Integrated hub motor

A technology of in-wheel motor and motor shaft, which is applied to synchronous motors with static armatures and rotating magnets, electronic commutation motor control, electrical components, etc., can solve problems such as low reliability, increased processing difficulty, and signal phase deviation. , to achieve the effect of strong anti-shock and oil pollution, improving fast response, and no excitation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be described below in conjunction with specific preferred embodiments with reference to the accompanying drawings. However, those skilled in the art should understand that the present invention is not limited to the embodiments, but can be changed accordingly according to specific application requirements.

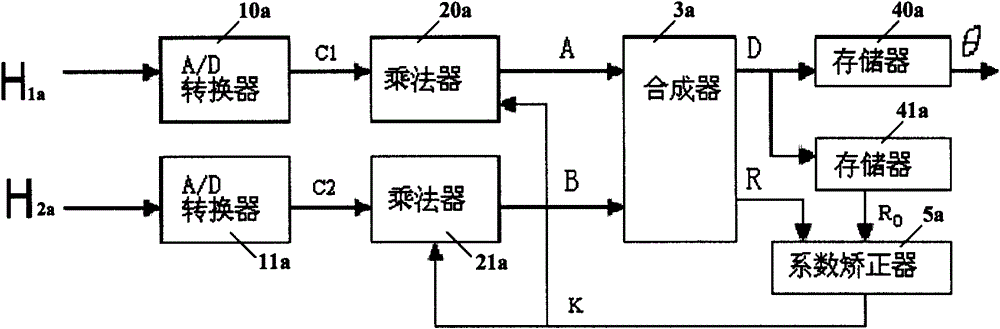

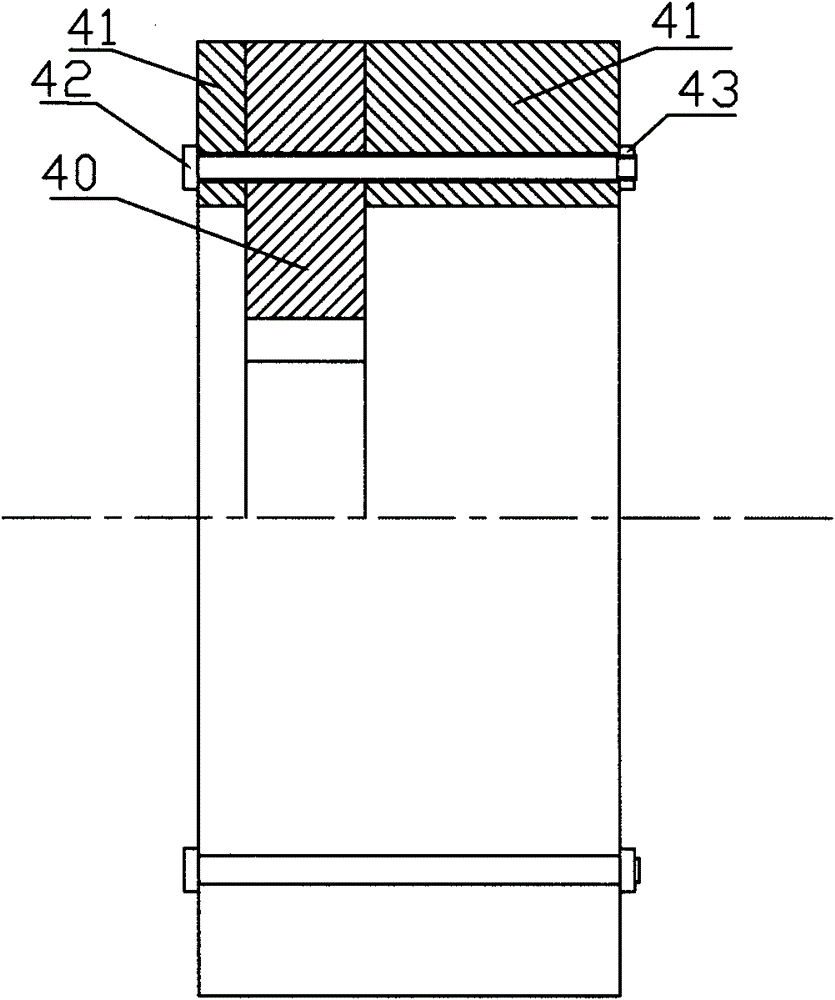

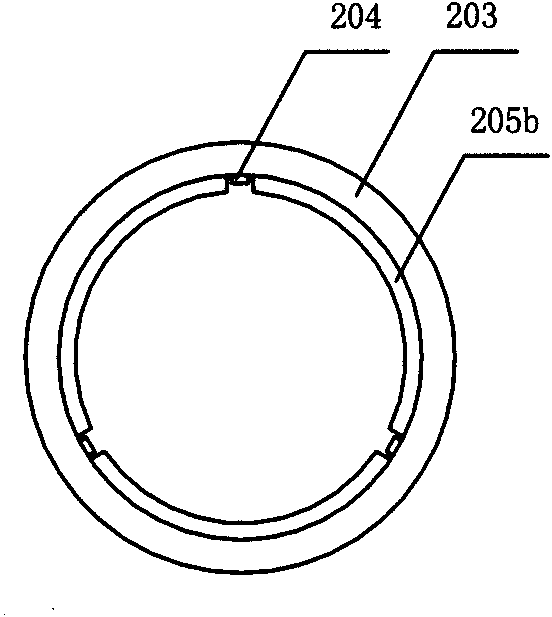

[0081] Such as figure 1 , figure 2 and combine image 3 As shown, the present invention provides an integrated in-wheel motor, comprising a motor shaft 4 and a stator 12 fixed thereon, the stator 12 is covered with a rotor housing 10, and the front and rear ends of the rotor housing 10 pass through rotor end covers 8, 14 and The bearing 6 and the bearing 19 are rotatably fixed on the motor shaft 4, and the two ends of the motor shaft 4 protrude outside the rotor cover 8, 14 to form a short end and a long end, and the outer side of the rotor cover 8 is fixed with a bearing cover 1 , the short end of the motor shaft 4 is covered in it, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com