Multifunctional long-acting antirust film and preparation method thereof

A multi-functional, manufacturing method technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems that cannot be applied to large-scale equipment occasions, low durability, poor barrier properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

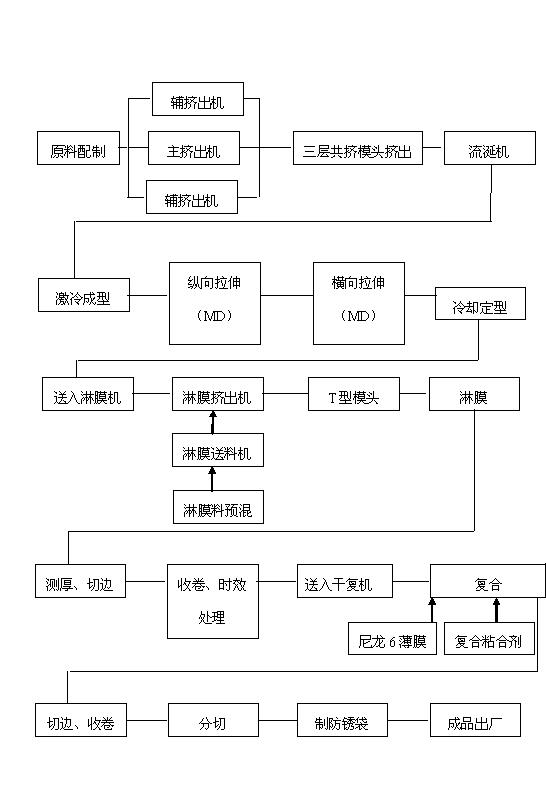

Method used

Image

Examples

Embodiment 1

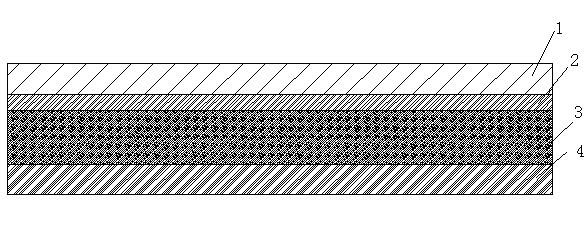

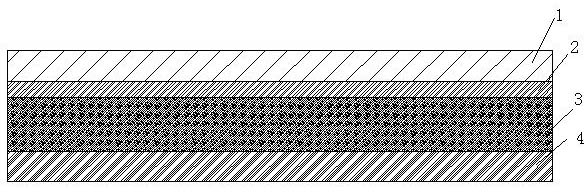

[0042] refer to figure 1 , a multifunctional long-acting antirust film, the multifunctional long-acting antirust film includes a nylon 6 film layer 1, a glue layer 2, an antibacterial agent layer 3 and an antirust agent layer 4; the antibacterial agent layer 3 covers On the antirust agent layer 4, the adhesive layer 2 is covered on the antibacterial agent layer 3, and the nylon 6 film layer 1 is covered on the adhesive layer 2;

[0043] In the multifunctional long-acting antirust film, the nylon 6 film layer 1 accounts for 25-32% of the total mass, the adhesive layer 2 accounts for 6-8% of the total mass, and the antibacterial agent layer 3 accounts for 30-35% of the total mass , the antirust agent layer 4 accounts for 26~35% of the total mass;

[0044] The antirust agent layer 4 includes binary copolymerized PP, thermoplastic elastomer, anti-sticking agent and antirust masterbatch, and the mass-number ratio of the four components is: binary copolymerized PP 23.5~26 parts, th...

Embodiment 2

[0084] refer to figure 1 , in the present embodiment, in the multi-functional long-acting antirust film, the nylon 6 film layer 1 accounts for 28% of the total mass, the adhesive layer 2 accounts for 7% of the total mass, and the antibacterial agent layer 3 accounts for 32.5% of the total mass , the antirust agent layer 4 accounts for 32.5% of the total mass;

[0085] Other schemes and working process of this embodiment are all the same as in Embodiment 1.

Embodiment 3

[0087] refer to figure 1 , in the present embodiment, in the multifunctional long-acting antirust film, the nylon 6 film layer 1 accounts for 30% of the total mass, the adhesive layer 2 accounts for 7.5% of the total mass, and the antibacterial agent layer 3 accounts for 32% of the total mass , the antirust agent layer 4 accounts for 30.5% of the total mass;

[0088] Other schemes and working process of this embodiment are all the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com