Control device for supercharging system

一种控制装置、增压系统的技术,应用在电气控制、发动机控制、机器/发动机等方向,能够解决设备破损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

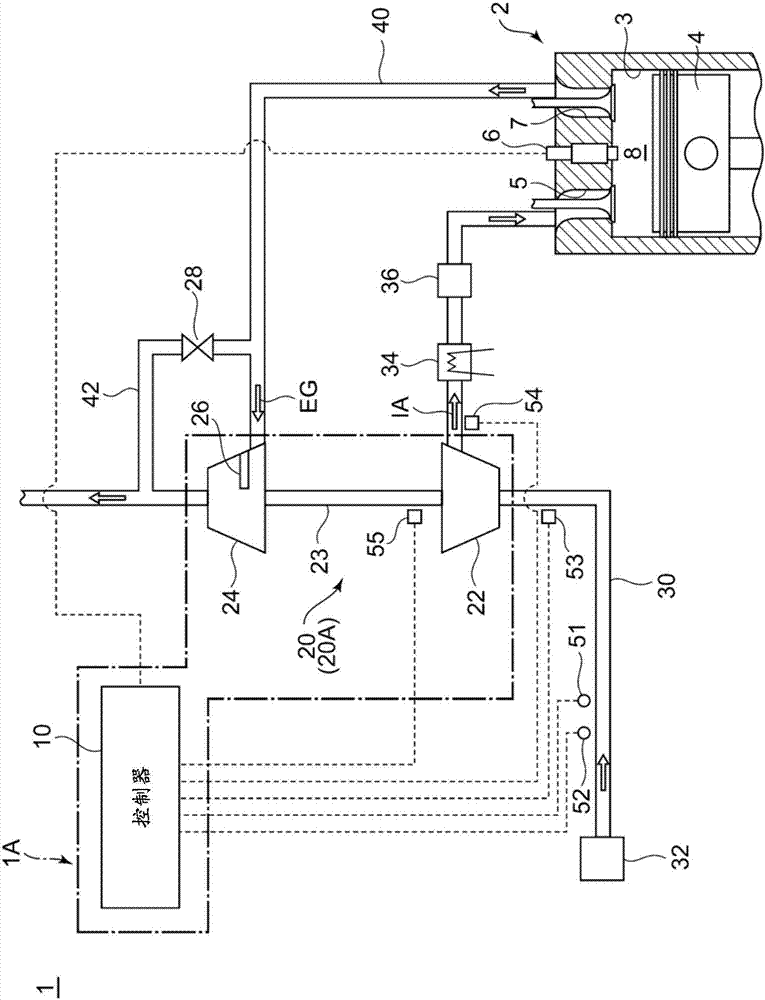

[0055] figure 1 It is a diagram showing the overall configuration of a supercharging system to which a supercharging system control device according to an embodiment of the present invention is applied. A supercharging system control device 1A according to an embodiment of the present invention is a supercharging system control device 1A for supplying compressed intake air IA to an engine 2, such as figure 1 As shown, there are: a supercharger 20 including a compressor 22 that compresses intake air IA supplied to the engine 2 , and a controller 10 that controls a control device that affects the operation of the compressor 22 .

[0056] In the illustrated embodiment, the supercharger 20 is constituted by a turbocharger 20A that rotates a compressor 22 by a turbine 24 that is rotated by exhaust gas EG discharged from the engine 2 .

[0057] exist figure 1 In the supercharging system 1 shown, the air (intake air) introduced into the intake line 30 via the air cleaner 32 flows i...

no. 2 approach

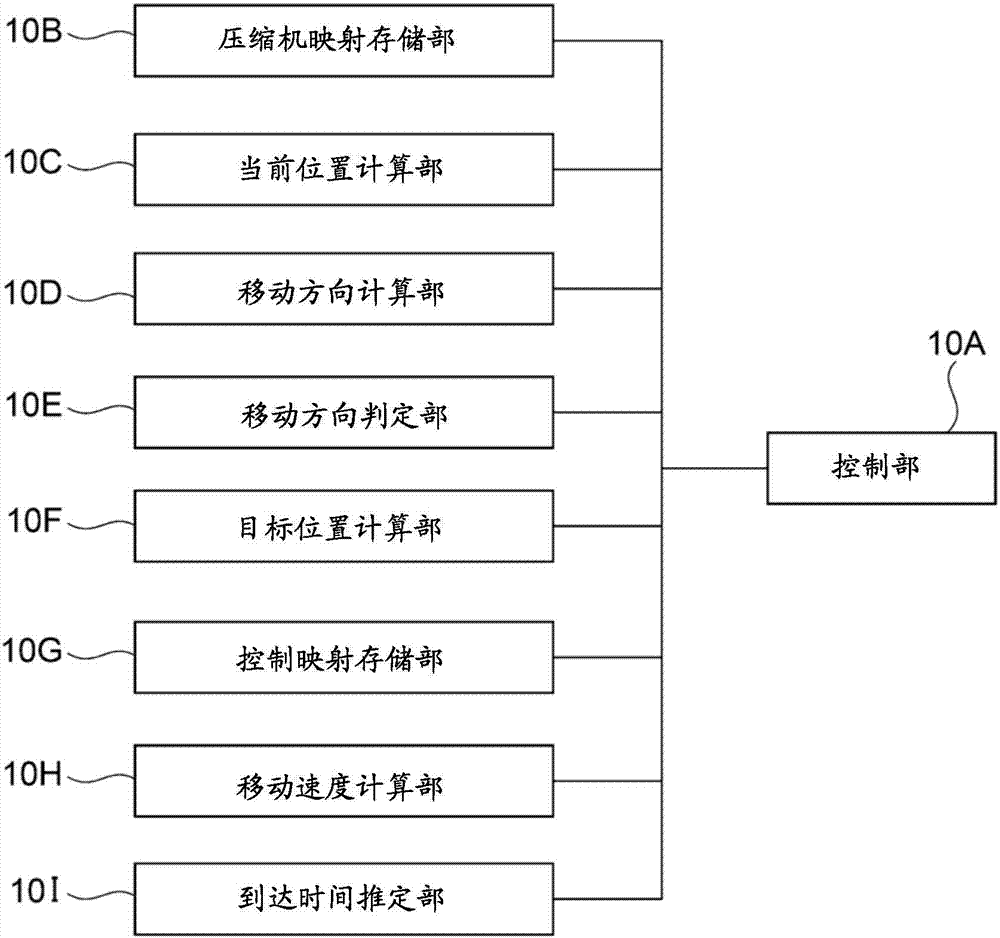

[0088] In several embodiments, such as figure 2 As shown, the controller 10 further includes a movement speed calculation unit 10H. The moving speed calculation unit 10H is a part of the controller 10 that realizes the function of calculating the moving speed of the operating point 61 based on the change amount per unit time of the current position of the operating point 61 calculated by the current position calculating unit 10C.

[0089] Moreover, as described later Figure 7 , 8 As described in , the control unit 10A is configured based on the current position of the operating point 61 calculated by the current position calculating unit 10C, the moving direction of the operating point 61 calculated by the moving direction calculating unit 10D, and the moving direction calculated by the moving speed calculating unit 10H. The calculated movement speed of the operating point 61 is used to control the control devices 6, 26, 28 and the like.

[0090] According to such an embo...

no. 3 approach

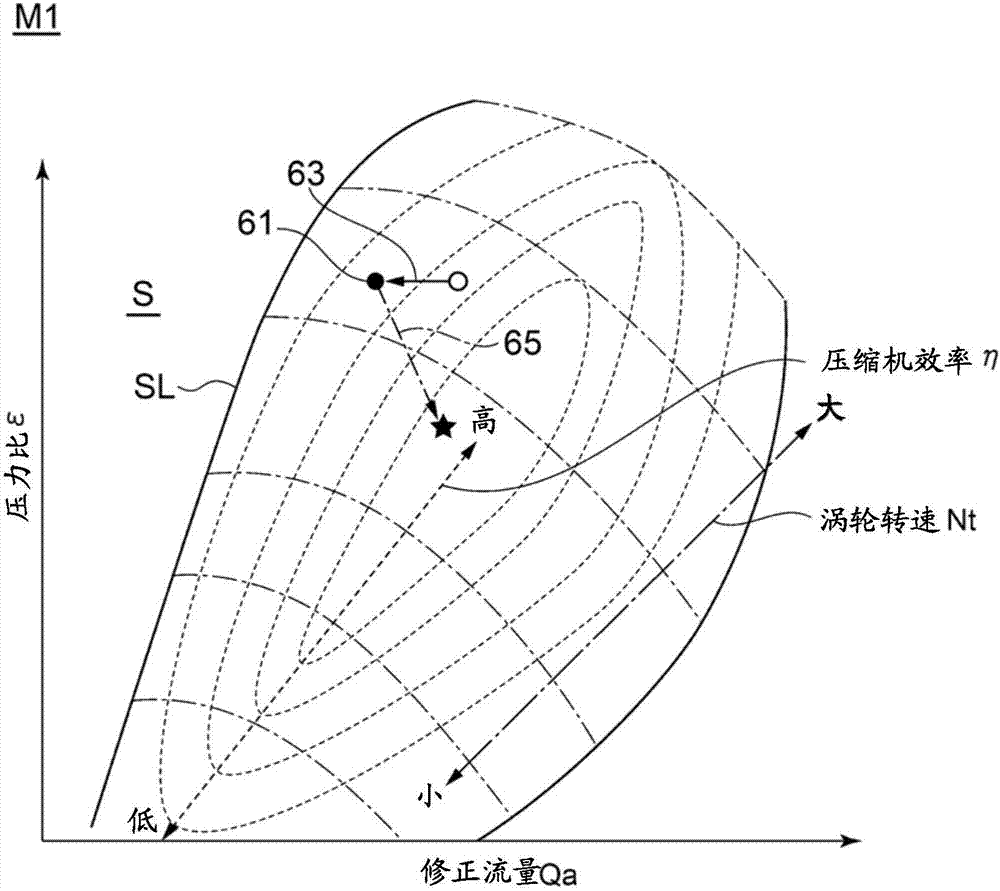

[0106] In several embodiments, as described below Figure 10-11 As described in , when the arrival time tb of the operating point 61 from the current position to the target position is shorter than the second predetermined time td, the control unit 10A controls the control devices 6, 26, 28, etc. so that The operating point 61 is made to reach the target position earlier than the second predetermined time td.

[0107] According to such an embodiment, when the arrival time of the operating point 61 from the current position to the target position is shorter than the second predetermined time td, the compressor 22 is controlled so that the operating point 61 is shorter than the second predetermined time td. Arrive at the target location ahead of schedule. The target position is, for example, a position on the compressor map M1 where the compressor efficiency η is higher than a predetermined efficiency (for example, a position where the compressor efficiency η is 75% or more). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com