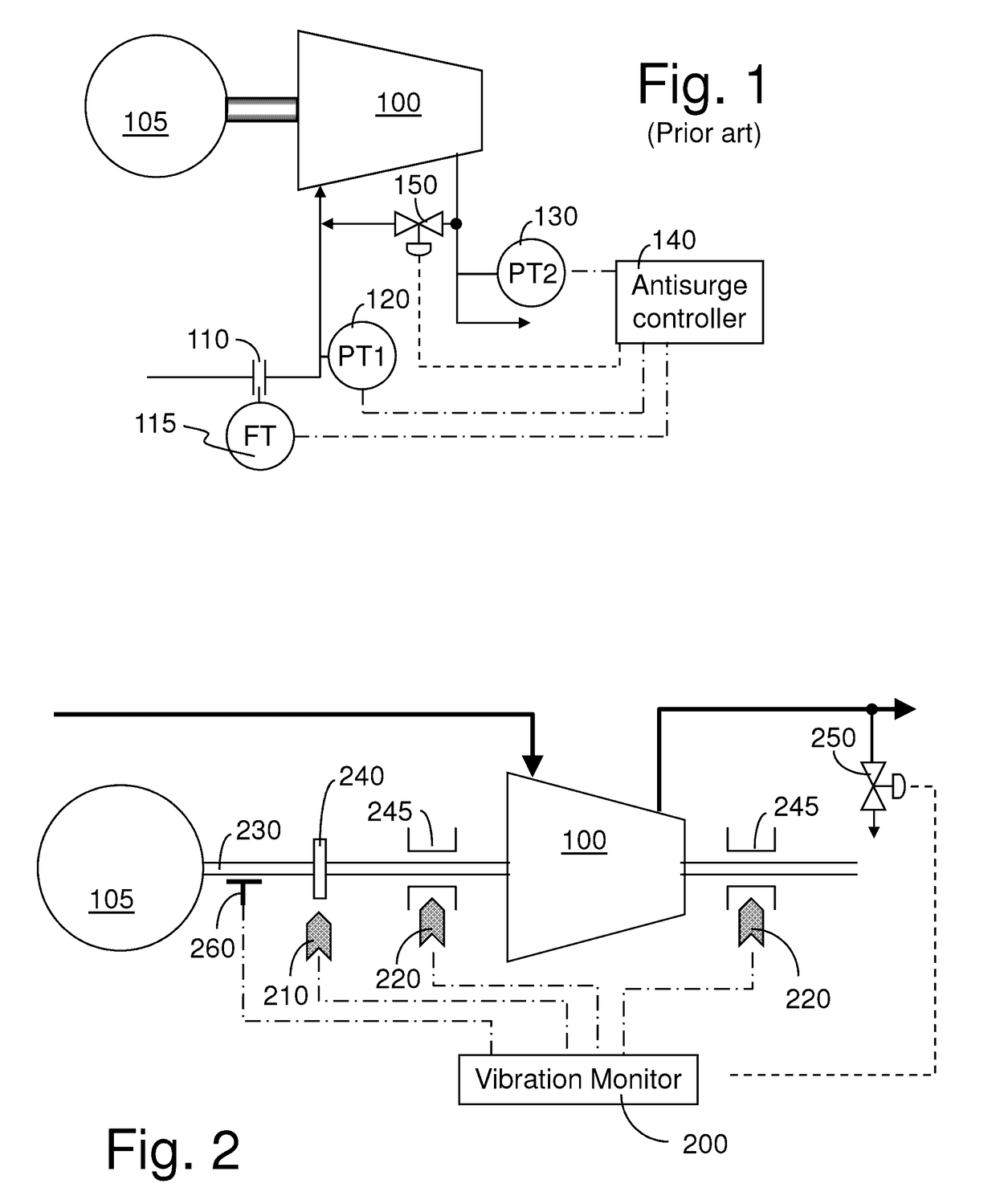

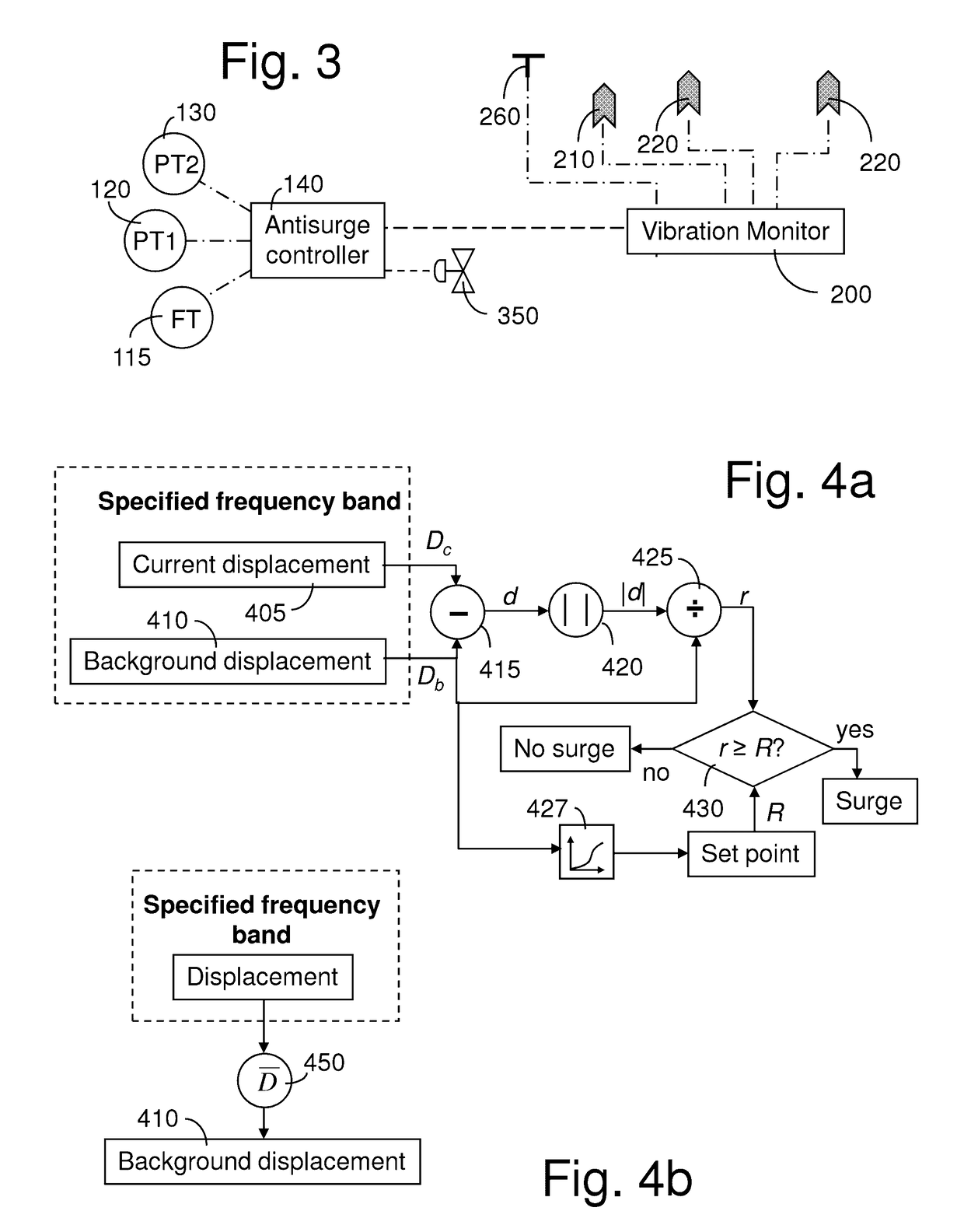

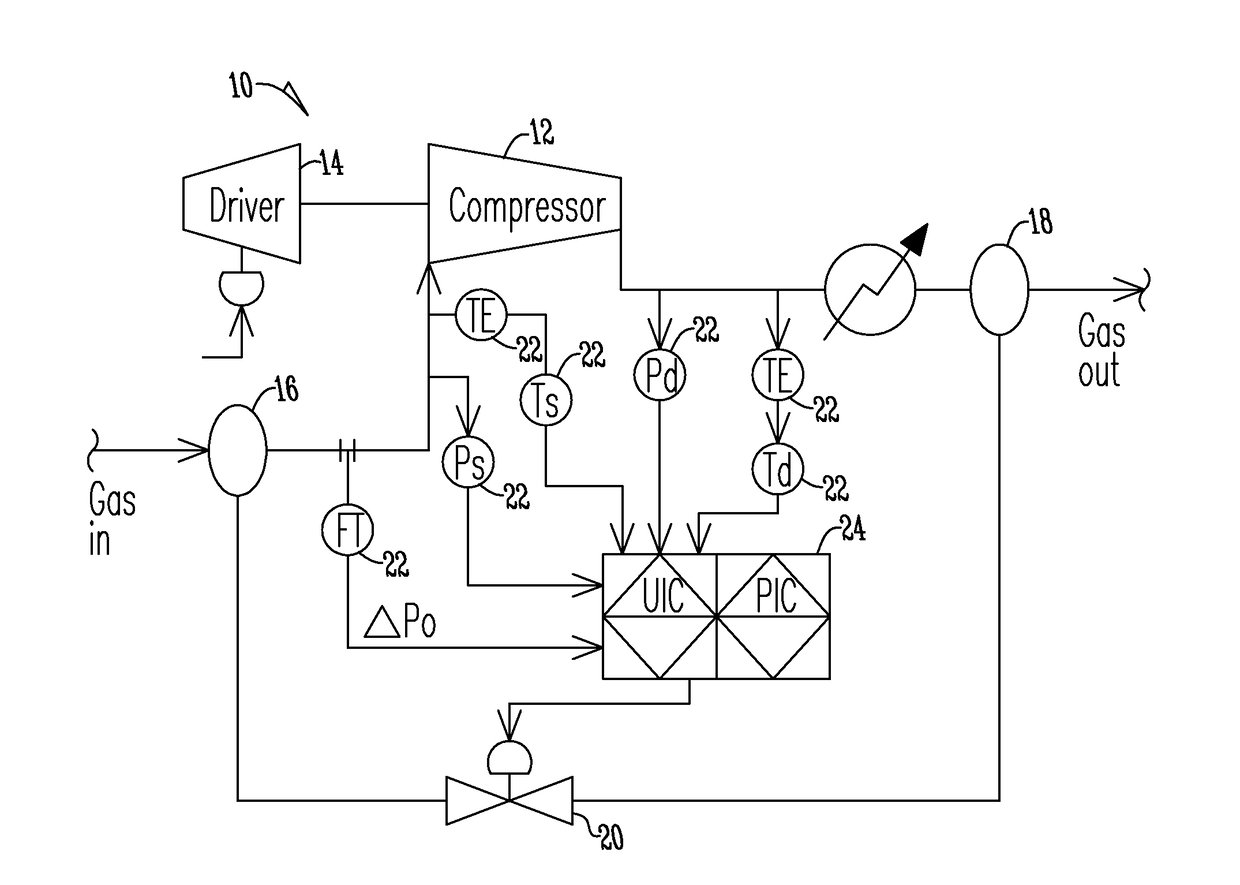

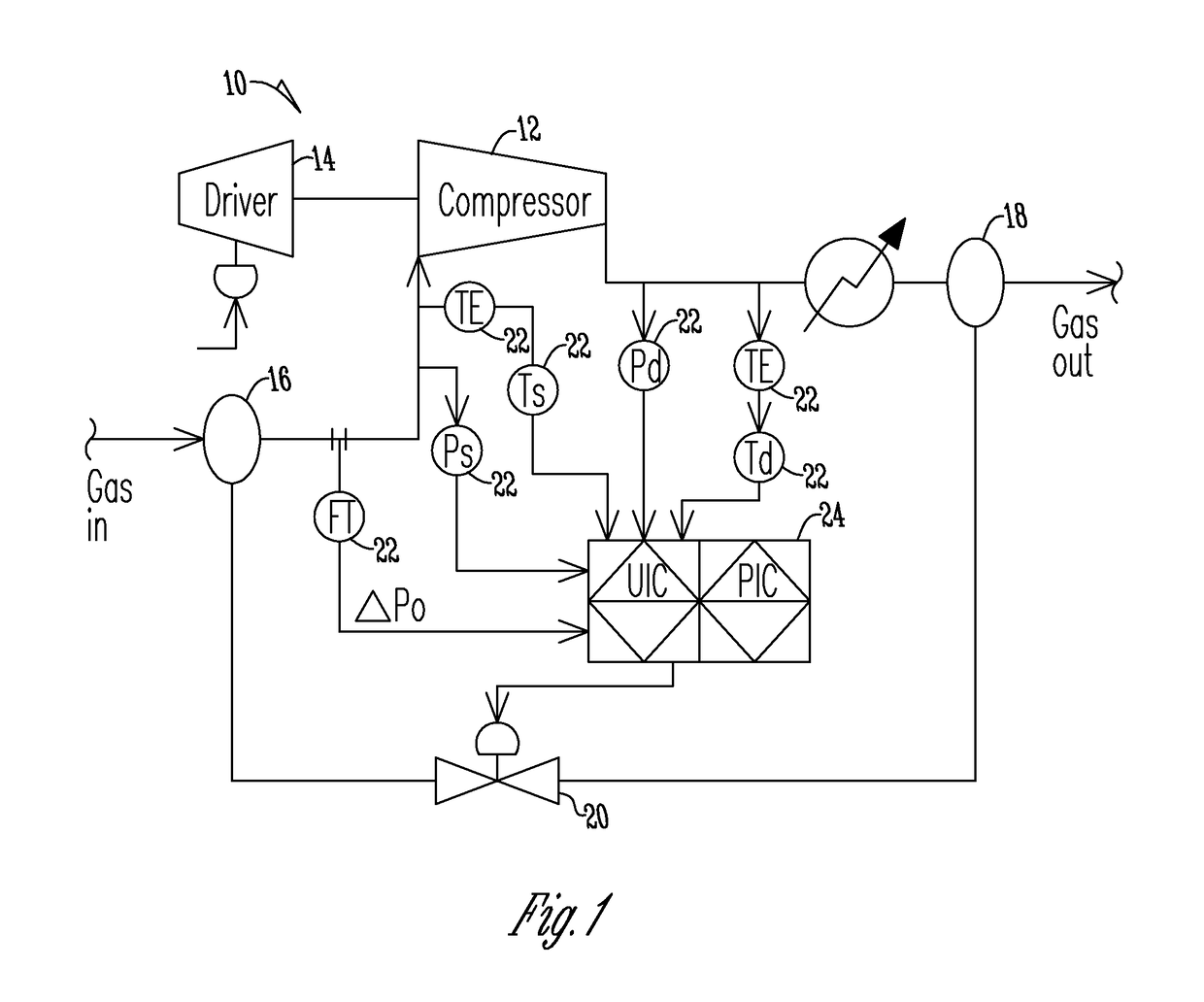

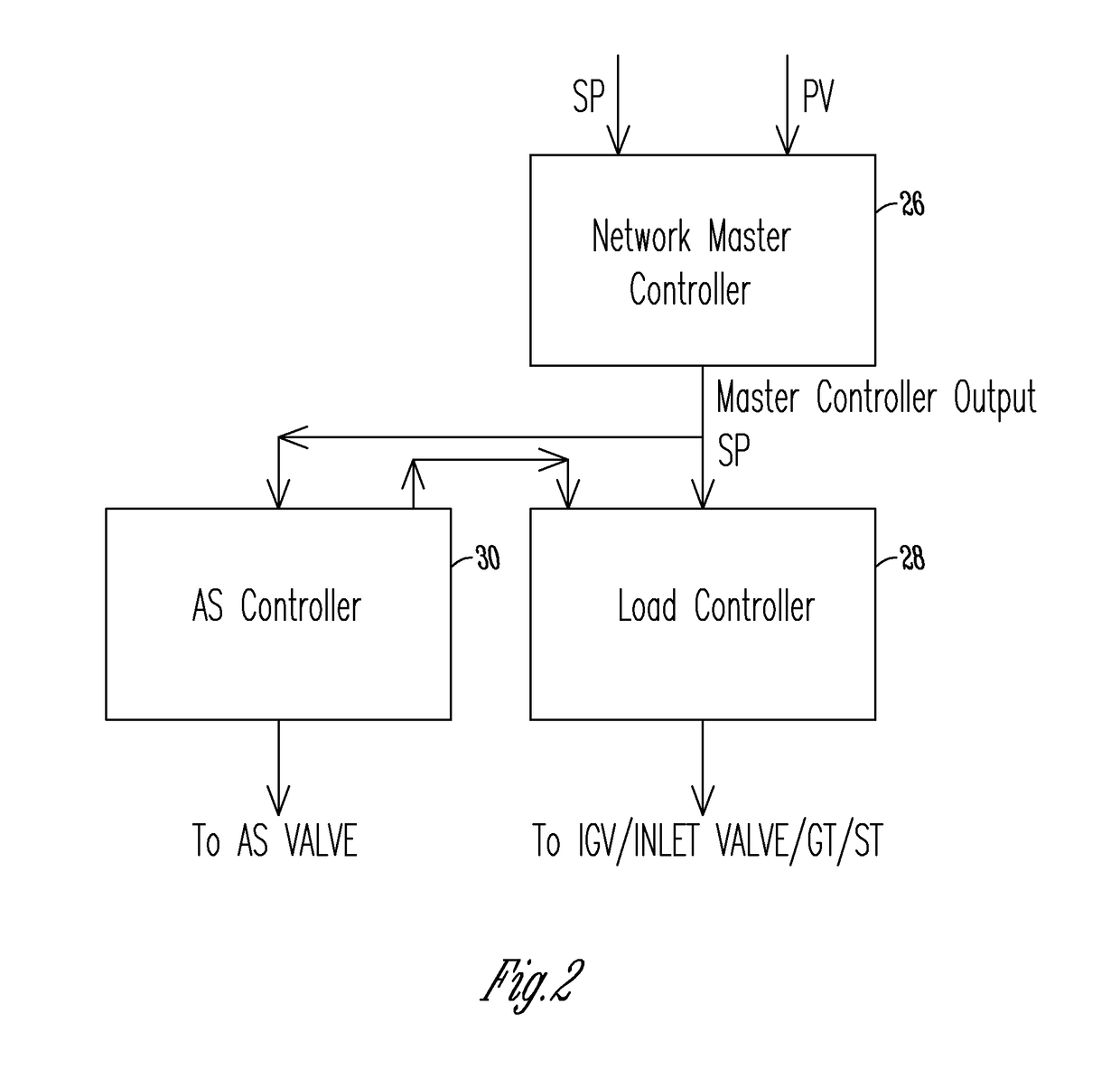

Turbocompressor Antisurge Control by Vibration Monitoring

ActiveUS20130309060A1Efficient detectionVibration measurement in solidsElectrical controlPresent dayOperating point

The proposed mechanical method of turbocompressor surge detection uses vibration signals from vibration monitoring equipment mounted on the compressor components to detect a surge event and provide antisurge control thereby. This method utilizes only mechanical information to identify surge, as compared to present day antisurge controllers that use compressor thermodynamic information such as flow, pressure, and temperature to locate a compressor's operating point on a compressor map compared to a surge region.

Owner:COMPRESSOR CONTROLS LLC

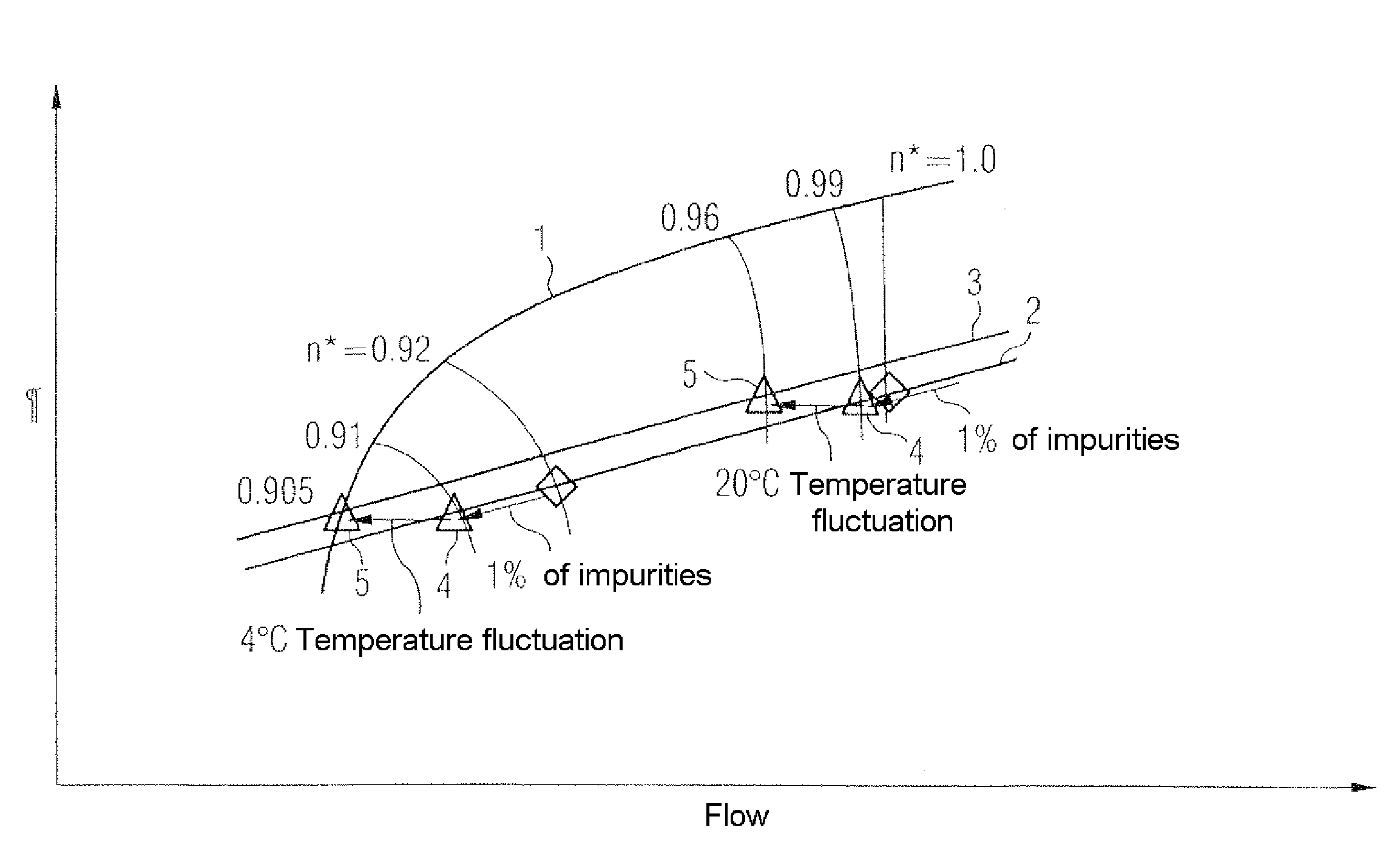

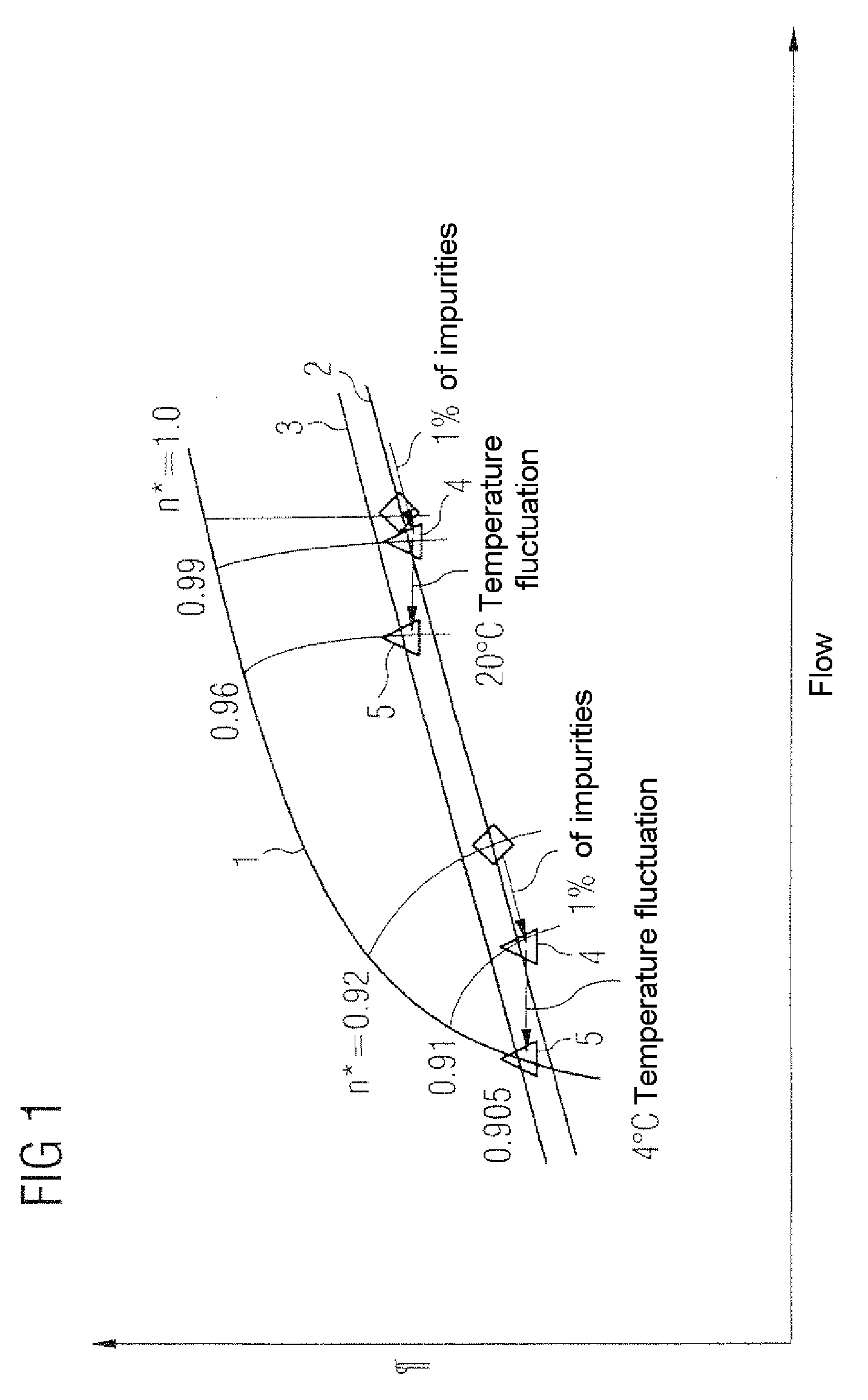

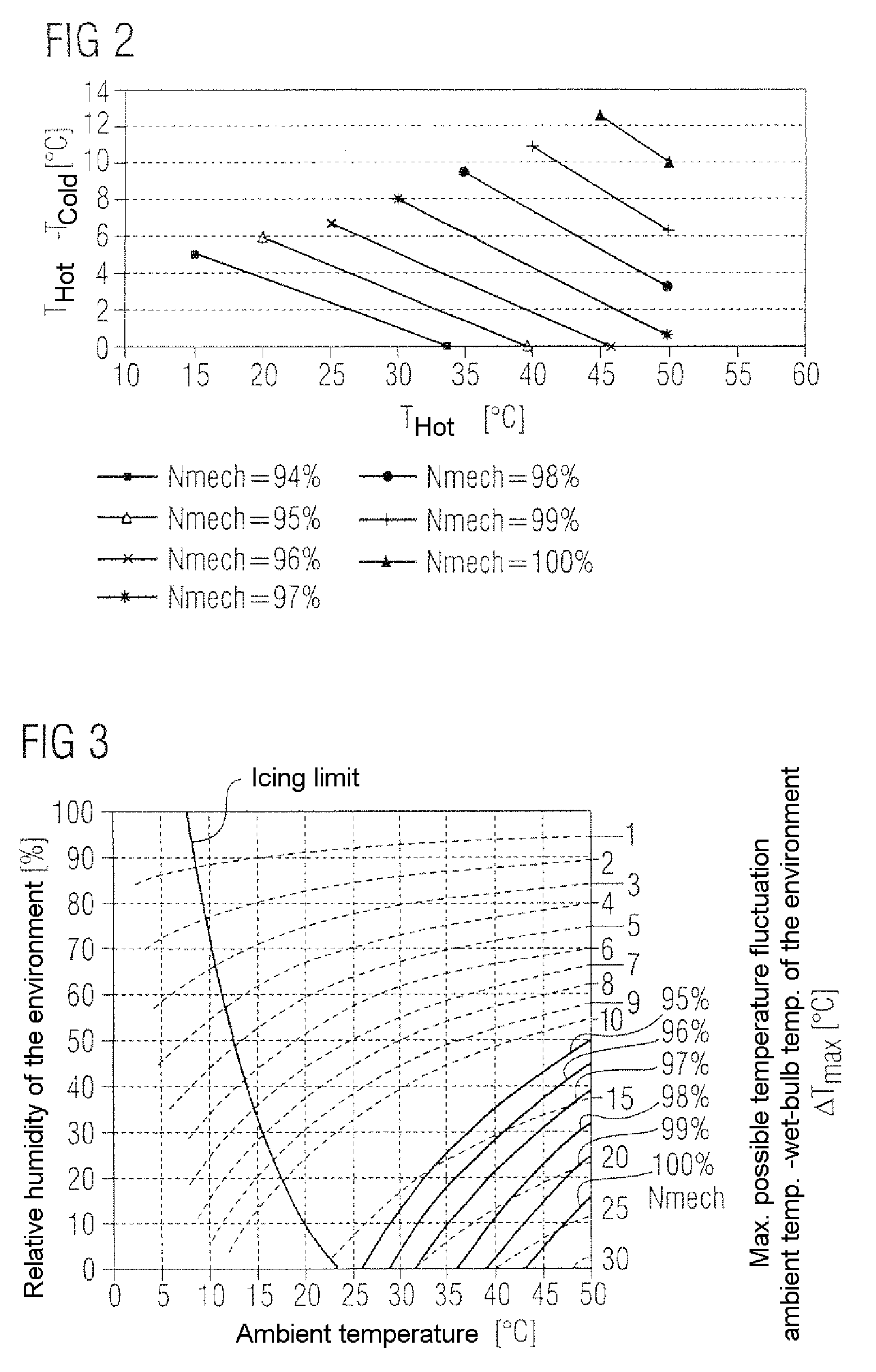

Method for the operation of a compressor of a gas turbine with evaporative cooling of the compressor induction air

In a method of operating a compressor of a gas turbine, where compressor air sucked in from the environment is cooled down by evaporation cooling before entering the compressor, before starting operation of the compressor, maximum possible temperature drops which could be achieved by evaporation cooling are determined dependent on different ambient conditions and / or are provided as a data set. These temperature drops are correlated with a compressor map containing maximum temperature distortions at different ambient conditions and different rotation frequencies of the compressor which have to be met in order to avoid pumping. The evaporation cooling is then only operated when current ambient condition result in a maximum possible temperature drop from which a predetermined fraction of between 50% and 100% does not exceed the maximum distortion which can be taken from the compressor map for these ambient conditions and the current rotation frequency of the compressor. Safe operation of the compressor can be achieved without the need or monitoring temperature distortions in the sucked in air stream.

Owner:ANSALDO ENERGIA IP UK LTD

System and method for inspection of stator vanes

Embodiments of the invention include an inspection system to inspect internal components of a compressor of a gas turbine engine. The inspection system includes an image recording assembly having one or more image recording devices, light sources, storage devices, and power supplies. The image recording assembly may be inserted into a compressor without removal of the compressor housing or disassembly of the compressor. The image recording assembly may be removably coupled to a rotary component of the compressor, e.g., a rotor blade, and used to record images of stationary components, e.g., stator vanes, of the compressor. The images may be inspected to identify wear and / or defects in the stationary components, e.g., stator vanes

Owner:GENERAL ELECTRIC CO

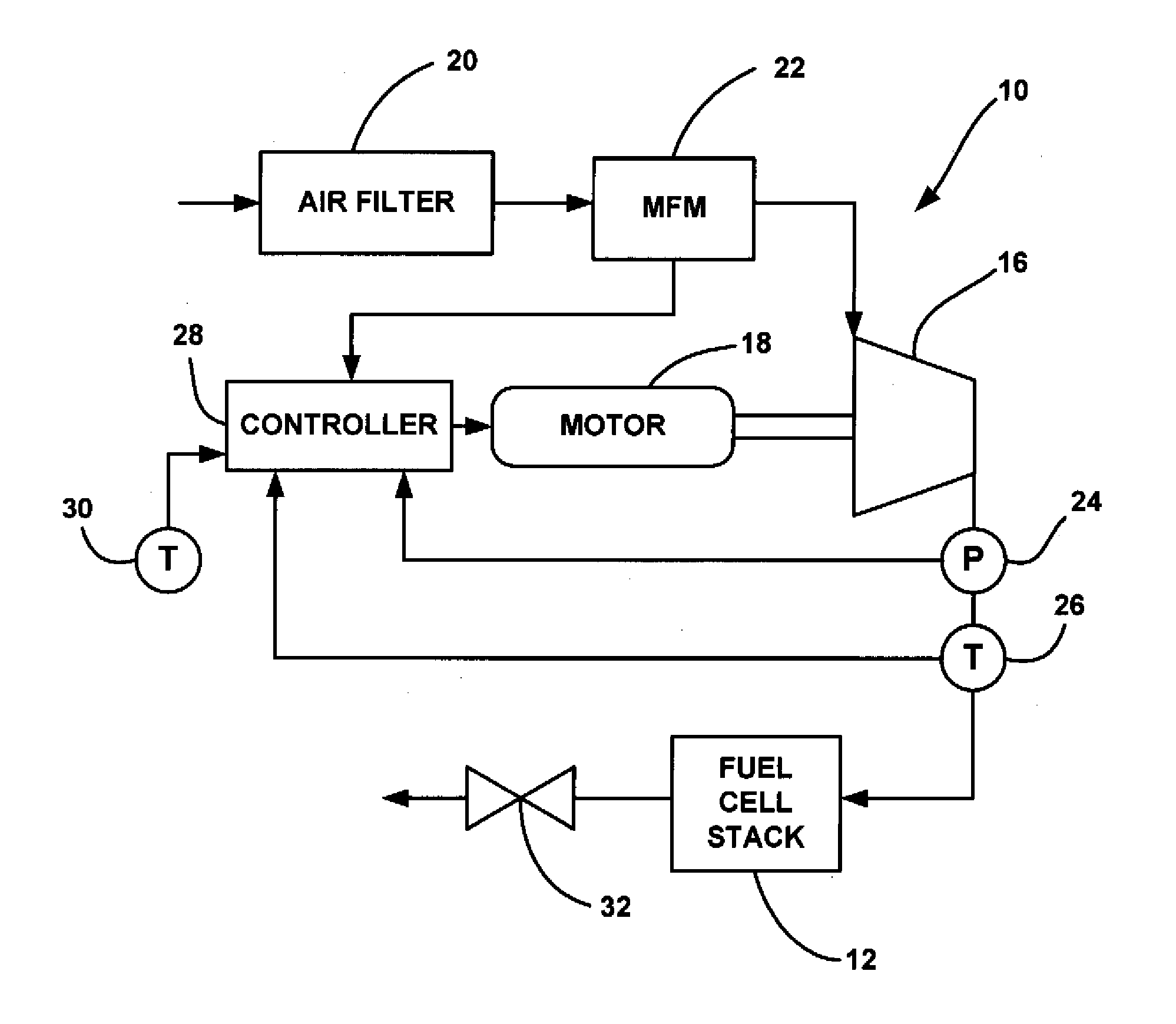

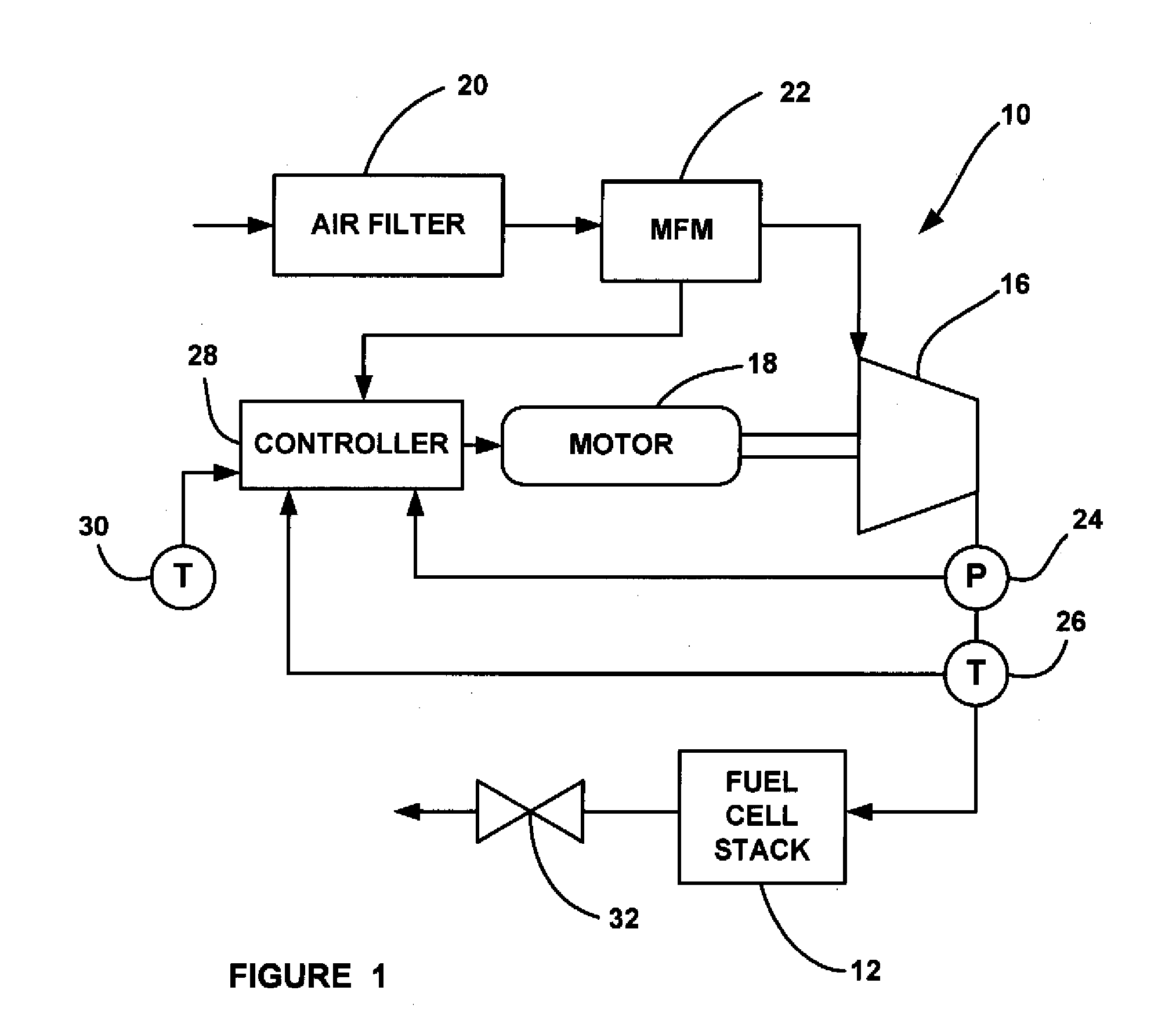

Adaptive compressor surge control in a fuel cell system

ActiveUS20090325010A1Maximize efficiencyQuantity minimizationWind motor controlFuel cell auxillariesAdaptive compressionOperating point

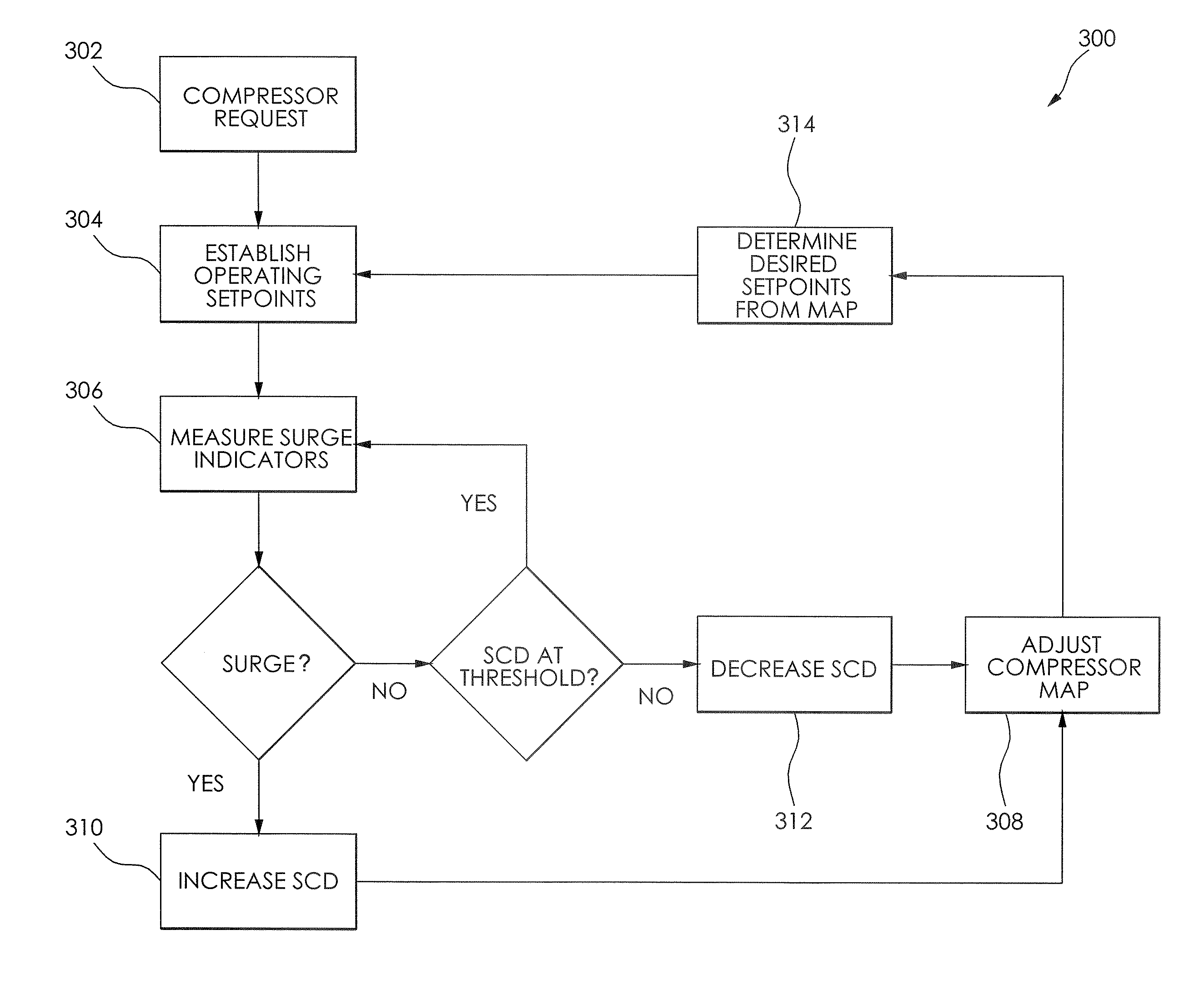

A fuel cell system having an adaptable compressor map and method for optimizing the adaptable compressor map is provided. The method includes the steps of establishing an initial operating setpoint for an air compressor based on the adaptable compressor map; monitoring a surge indicator; adjusting the adaptable compressor map based on the monitored surge indicator; determining a desired operating setpoint based on the adjusted adaptable compressor map; and establishing an adapted operating setpoint for the air compressor based on the adaptable compressor map following the adjustment thereof. The steps are repeated until the adaptable compressor map for the air compressor is optimized.

Owner:GM GLOBAL TECH OPERATIONS LLC

Cathode filter replacement algorithm in a fuel cell system

InactiveUS20100151294A1Avoid enteringReactant parameters controlMotive system fuel cellsParticulatesFuel cells

A fuel cell system that includes a compressor for providing cathode air to the cathode side of a fuel cell stack and an air filter for filtering the air sent to the compressor to prevent particulates and other contaminants from entering the compressor and the fuel cell stack. The fuel cell system also includes a mass flow meter that measures the flow of air to the compressor and a pressure sensor that measures the pressure of the airflow at the output of the compressor. An electronic compressor map is provided that defines the operating characteristics of the compressor. By knowing the flow through the compressor and the pressure at the outlet of the compressor, an algorithm can determine where on the compressor map the compressor is operating, and from that determine the inlet pressure to the compressor, which in turn shows whether the air filter is clogged or otherwise damaged.

Owner:GM GLOBAL TECH OPERATIONS LLC

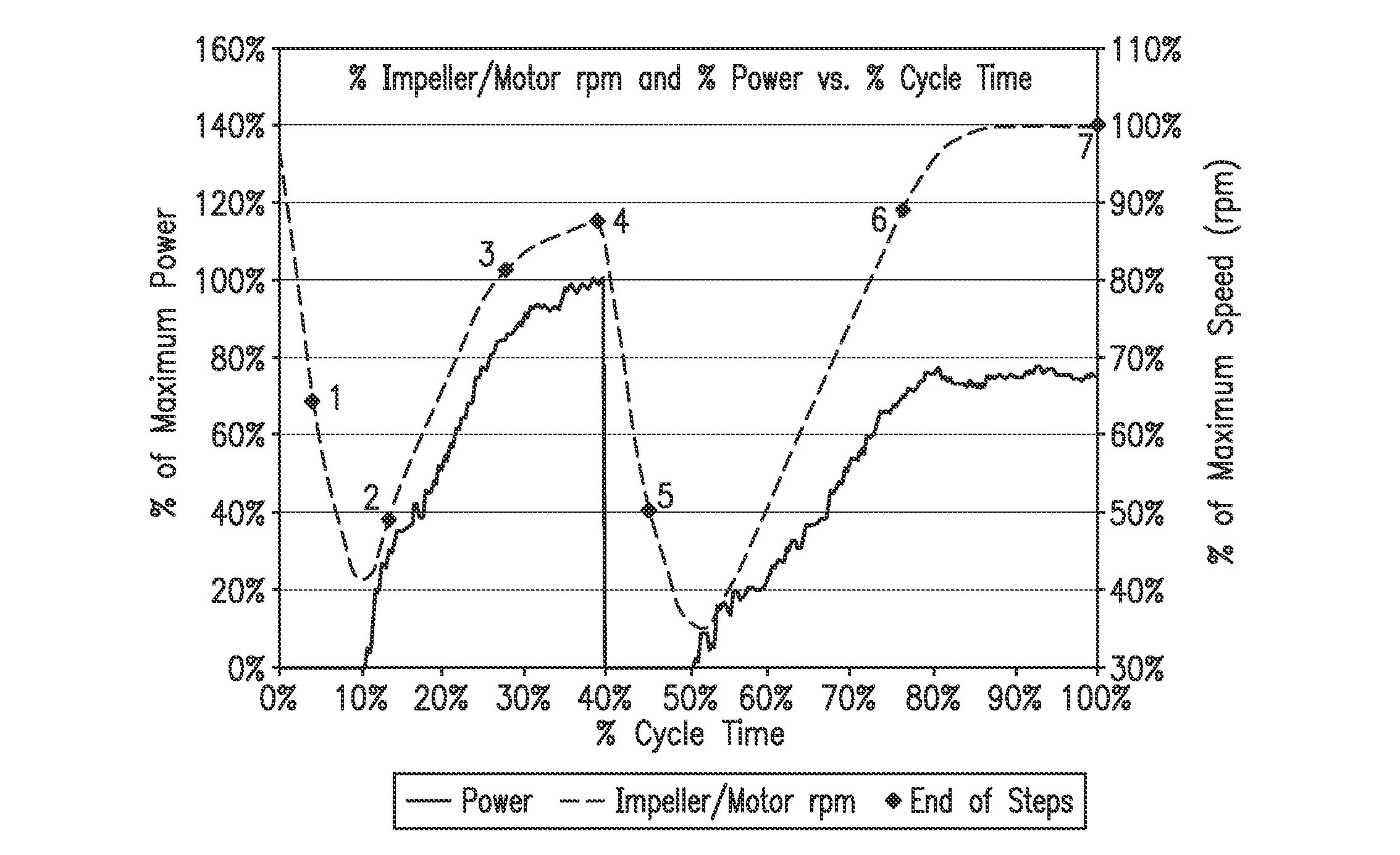

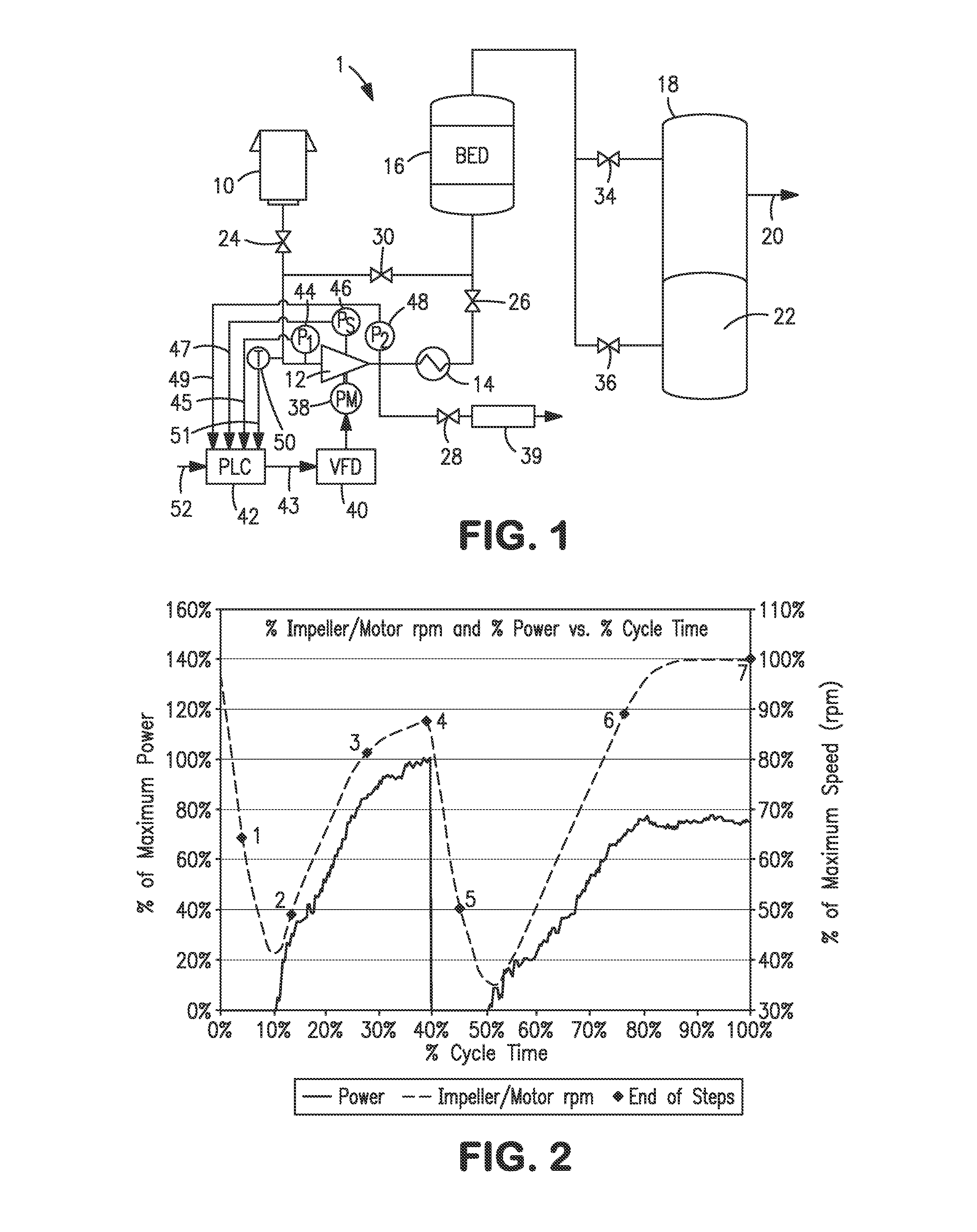

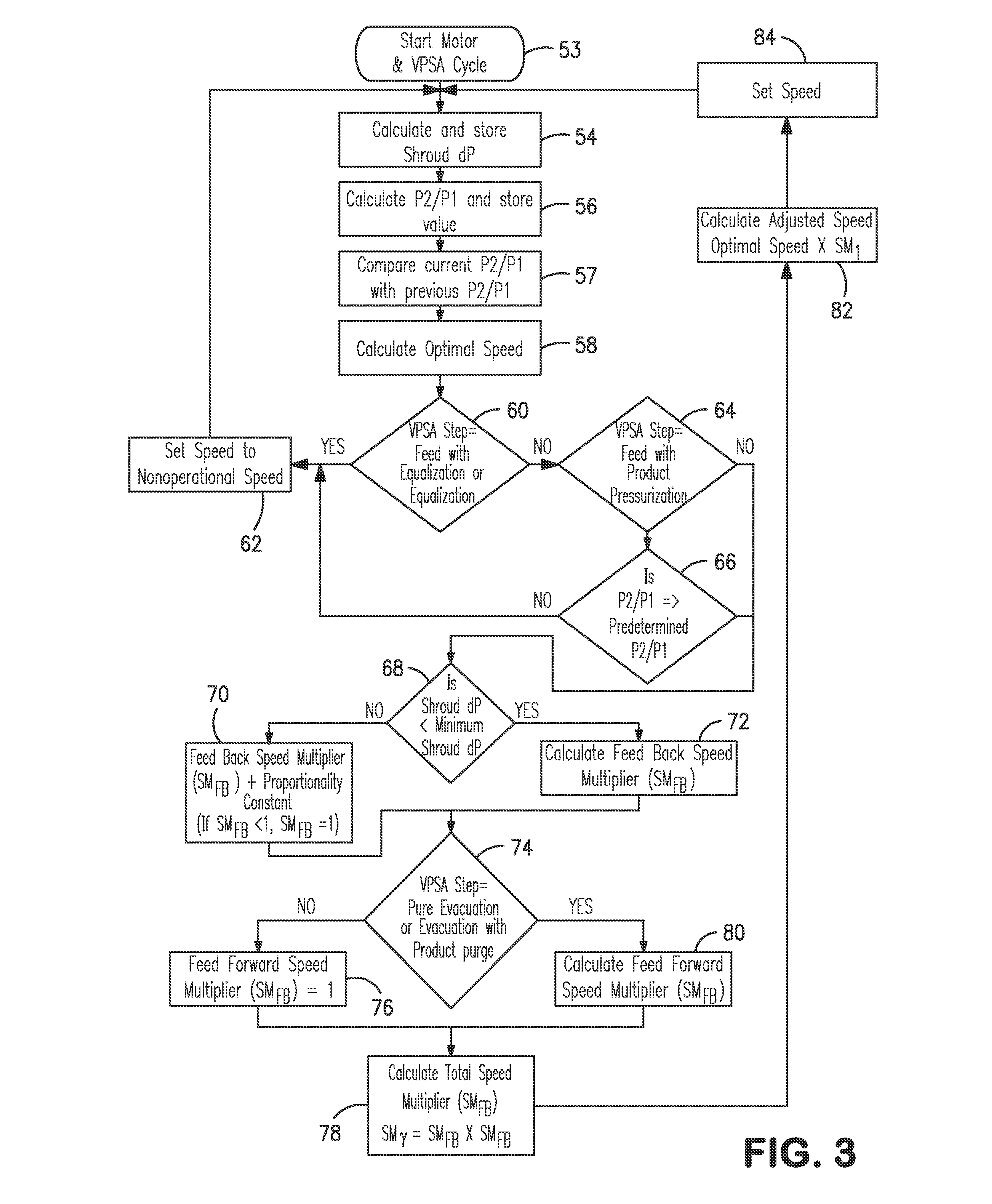

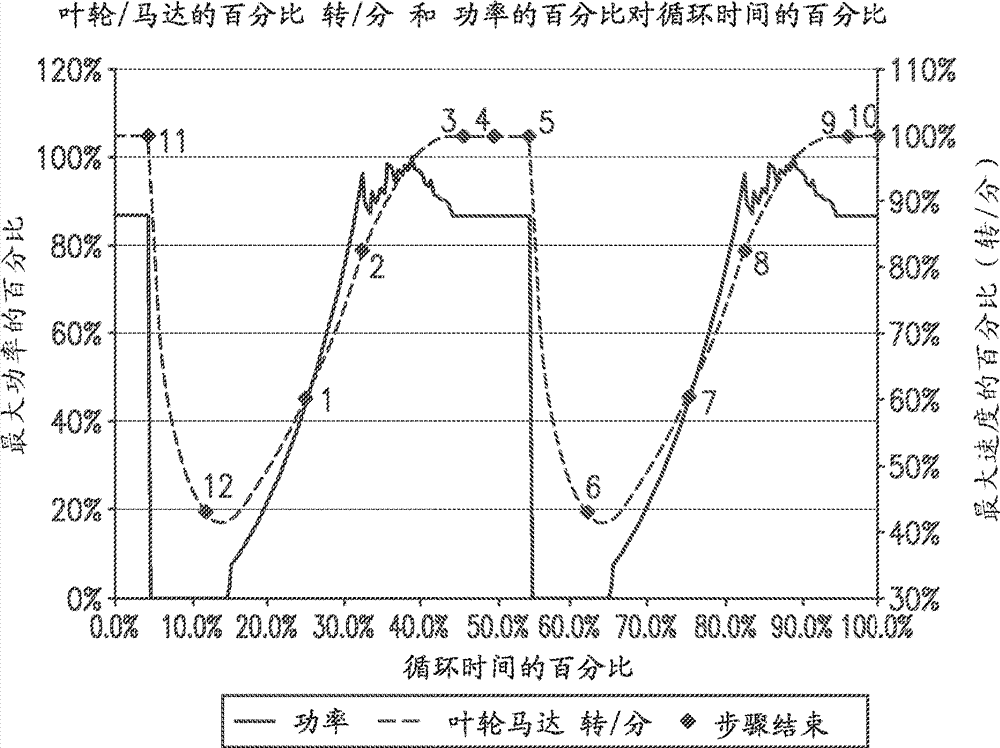

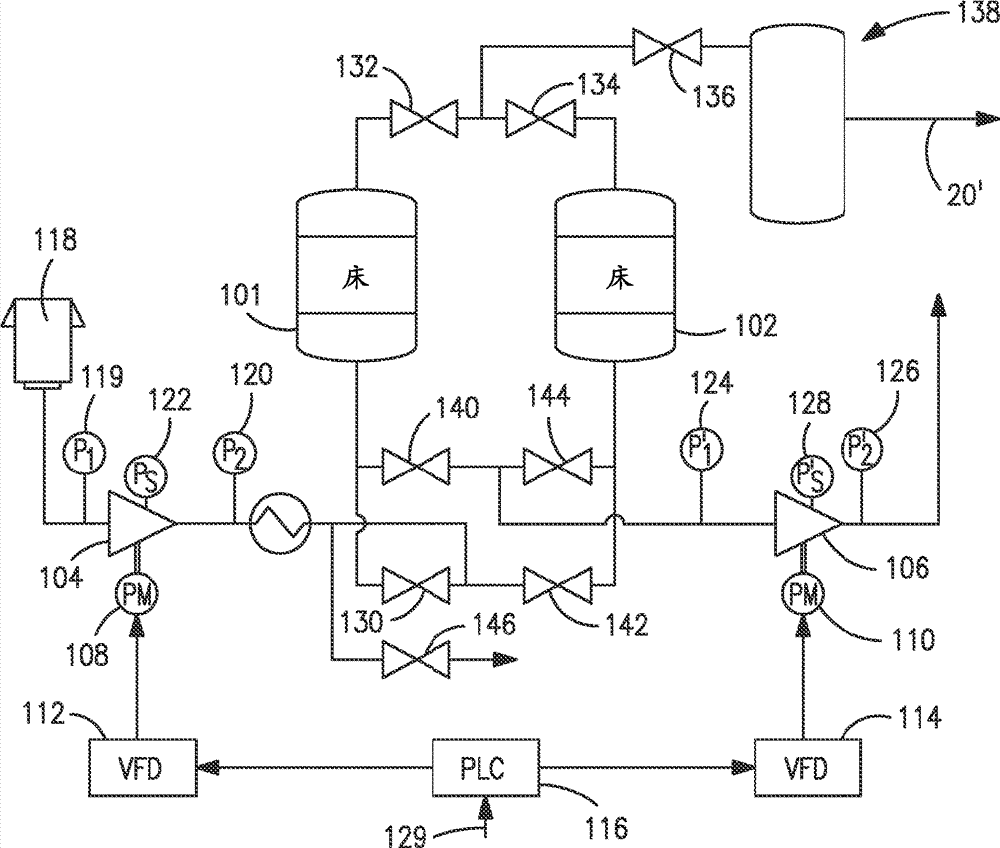

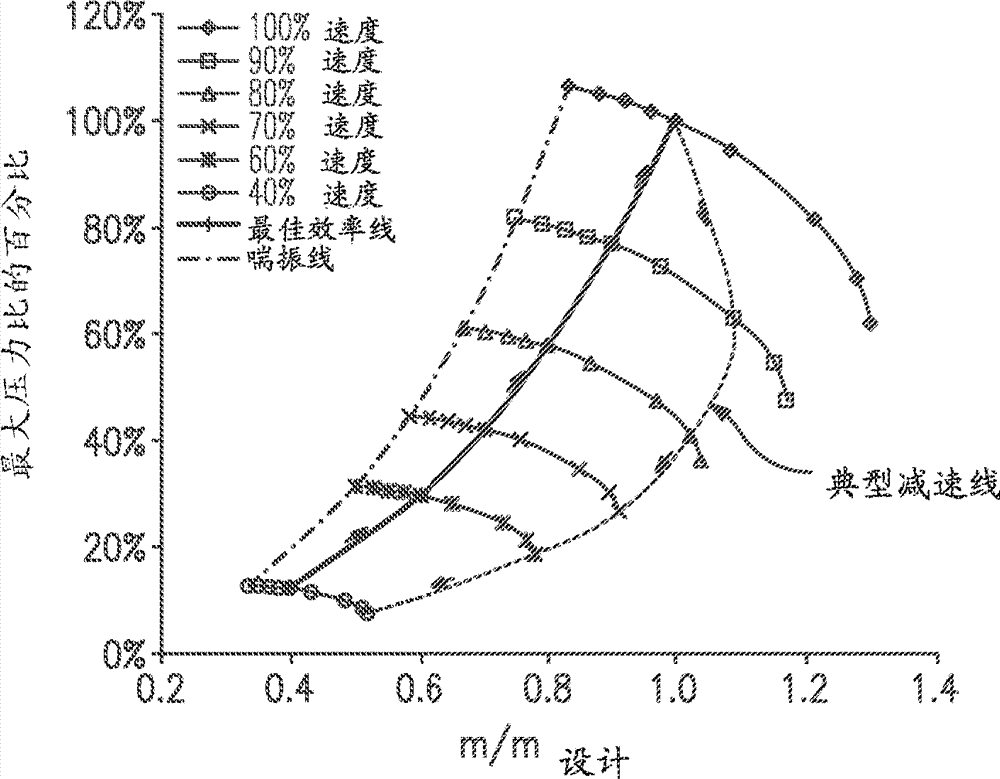

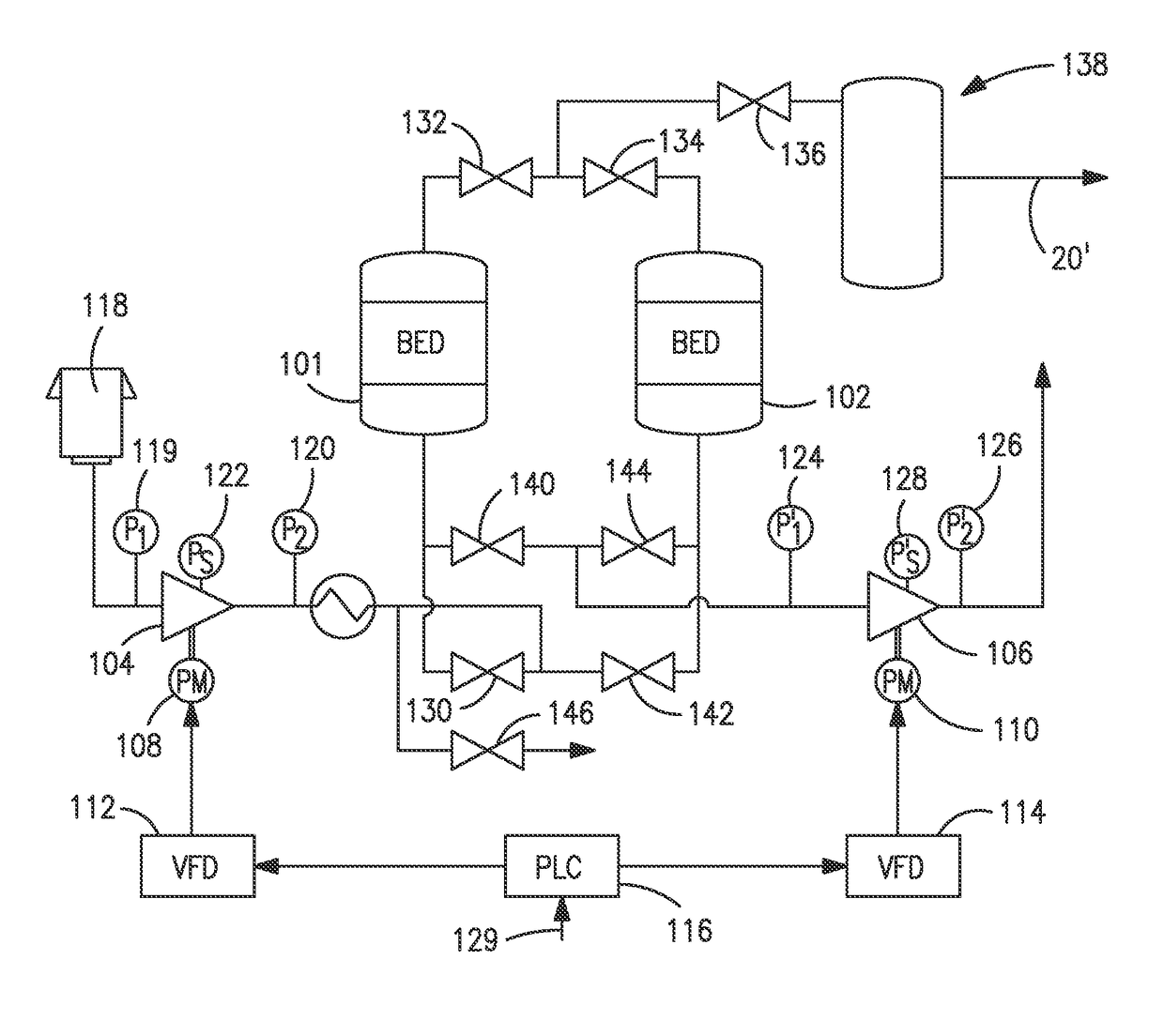

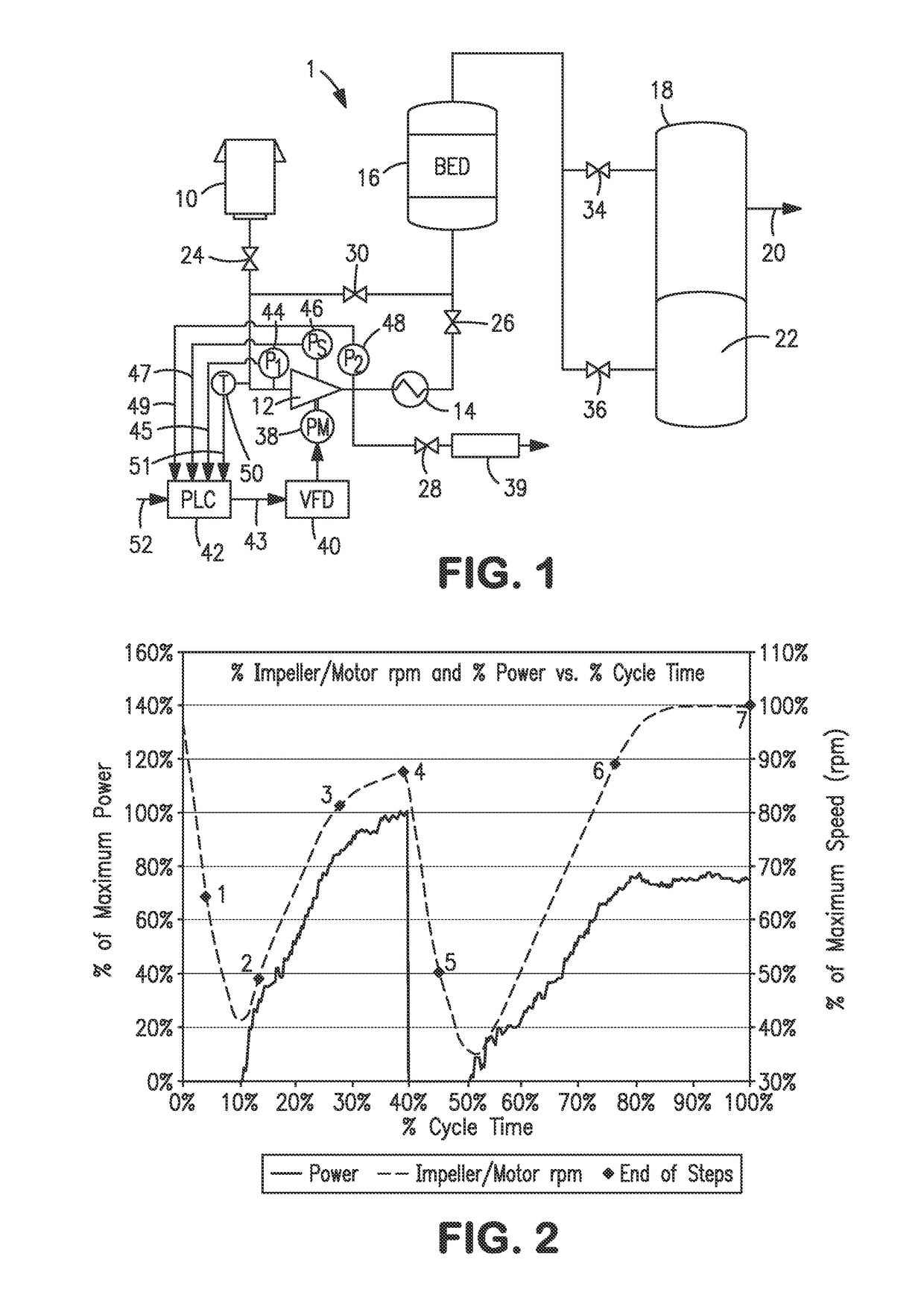

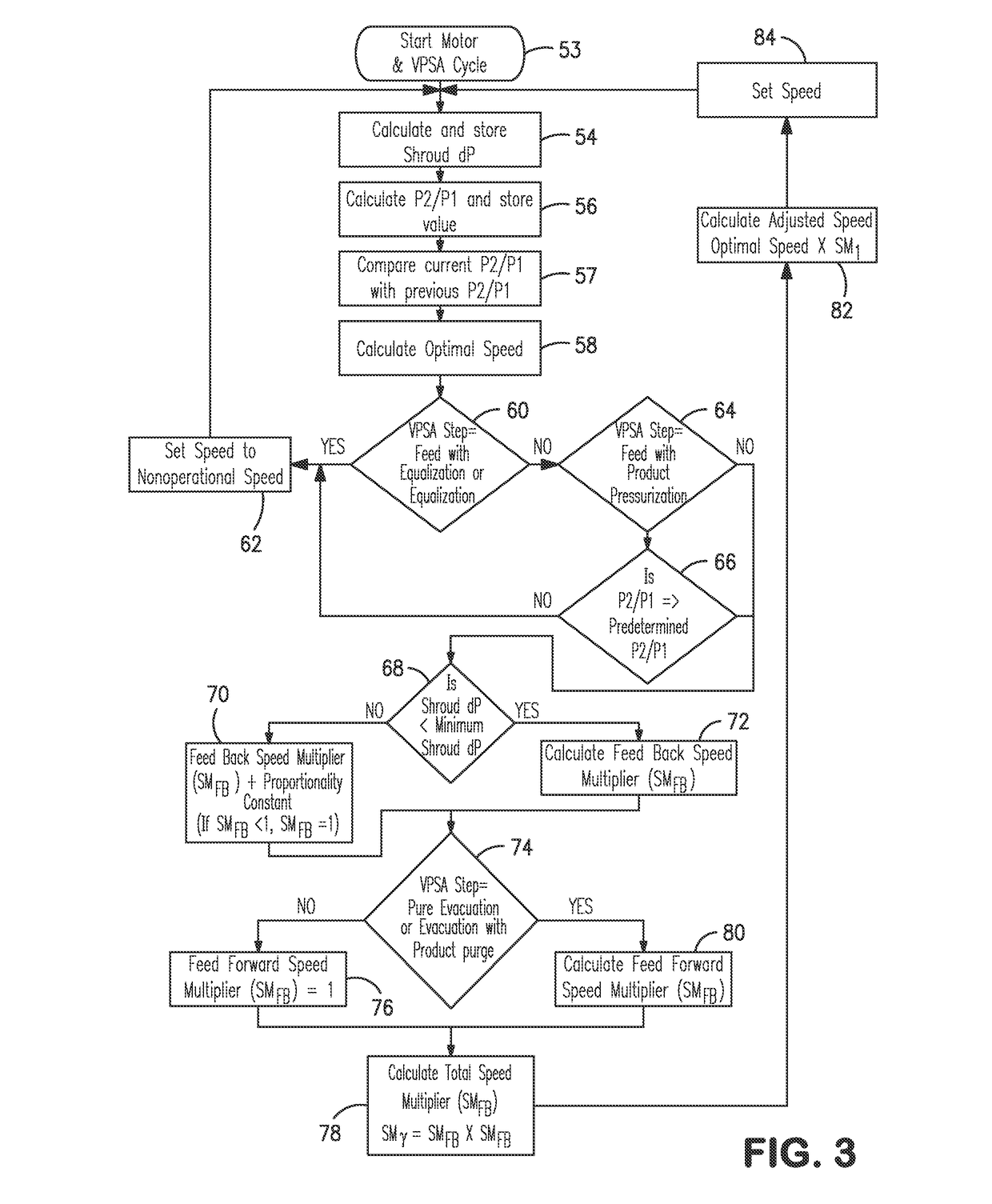

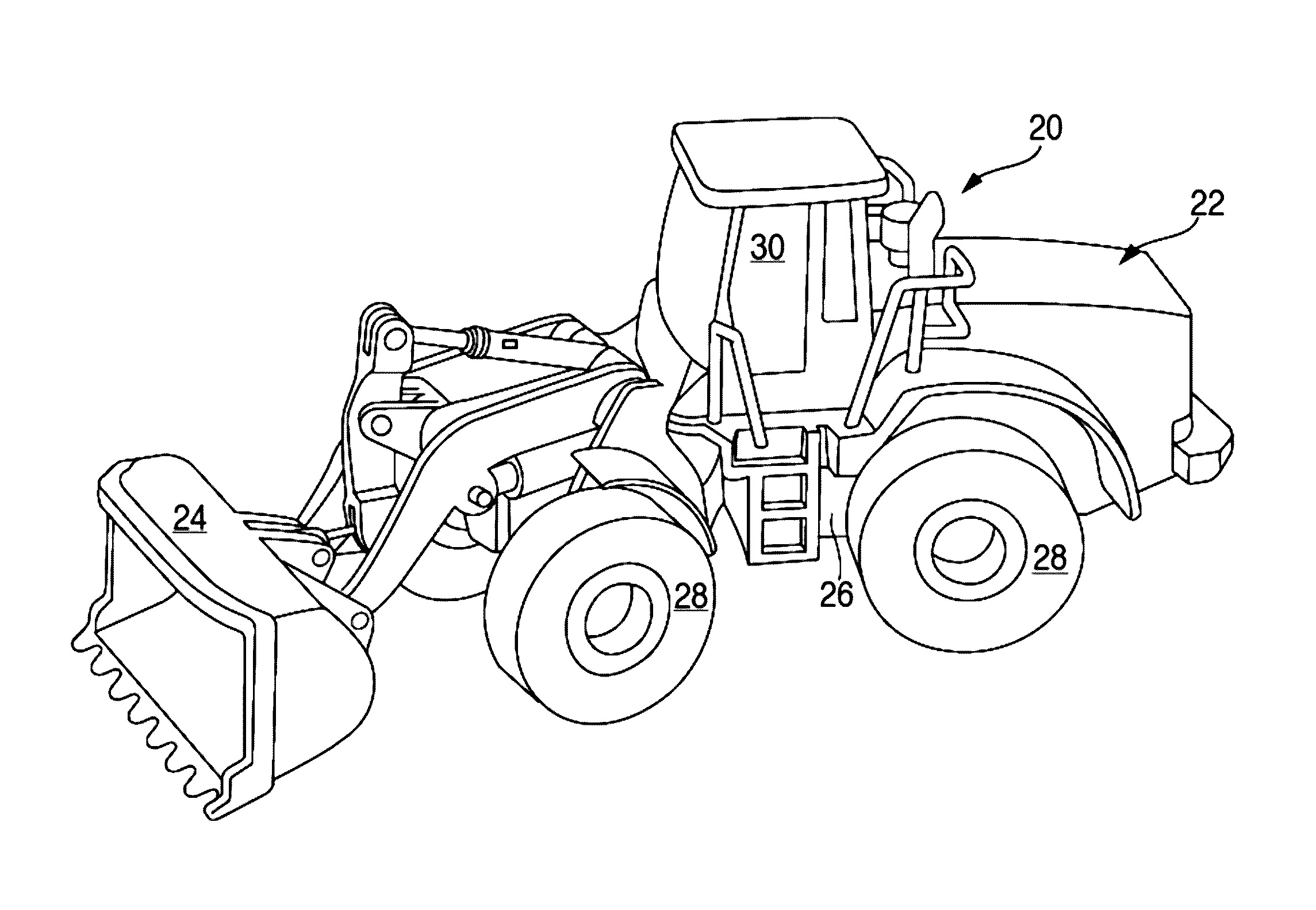

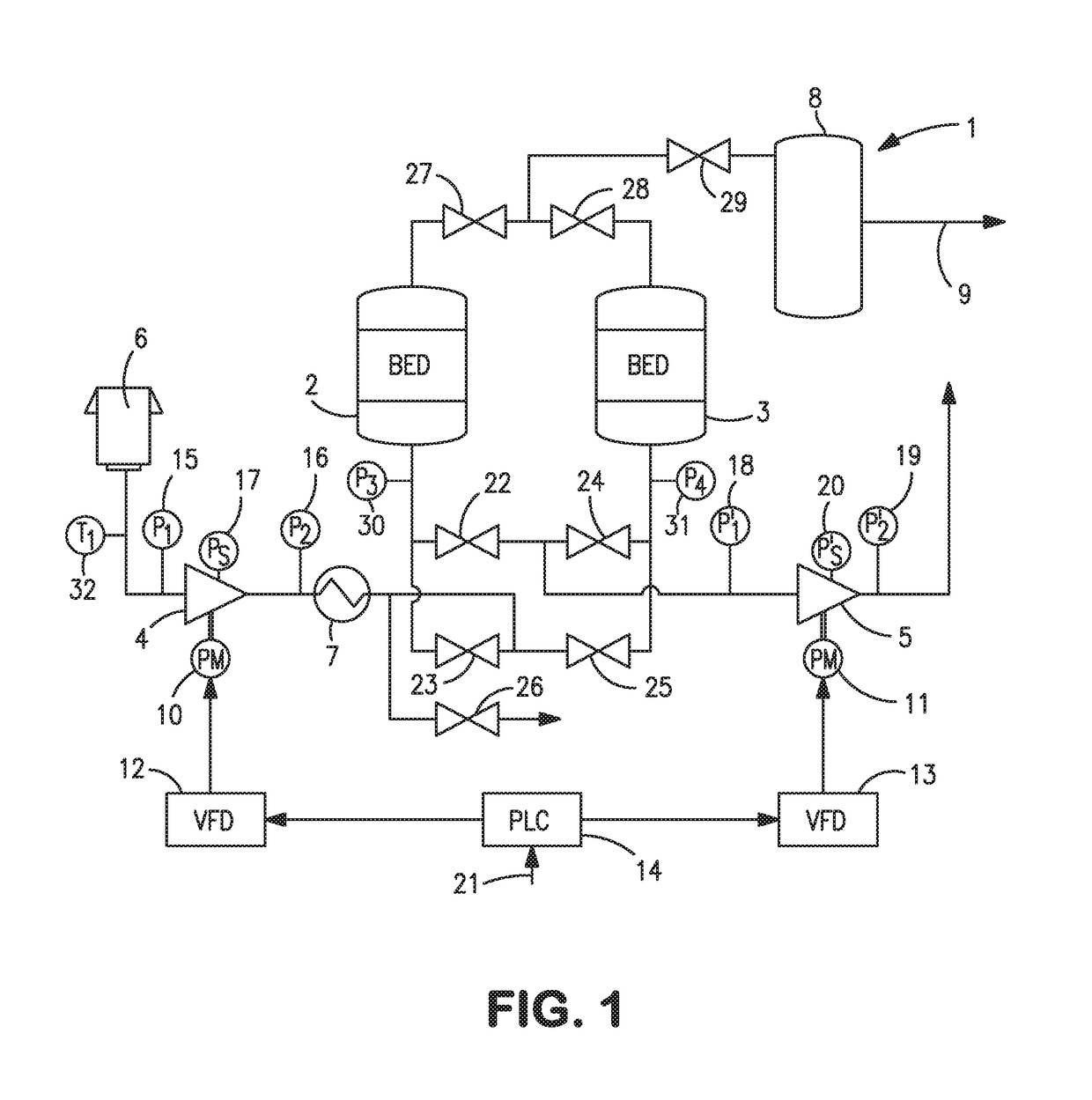

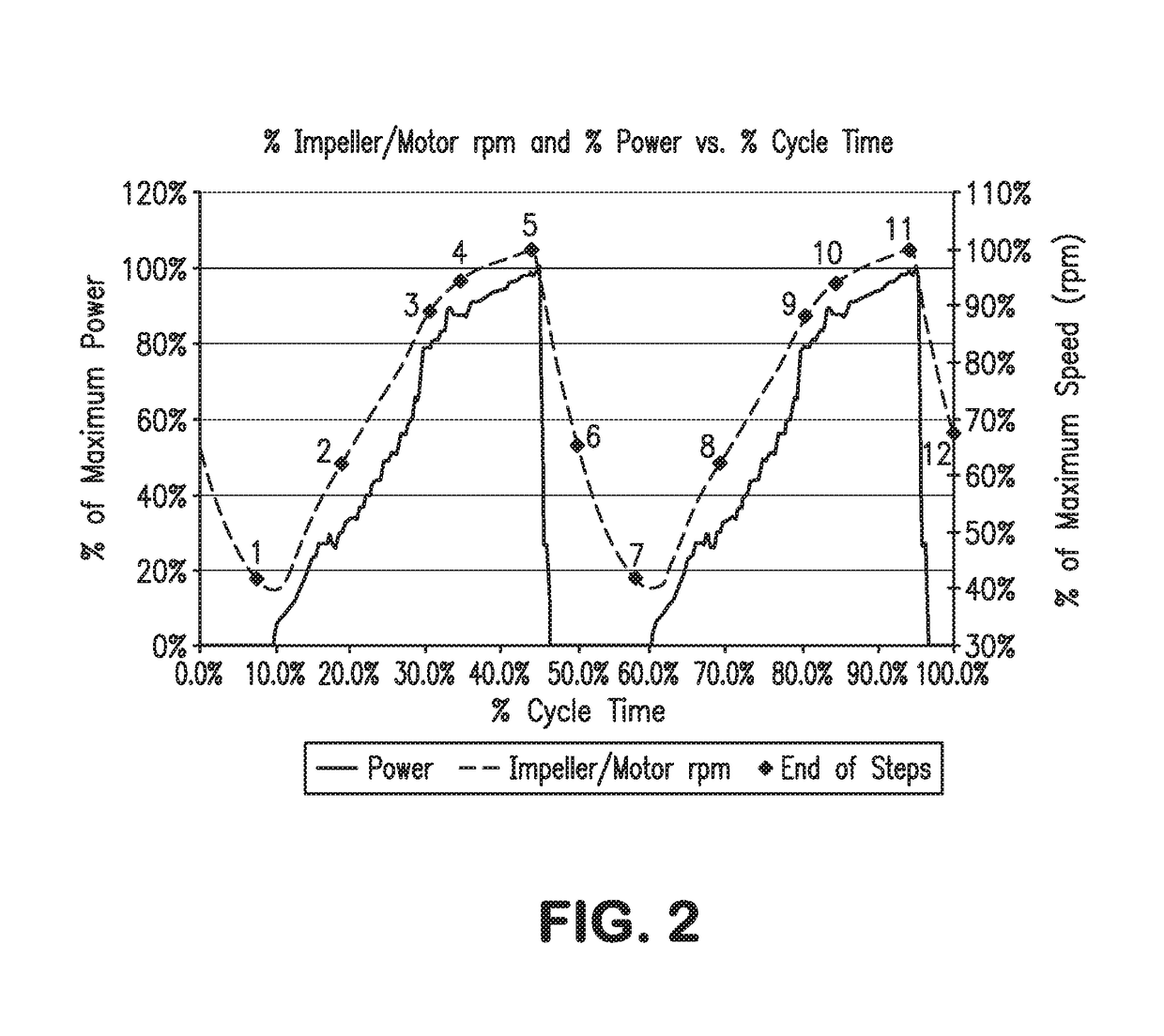

Anti-surge speed control

InactiveUS20130323082A1Removal of powerEfficient regulation technologiesPump controlVacuum pressureControl system

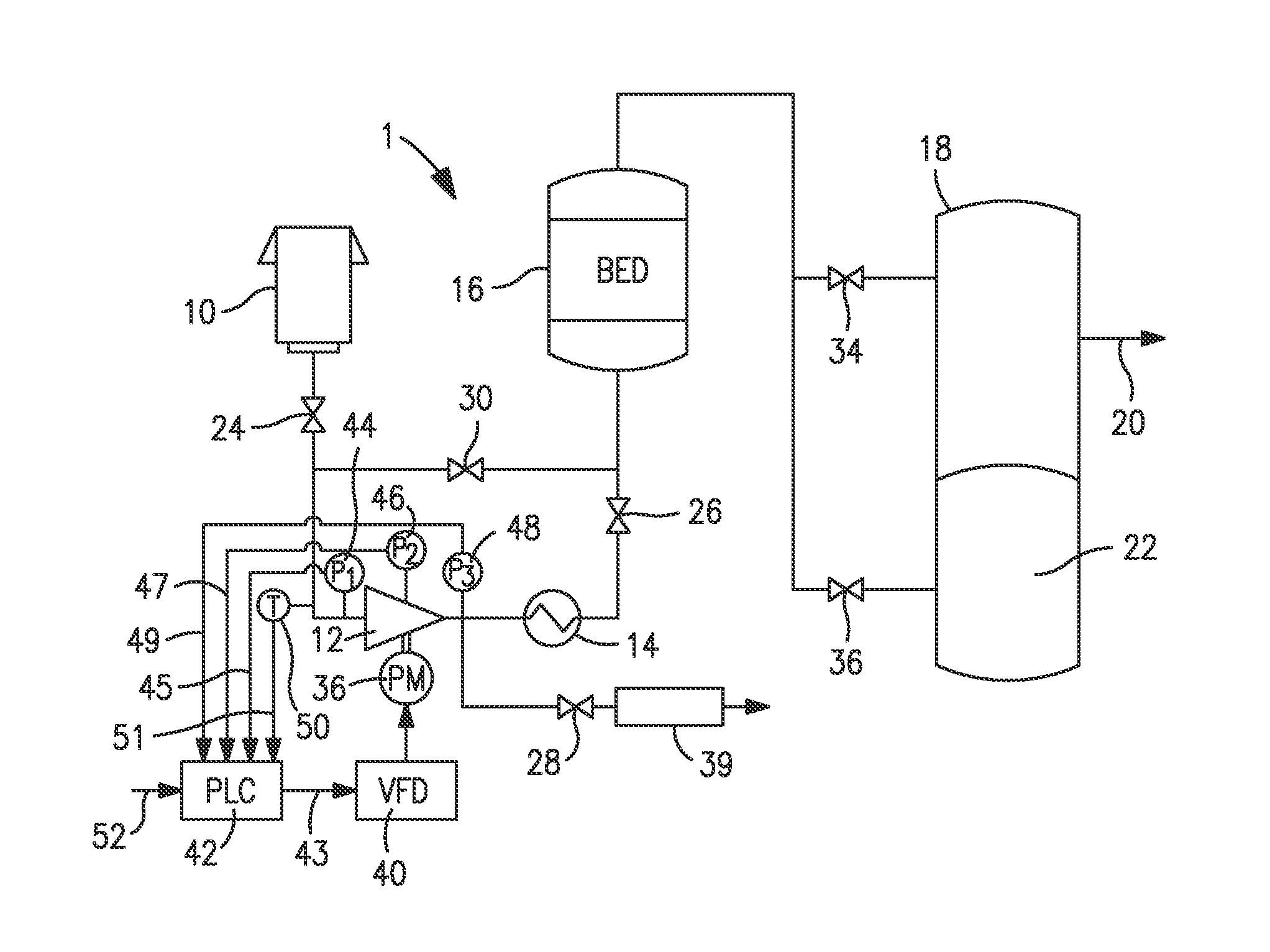

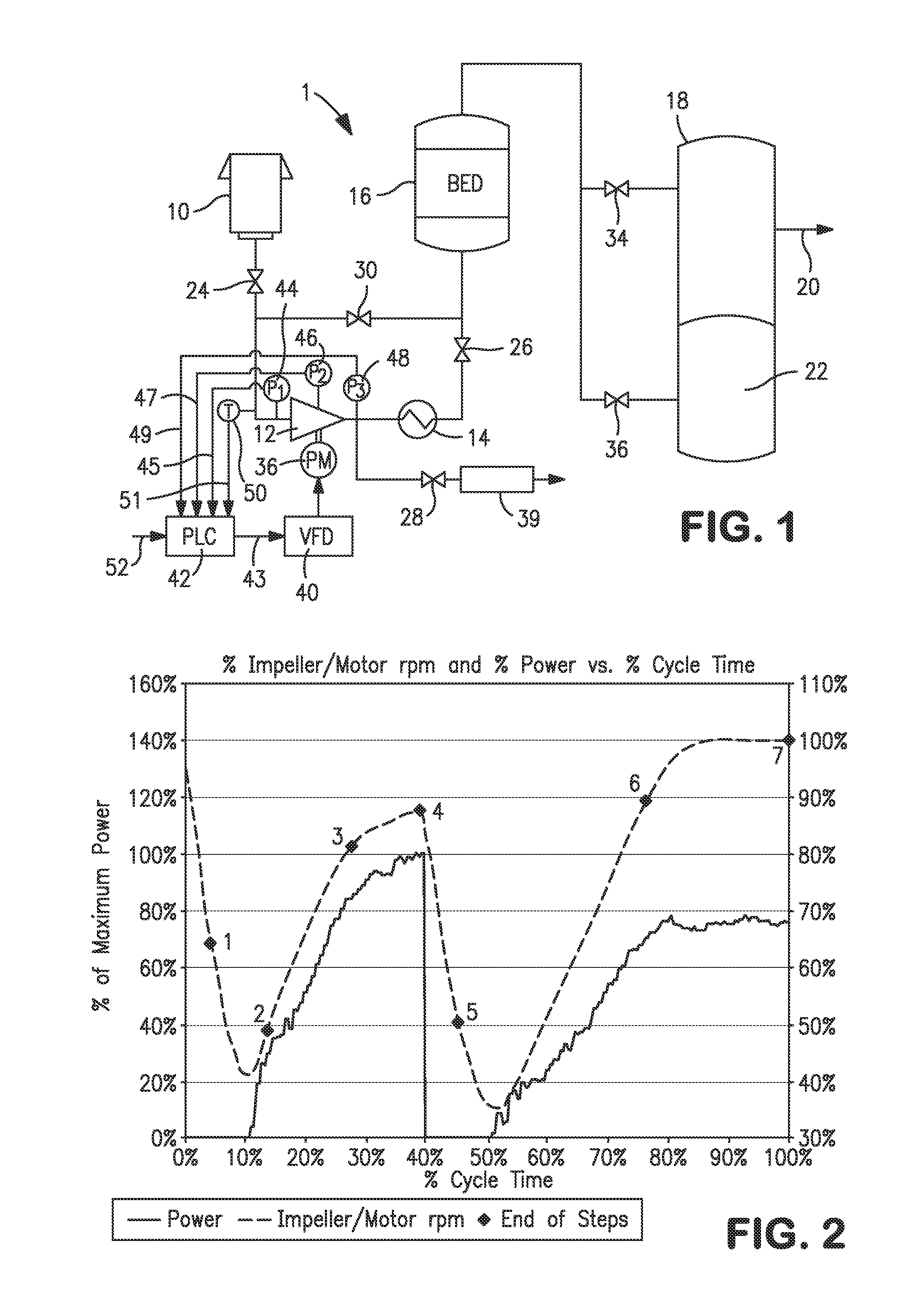

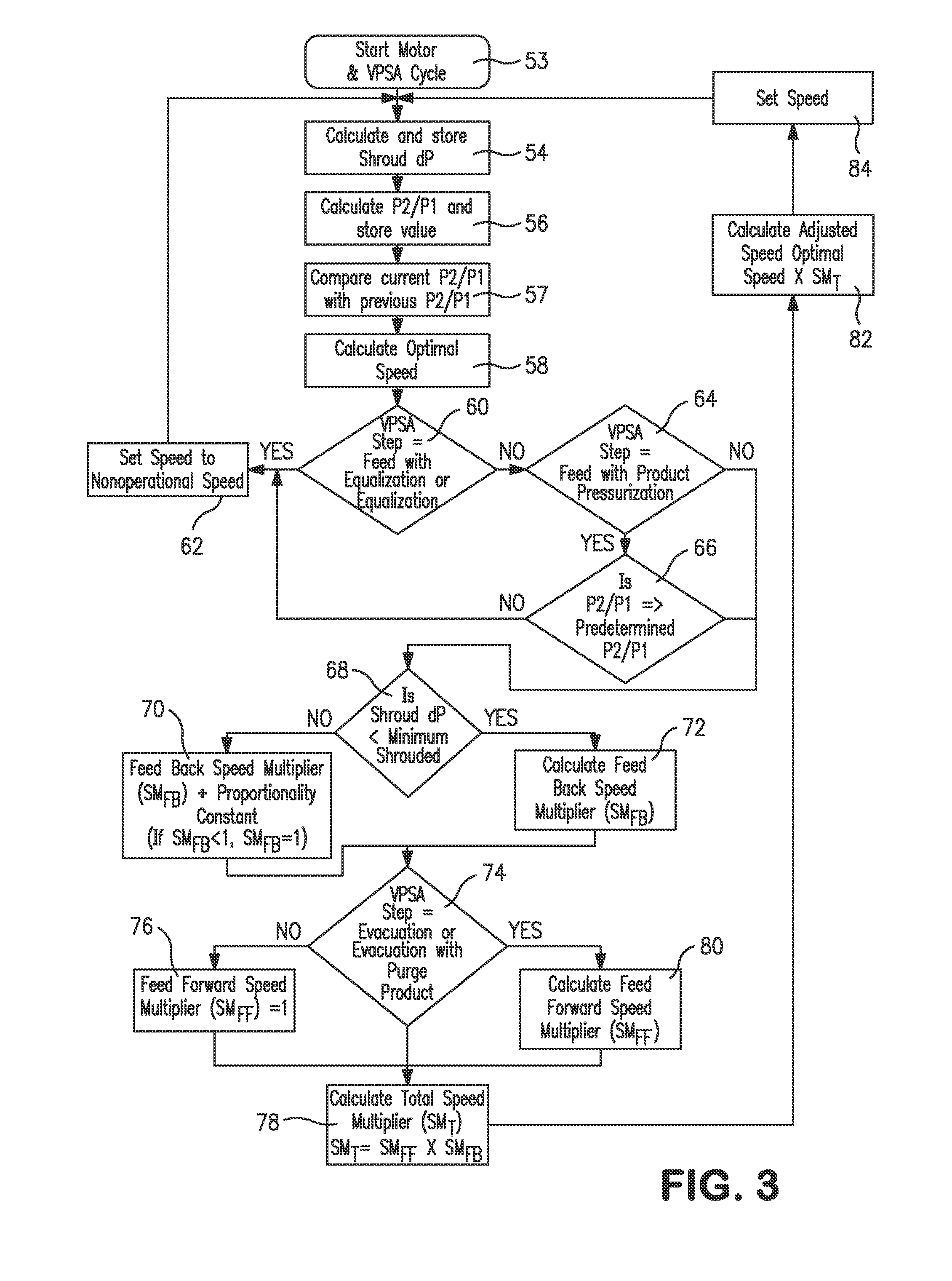

The present invention relates to a method and control system to control the speed of a centrifugal compressor operating within a vacuum pressure swing adsorption process to avoid an operation at which surge can occur and directly driven by an electric motor that is in turn controlled by a variable frequency drive. In accordance with present invention an optimal speed for operation of the compressor is determined at which the compressor will operate along a peak efficiency operating line of a compressor map thereof. This speed is adjusted by a feed back speed multiplier when the flow or other parameter referable to flow through the compressor is below a minimum and a feed forward multiplier during evacuation and evacuation with purge steps that multiplies the feed back multiplier to increase speed of the compressor and thereby avoid surge.

Owner:PRAXAIR TECH INC

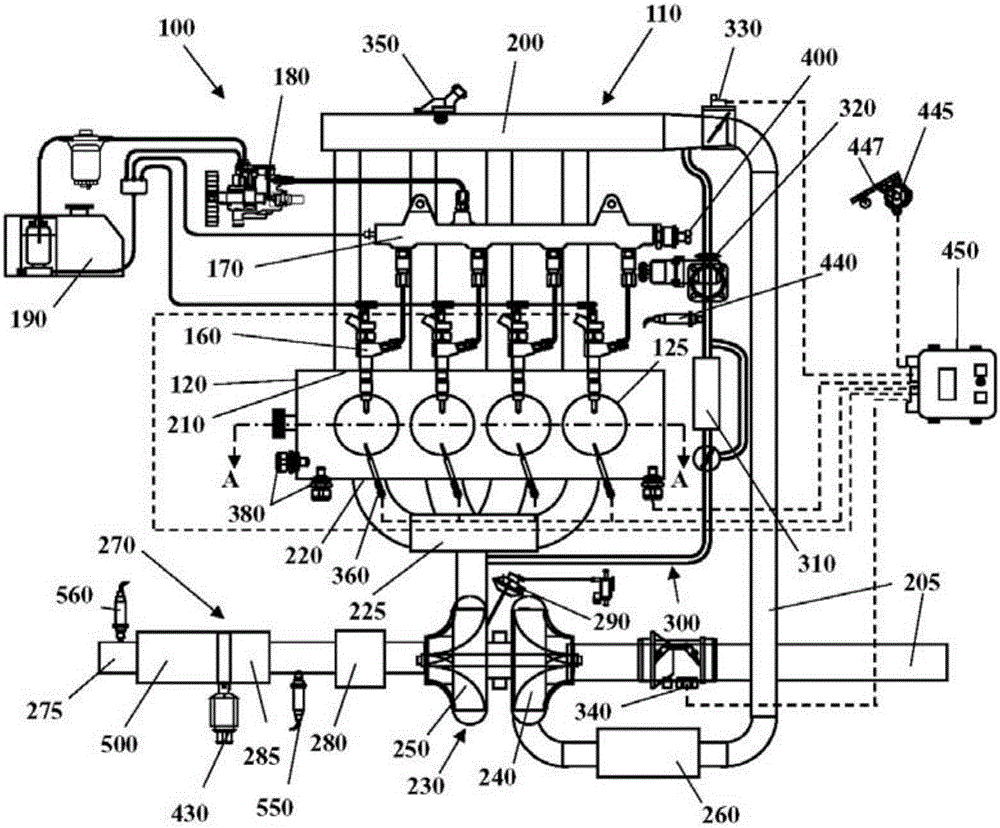

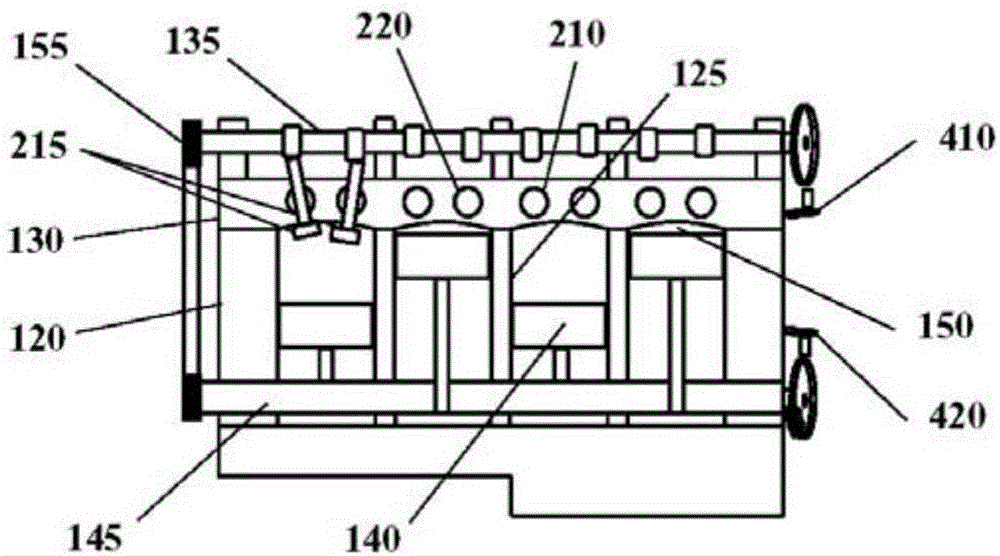

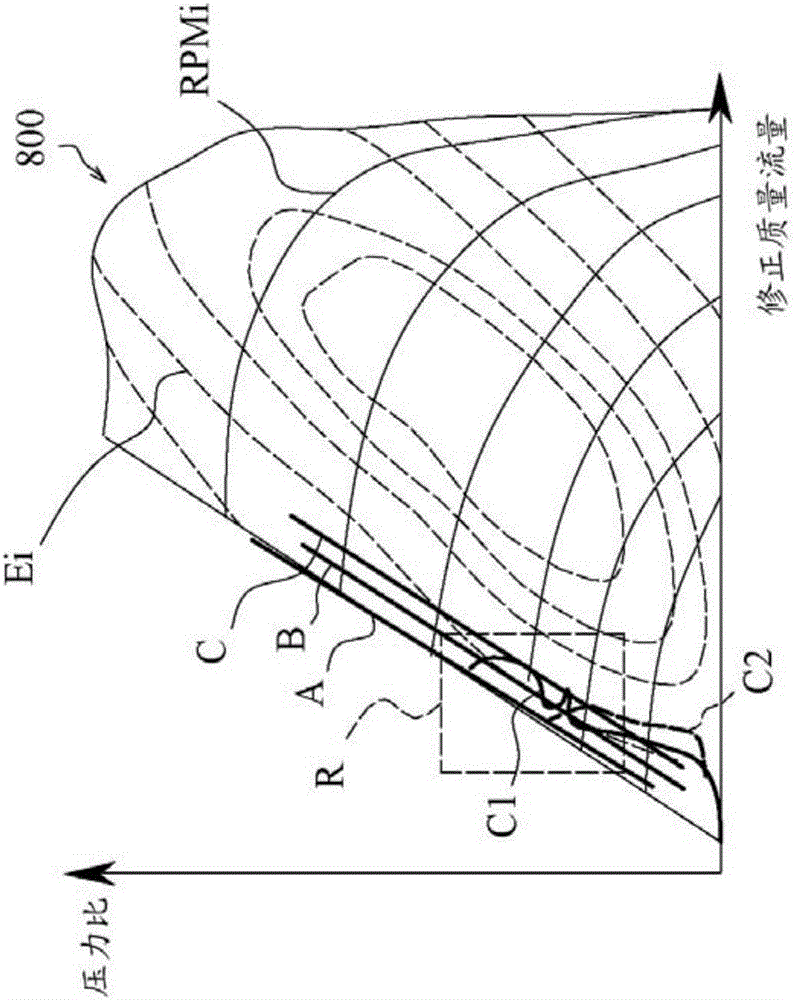

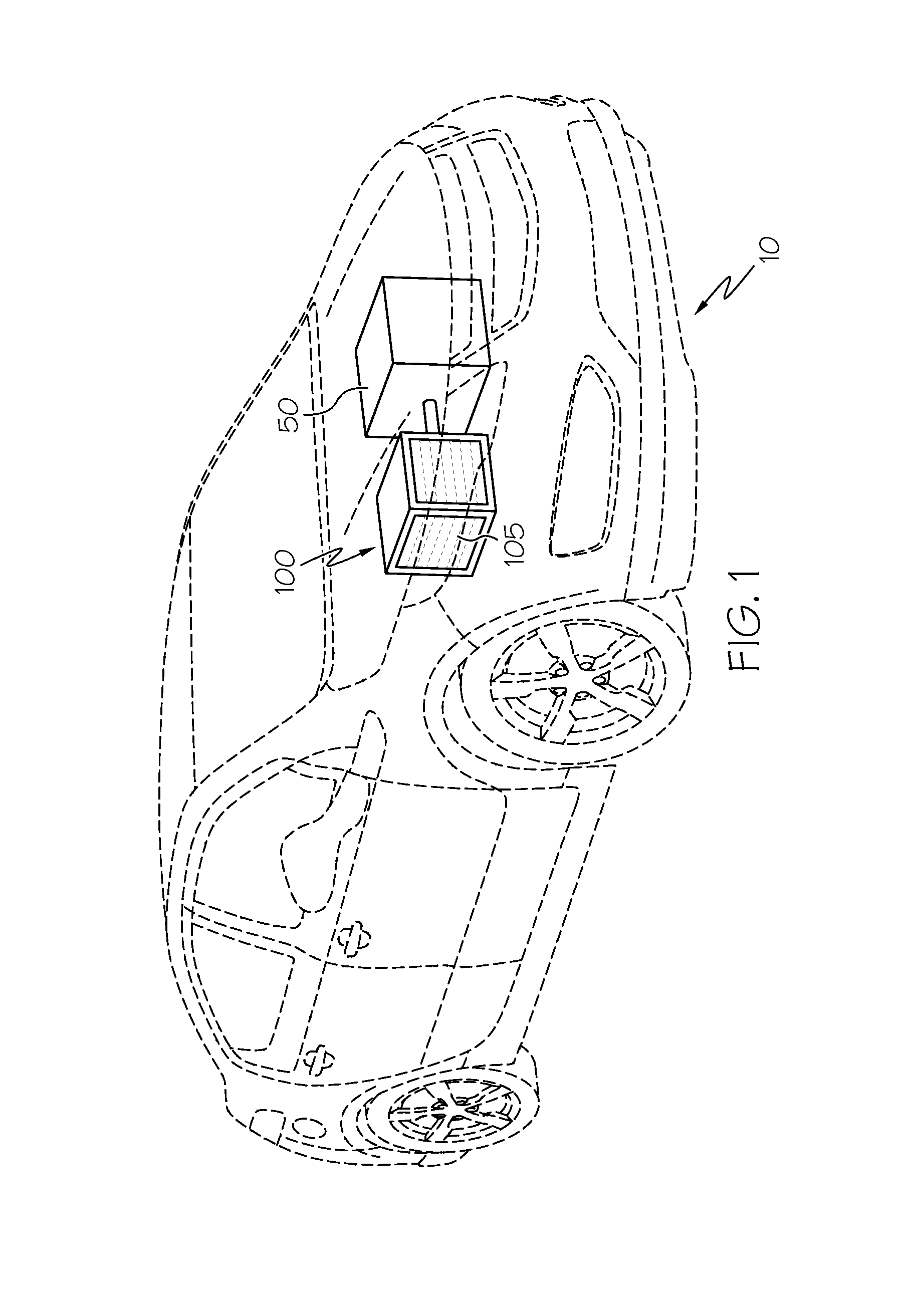

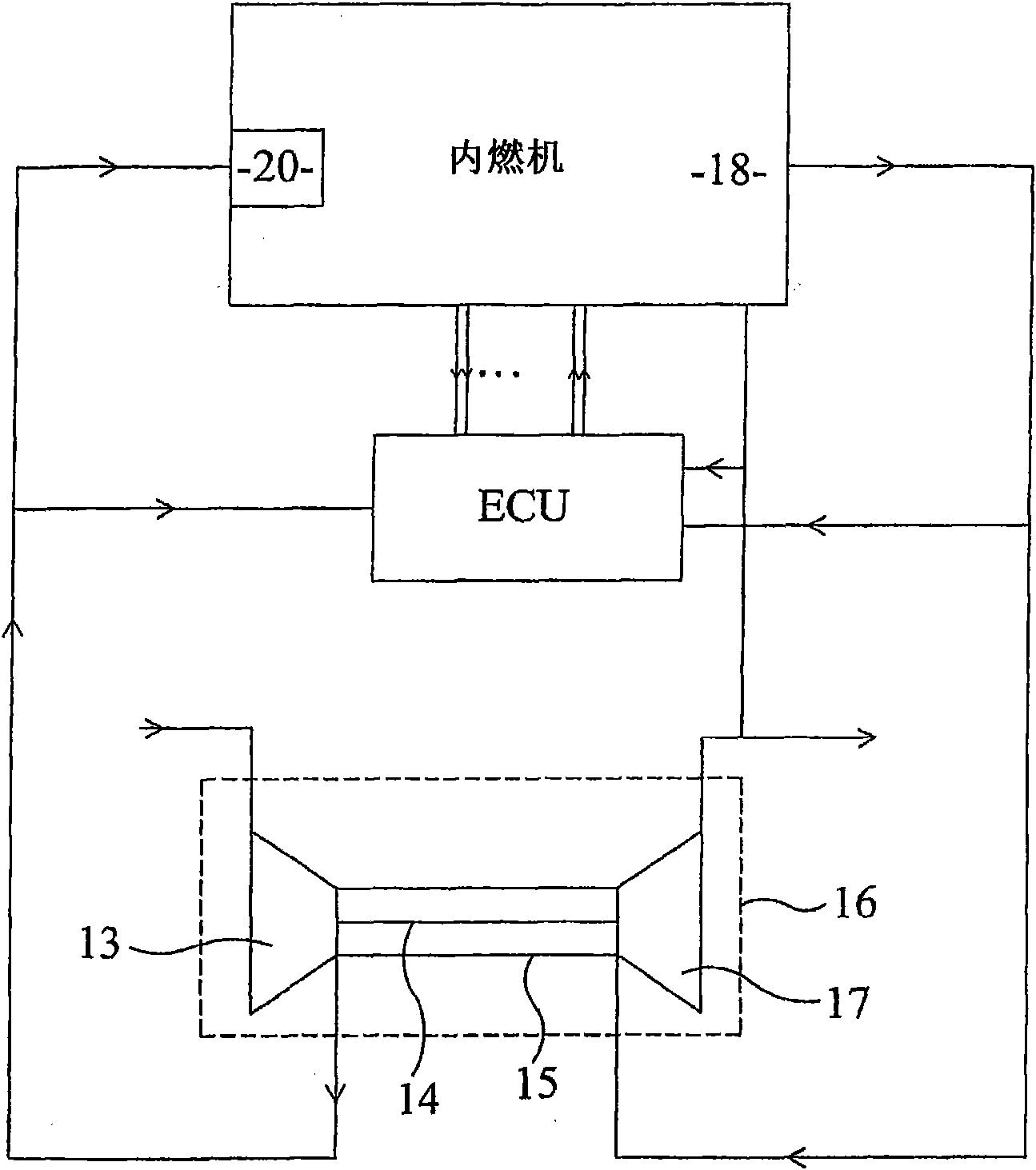

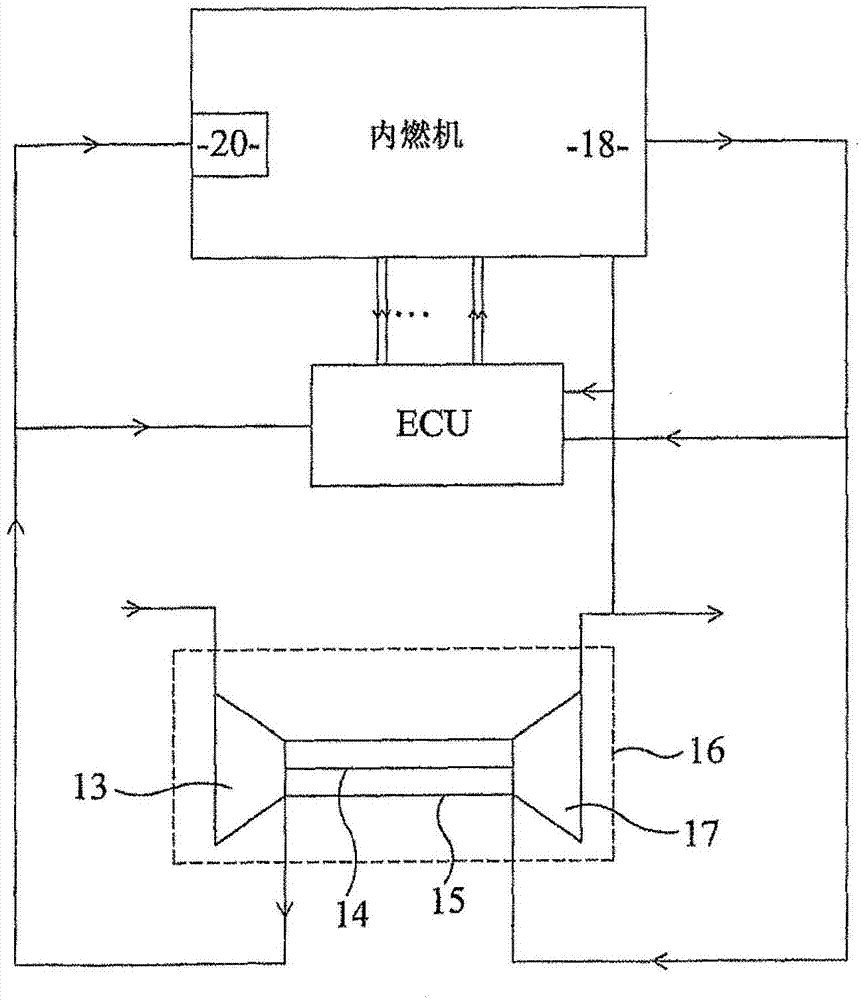

Method of operating a turbocharged automotive system

InactiveCN106438021AImprove consumption rateReduce startElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

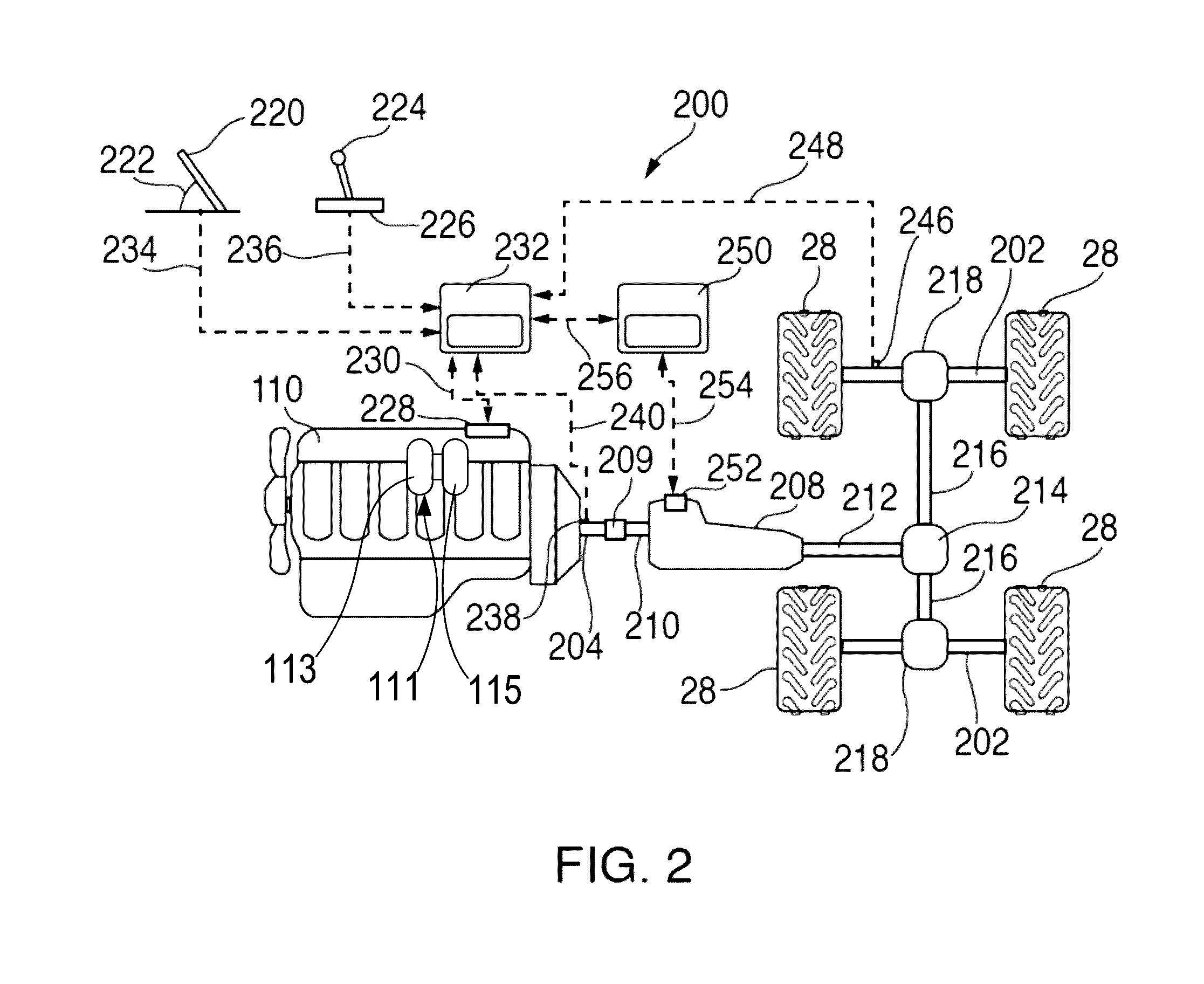

A method of operating an automotive system having an internal combustion engine equipped with an electric compressor and a turbocharger having a turbocharger compressor is disclosed. A surge threshold line and a pre-surge threshold line in a turbocharger compressor map are defined as a function of a turbocharger compressor pressure ratio and mass flow rate. The pre-surge threshold line is defined in terms of greater mass flow values for each corresponding pressure ratio value of the surge threshold line. The position of a turbocharger compressor working point in the turbocharger compressor map is monitored as a function of the turbocharger compressor pressure ratio and mass flow rate. When an increased torque request is detected, the electric compressor is activated to assist the turbocharger compressor in delivering the requested torque when the turbocharger compressor working point crosses the pre-surge threshold line in a direction towards the surge threshold line.

Owner:GM GLOBAL TECH OPERATIONS LLC

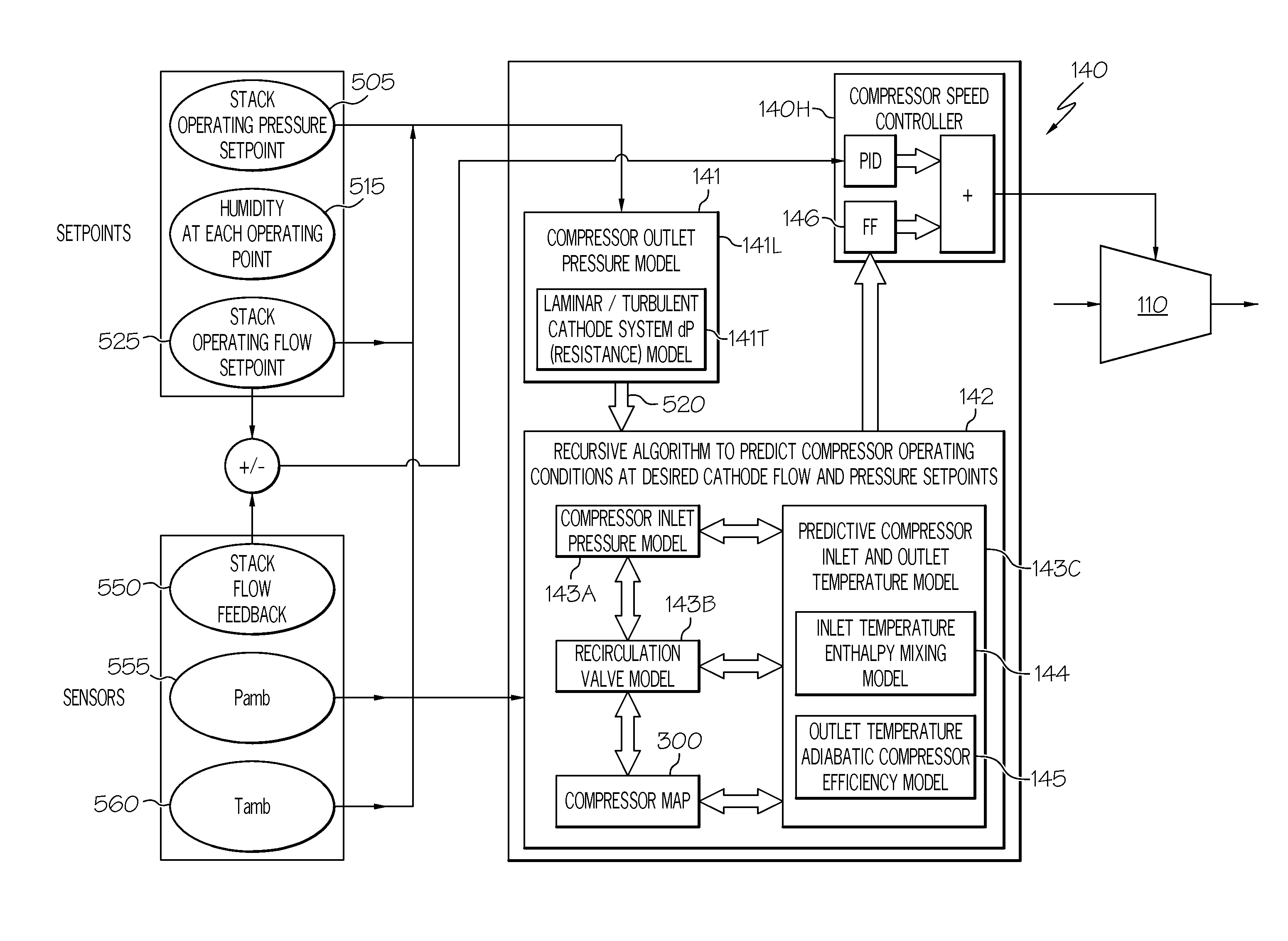

Predictive cathode compressor speed control in a fuel cell power system

A method and device for predictively controlling the speed of a compressor used in conjunction with a fuel cell stack. Feedforward command signals are generated based on fuel cell stack setpoints that are based on stack humidification requirements. A pressure drop model uses these setpoints to determine a compressor outlet pressure setpoint change brought about by an operational transient. A recursive approach is used to solve for one or more future or desired compressor operating conditions. The results of this recursive approach are used to determine the feedforward speed command of the compressor, where known operational parameters (such as can be found on a compressor map) may be used. This permits rapid changes in compressor speed to comply with the new operating point of the fuel cell system that is brought about by the operational transient.

Owner:GM GLOBAL TECH OPERATIONS LLC

Wide flow compressor with diffuser bypass

A centrifugal compressor is modified by forming a bypass between the leading edge of the compressor diffuser and a point downstream from the throat of the diffuser. The bypass may be unidirectional or bi-directional. In a bi-directional embodiment, an operable flow range of the compressor can be widened in both directions of a compressor map, i.e., extending both the surge and choke margins of a compressor at the expense of normal operating efficiencies. In a unidirectional bypass embodiment the flow range may be increased only in one direction, but there is no diminishment of efficiency of the compressor at normal operating conditions. The modification provides a simple expedient for increasing flow range without a need to redesign a compressor.

Owner:HONEYWELL INT INC

Anti-surge speed control

The present invention relates to a method and control system to control the speed of a centrifugal compressor operating within a vacuum pressure swing adsorption process to avoid an operation at which surge can occur and directly driven by an electric motor that is in turn controlled by a variable frequency drive. In accordance with present invention an optimal speed for operation of the compressor is determined at which the compressor will operate along a peak efficiency operating line of a compressor map thereof. This speed is adjusted by a feed back speed multiplier when the flow or other parameter referable to flow through the compressor is below a minimum and a feed forward multiplier during evacuation and evacuation with purge steps that multiplies the feed back multiplier to increase speed of the compressor and thereby avoid surge.

Owner:PRAXAIR TECH INC

Wide flow compressor with diffuser bypass

A centrifugal compressor is modified by forming a bypass between the leading edge of the compressor diffuser and a point downstream from the throat of the diffuser. The bypass may be unidirectional or bi-directional. In a bi-directional embodiment, an operable flow range of the compressor can be widened in both directions of a compressor map, i.e., extending both the surge and choke margins of a compressor at the expense of normal operating efficiencies. In a unidirectional bypass embodiment the flow range may be increased only in one direction, but there is no diminishment of efficiency of the compressor at normal operating conditions. The modification provides a simple expedient for increasing flow range without a need to redesign a compressor.

Owner:HONEYWELL INT INC

Virtual compressor operational parameter measurement and surge detection in a fuel cell system

A fuel cell system that employs surge prevention by electronically mapping the compressor for discharge pressure versus mass airflow. In one embodiment, the fuel cell system employs a mass flow meter that measures the airflow to the compressor. A controller receives a signal from the mass flow meter indicative of the flow rate of the charge airflow to the compressor, and determines the outlet pressure and temperature of the compressor from the compressor speed and the measured airflow. This gives the compressor map location at which the compressor is operating. In another embodiment, the fuel cell system employs a pressure sensor that measures the output pressure of the compressor, and provides a pressure signal to the controller. The controller determines the mass airflow to the compressor to determine the compressor map location.

Owner:GM GLOBAL TECH OPERATIONS LLC

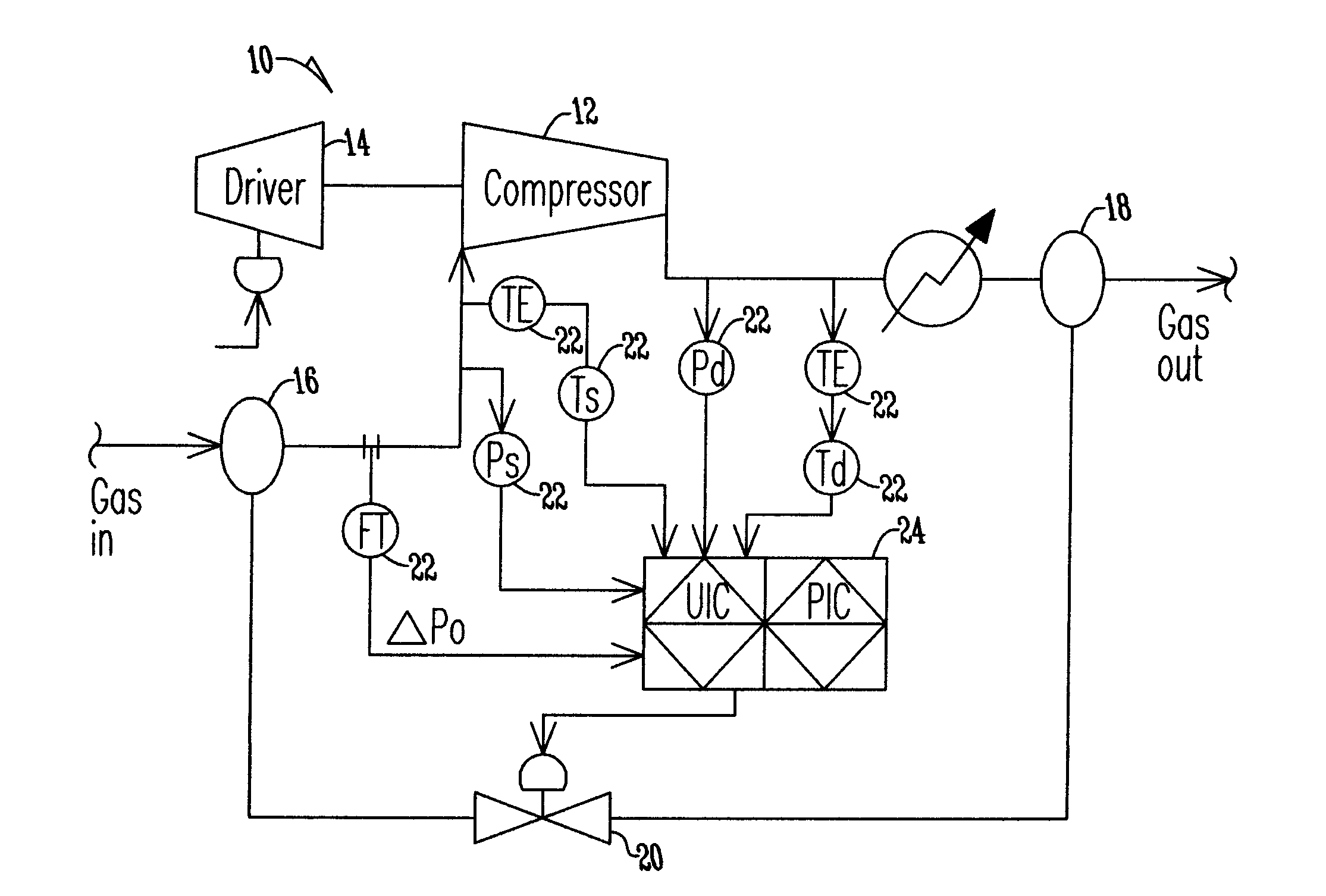

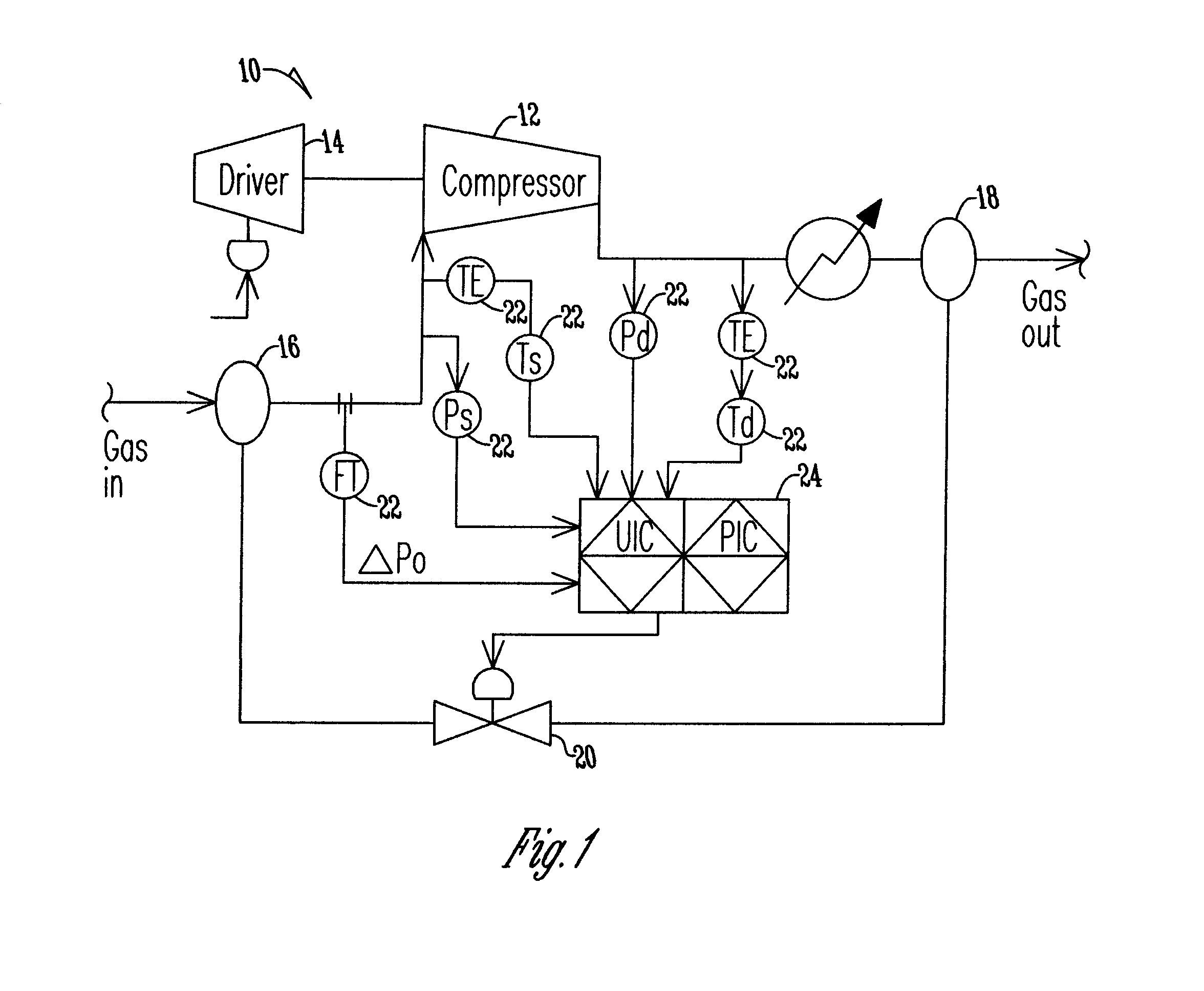

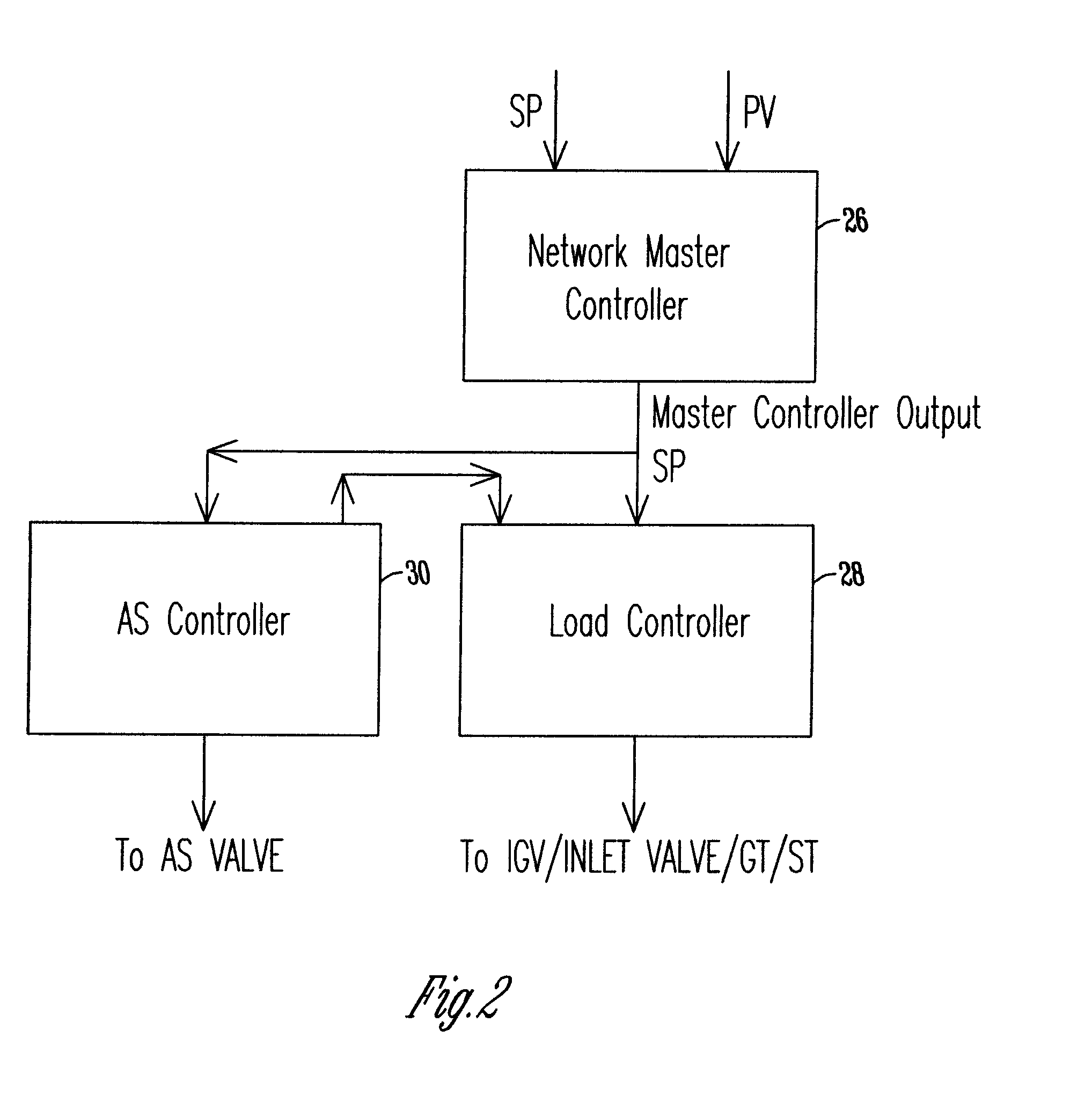

Method of surge protection for a dynamic compressor using a surge parameter

Owner:ENERGY CONTROL TECH

Predictive cathode compressor speed control in a fuel cell power system

ActiveUS20140120445A1Easy to adjustAdjustable speedReactant parameters controlMotive system fuel cellsOperating pointFuel cells

A method and device for predictively controlling the speed of a compressor used in conjunction with a fuel cell stack. Feedforward command signals are generated based on fuel cell stack setpoints that are based on stack humidification requirements. A pressure drop model uses these setpoints to determine a compressor outlet pressure setpoint change brought about by an operational transient. A recursive approach is used to solve for one or more future or desired compressor operating conditions. The results of this recursive approach are used to determine the feedforward speed command of the compressor, where known operational parameters (such as can be found on a compressor map) may be used. This permits rapid changes in compressor speed to comply with the new operating point of the fuel cell system that is brought about by the operational transient.

Owner:GM GLOBAL TECH OPERATIONS LLC

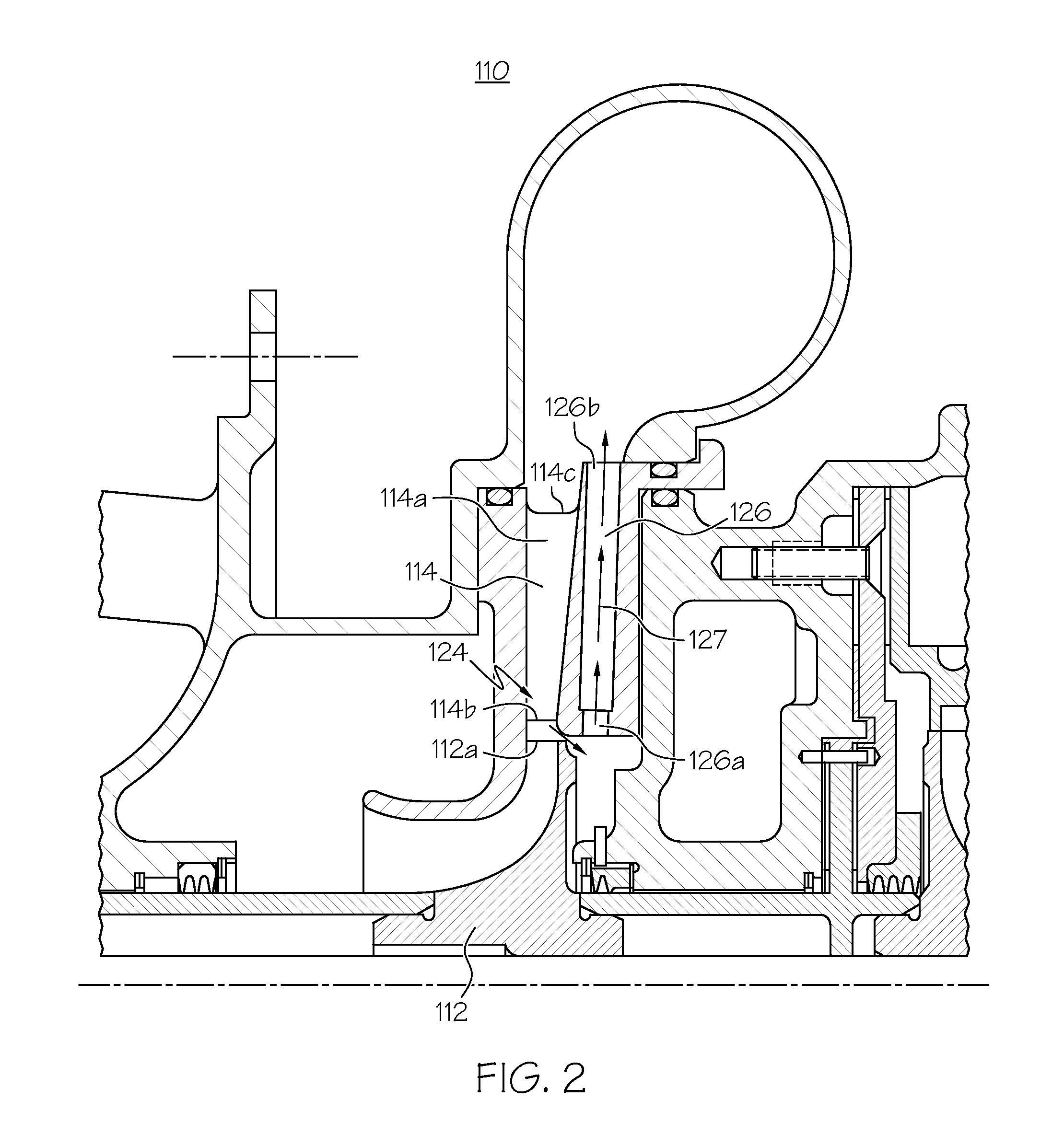

Anti-surge speed control of a compressor in a VPSA apparatus

The present invention relates to a method and control system to control the speed of a centrifugal compressor operating within a vacuum pressure swing adsorption process to avoid an operation at which surge can occur and directly driven by an electric motor that is in turn controlled by a variable frequency drive. In accordance with present invention an optimal speed for operation of the compressor is determined at which the compressor will operate along a peak efficiency operating line of a compressor map thereof. This speed is adjusted by a feed back speed multiplier when the flow or other parameter referable to flow through the compressor is below a minimum and a feed forward multiplier during evacuation and evacuation with purge steps that multiplies the feed back multiplier to increase speed of the compressor and thereby avoid surge.

