Manufacturing method of metal product with decoration veins and finished product thereof

The technology of a metal product and a manufacturing method, which is applied to the metal products with decorative patterns and the manufacturing field thereof, can solve the problems of high cost, complexity and lack of metallic luster aesthetics of the shell, and achieve the effect of ensuring the integrity and increasing the aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The detailed description and technical content of the present invention are described below with accompanying drawings. However, the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

[0042] The metal plate with ornamentation made by the present invention, such as Figure 6 As shown, it mainly includes a metal substrate 10 and a decorative pattern 20 , the metal substrate 10 has an outer surface 11 , and the decorative pattern 20 is formed on the outer surface 11 by brushing.

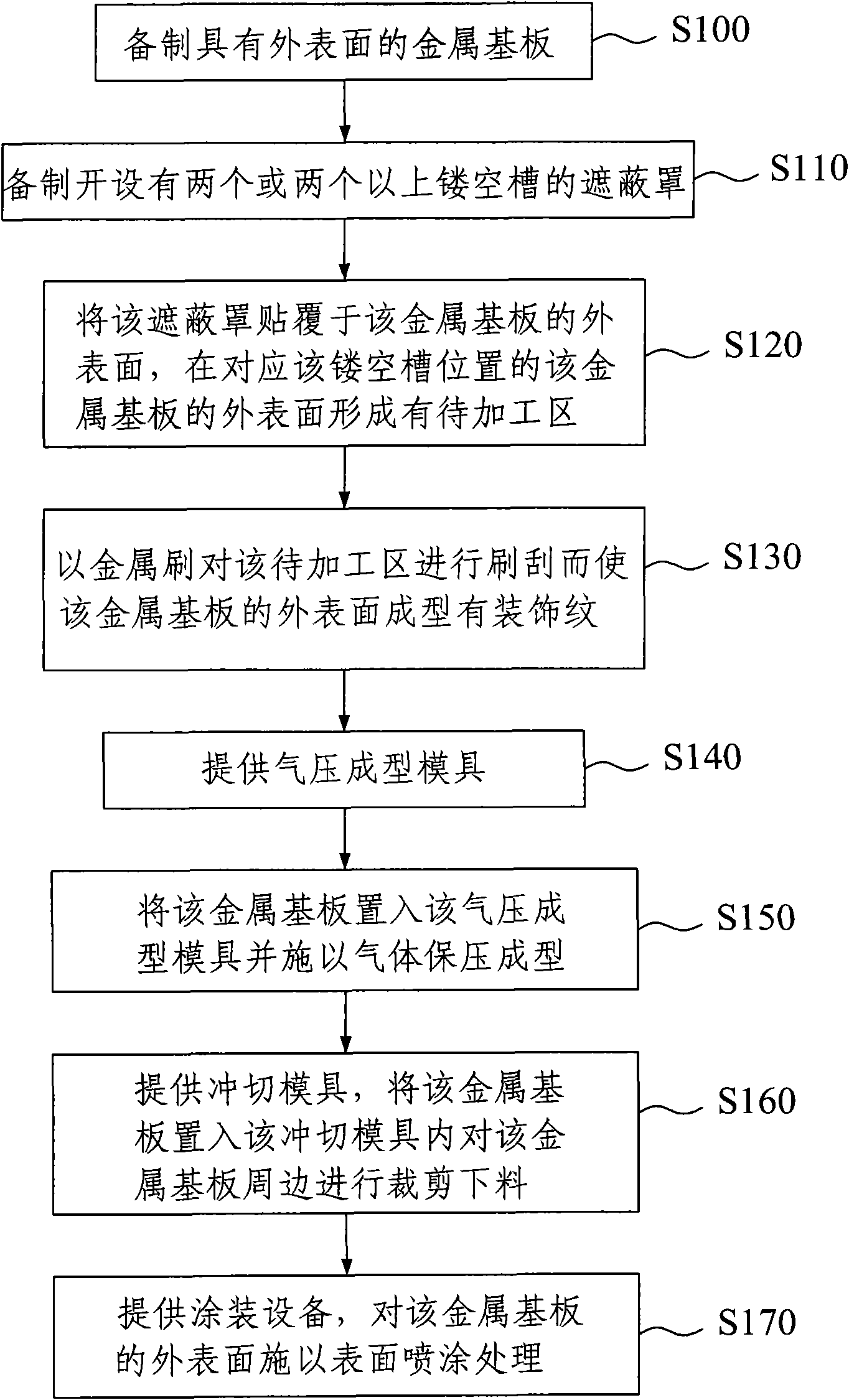

[0043] Please refer to Figure 2 to Figure 8 As shown, the present invention provides a method for manufacturing a metal product with decorative patterns and its finished product. The metal product can be a metal plate or a metal shell. This embodiment is a method for making a metal shell. The steps include:

[0044] S100: Prepare a metal substrate 10 with an outer surface 11 (such as image 3 shown); in this step, metal substrates ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap