Movable transition track bridge for heating furnace

A transitional track, movable technology, used in lighting and heating equipment, furnaces, furnace components, etc., can solve the problem of inability to meet the use of large-scale equipment and technological development, occupying space and shortening the length of the entire machine train, furnace sealing and poor insulation effect, etc. problems, to achieve the effect of significant economic and social effects, compact structure and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

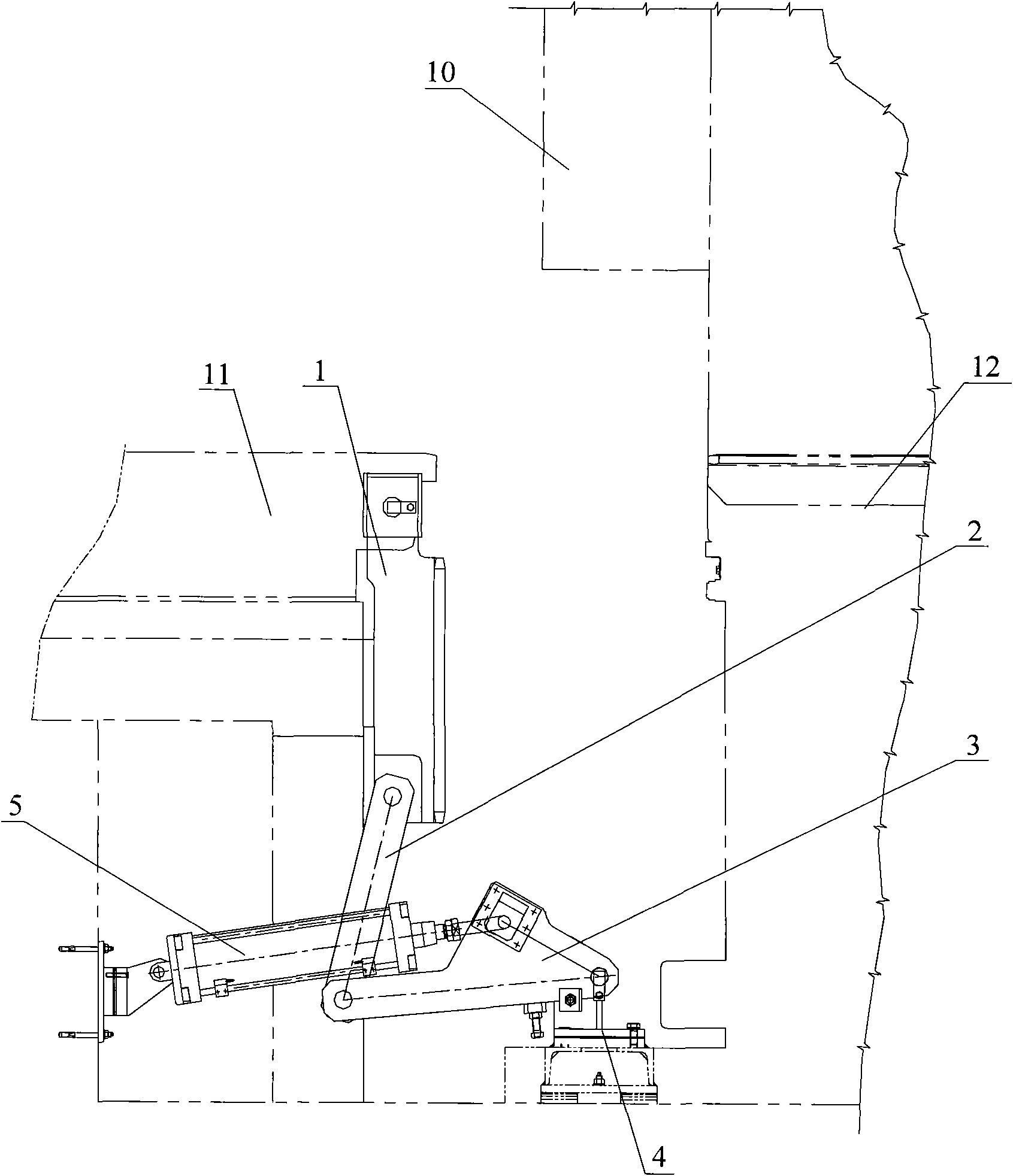

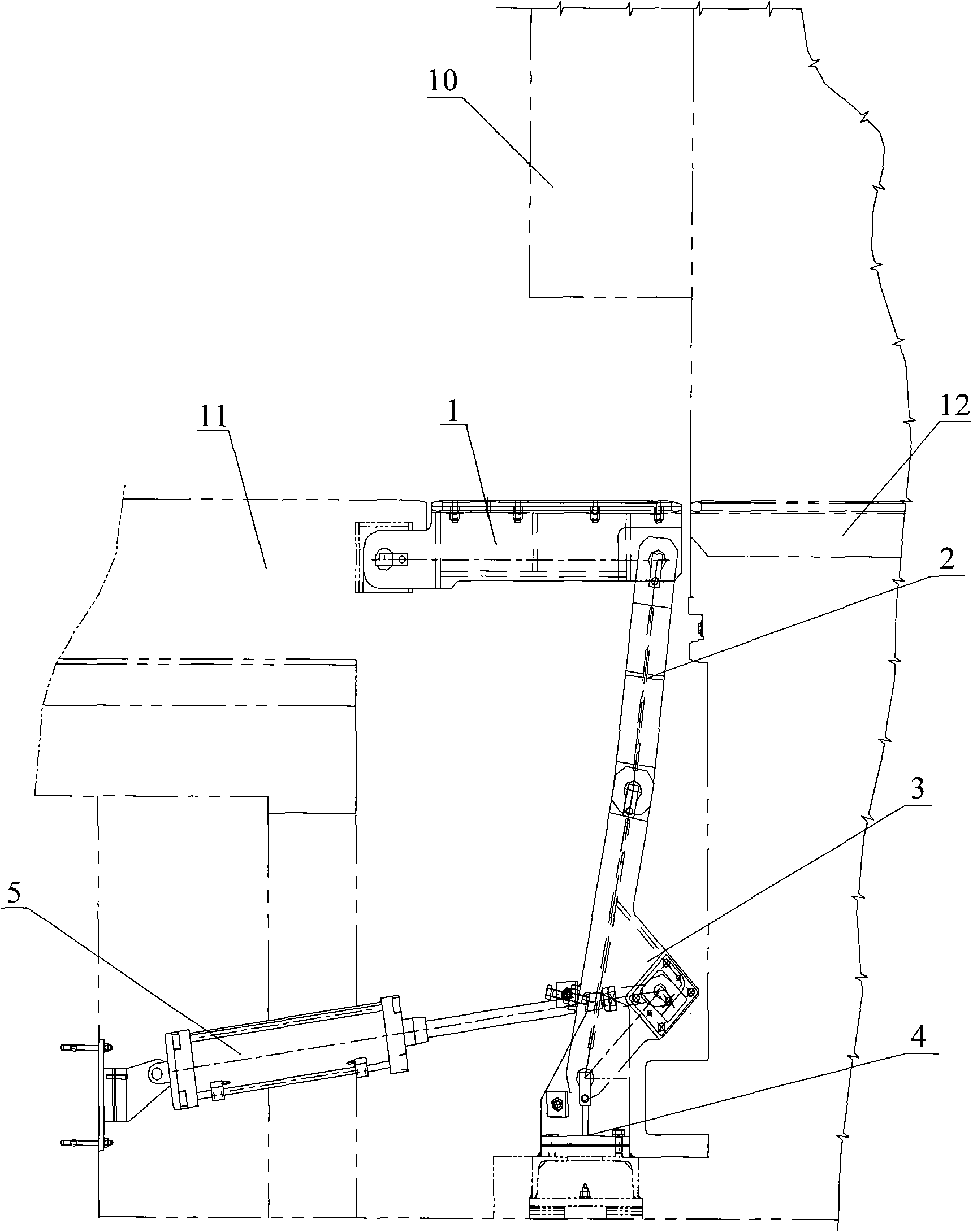

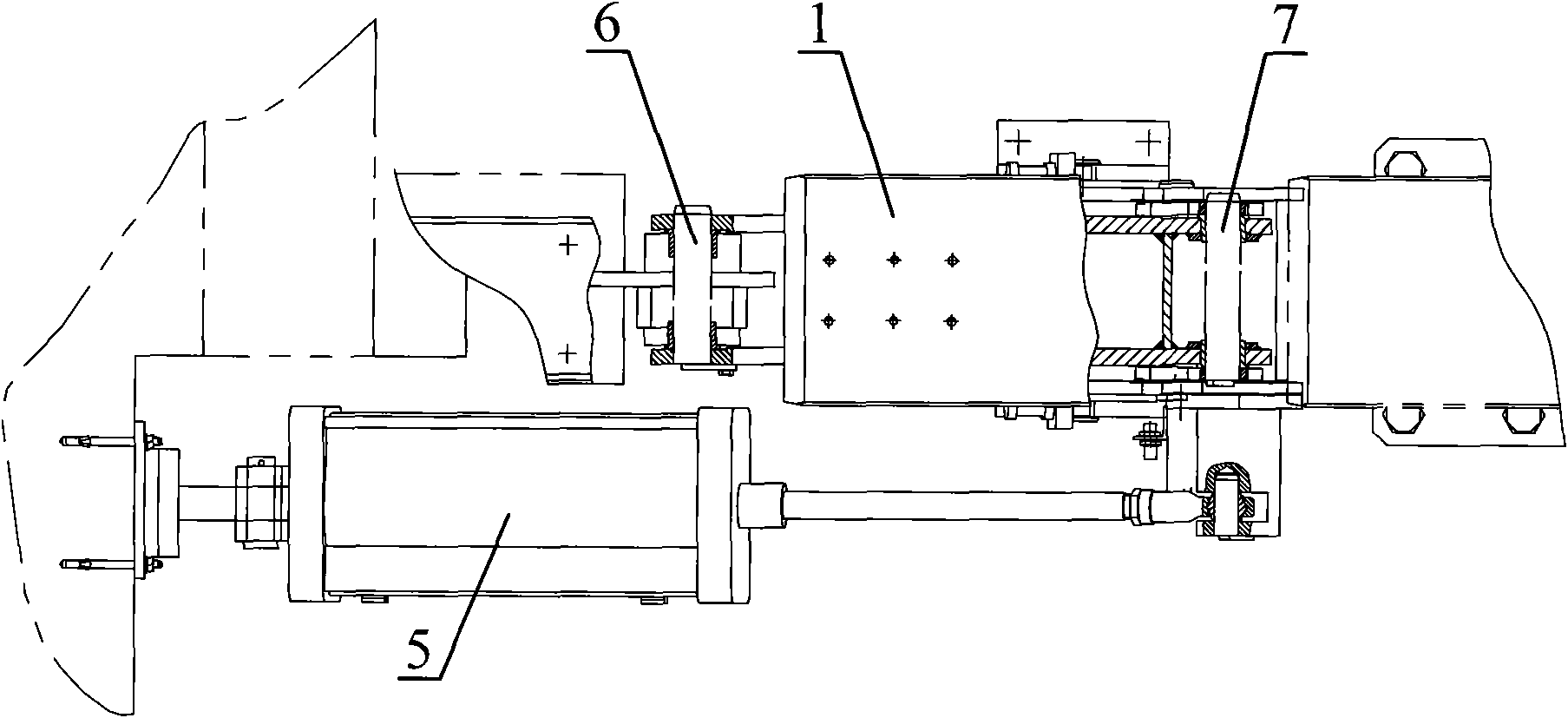

[0021] The track bridge is a transitional part used in the process of moving the ingot from the inside of the heating furnace to the track outside the furnace or from the outside of the furnace to the track inside the furnace. The reliability and characteristics of its performance determine the mechanization level of the heating furnace equipment and the characteristics of the furnace door. The movable track bridge of the present invention is a movable structural member similar to the movable knee joint of a human body, and is assembled from a plurality of detachable and movable parts, and its action is driven by a cylinder. When the furnace needs to feed or discharge materials, the cylinder piston rod is stretched out to push the crank and the track out from the vertical state to the horizontal state. When the feed or discharge action is completed, the cylinder piston rod retracts and returns to its original position.

[0022] figure 1 and figure 2 As shown, the movable tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com