Combined bonding-free machine head

A combined, non-adhesive technology, applied in the direction of textiles and papermaking, rope-making auxiliary devices, textile cables, etc., can solve the problems that are not easy to find, not suitable for quick replacement of multiple models, and the structure of the non-adhesive machine head is single and other issues, to achieve the effect of facilitating popularization and implementation, simple structure, and easy manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

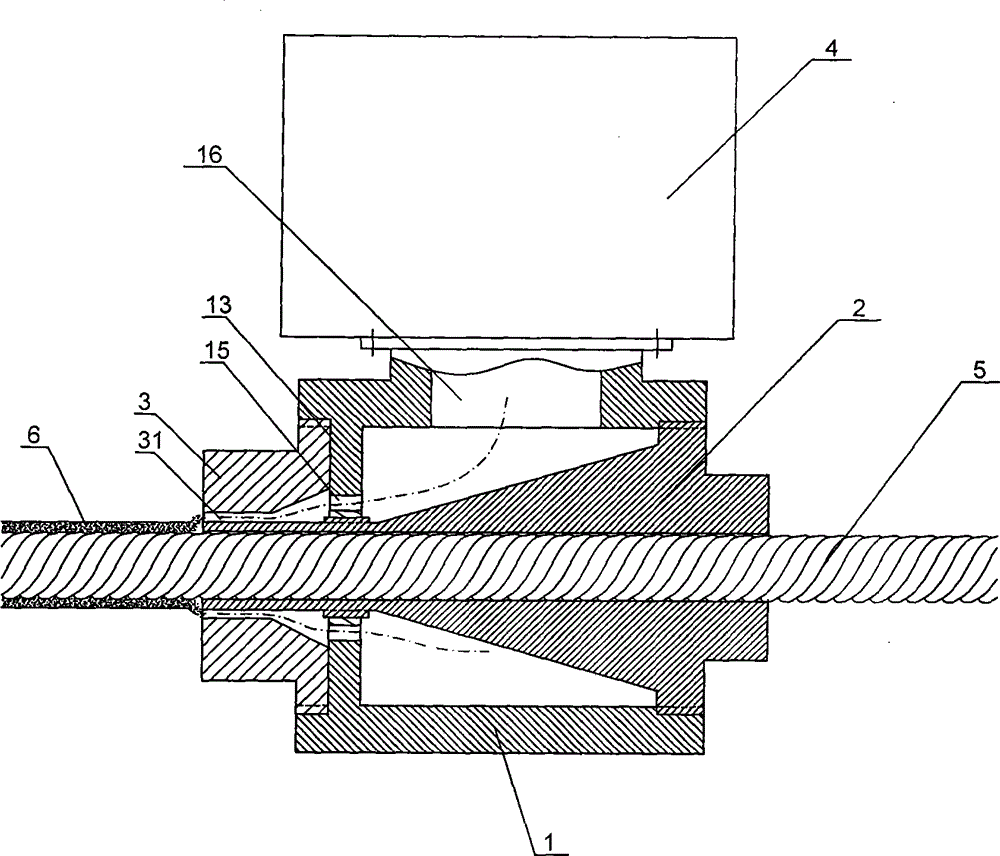

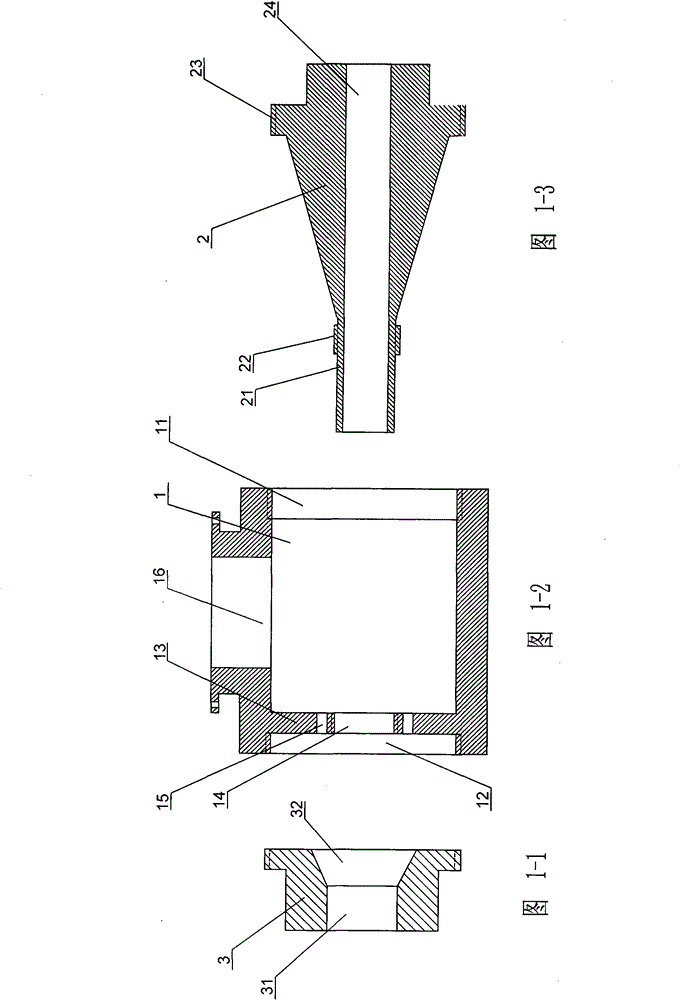

[0014] Embodiment one: see figure 1 , Picture 1-1 , Figure 1-2 , Figure 1-3 , a combined non-bonding head.

[0015] Number 1 in the figure is the cylindrical machine head shell, 2 is the movable inner sleeve, 3 is the movable spout head, 11 is the rear internal thread section, 12 is the front internal thread section, 13 is the partition, 14 is the threaded through hole, 15 is the glue outlet hole, 16 is the glue inlet, 21 is the sizing port, 22 is the front end external thread, 23 is the rear end external thread, 24 is the cable perforation, 31 is the sizing port, 32 is the tapered enlarged port , 33 are external threads.

[0016] There is a glue inlet at the upper end of the non-bonded machine head, which communicates with the glue storage chamber at the upper end. The machine head is a combined type, including three parts: a horizontal cylindrical machine head shell 1, a movable inner sleeve 2, and a movable spouting head 3. The movable inner sleeve 2 and the movabl...

Embodiment 2

[0019] Embodiment 2: The drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that there is a glue inlet at the upper end of the non-bonded machine head, which communicates with the glue storage chamber at the upper end. The machine head is a combined type, including three parts: a horizontal cylindrical machine head shell, a movable inner sleeve, and a movable spouting head. The movable inner sleeve and the movable glue applicator are respectively located at the rear side and the front side of the cylindrical head shell. In this embodiment, the cylindrical nose shell, the movable inner sleeve, and the movable ejection head are not fixed by screw connection, but by flange connection.

[0020] Wherein the inner cavity of the cylindrical housing is provided with a partition near the front end, and a through hole is arranged in the center of the partition, and a certain number of glue o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com