Operational method for lifting lead wire of aerial lift device with insulating arm

A technology of insulated bucket arm truck and insulated arm, which is applied to the installation of cable installation devices, electrical components, cables, etc., can solve the problems of necessary power failure poles, etc., and achieve insulation isolation measures in place, clear steps, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

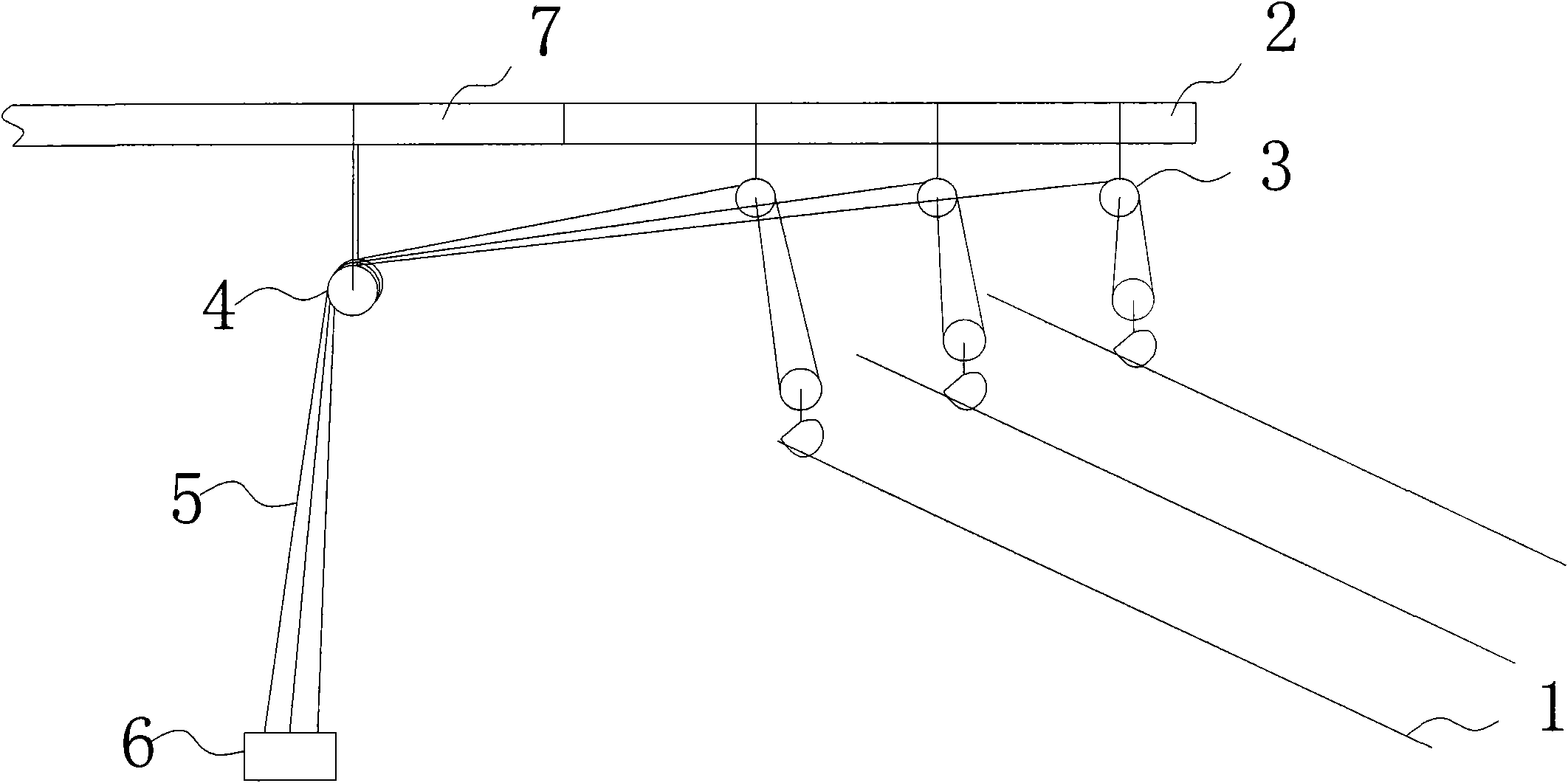

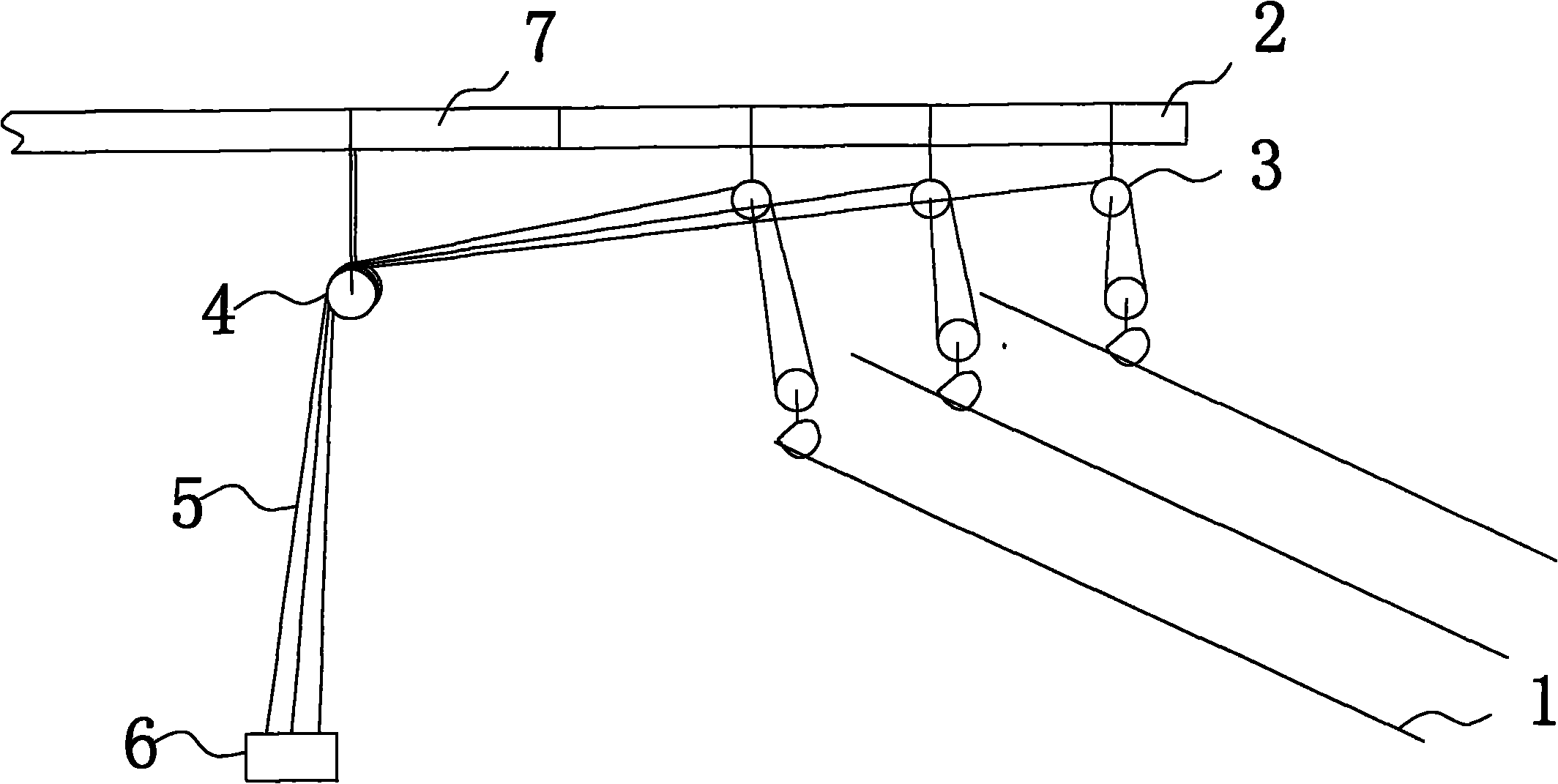

[0012] see figure 1 , the insulated bucket arm truck lifting wire operation method of the present invention comprises the following steps:

[0013] Install the three go-a-go-one insulating pulley blocks 3 on the insulating arm 2 of the 26m bucket arm truck respectively, the distance between the three go-go-go-one insulating pulley blocks 3 is 1m, and then control the bucket arm car to adjust the insulating arm to the wire 1 2m above, install a guide insulating pulley block 4 composed of three insulating pulleys side by side on the metal arm 6m away from the top of the insulating arm, and pass the insulating tail rope 5 of the insulating pulley block 3 through the guide in turn. Insulated pulley block 4, the top of the insulating tail rope 5 is provided with a boom tackle; put an insulating sleeve on the place where the wire 1 is lifted, place the wire 1 in the boom tackle, close the safety, and pull down the insulation tail rope 5 The other end of the wire 1 is slowly lifted ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap