Motor-driven control chip provided with ESD circuit

A control chip and motor control technology, which is applied to emergency protection circuit devices, electrical components, circuit devices, etc. for limiting overcurrent/overvoltage, and can solve problems such as correct signal transmission and failure of the motor speed output terminal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

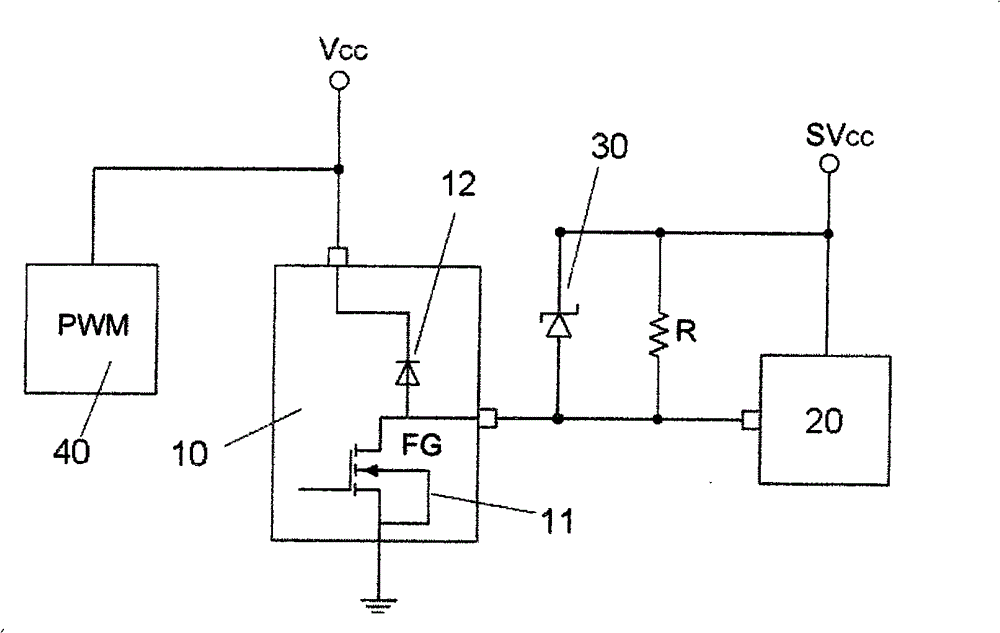

[0017] The control chip driven by the single-phase motor of the present invention is in its V CC The terminal is used for PWM control, and the motor rotation signal needs to be output from the FG pin to the control board, so that the control board can correctly control the motor. At the same time, because the voltage design between the single-phase motor drive control chip and the control board is not necessarily the same, the FG pins are designed as open drain or open collector circuits. However, the circuit structure of open drain or open collector cannot achieve ESD protection, so the ESD protection of the PWM control chip is relatively weak.

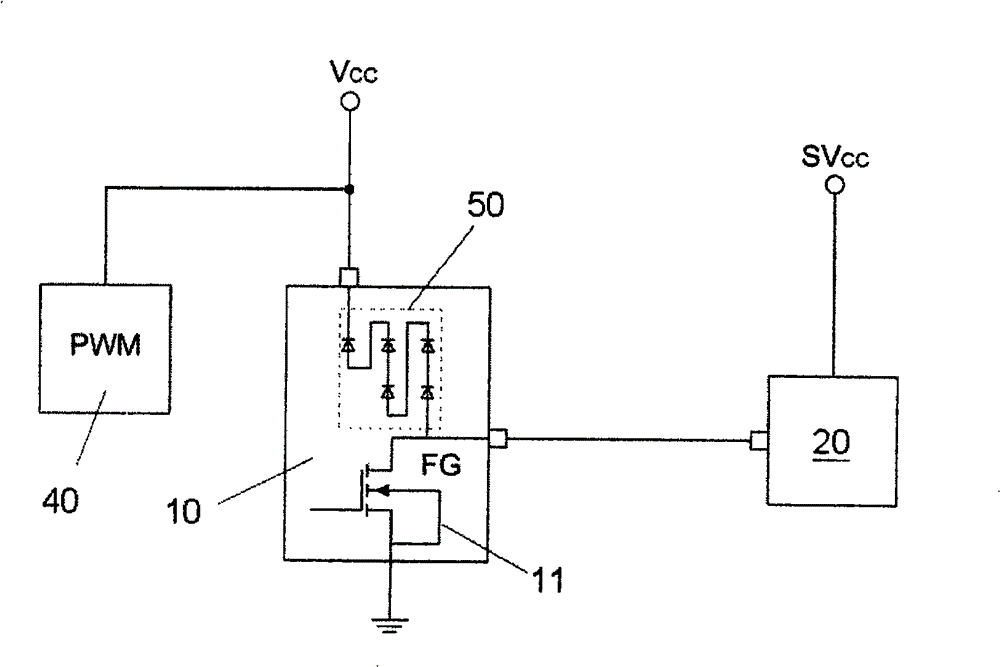

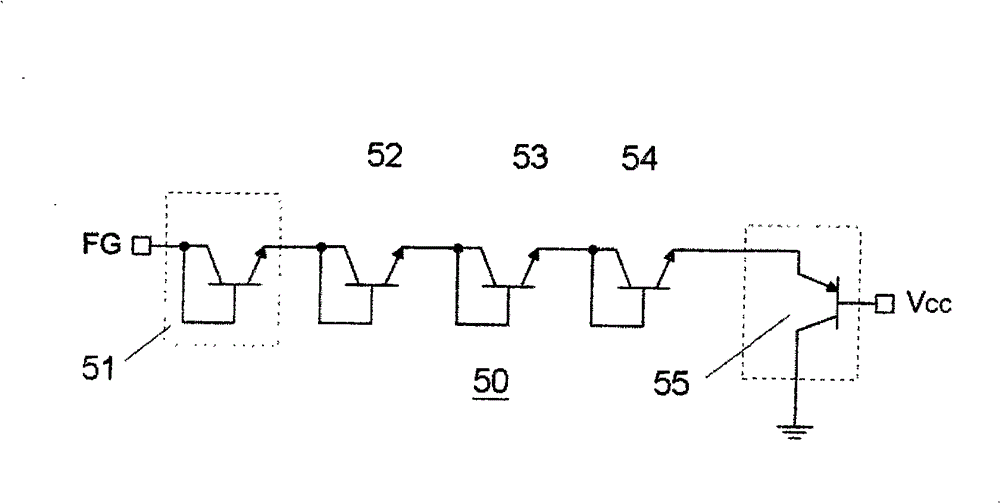

[0018] According to above-mentioned situation, the present invention is in the V of the control chip driven by single-phase motor CC An ESD (Electrostatic Discharge) circuit is arranged between the voltage terminal and the output terminal (FG) of the single-phase motor speed, such as figure 2 Shown, where the structure of the ESD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com