Water-swelling rubber water bar fixing method

A water-swellable rubber and fixing method technology, which is applied in the direction of construction and building construction, can solve the problems of difficult to ensure the quality of fixing, high concrete strength of the lower layer, and difficulty in nailing cement nails, etc., and achieves easier quality assurance, cost saving, The effect of convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in detail below in conjunction with accompanying drawing.

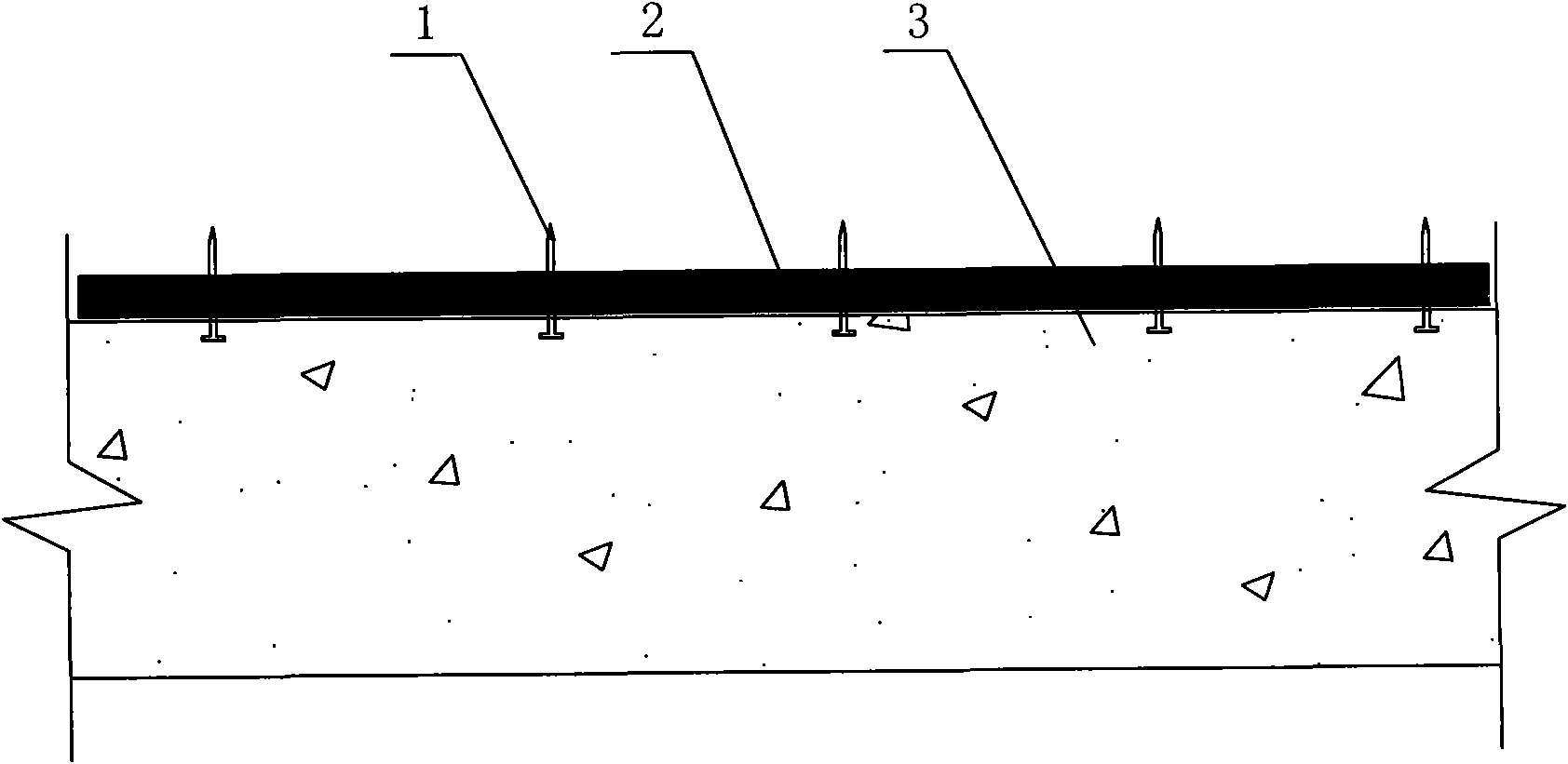

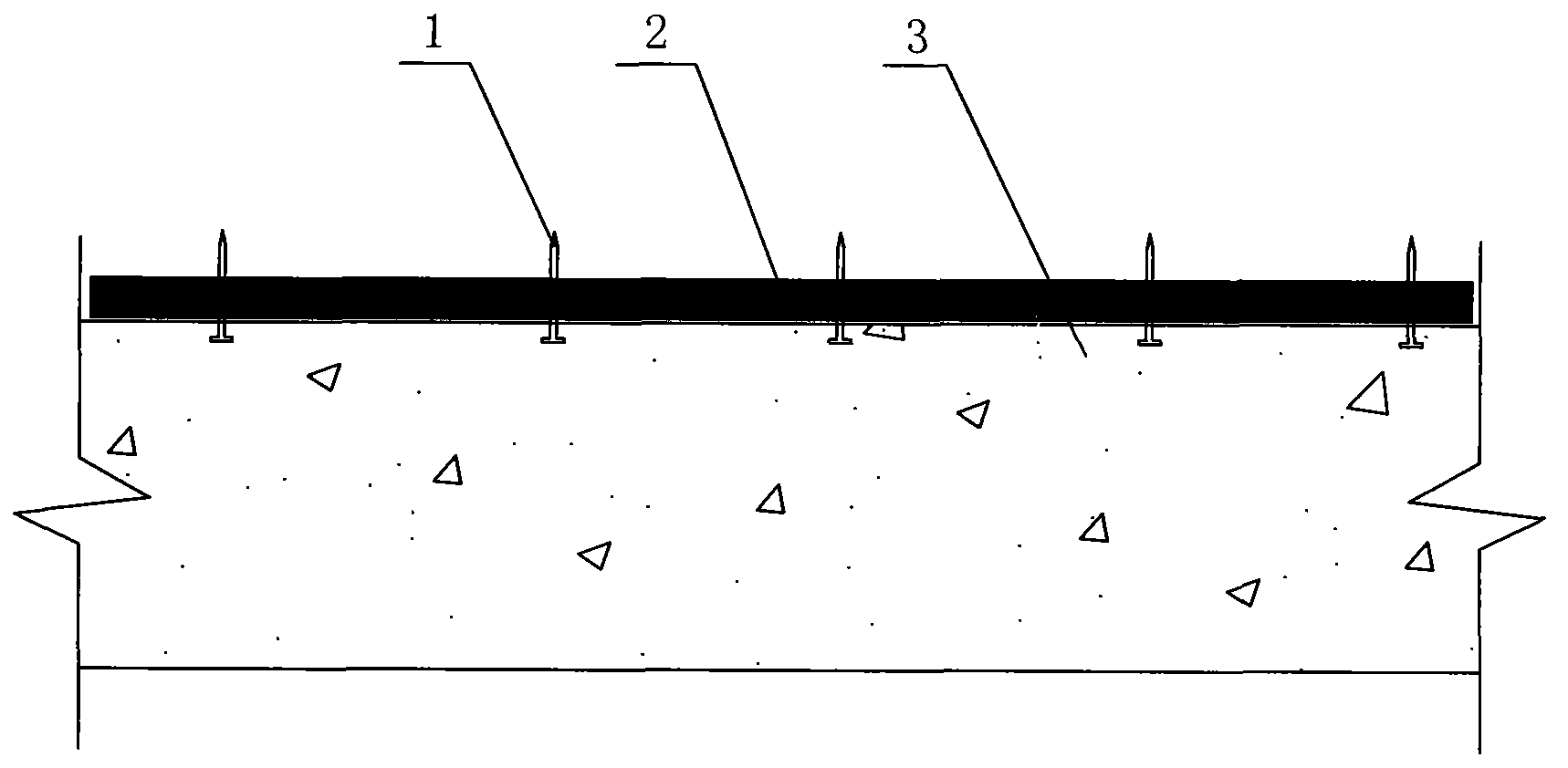

[0014] see figure 1 , the method for fixing the water-swellable rubber waterstop of the present invention is carried out as follows:

[0015] a. Prepare steel nail 1 with a length of 55mm;

[0016] b. When the concrete of the lower layer has just been poured, smooth the surface of the concrete structure construction joint 3, and then insert a steel nail 1 along the center line of the concrete structure construction joint 3 at intervals of 800-1000 mm, with the nail point facing upwards. The steel nail 1 Embed 15mm below the concrete surface and expose 40mm on the concrete surface;

[0017] c. When the concrete is solidified and the strength is sufficient, press the water-expandable rubber water-stop strip 2 firmly, so that the steel nail 1 is inserted into the water-expandable rubber water-stop strip 2, and the lower surface of the water-expandable rubber water-stop strip 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap