Apparatus, system and method of in-situ identification

A technology of detection device and detection method, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as cross-contamination, work safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

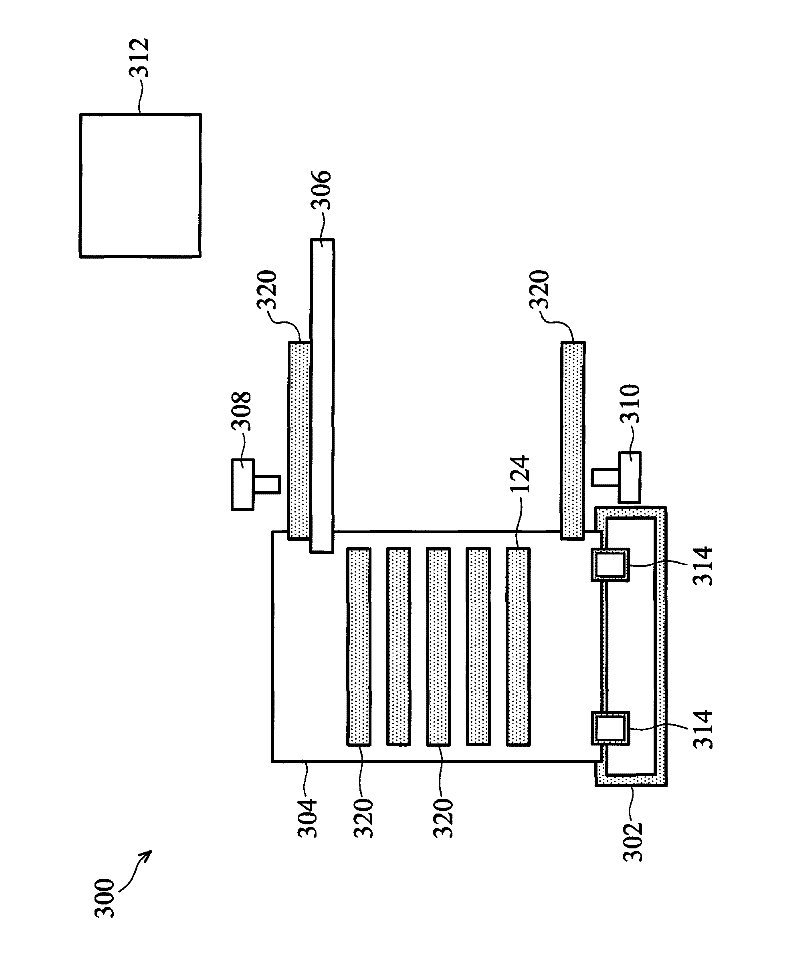

[0016] It is to be understood that the following disclosure provides various examples to illustrate various features of the invention. In order to simplify the description, specific embodiments, units, and combinations will be used for description. However, these specific examples are not intended to limit the present invention. In addition, in order to simplify the description, the present invention uses the same symbols in different drawings to indicate similar components in different embodiments, and the above repeated symbols do not mean that the components in different embodiments have the same corresponding relationship. For example, forming an element on another element includes the two elements being in direct contact, or the two elements being separated by other elements.

