Oil smoke purification filtering device capable of automatically replacing filter belt

A filtering device and oil fume purification technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of cumbersome replacement process, filter belt clogging, time-consuming and labor-intensive problems, and achieve simple replacement process, reduced construction period, Easy to use and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

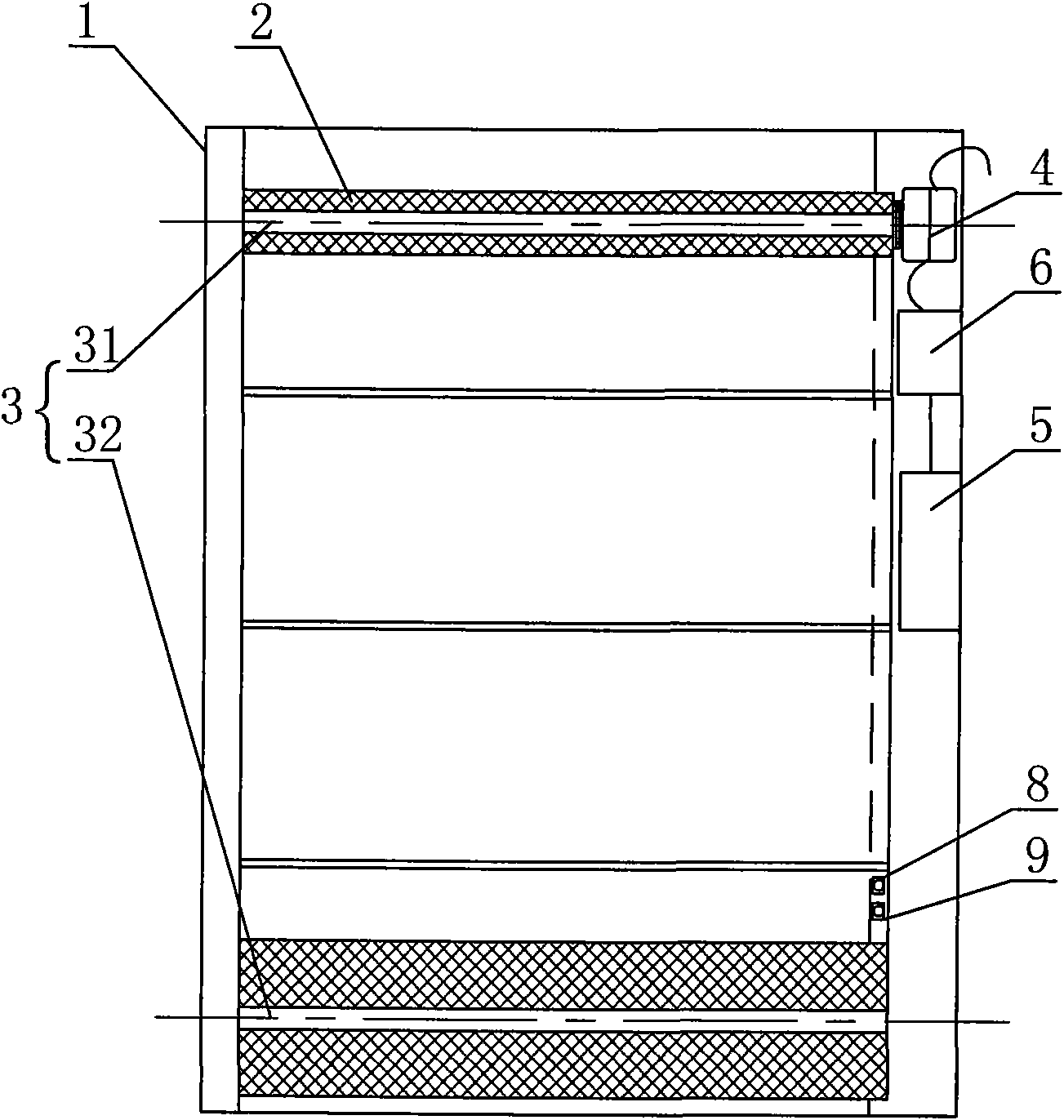

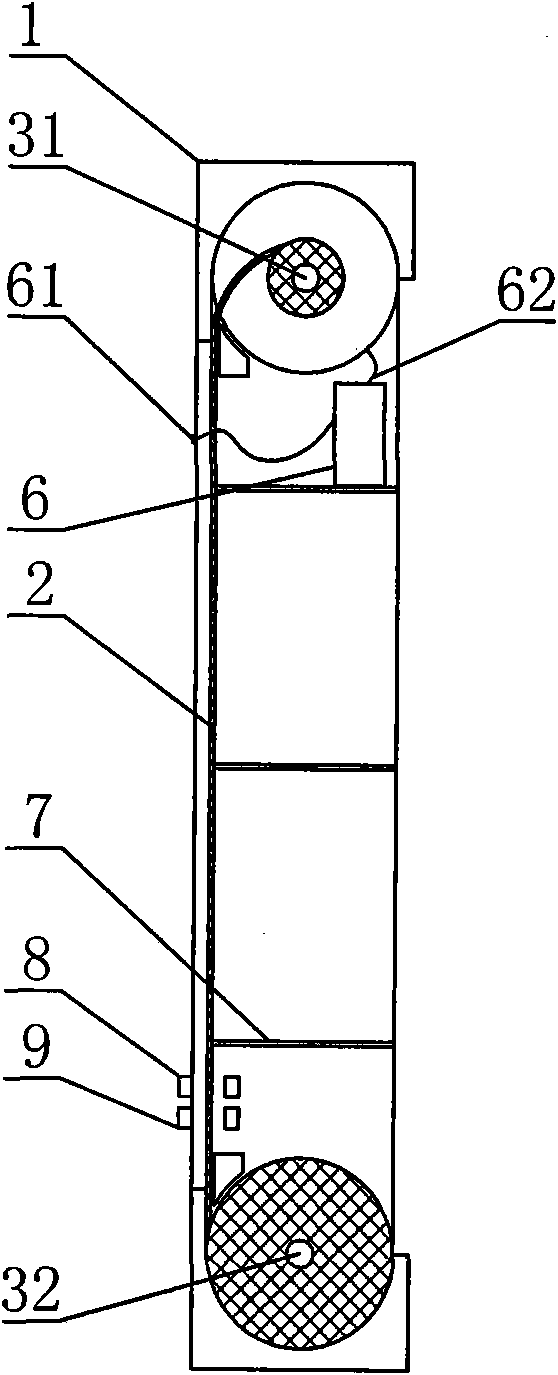

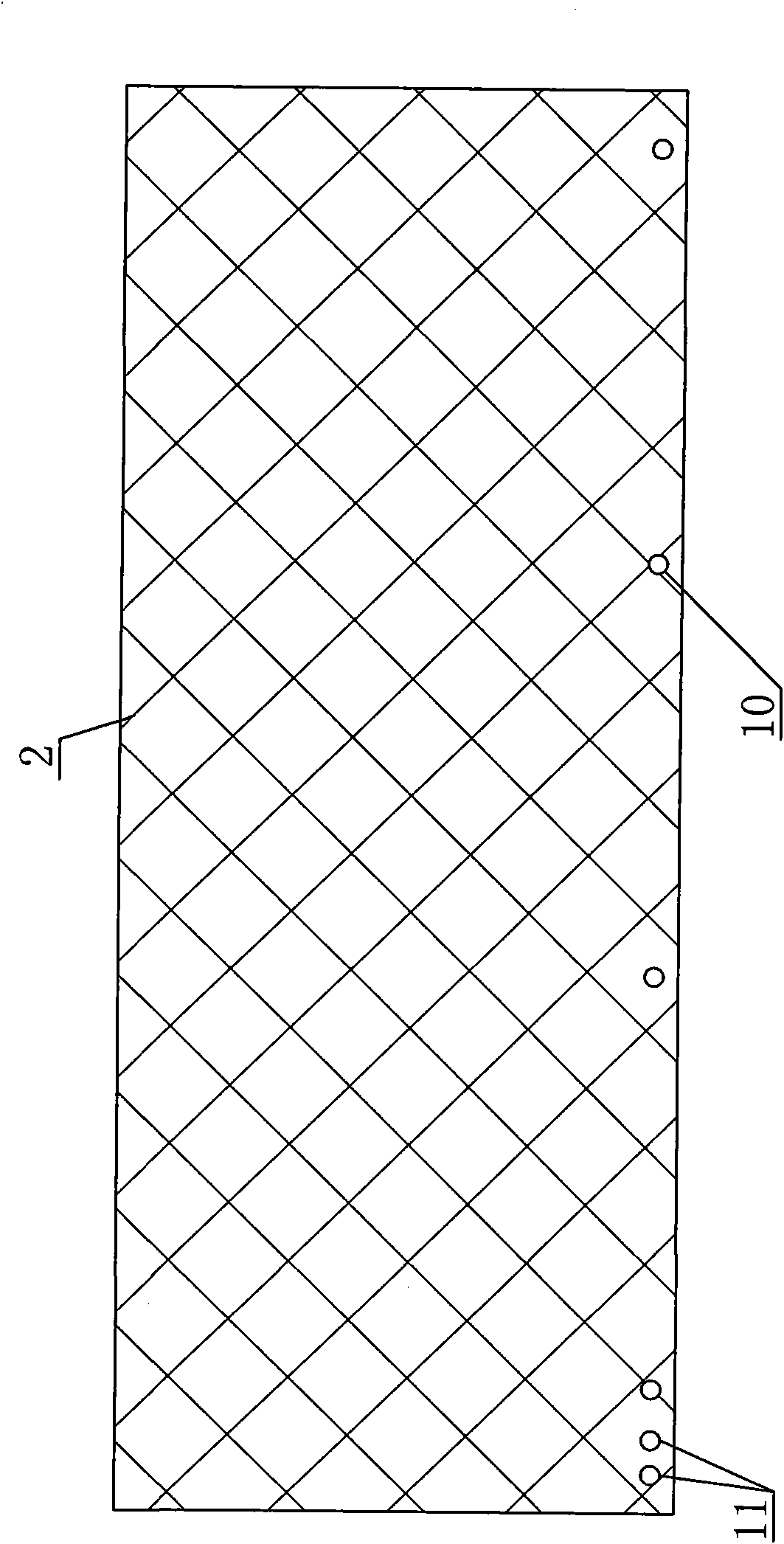

[0021] Such as figure 1 , figure 2 As shown, the oil fume purification filter device that can automatically replace the filter belt of the present invention includes an outer frame 1 and a filter belt 2 placed inside the outer frame 1, the filter belt 2 is a rolled filter belt, and the outer Both ends of the frame 1 are provided with a winding device 3 that automatically winds the rolled filter belt, and a drive motor 4 that drives the winding device 3 to rewind the blocked filter belt and pull out a new filter belt. Shaped filter belt 2 can be used according to the user's own needs, and usually one roll can be used for 10 to 20 purification cycles. A control box 5 is installed on the outer frame 1, and the control box 5 is connected with the driving motor 4, and the whole filtering device is centrally controlled by a programmable controller in the control box 5.

[0022] Depend on figure 1 It can be seen that the winding device 3 includes a driving reel 31 placed at one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com