Metallic heat exchanger tube

An exchanger tube, metal heat technology, applied in heat exchange equipment, indirect heat exchangers, metal processing equipment, etc., can solve problems such as unfavorable blocking of heat transfer, and achieve the effect of reducing dangerous potential and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Mutually corresponding parts are represented by the same example in all figures.

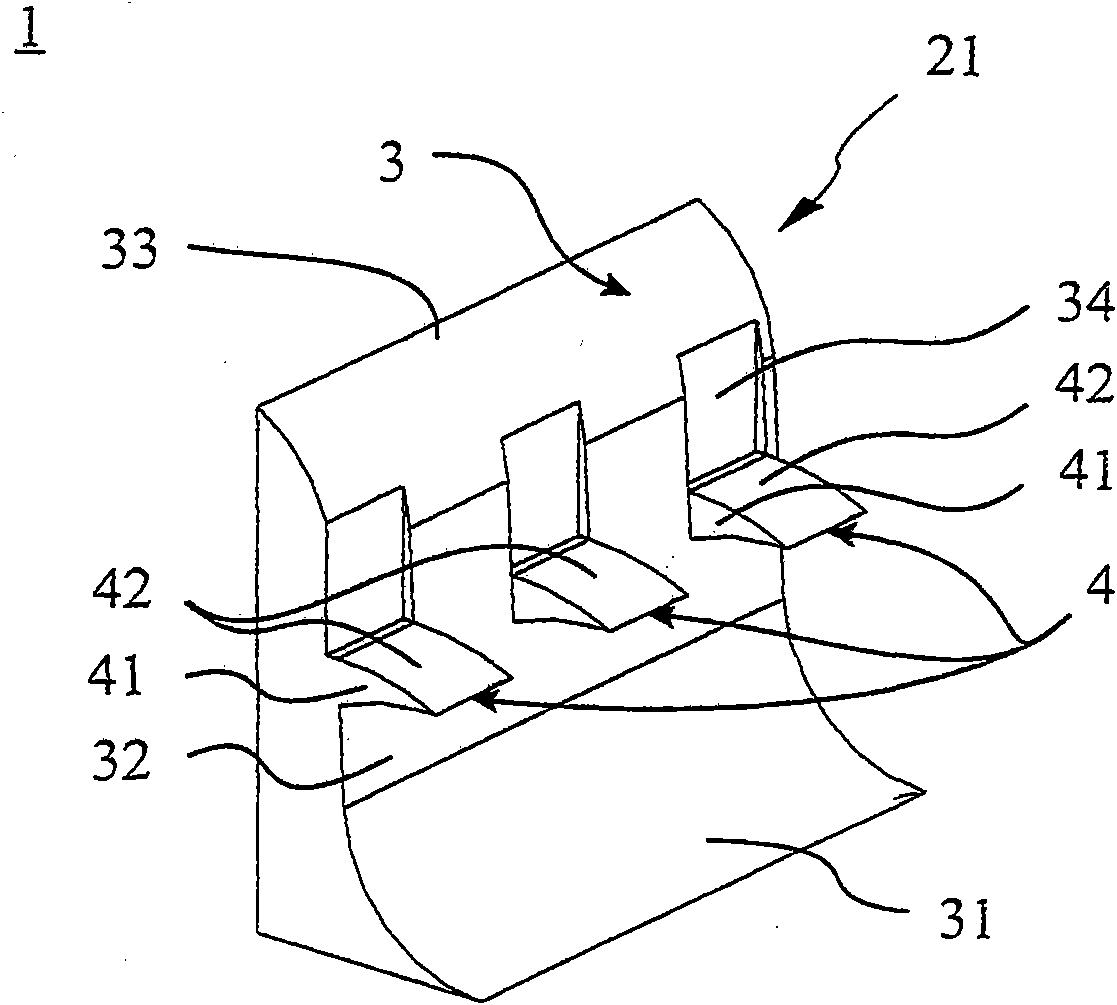

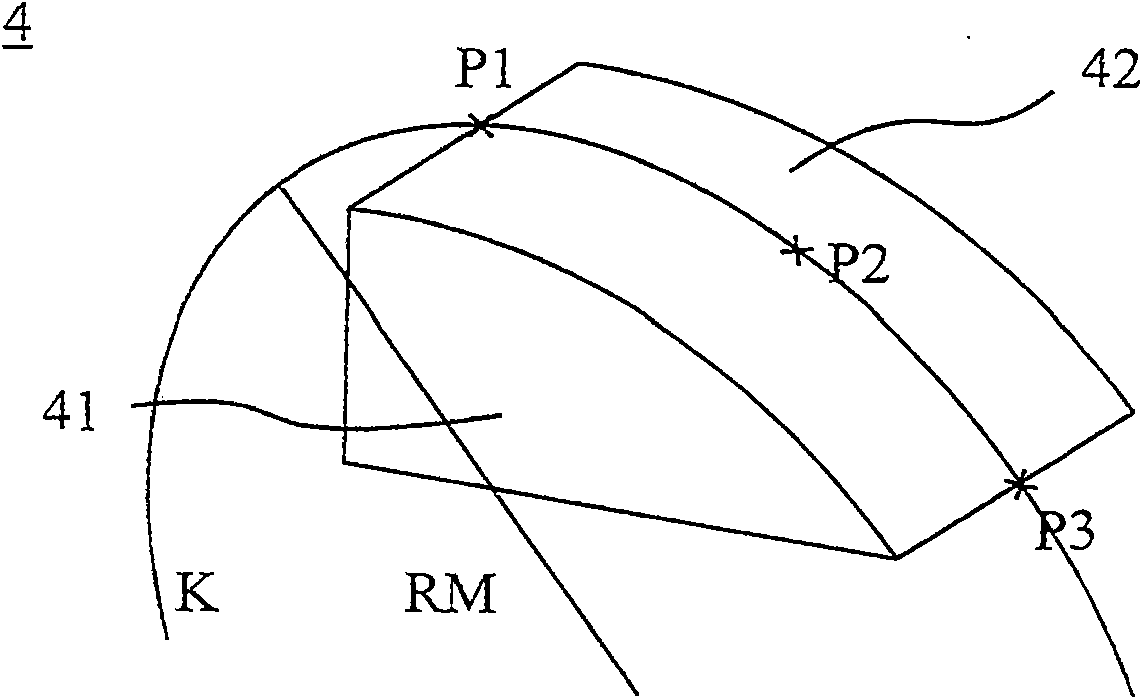

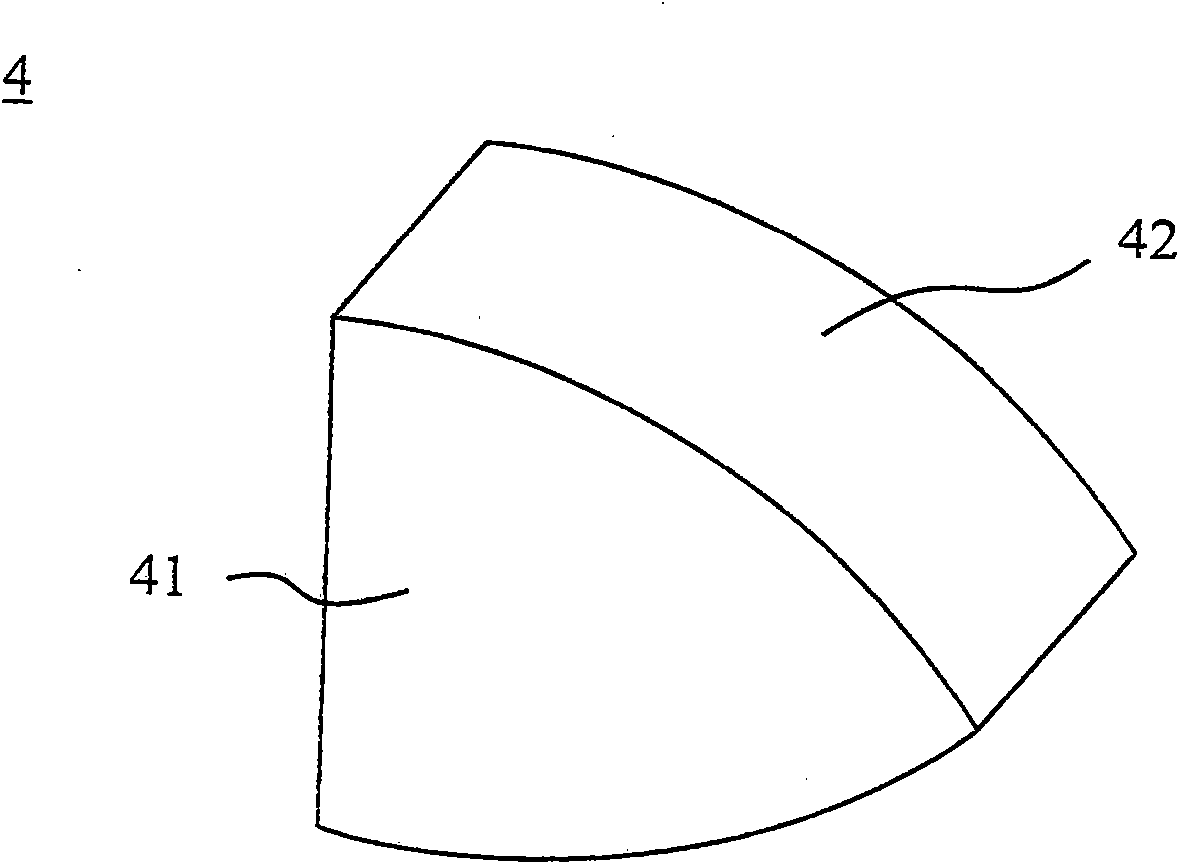

[0037] figure 1 A perspective sectional view showing a rib section of a heat exchanger tube with three material projections 4 . The surrounding, integrally formed rib 3 is only partially formed from the tube outer side 21 . The rib 3 has a rib foot 31 , which is placed against the tube wall shown in the illustration here, a rib side wall 32 and a rib tip 33 . The ribs 3 are at a substantially radial distance from the pipe wall. The rib side wall 32 is equipped with an additional structural element, which is formed by a material projection 4 , which is placed laterally on the rib side wall 32 . The material projections 4 have delimiting surfaces 41 and 42 . In the embodiment formed, the three illustrated limiting surfaces 42 of the material projection 4 are curved convexly on the side facing the tube wall. In principle, however, according to the invention each material projection part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com