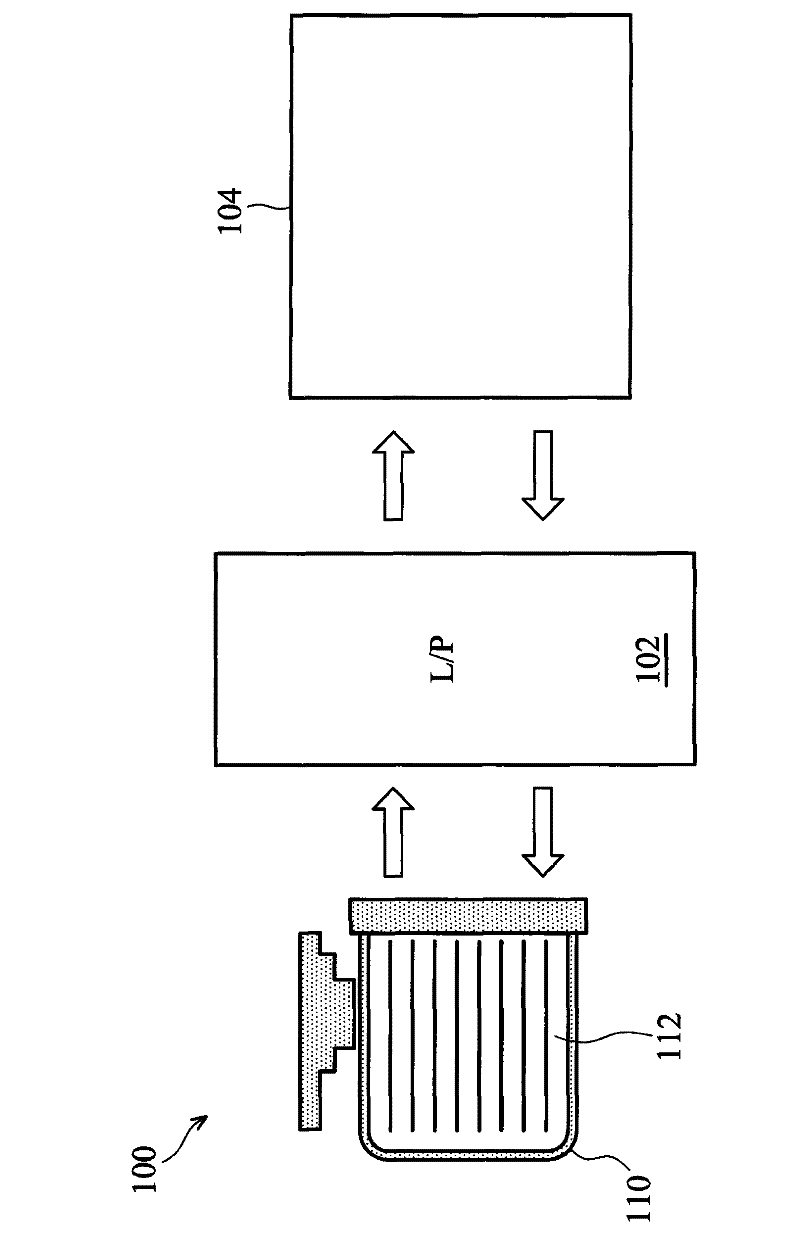

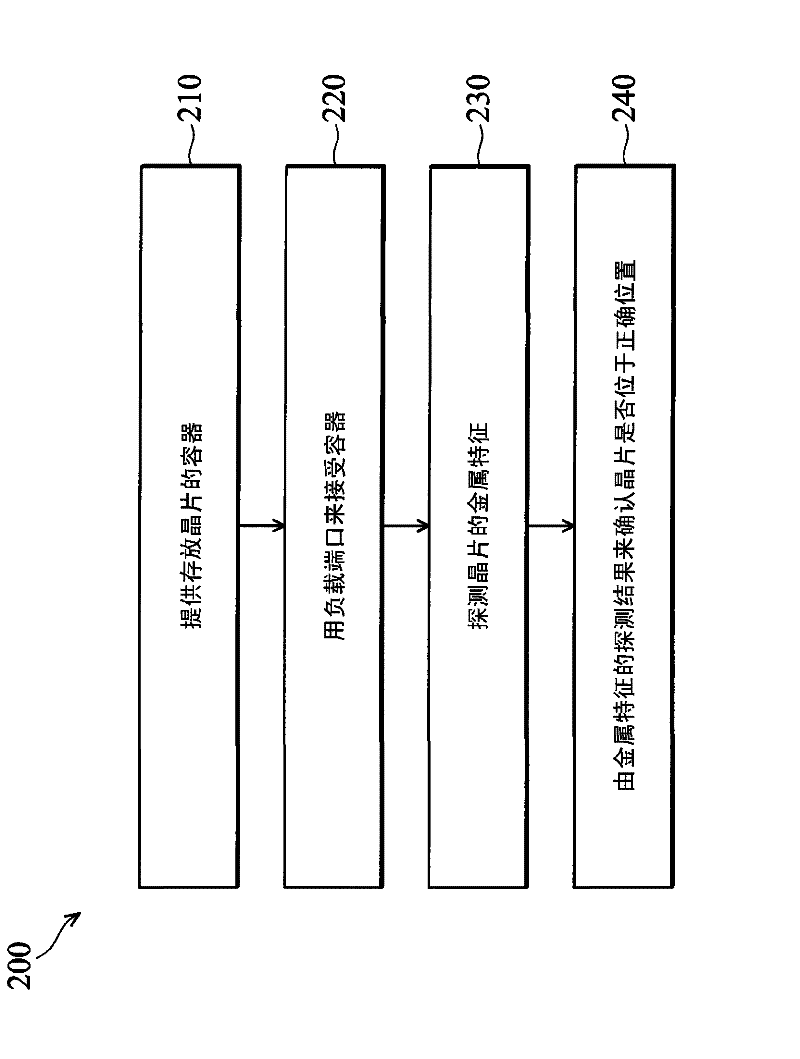

[0017] In the semiconductor process, different wafer fabrication facilities (FAB) are required to form integrated circuit devices. Integrated circuit devices can be formed after processing a sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com