Mechanism for reversing and transferring aluminium ingots discharged from aluminium slab ingot heating /soaking pit furnace

A soaking furnace and material turning technology, which is applied in the field of material turning mechanism, can solve the problems of high maintenance cost of special equipment, occupation of manpower, and high requirements for workshop space, and achieve significant economic and social effects, reliable mechanism action, and flexible tilting free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

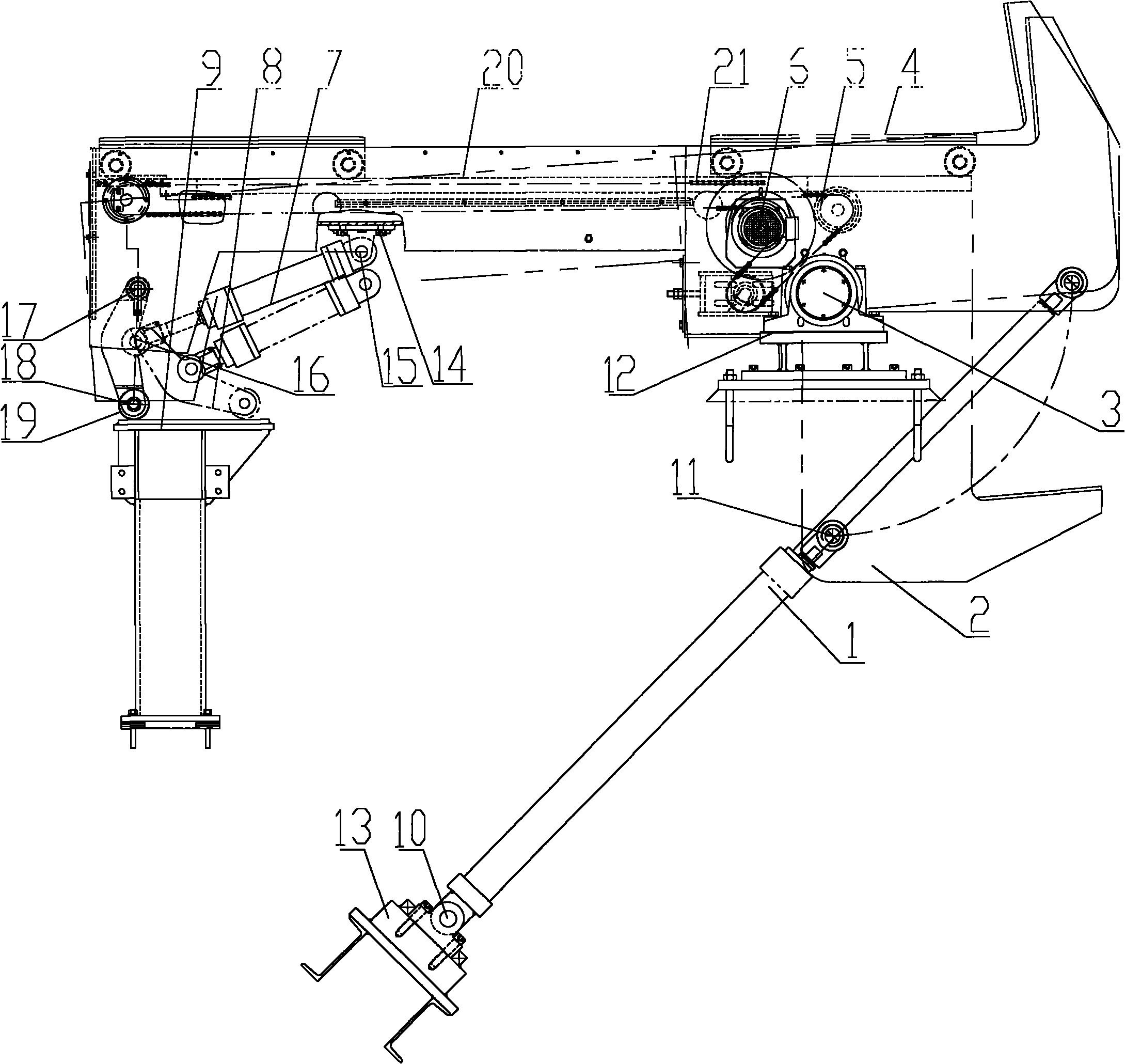

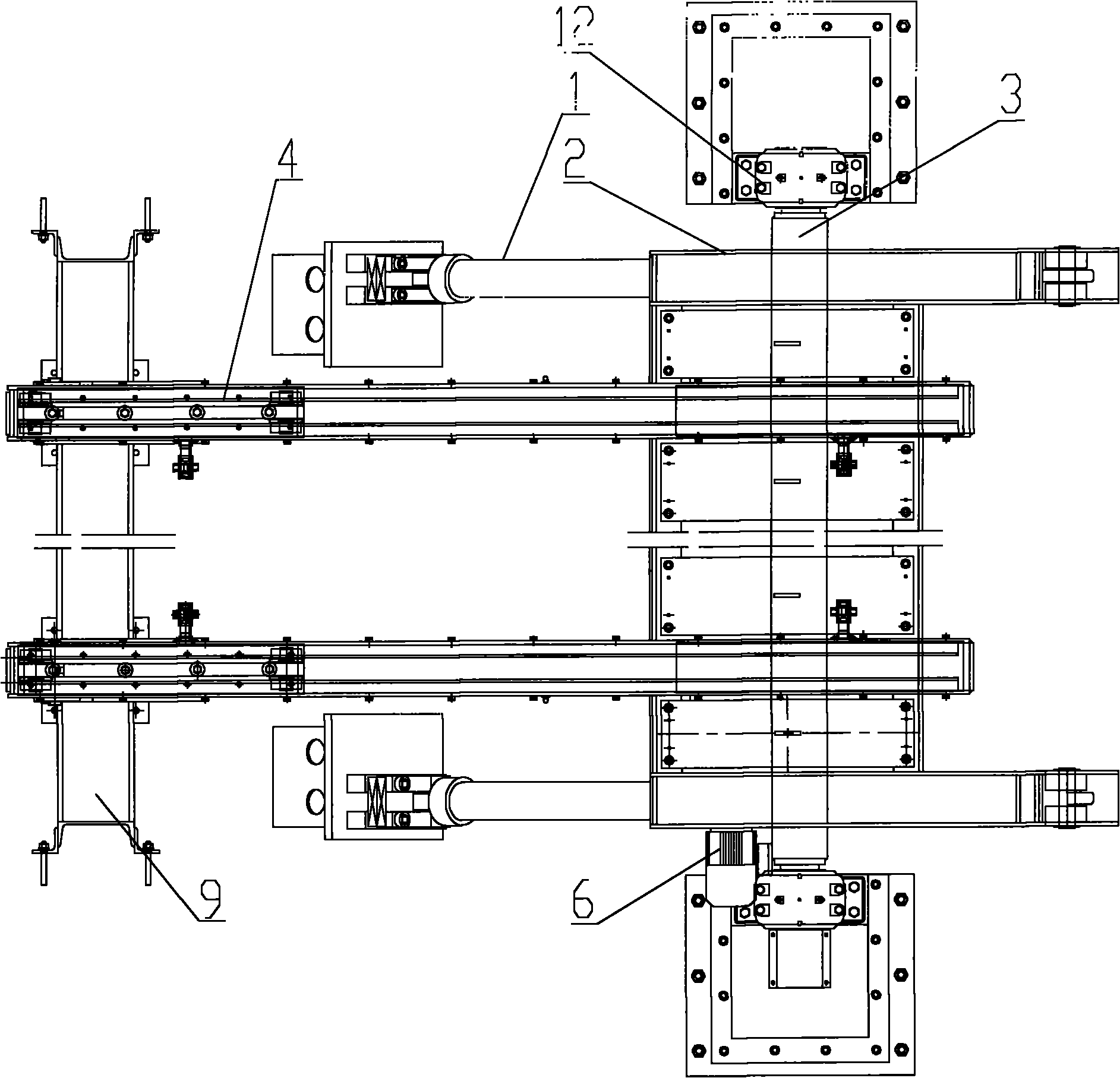

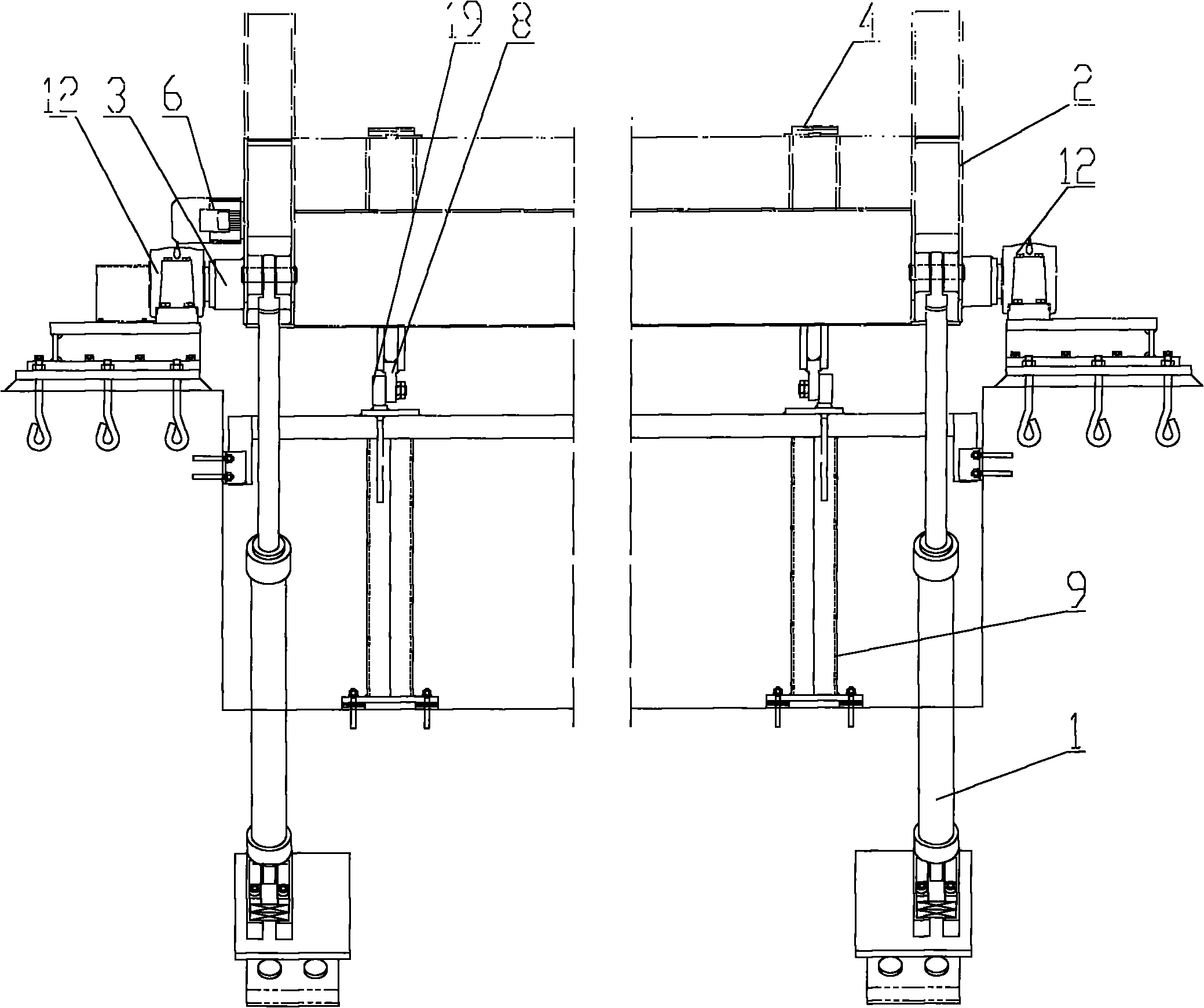

[0029] The turning and transfer mechanism is the mechanical part outside the furnace that turns the vertical ingot horizontally after the aluminum flat ingot comes out of the heating / soaking furnace, and transports it to the center of the hot rolling roller table and puts it on the hot rolling roller table. Its performance is reliable. Determines the mechanization level of the heating furnace equipment. The invention provides a novel aluminum slab heating / soaking furnace aluminum ingot turning and transfer mechanism, which can realize the automation of the whole production and improve the production efficiency.

[0030] like Figure 1~4 As shown, an aluminum flat ingot heating / soaking furnace aluminum ingot turning and transfer mechanism includes a turning cylinder 1, a turning frame 2, a rotating shaft 3, an ingot transport trolley 4, a sprocket group 5, a motor and a reducer 6. The support cylinder 7, the crank 8 and the support frame 9, the turning frame 2 are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com