Connecting structure of engine camshaft cover and cylinder cover

A technology of cylinder head cover and connection structure, which is applied to the sealing device of the engine, engine components, machines/engines, etc. It can solve the problems of higher precision requirements and large pressure changes, so as to improve the sealing performance, increase the surface pressure, Effect of improving NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

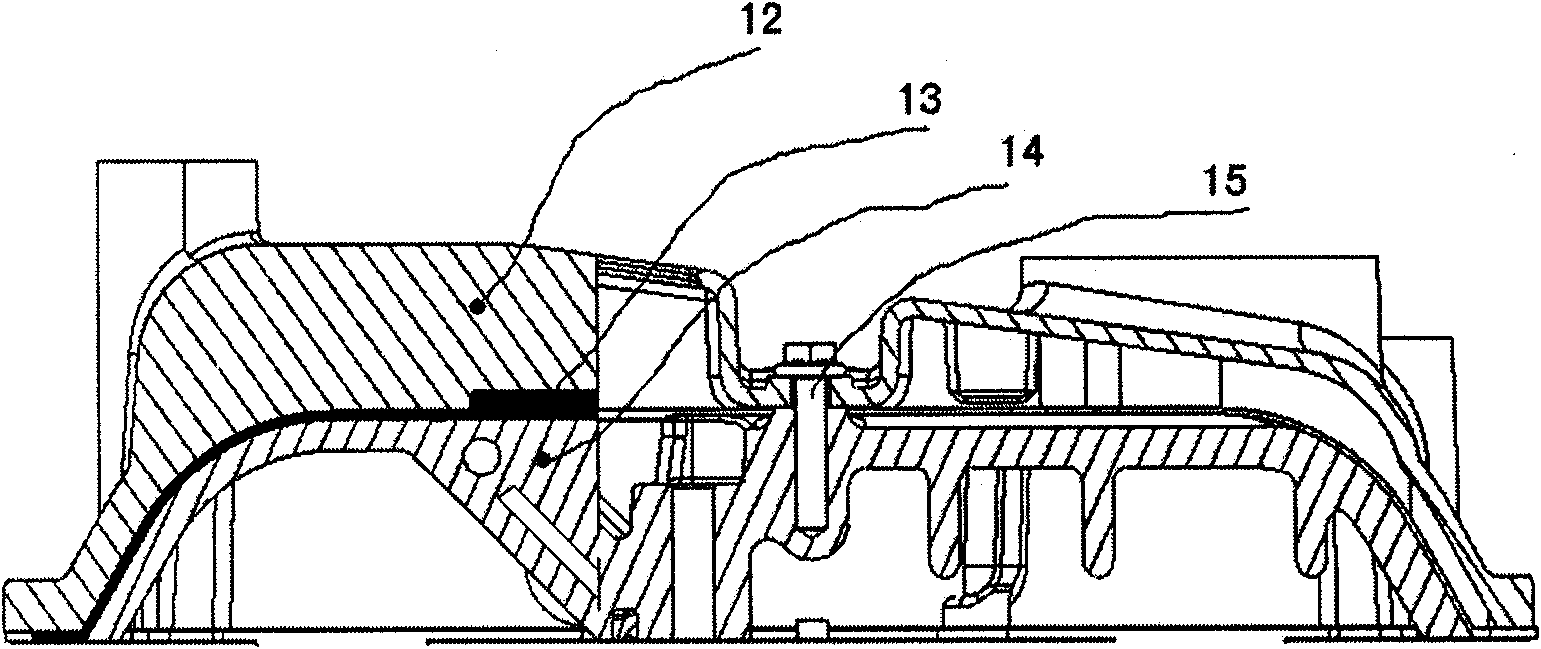

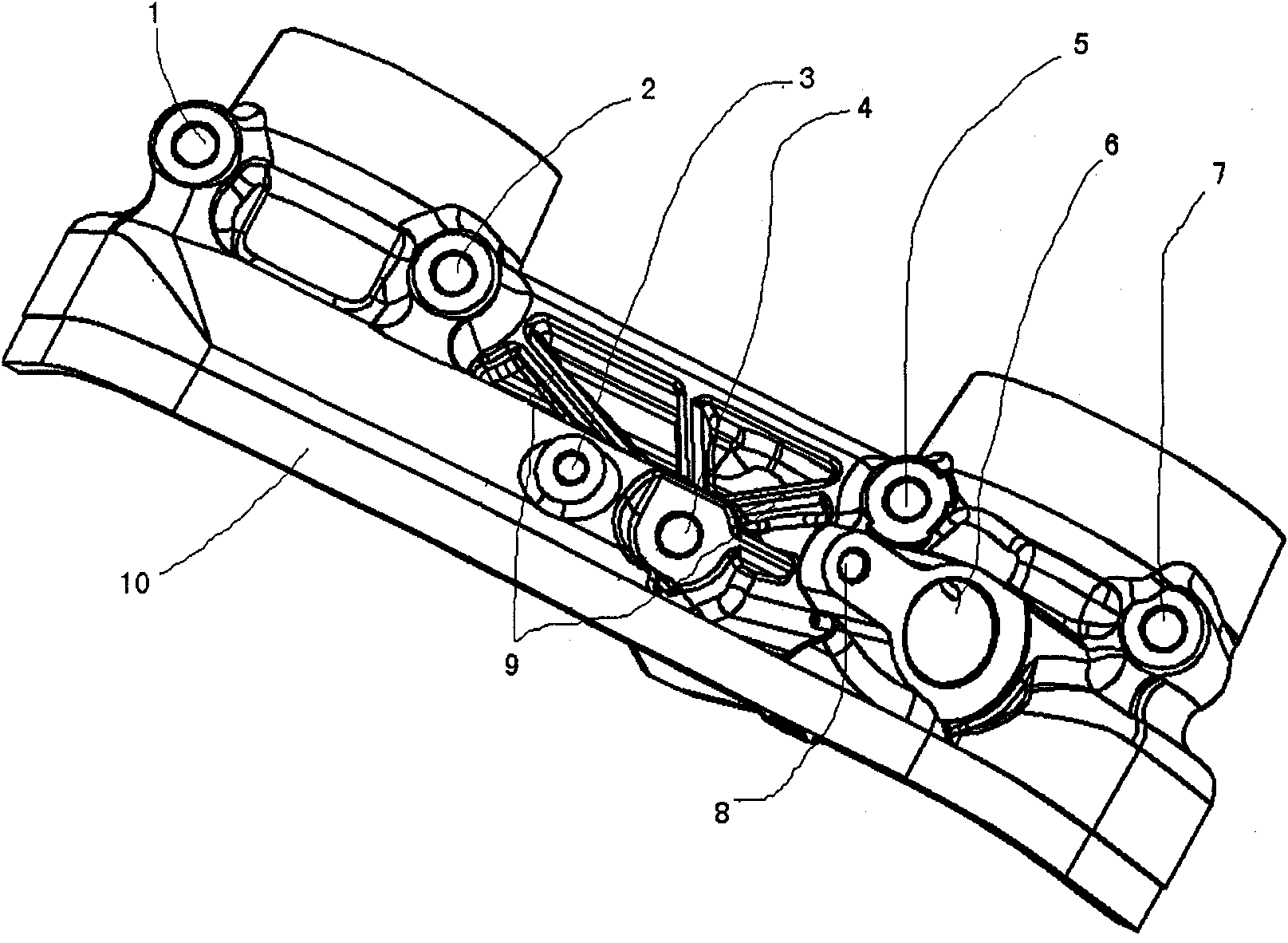

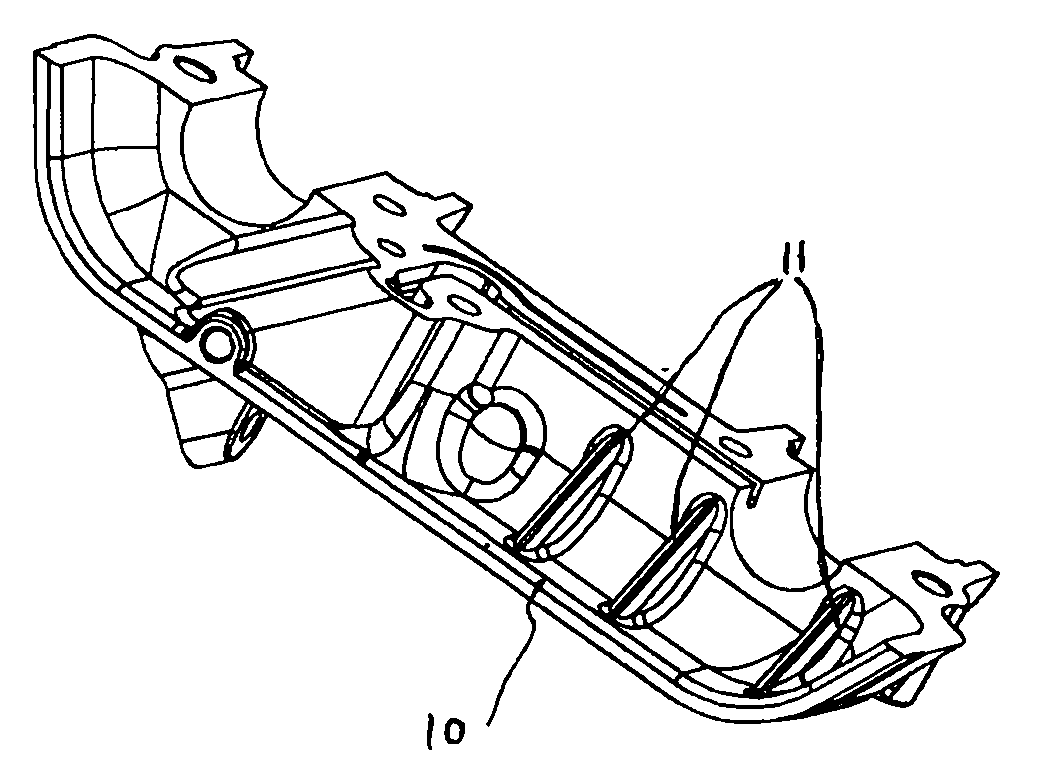

[0013] The structure of the present invention is further described in detail below with the connection of the No. 1 bearing cap of the engine camshaft of the VVT on the single intake side and the cylinder head cover as an example:

[0014] Such as figure 1 As shown, a gasket 13 is arranged between the shaft cover 14 and the cylinder head cover 12 of the present invention. Generally, the cylinder head cover 12 and the shaft cover 14 are independently fixed on the upper surface of the cylinder head. When considering the cumulative tolerance, the shaft cover and the There will be a situation where the gasket cannot be fully compacted between the cylinder covers. Such as figure 1 and figure 2 As shown, the shaft cover 14 of the present invention is designed with bolt holes 1, 2, 3, 4, 5 and 7, and the shaft cover 14 and the cylinder head cover 12 are connected by bolts 15. Compared with the general design method, the shaft cover 14 and the cylinder head cover 12 can effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com