Owner:PRAXAIR TECH INC

Anti-surge speed control

The invention relates to a method and control system to control the speed of a centrifugal compressor operating within a vacuum pressure swing adsorption process to avoid an operation at which surge can occur and directly driven by an electric motor that is in turn controlled by a variable frequency drive. The claimed method determines the optimal speed for operation of the compressor along a peak efficiency operating line of a compressor map thereof. Speed of the compressor is adjusted by a feed back speed multiplier when the flow or other parameter referable to flow through the compressor is below a minimum and a feed forward multiplier during evacuation and evacuation with purge steps that multiplies the feed back multiplier to increase speed of the compressor and thereby avoid surge.

Owner:PRAXAIR TECH INC

Turbocharger Compressor Anti-Surge Engine Control Strategy and Method

ActiveUS20160341136A1Electrical controlInternal combustion piston enginesElectronic controllerInternal combustion engine

A method for operating an internal combustion engine includes monitoring engine parameters using an electronic controller, determining a surge speed limit for the engine based on a compressor map, determining an offset engine speed based on a margin between the surge speed limit and an engine speed, determining a minimum engine speed based on the margin, applying the offset engine speed to an engine speed signal to provide an adjusted engine speed, and applying the adjusted engine speed to a desired engine speed when a speed of the engine approaches the surge speed limit.

Owner:CATERPILLAR INC

Adaptive compressor surge control in a fuel cell system

ActiveUS8101308B2Maximize efficiencyQuantity minimizationWind motor controlFuel cell auxillariesAdaptive compressionOperating point

A fuel cell system having an adaptable compressor map and method for optimizing the adaptable compressor map is provided. The method includes the steps of establishing an initial operating setpoint for an air compressor based on the adaptable compressor map; monitoring a surge indicator; adjusting the adaptable compressor map based on the monitored surge indicator; determining a desired operating setpoint based on the adjusted adaptable compressor map; and establishing an adapted operating setpoint for the air compressor based on the adaptable compressor map following the adjustment thereof. The steps are repeated until the adaptable compressor map for the air compressor is optimized.

Owner:GM GLOBAL TECH OPERATIONS LLC

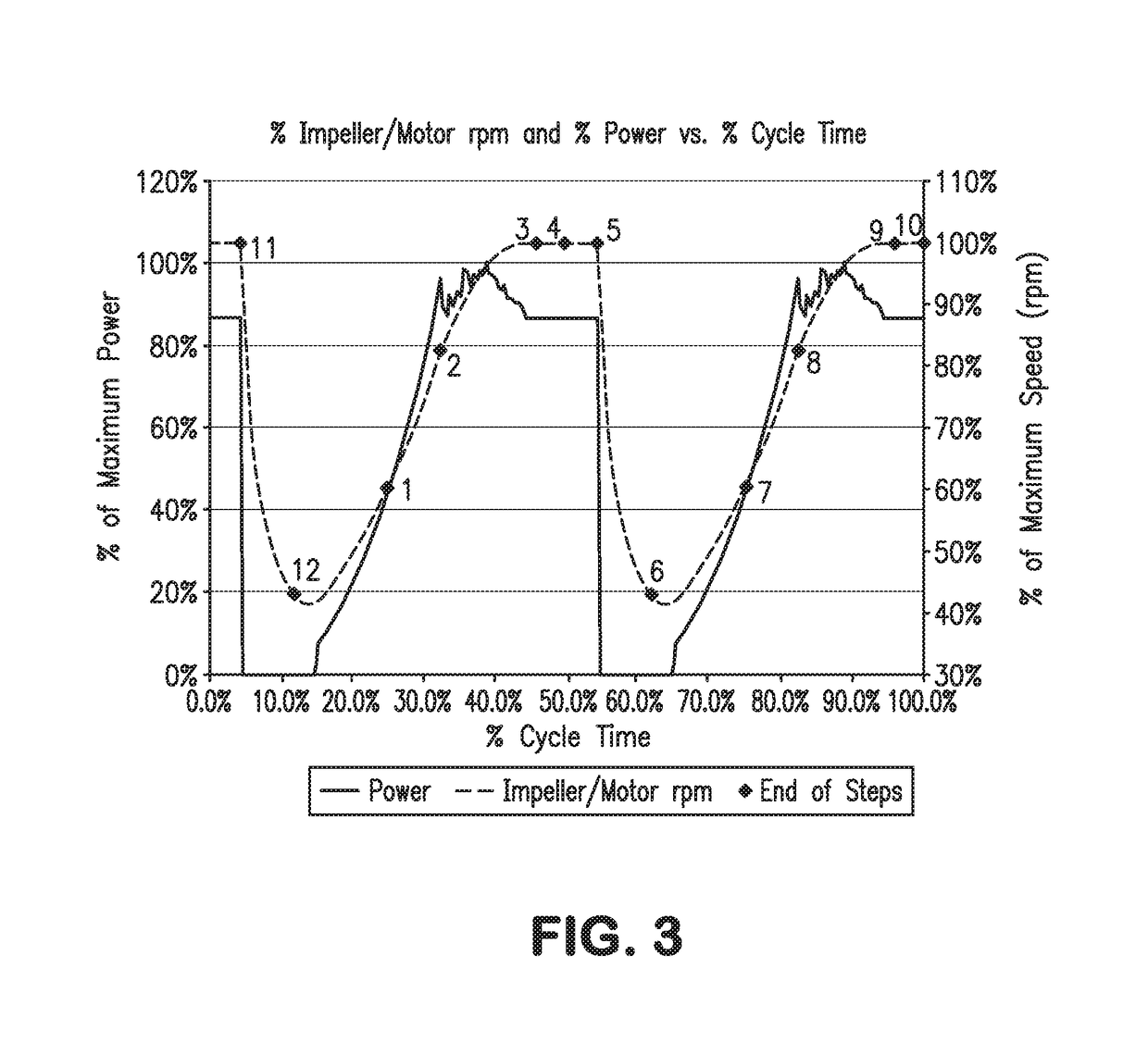

Anti-surge speed control for two or more compressors

ActiveUS20190010949A1Reduces and increases speed of compressorReduces and increases average speed of compressorGas treatmentDispersed particle separationVacuum pressureDesorption

The present invention relates to a method and control system to control the speed of centrifugal compressors operating within a vacuum pressure swing adsorption process to avoid an operation at which surge can occur and directly driven by an electric motor that is in turn controlled by a variable frequency drive, while subsequently operating the vacuum pressure swing process between set limits of highest adsorption and lowest desorption pressure. In accordance with present invention an optimal speed for operation of the compressor is determined at which the compressor will operate along a peak efficiency operating line of a compressor map thereof. This speed is adjusted by a feed back speed multiplier when the flow or other parameter referable to flow through the compressor is below a minimum and a feed forward multiplier during evacuation and evacuation with purge steps that multiplies the feed back multiplier to increase speed of the compressor and thereby avoid surge. The speed is then adjusted by a global speed factor which serves to adjust the average speed of the motors over all steps of the repeating cycle such that the process operates within high and low pressure limits.

Owner:PRAXAIR TECH INC

Turbocompressor antisurge control by vibration monitoring

ActiveUS9624936B2Efficient detectionVibration measurement in solidsElectrical controlPresent dayOperating point

Owner:COMPRESSOR CONTROLS LLC

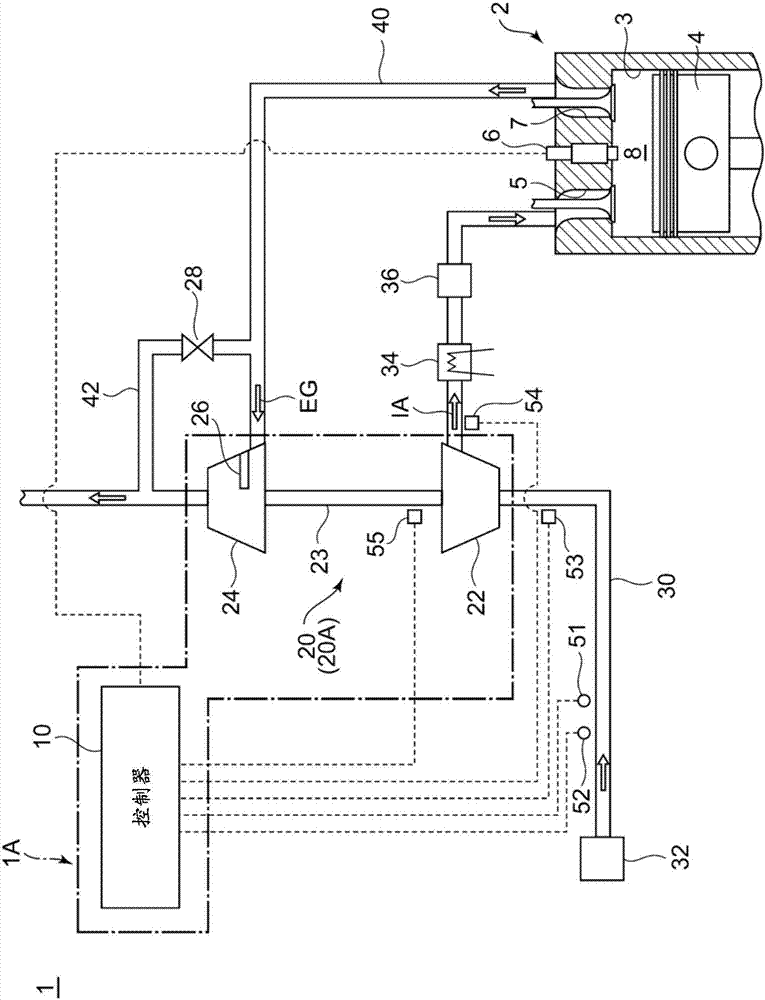

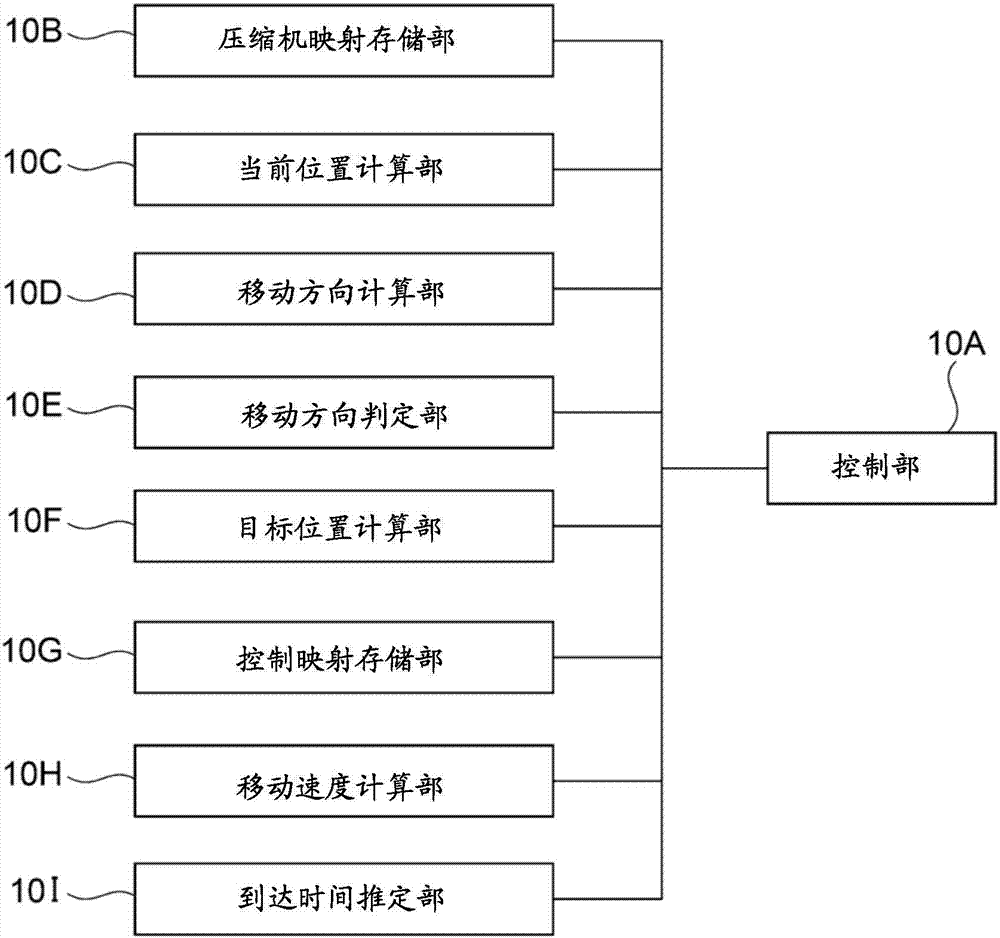

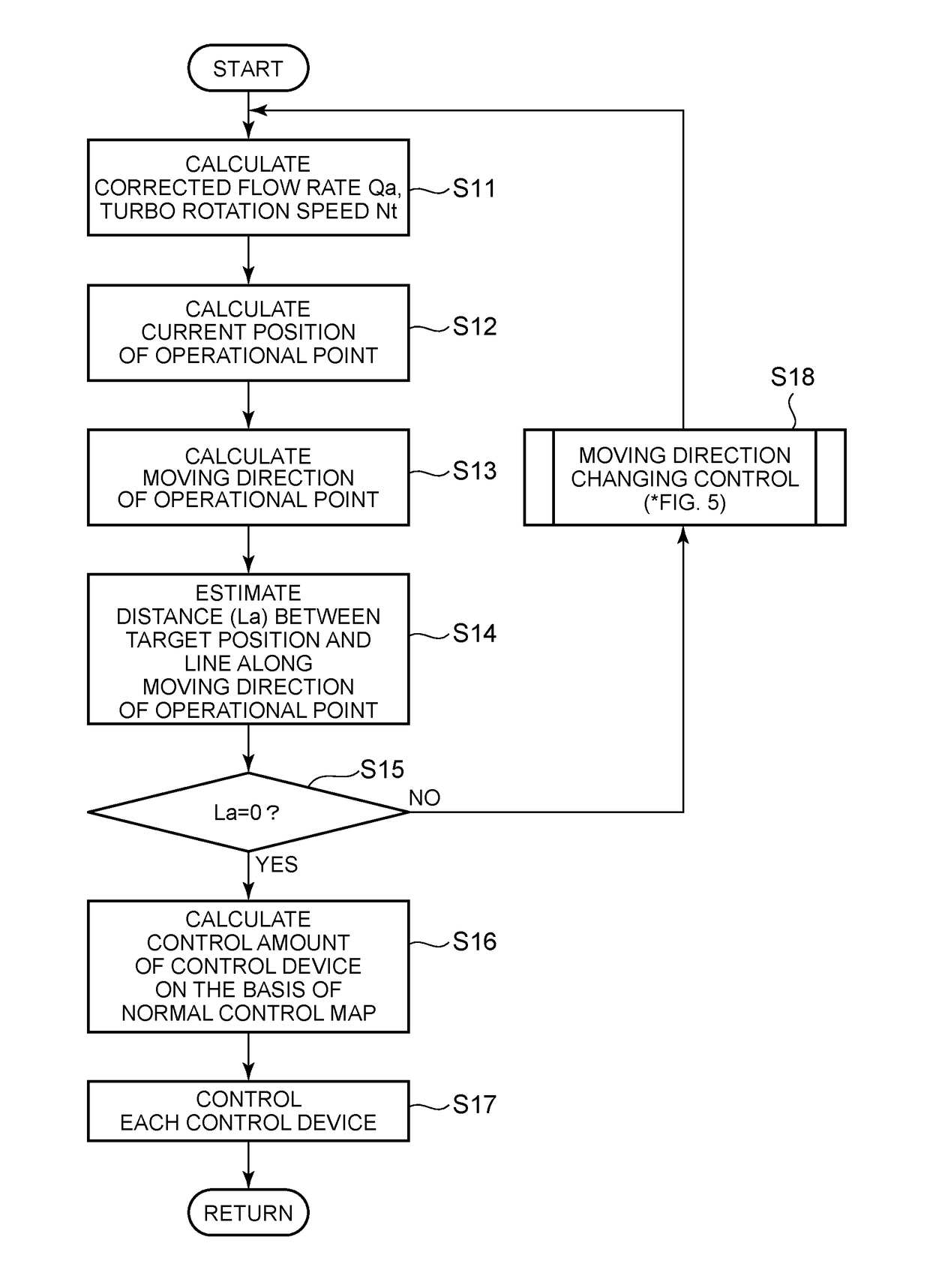

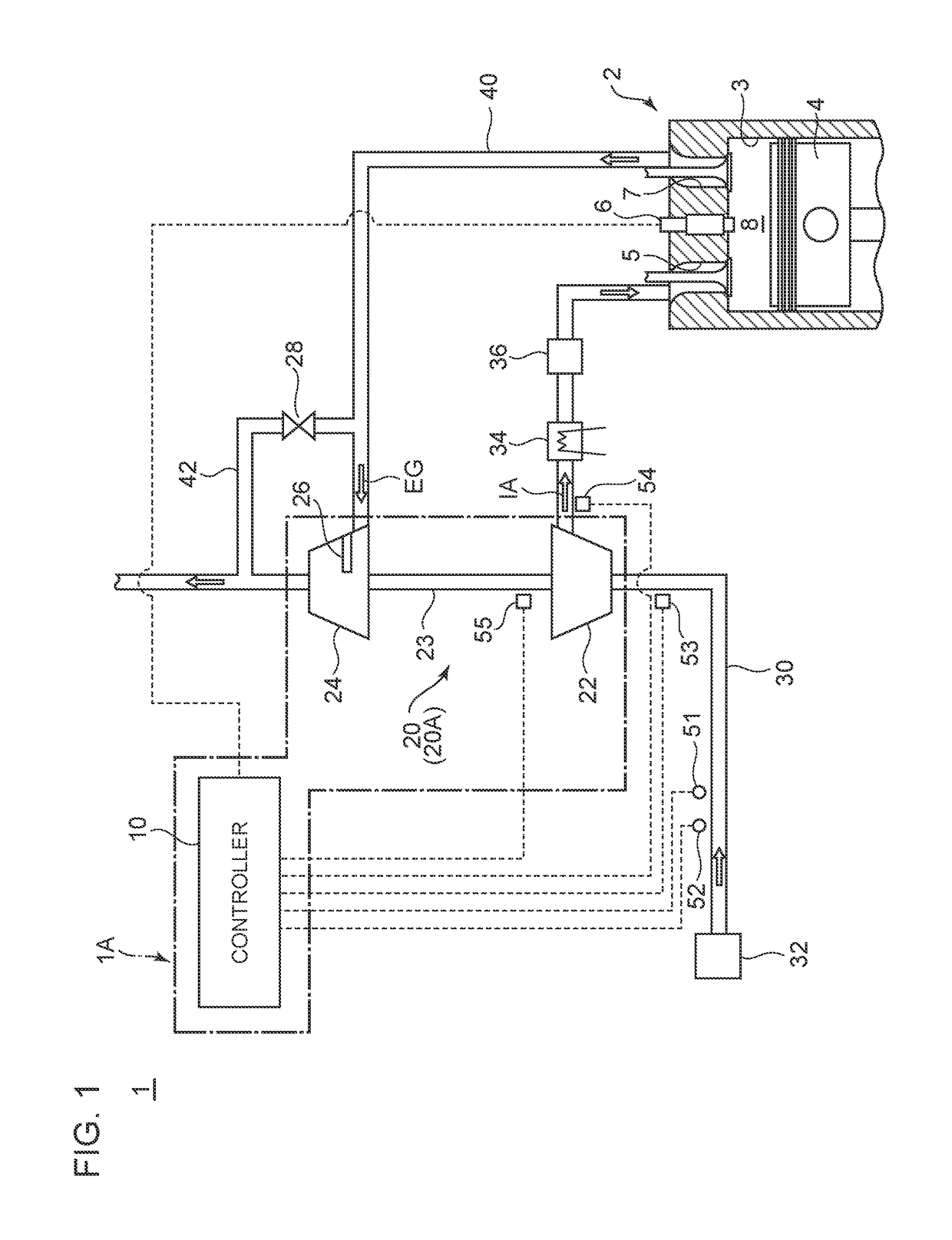

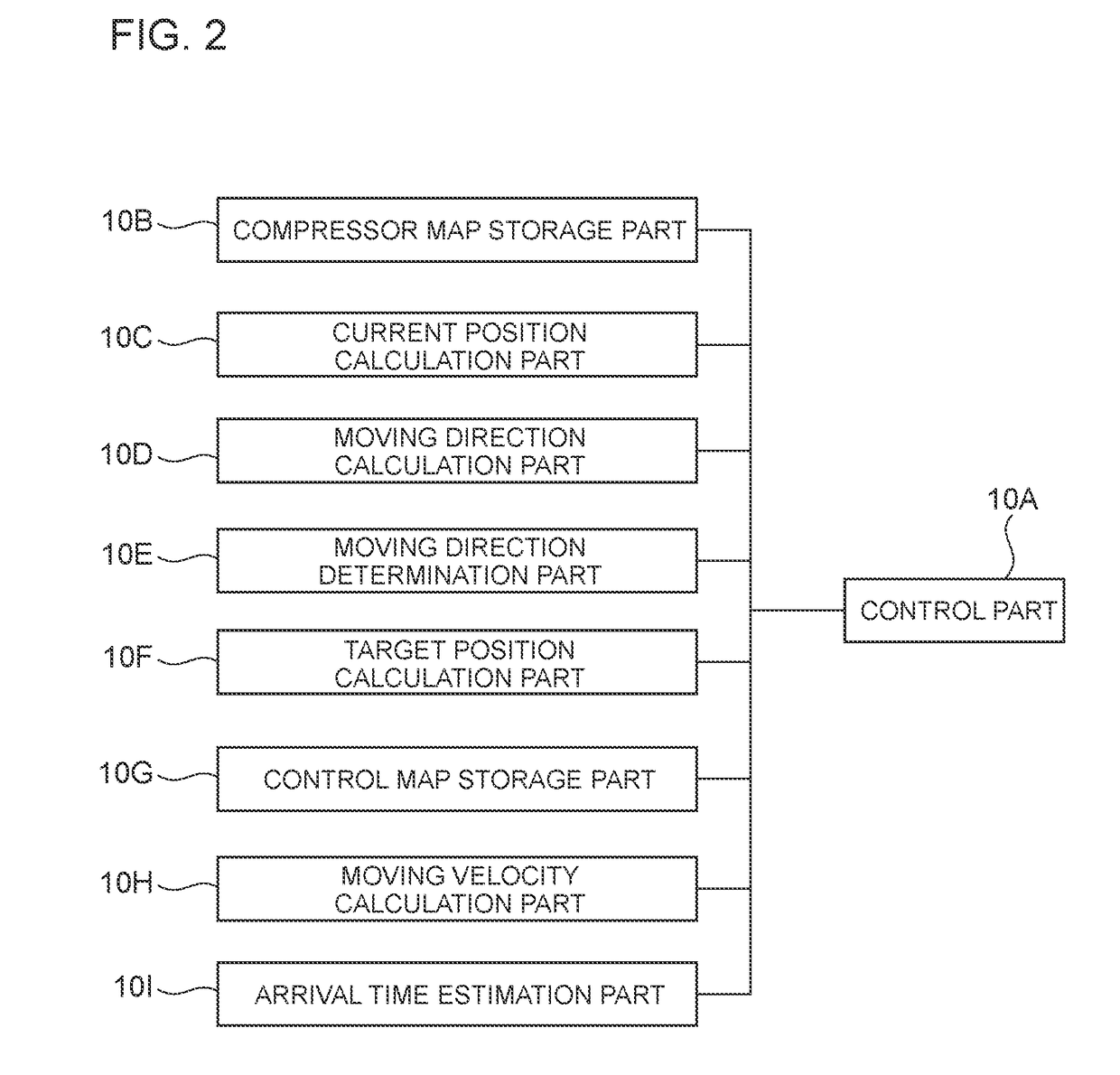

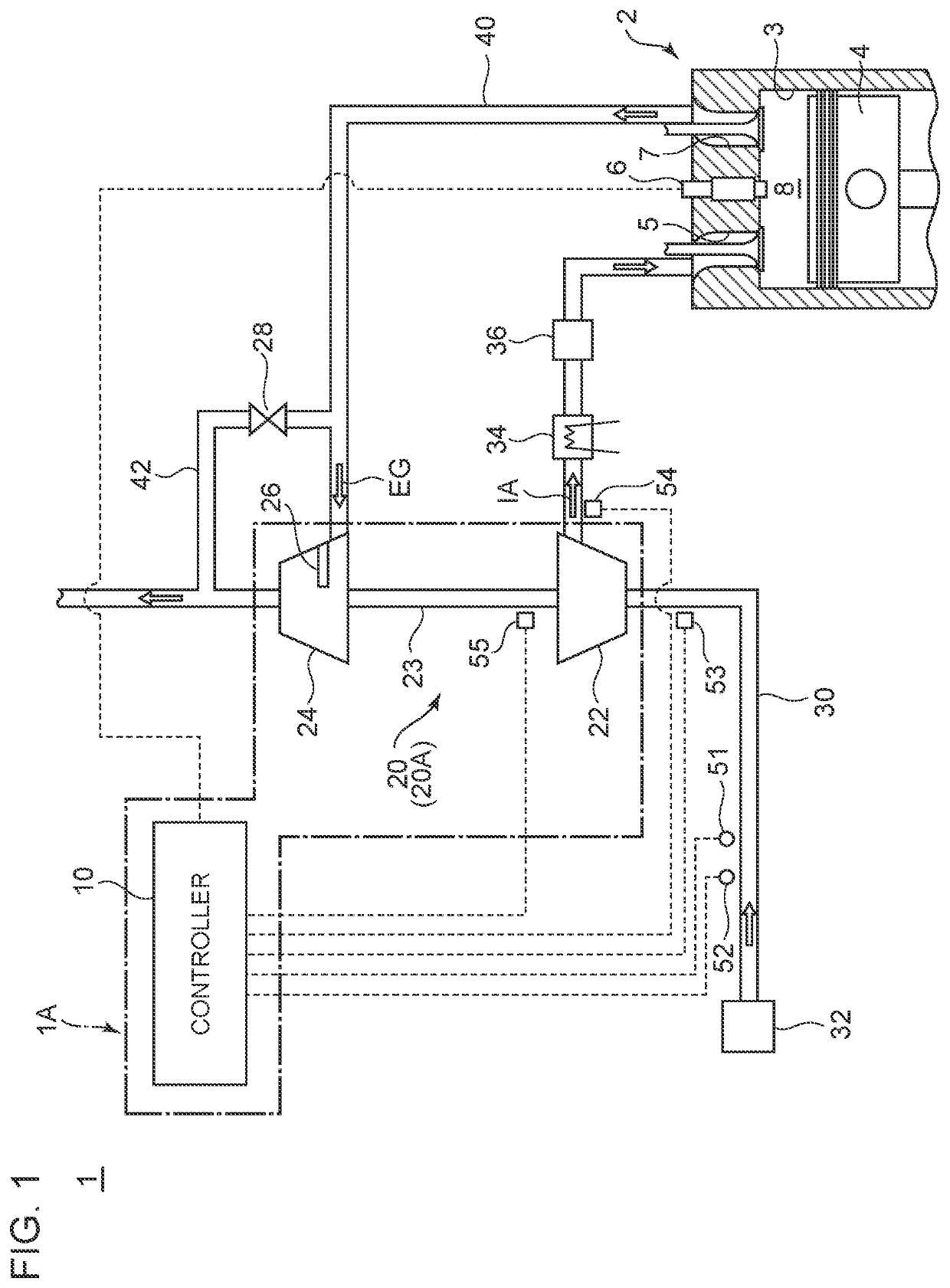

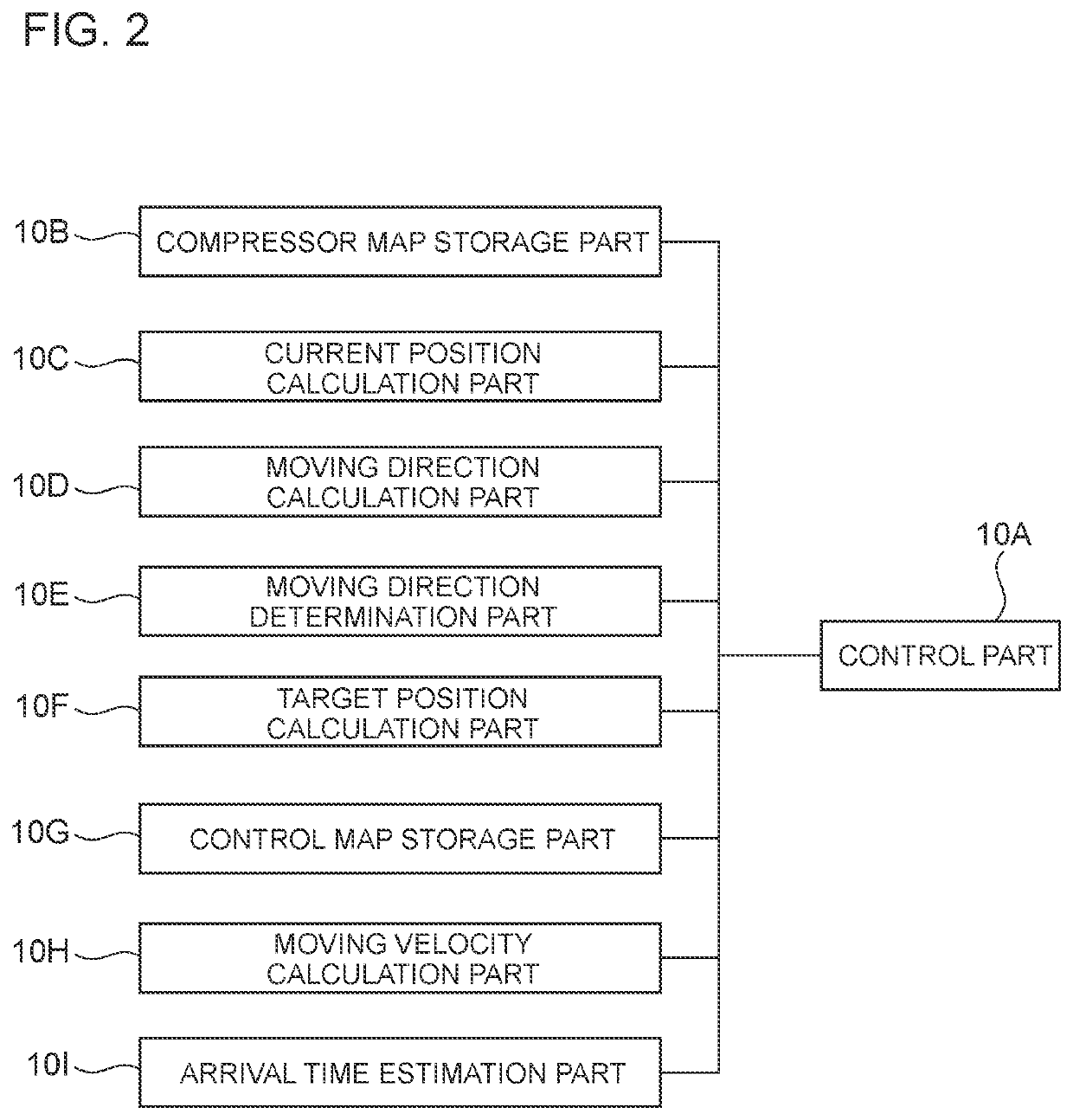

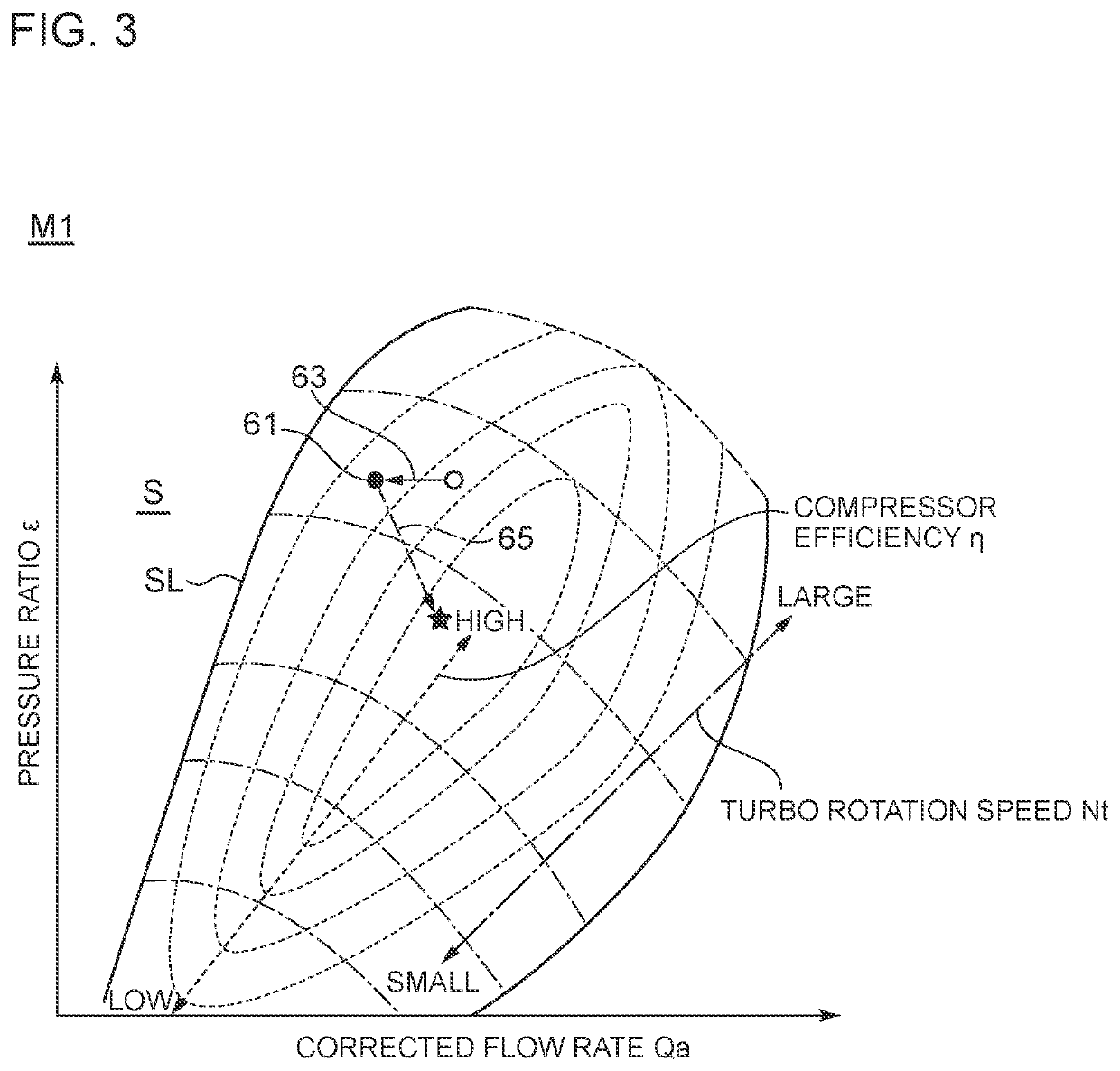

Control device for supercharging system

InactiveCN107532526APerformanceElectrical controlInternal combustion piston enginesSimulationOperation point

A control device for a supercharging system for supplying compressed intake air to an engine, is equipped with: a supercharger containing a compressor that compresses the intake air supplied to the engine; and a controller that controls control devices affecting the operation of the compressor. The controller includes: a compressor map storage unit storing a compressor map indicating the relationship between the intake air volumetric flow rate and the pressure ratio in the compressor and the compressor rotational frequency; a current position calculation unit that calculates, for each prescribed period, the current position of the operation point of the compressor in the compressor map; a movement direction calculation unit that calculates the direction of movement of the operation point in the compressor map, on the basis of the current position of the operation point as calculated by the current position calculation unit; and a control unit that controls the control devices on the basis of the current position of the operation point as calculated by the current position calculation unit, and the movement direction of the operation point as calculated by the movement direction calculation unit.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

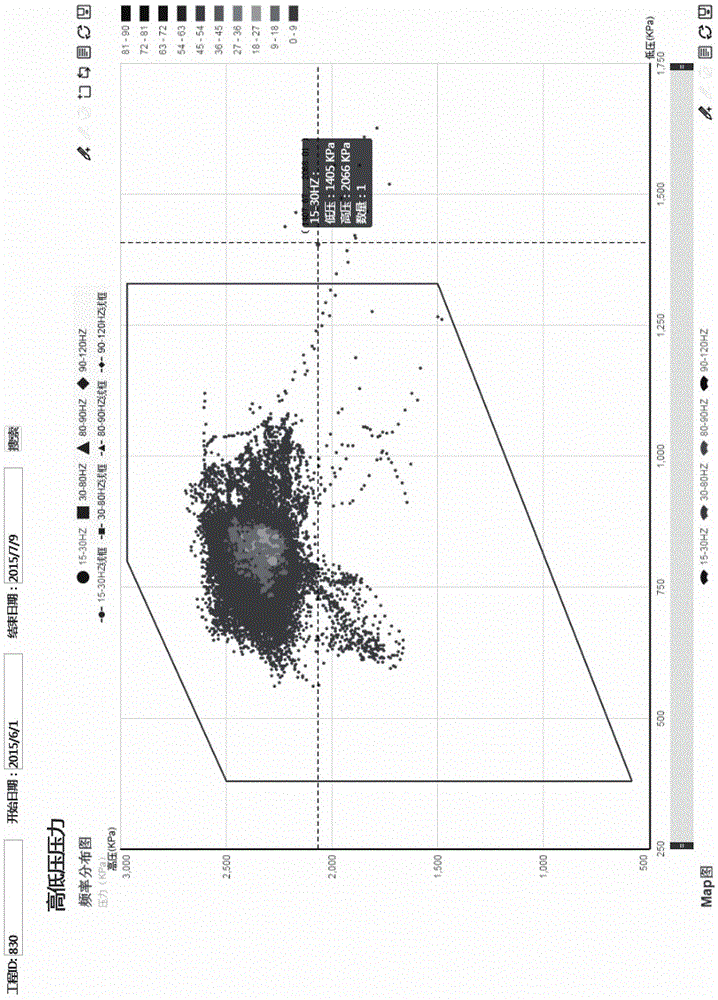

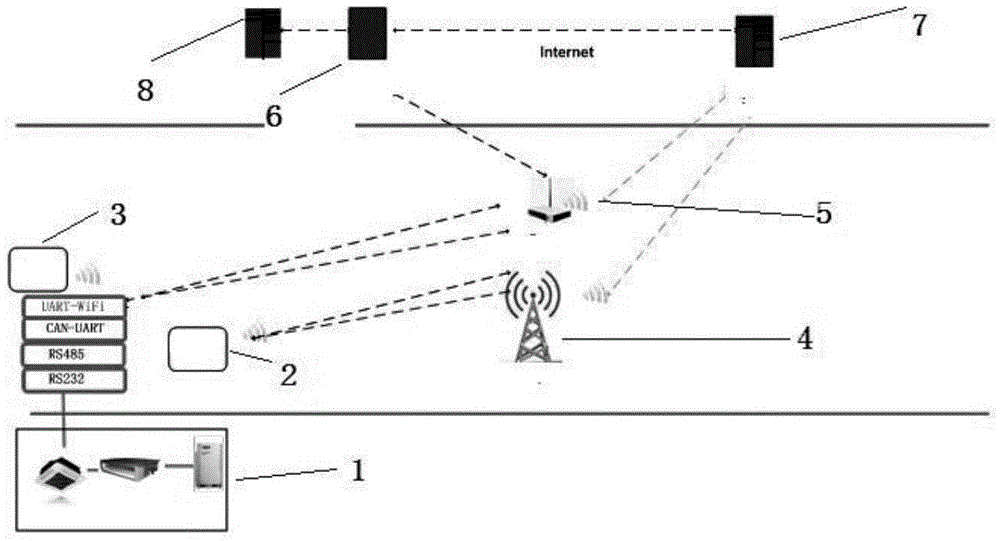

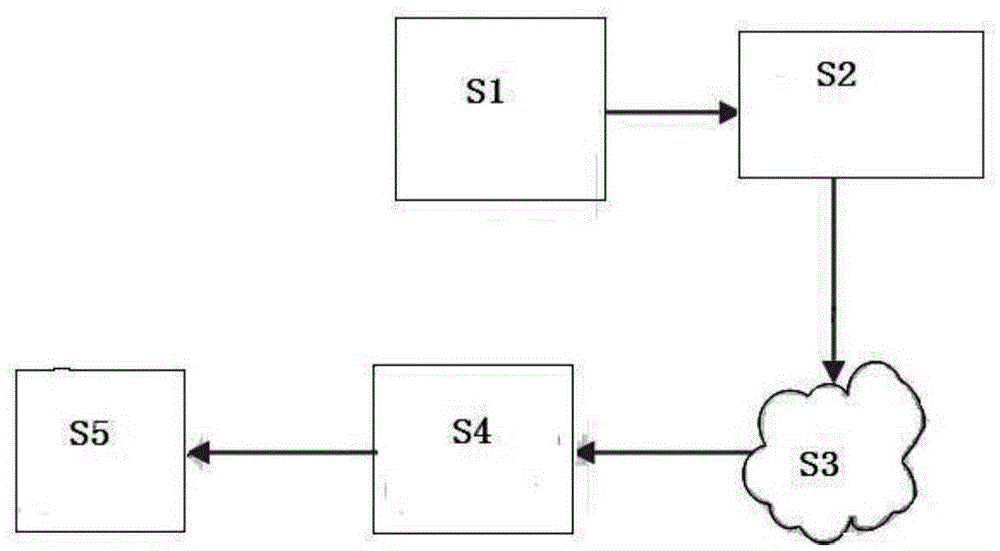

Compressor working abnormity detection method and compressor adopting same

ActiveCN105626498AAvoid damage and report failureImprove efficiencyPump controlPositive-displacement liquid enginesDatabase serverGas compressor

The invention discloses a compressor working abnormity detection method and a compressor adopting the same. The method includes the following steps that S1, originally-set operating data of the compressor are stored in a database server; S2, actual operating data of the compressor are extracted; S3, a compressor MAP of the compressor is obtained; S4, the abnormity state information of the compressor is extracted; and S5, the extracted abnormity state information of the compressor is uploaded and processed. By the adoption of the compressor working abnormity detection method and the compressor adopting the same, the efficiency of finding the abnormal working state of the compressor can be improved, meanwhile maintenance cost is reduced, and user comfort is improved as well.

Owner:GREE ELECTRIC APPLIANCES INC

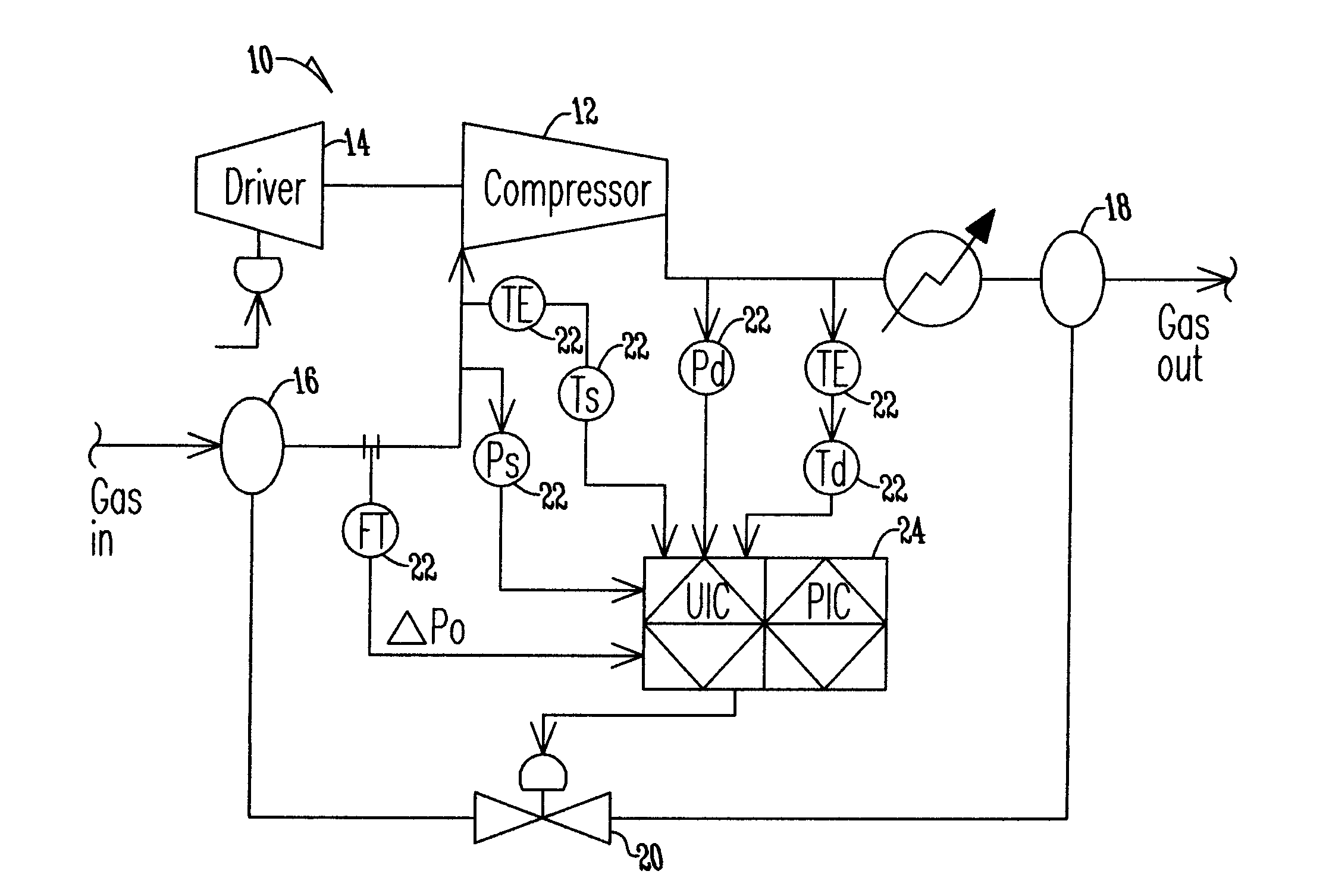

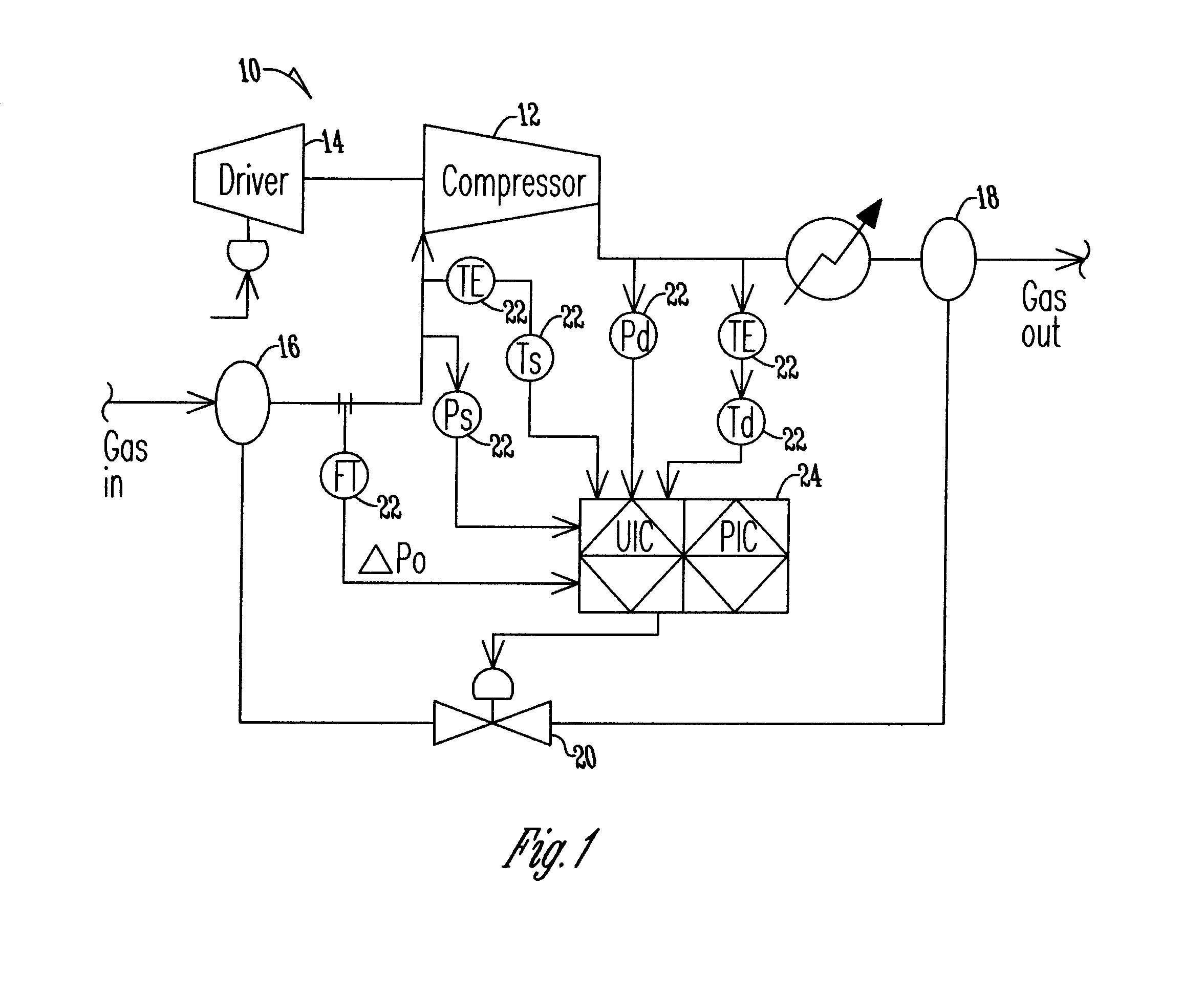

Method of surge protection for a dynamic compressor using a surge parameter

A method of surge protection for a dynamic compressor that has a corresponding compressor map. A control system continually calculates an equivalent polytropic head parameter in order to define a surge limit line. The system then calculates a control parameter and determines the distance the control parameter to the surge limit line wherein the control parameter is dynamic to changes in compressor load and invariant to changes in suction conditions and gas compressibility. As a result of the distance of the control parameter to the surge limit line, the surge valve of a dynamic compressor is actuated to prevent surge.

Owner:ENERGY CONTROL TECH

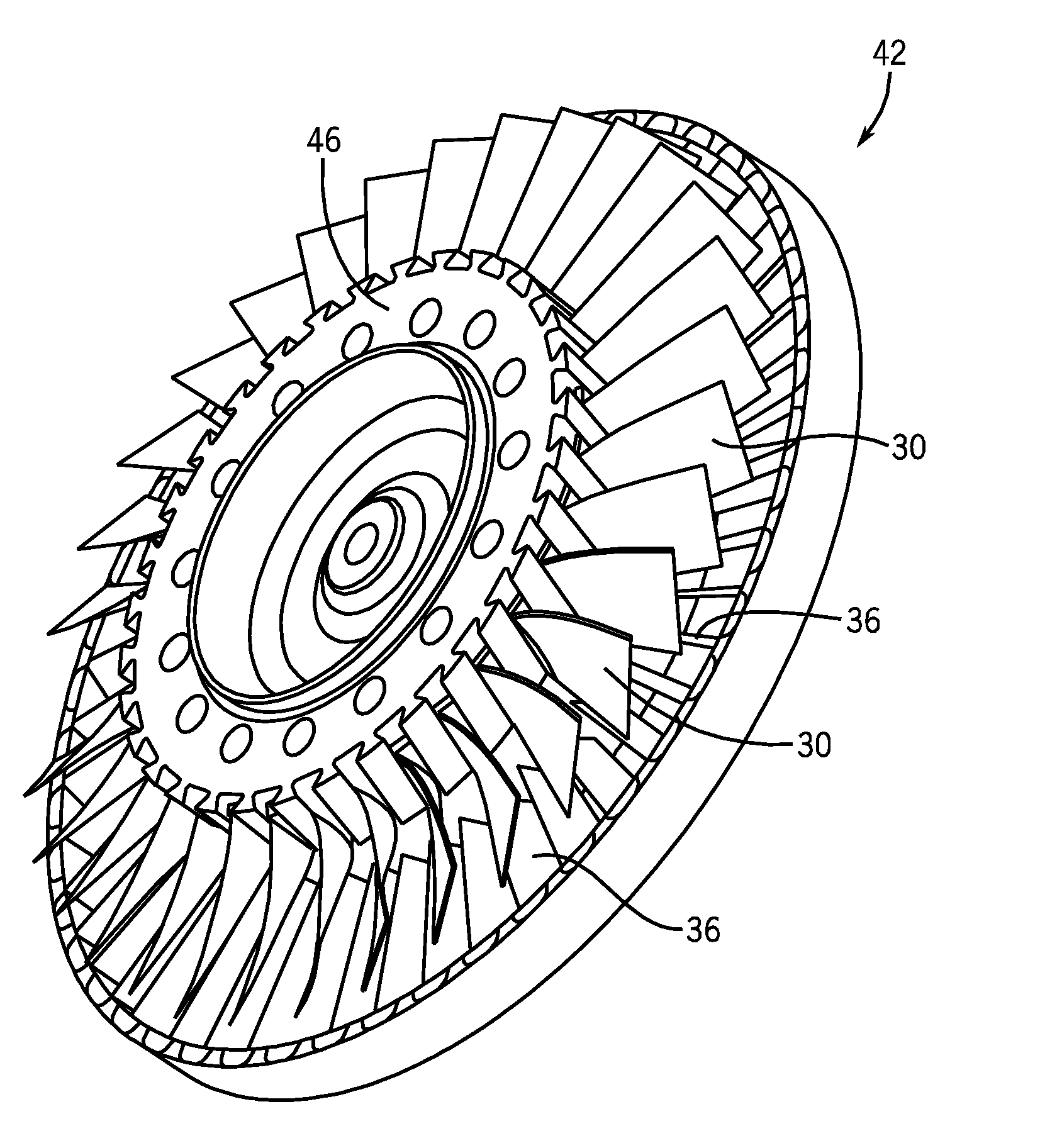

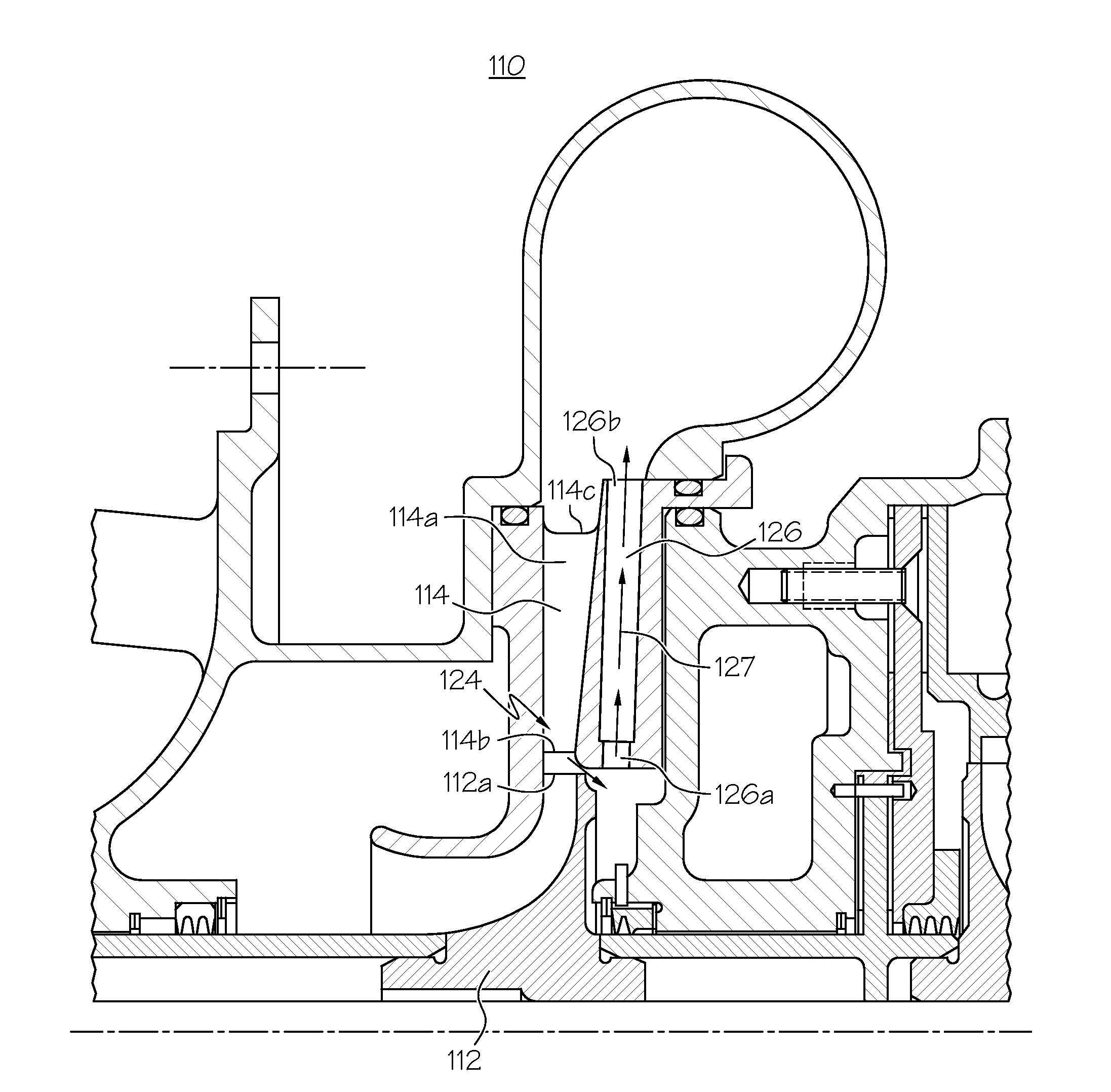

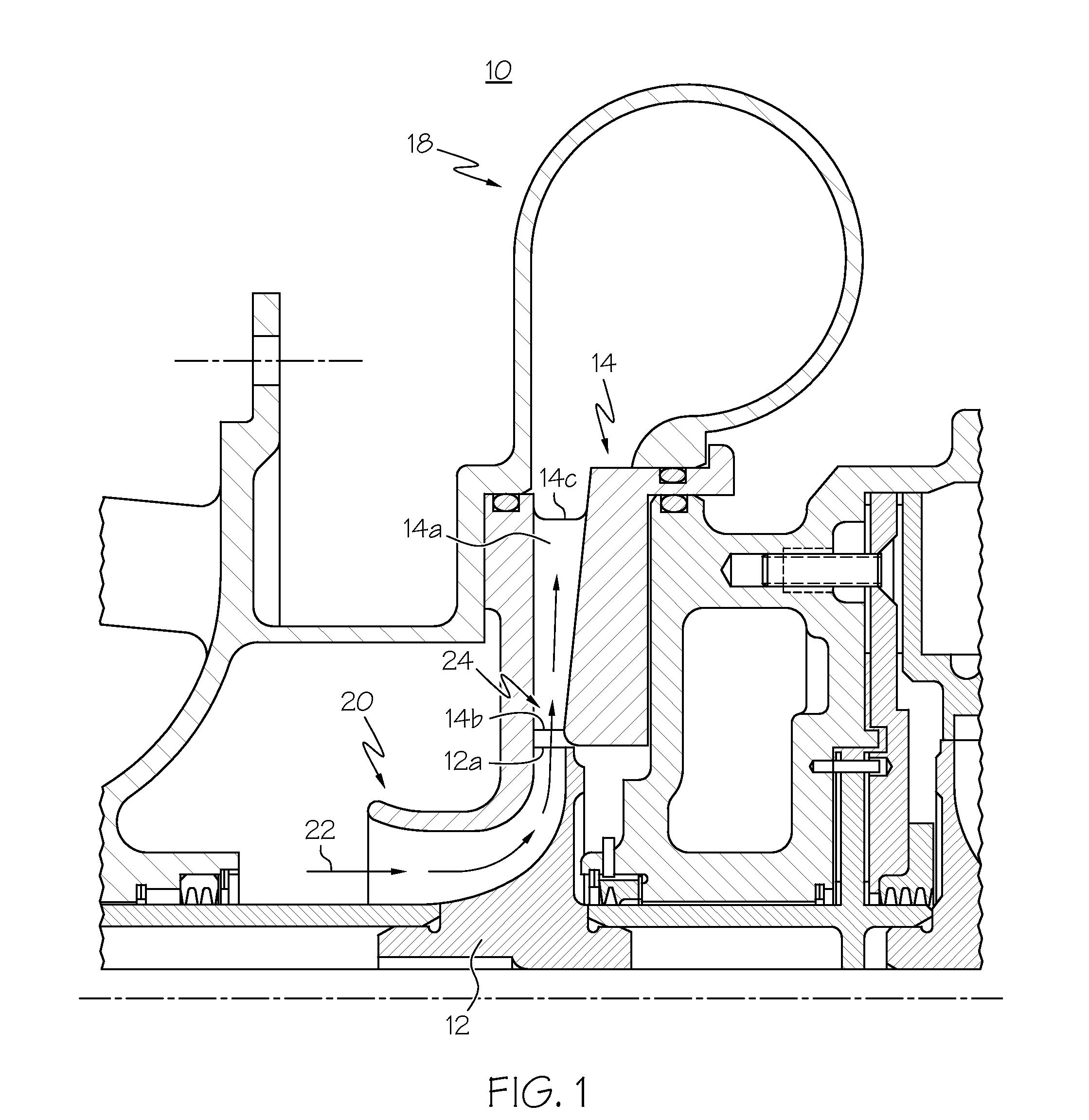

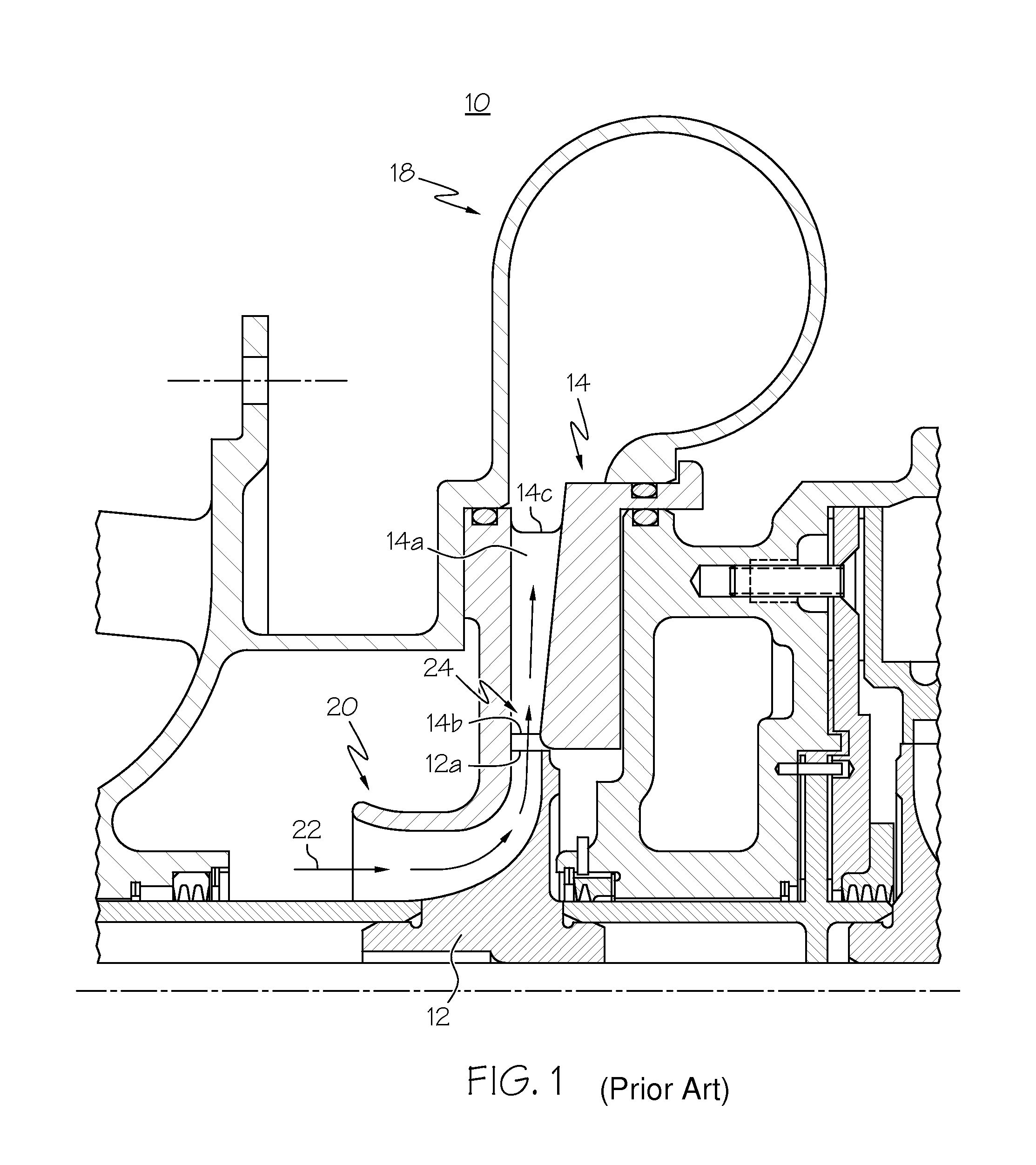

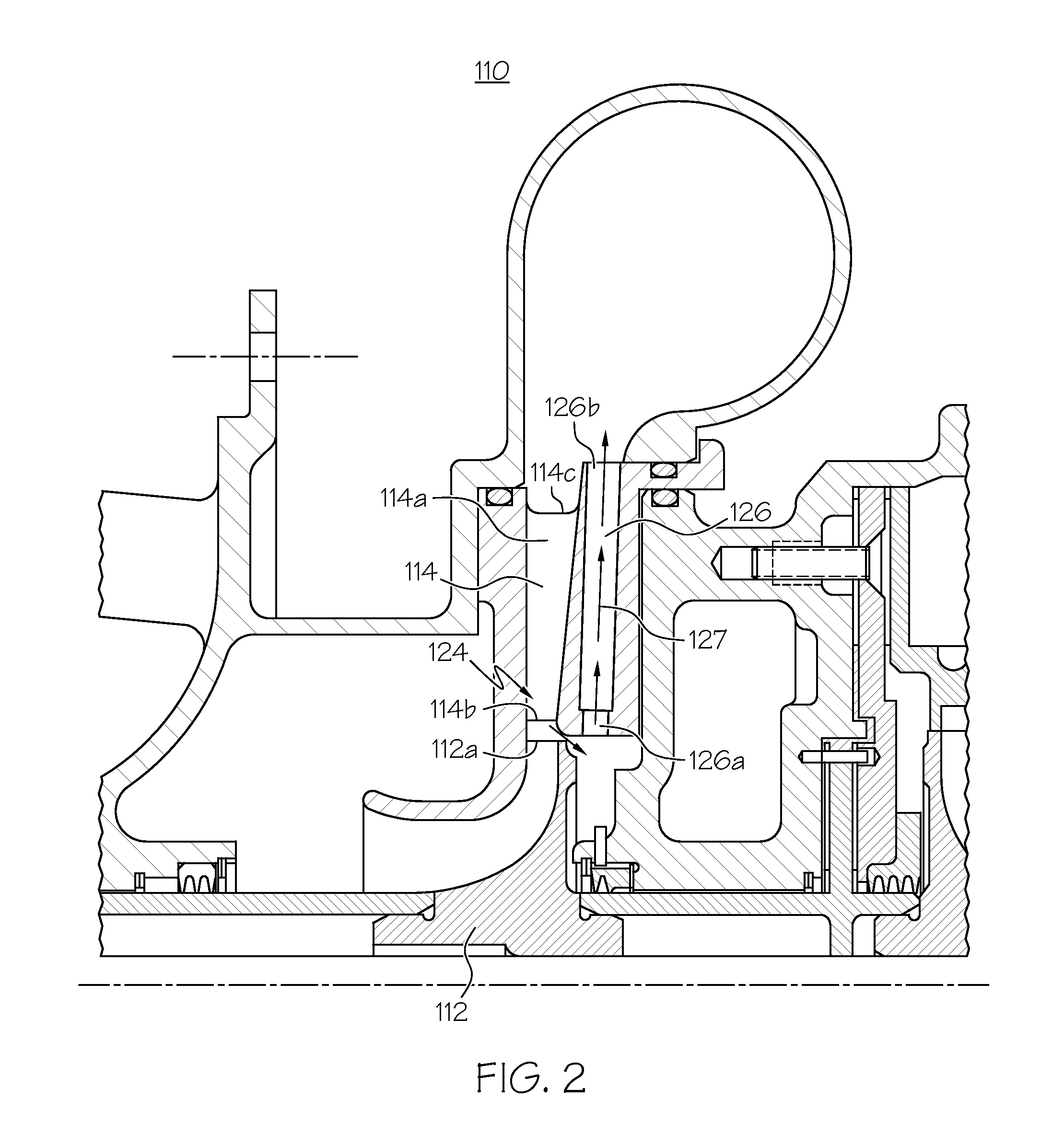

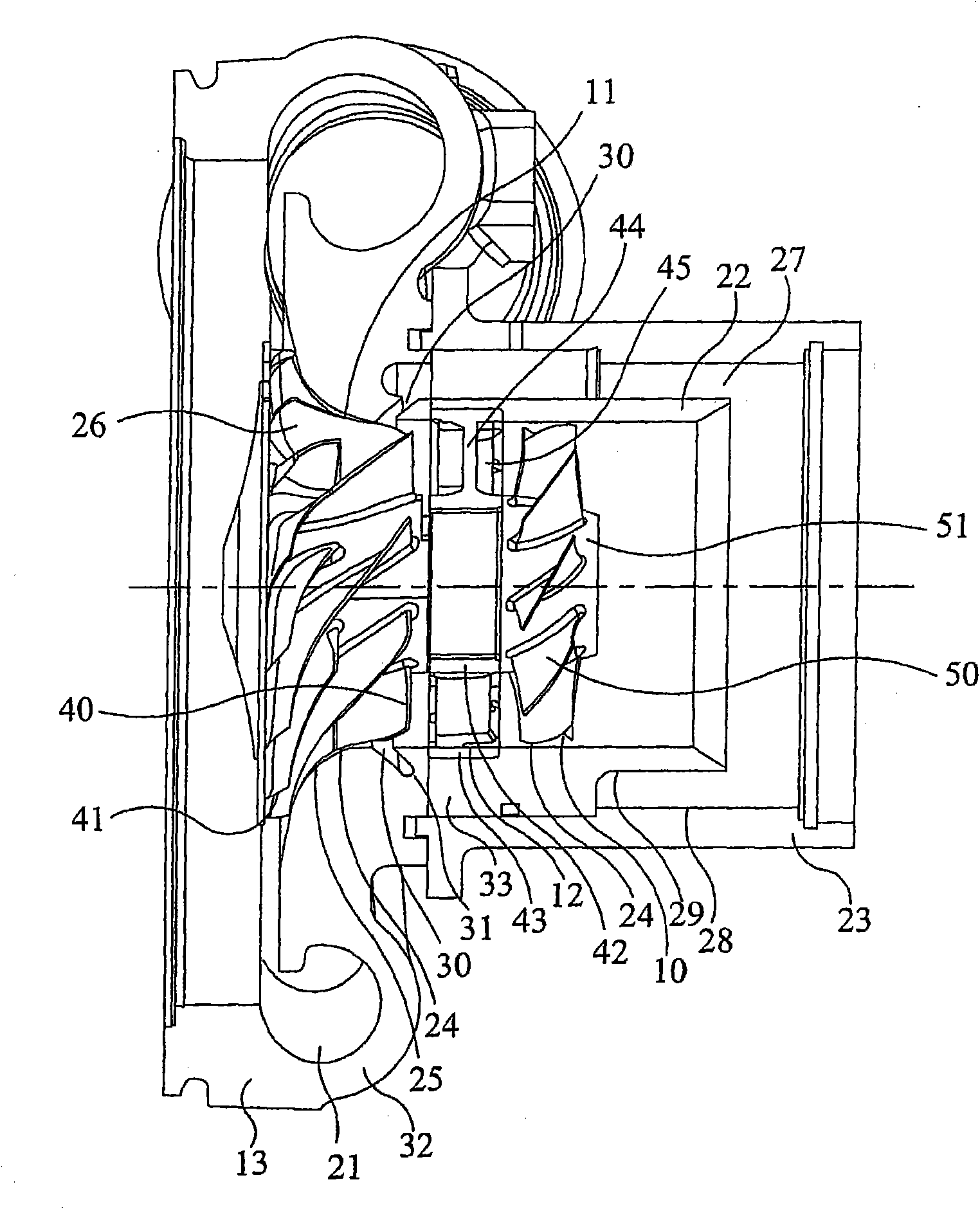

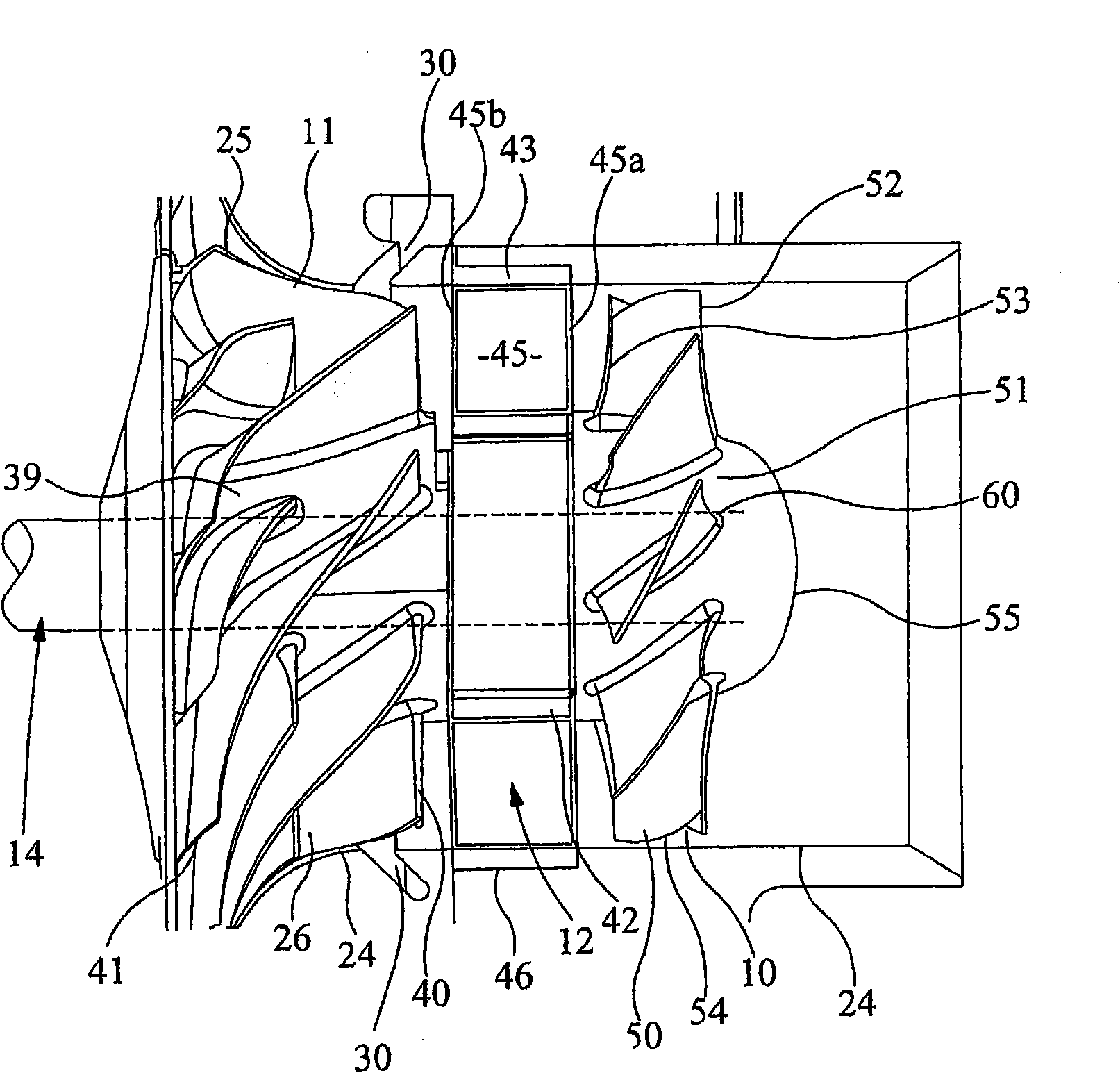

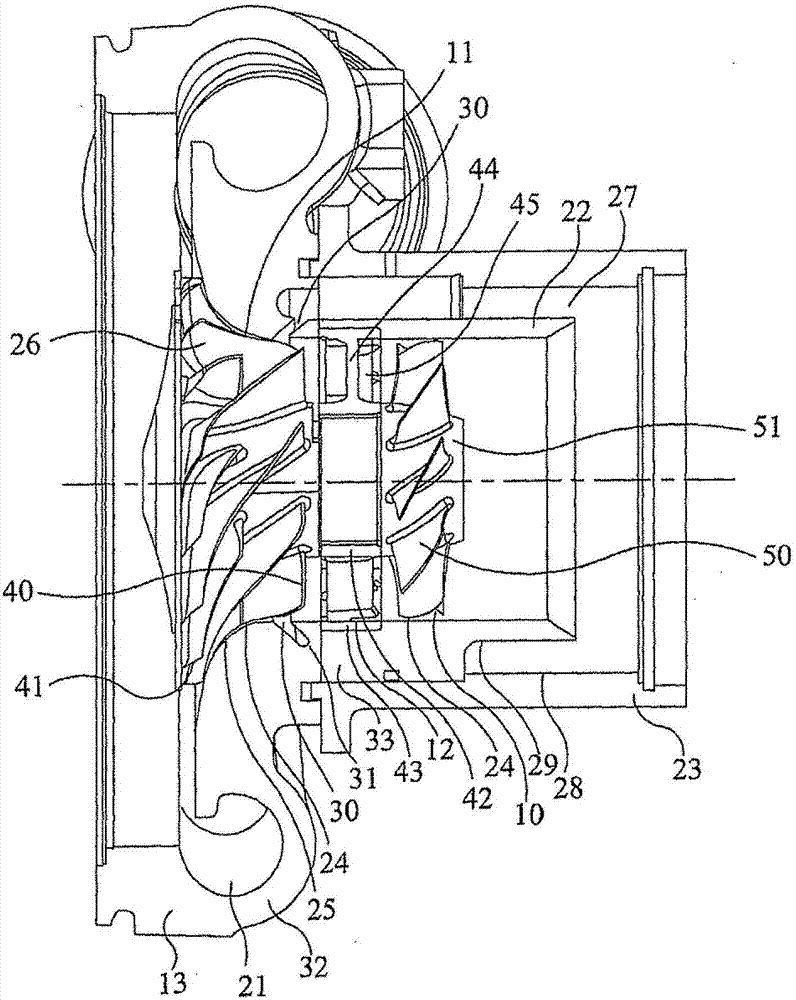

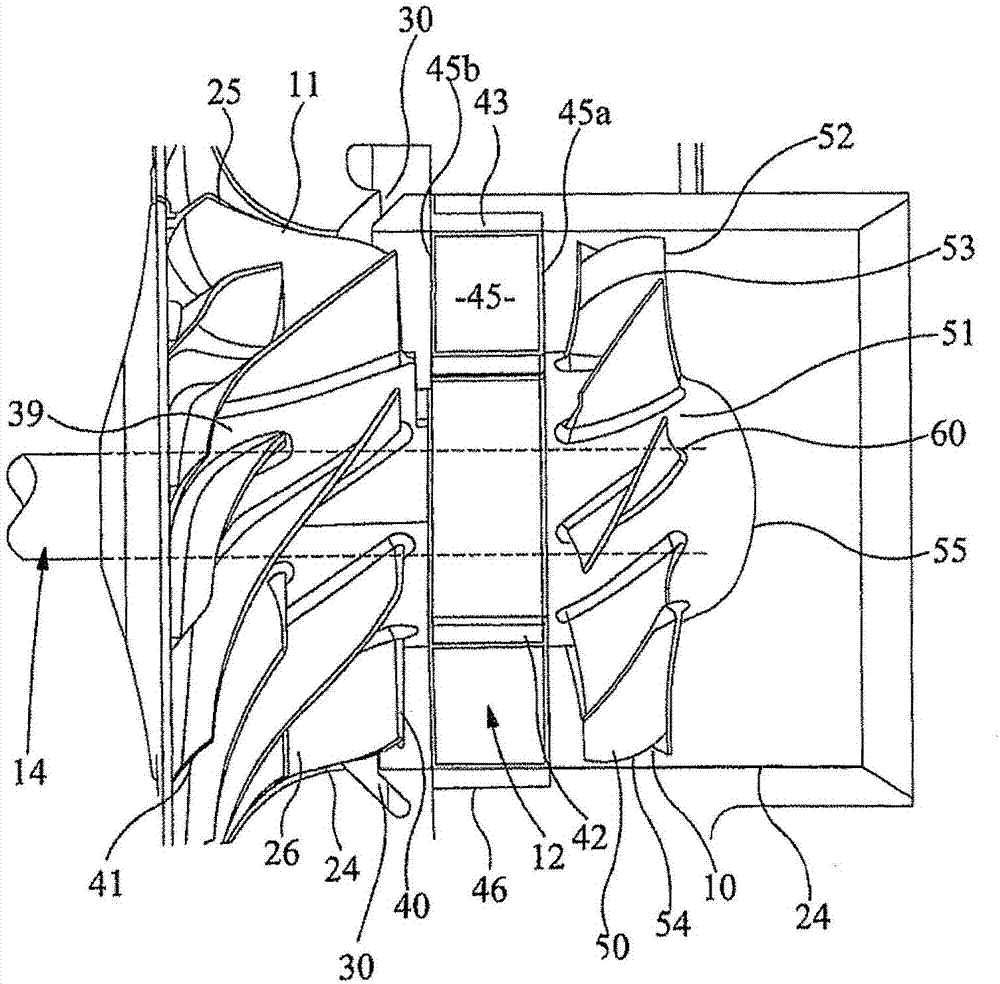

Compressor

A compressor typically for use in a turbocharger comprises a downstream radial compressor impeller wheel (11), an upstream axial compressor impeller wheel (10) and an intermediate stator (12). The compressor housing (13) has an inlet (19) with inner and outer walls (22, 23) that define between them an MWE gas flow passage (27). An upstream opening defined by the flow passage (27) provides communication between said passage and the intake (19) and at least one first slot (30) downstream of the upstream opening provides communication between the passage (27) and the inner surface (24) of the inner wall (22). The stator (12) comprises a plurality of fixed vanes (45) and is disposed in the inner wall (22) of the inlet between the radial and axial impeller wheels (10, 11). The position of the slot (30) can be at one of several positions along the gas flow passage (27). In other embodiments there are second and third slots (70, 71) and the flow passage (27) is divided into two parts (27a, 27b). All the arrangements are designed to improve the compressor map with.

Owner:CUMMINS TURBO TECH

Compressor

A compressor typically for use in a turbocharger comprises a downstream radial compressor impeller wheel, an upstream axial compressor impeller wheel and an intermediate stator. The compressor housing has an inlet with inner and outer walls that define between them an MWE gas flow passage. An upstream opening defined by the flow passage provides communication between said passage and the intake and at least one first slot downstream of the upstream opening provides communication between the passage and the inner surface of the inner wall. The stator comprises a plurality of fixed vanes and is disposed in the inner wall of the inlet between the radial and axial impeller wheels. The position of the slot can be at one of several positions along the gas flow passage, hi other embodiments there are second and third slots and the flow passage is divided into two parts. All the arrangements are designed to improve the compressor map width.

Owner:CUMMINS TURBO TECH

Control device for supercharging system

ActiveUS20180156141A1Performance maximizationMove preciselyElectrical controlInternal combustion piston enginesOperating pointSimulation

A control apparatus of a supercharging system for supplying an engine with compressed intake air, includes: a supercharger including a compressor configured to compress the intake air to be supplied to the engine; and a controller for controlling a control device affecting operation of the compressor. The controller includes: a compressor map storage part configured to store a compressor map which indicates a relationship of an intake volume flow rate, a pressure ratio, and a compressor rotation speed in the compressor; a current position calculation part configured to calculate a current position of an operational point of the compressor on the compressor map every predetermined period; a moving direction calculation part configured to calculate a moving direction of the operational point on the compressor map on the basis of the current position of the operational point calculated by the current position calculation part; and a control part configured to control the control device on the basis of the current position of the operational point calculated by the current position calculation part and the moving direction of the operational point calculated by the moving direction calculation part.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Method of anti-surge protection for a dynamic compressor using a surge parameter

A method of surge protection for a dynamic compressor that has a corresponding compressor map. A control system continually calculates an equivalent polytropic head parameter in order to define a surge limit line. The system then calculates a control parameter and determines the distance the control parameter to the surge limit line wherein the control parameter is dynamic to changes in gas compressibility and invariant to changes in suction conditions and gas compressibility. As a result of the distance of the control parameter to the surge limit line, the surge valve of a dynamic compressor is actuated to prevent surge.

Owner:ENERGY CONTROL TECH

Control device for supercharging system

ActiveUS10697382B2Performance maximizationMove preciselyElectrical controlInternal combustion piston enginesControl theoryMechanical engineering

A control apparatus of a supercharging system for supplying an engine with compressed intake air, includes: a supercharger including a compressor configured to compress the intake air to be supplied to the engine; and a controller for controlling a control device affecting operation of the compressor. The controller includes: a compressor map storage part configured to store a compressor map which indicates a relationship of an intake volume flow rate, a pressure ratio, and a compressor rotation speed in the compressor; a current position calculation part configured to calculate a current position of an operational point of the compressor on the compressor map every predetermined period; a moving direction calculation part configured to calculate a moving direction of the operational point on the compressor map on the basis of the current position of the operational point calculated by the current position calculation part; and a control part configured to control the control device on the basis of the current position of the operational point calculated by the current position calculation part and the moving direction of the operational point calculated by the moving direction calculation part.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com