Pneumatic vehicle tire having protected side wall markings

A tire and vehicle technology, applied to vehicle parts, tire sidewalls, tire parts, etc., can solve the problem of increasing tire weight and achieve good recognizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

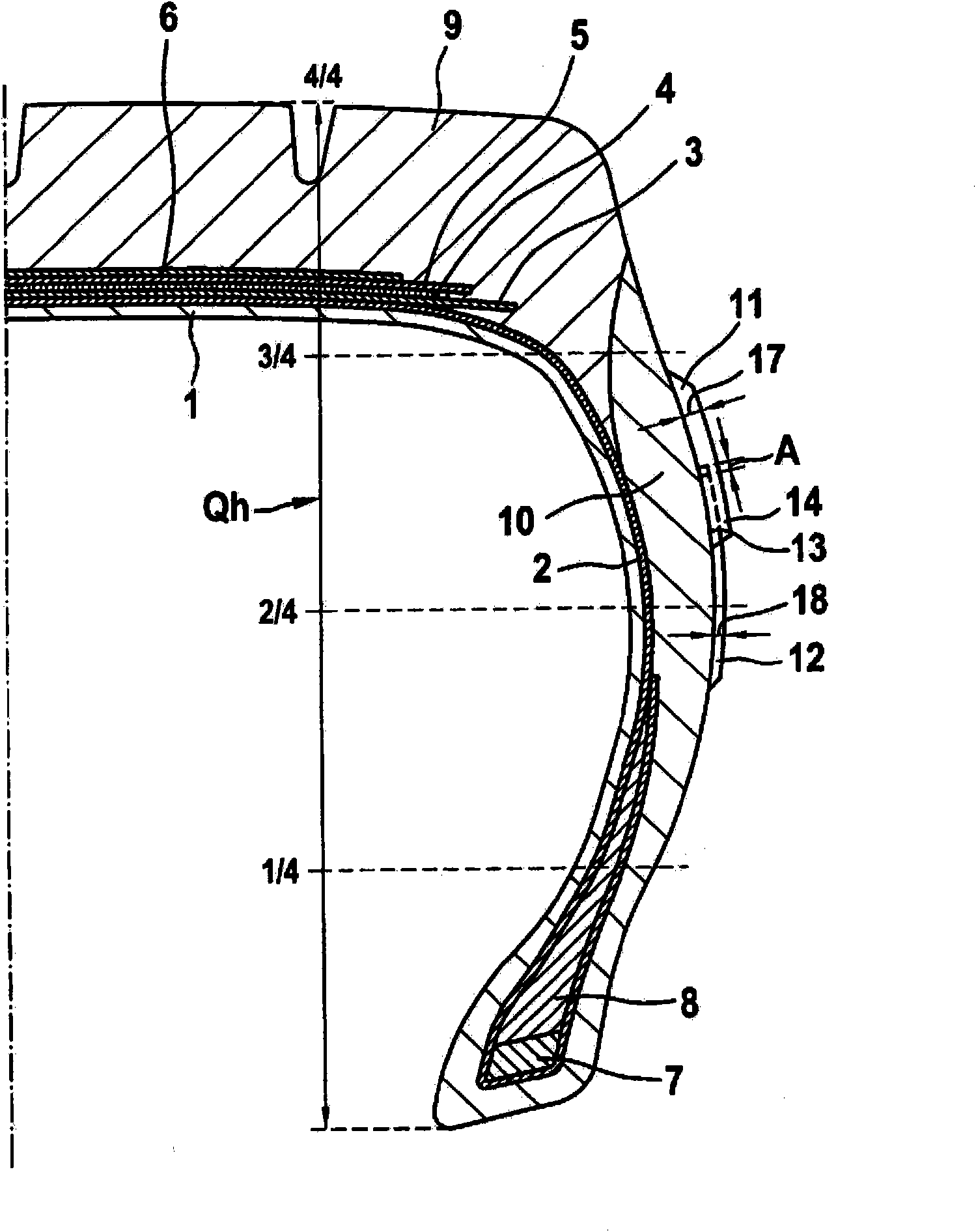

[0037] figure 1 Shown is a section through a tire of a commercial vehicle, the tire having a sealed inner layer 1, a carcass 2 (the carcass has in particular steel cords as reinforcing elements), the tire also has four A breaker belt assembly of the plies 3, 4, 5 and 6, sidewalls 10, bead regions with bead cores 7 and bead fillers 8, and a shaped crown 9. The carcass 2 is a radial carcass, the steel cords of which run substantially parallel to each other in radial direction from bead area to bead area. In the case of the embodiment represented, this fourth, radially outermost belt ply 6 is the narrowest of all these plies and forms the so-called protective ply. The first belt ply 3 is a barrier ply and the second and third belt plies 4, 5 are so-called working plies. The belt plies 3, 5 and 6 consist of steel cords embedded in a rubber compound, the belt rubber compound, and extend parallel to each other in each of the plies 3, 5 and 6 . The angle formed by the steel cords...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap