Four-head planet dual-operation grinding machine

A mechanical and planetary technology, applied in the field of four-head planetary double-running grinding machinery, can solve the problems of low mechanical efficiency of single disc, difficult mechanical operation, increased labor intensity, etc., to improve work efficiency and standards, easy mechanical operation, and faster The effect of large sanding width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

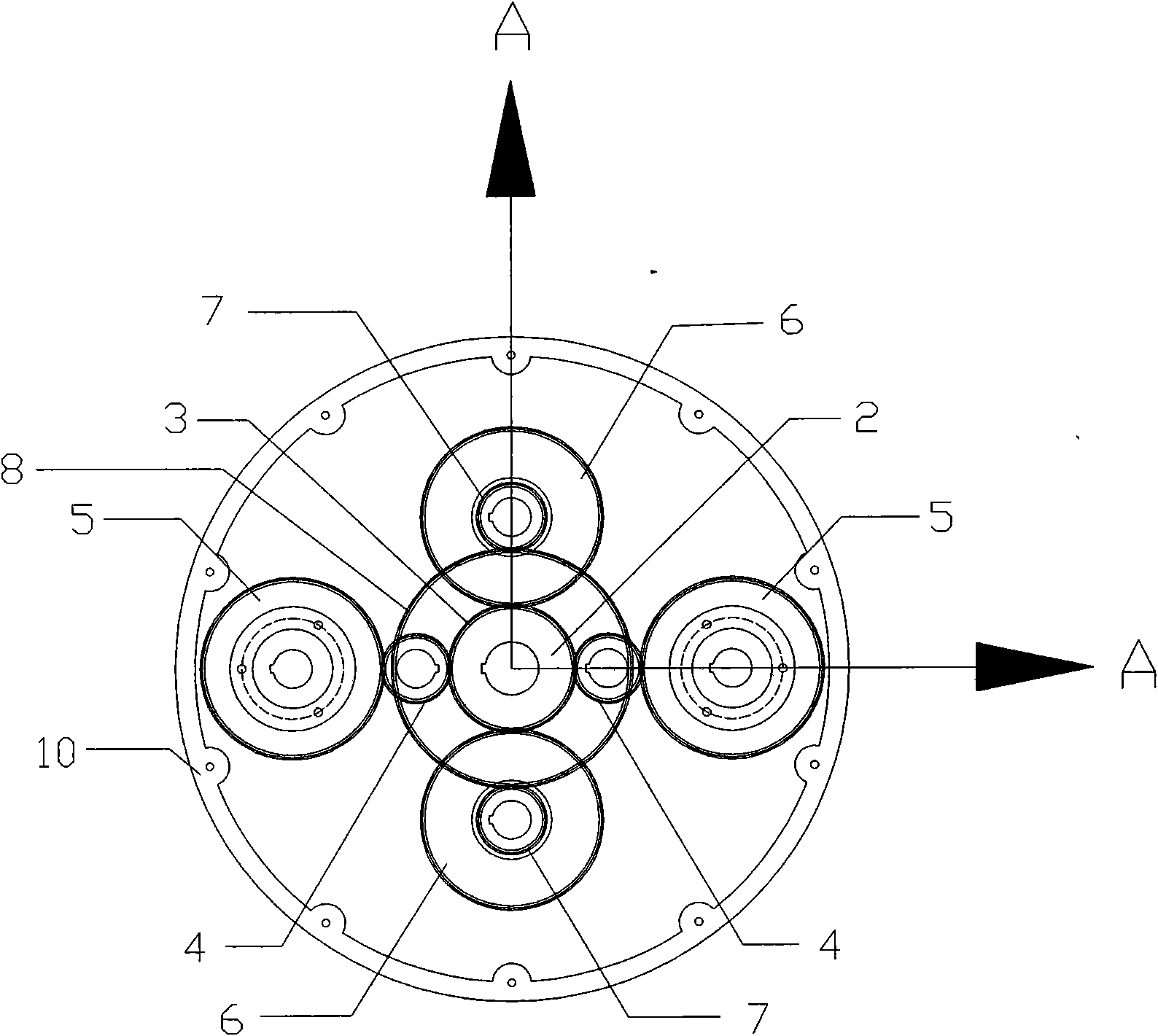

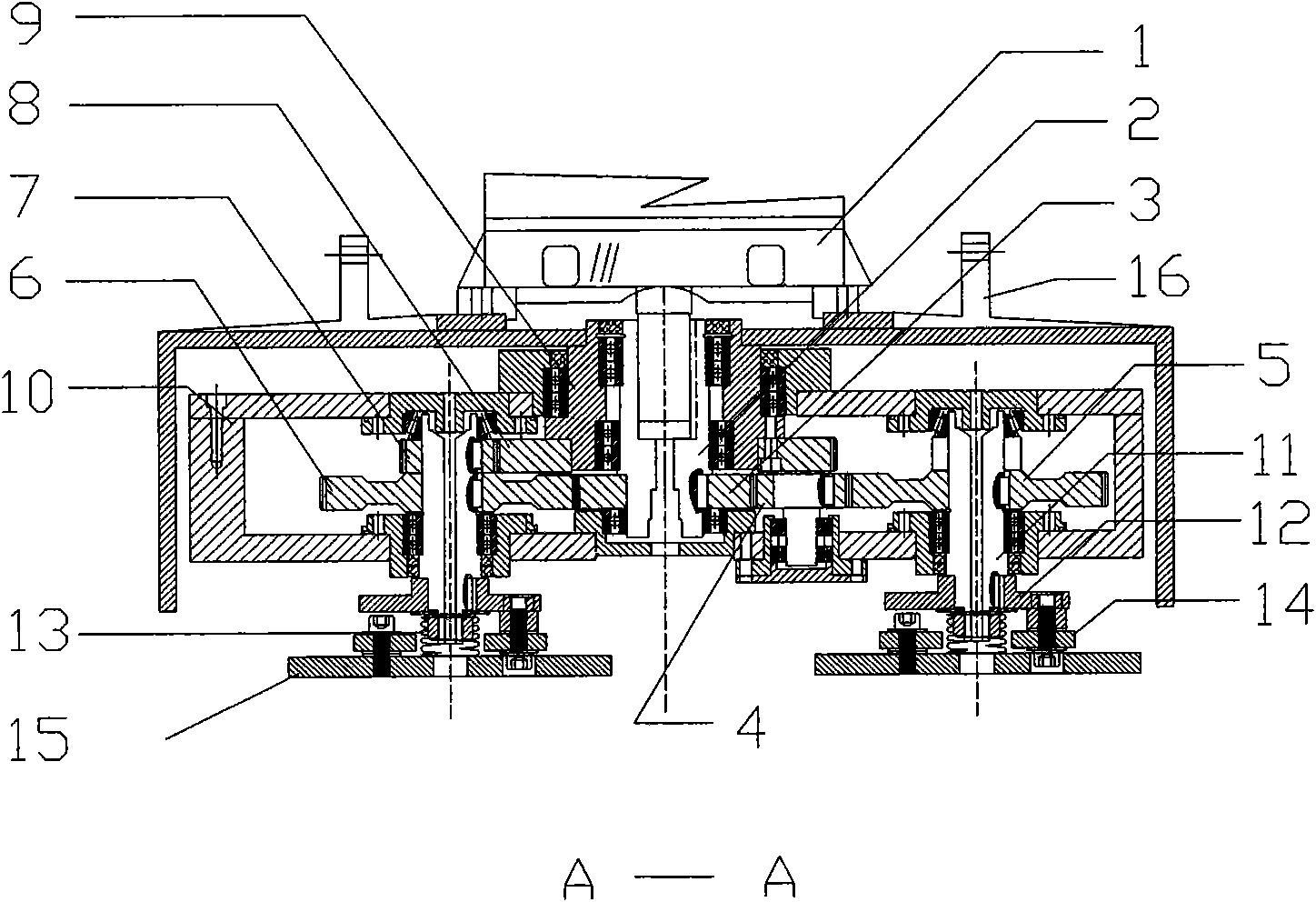

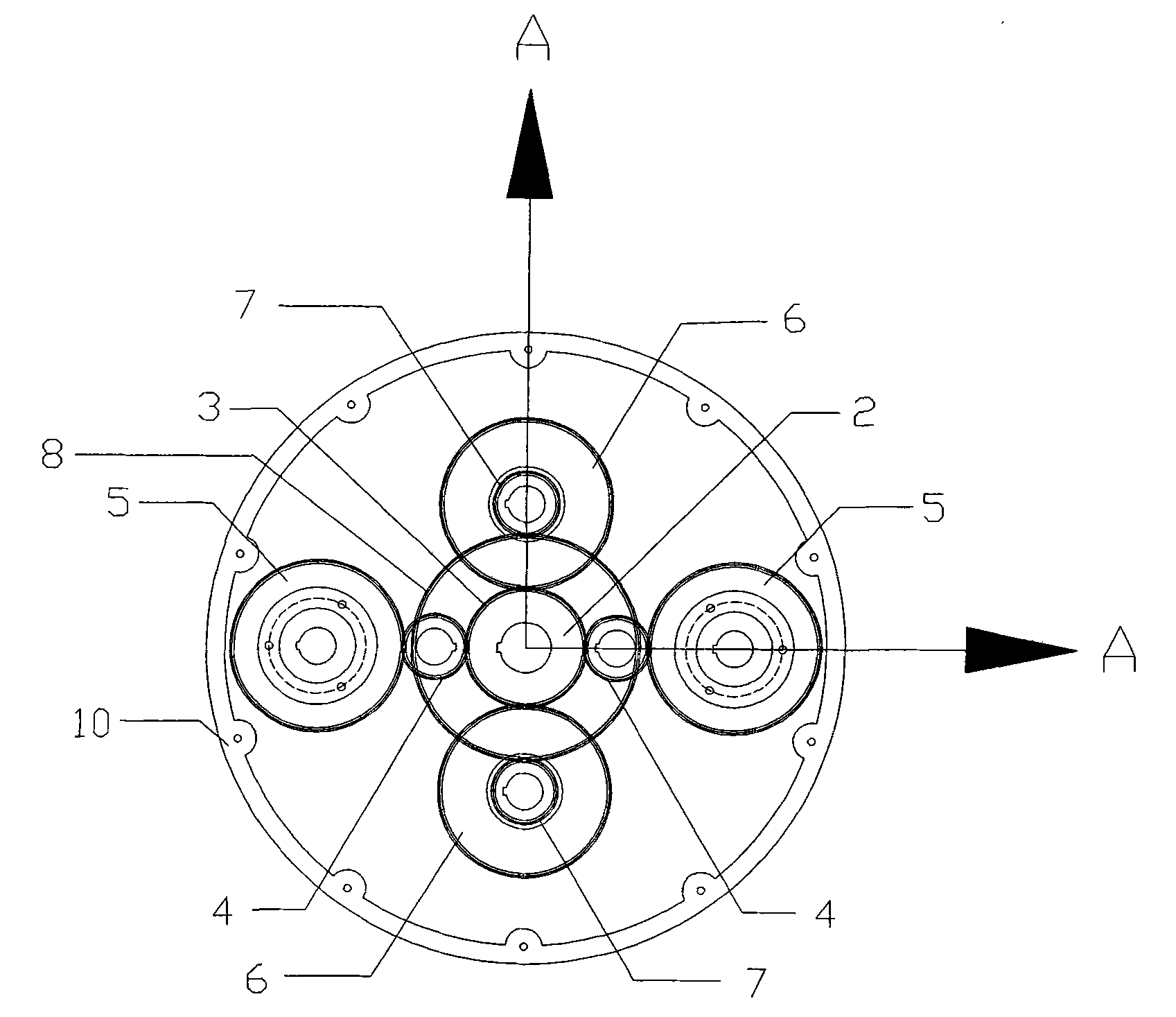

[0015] Attached below figure 1 with figure 2 Further explain how the present invention is realized:

[0016] Such as figure 1 and figure 2 As shown, the four-head planetary double-running mechanical grinding head is composed of a motor, a motor base, a gear box, and a grinding disc. The four transmission gear shafts are connected to the four grinding discs. The motor 1 is fixedly connected to the motor base 16, the motor transmission shaft is connected to the main rotating shaft 2, the main transmission gear 3 is fixed on the main transmission shaft, the main transmission gear 3 is engaged with two transition gears 4 and two transmission gears 6 at the same time, and the transition gear 4 meshes with transmission gear 5 again. A planetary gear 7 is installed on the transmission gear 6, and the planetary gear 7 is engaged with the sun gear 8, and the sun gear 8 is fixed on the sun gear base 9 (the sun gear base is in a positioning state). The rotation of the motor 1 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com