Belt type steering loader

A technology of loading and unloading machine and rotating arm, applied in the directions of loading/unloading, transportation and packaging, which can solve the problems of physical exhaustion, inability to turn, time-consuming, etc., and achieve the effect of utilizing site space and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

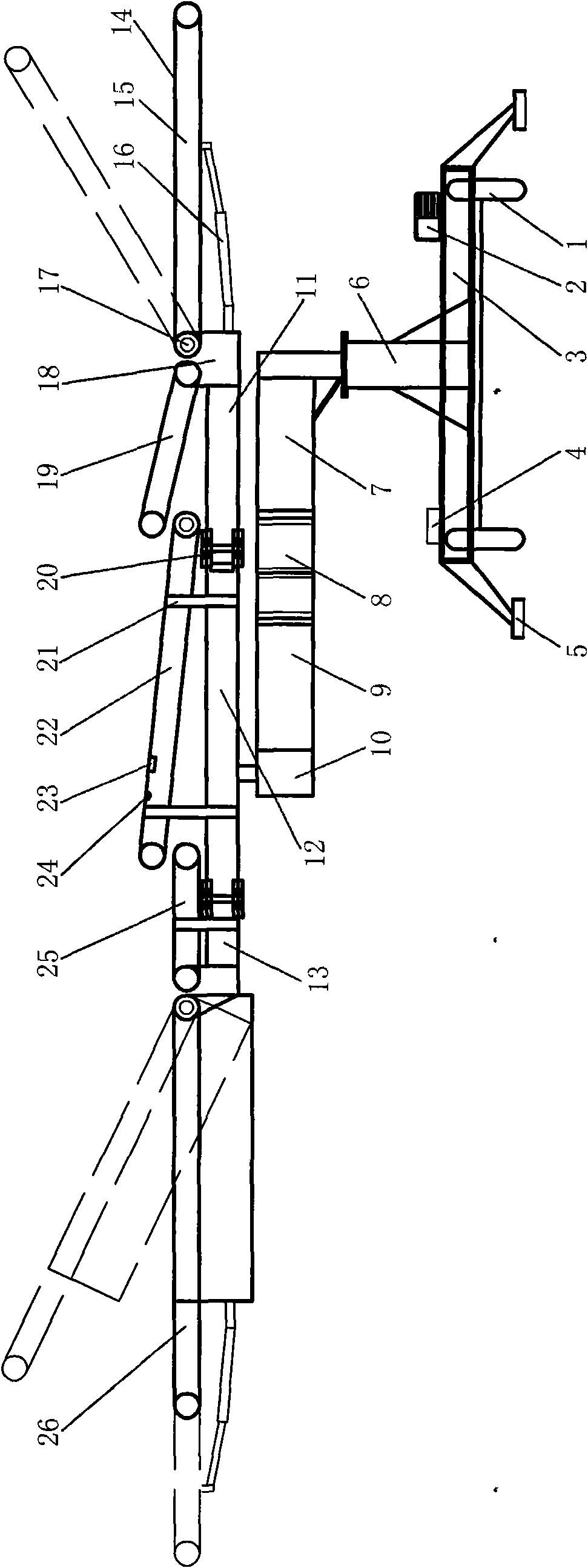

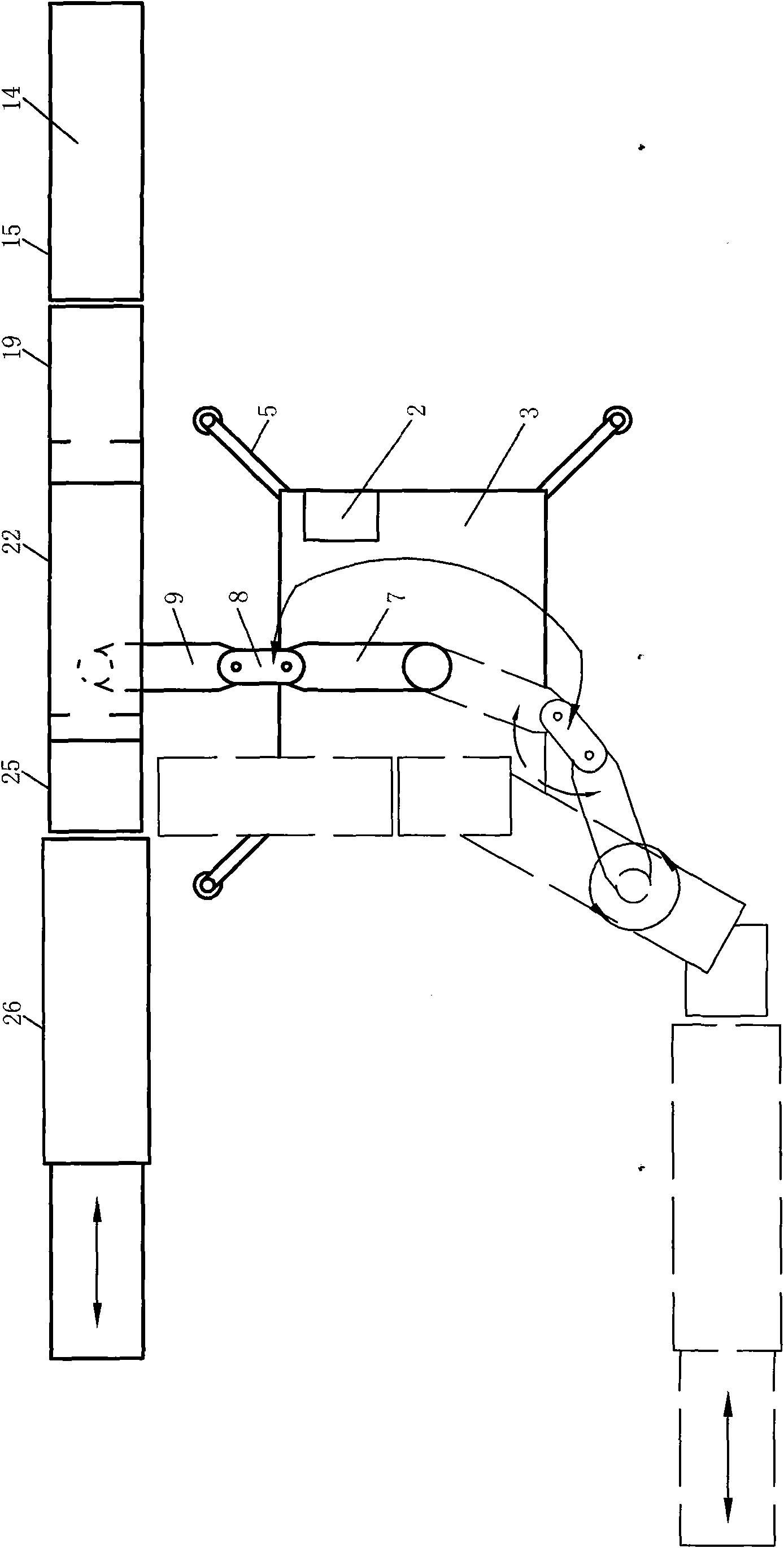

[0012] As shown in the figure: the front conveying arm 26 telescopic conveyor belt and the sleeve-type pull-out structure are the same as the prior art. The base of the loading and unloading machine is composed of wheels 1, four-corner support legs 5 and a counterweight chassis 3. The center of the counterweight chassis 3 is provided with a supporting main shaft 6. The main shaft 6 and the swing arm adopt a shaft and bearing down-pressing insertion structure. Arm 7 and outer swing arm 9 are formed, and gear set 8 is set between inner swing arm 7 and outer swing arm 9, and gear set 8 has four gears meshing and rotating, forming the bending joint of inner swing arm 7 and outer swing arm 9. The outer swing arm 9 is connected to the main rotating arm 12 through the vertical shaft 10, and the rear end of the main rotating arm 12 is connected to the rear rotating arm 11 through a movable joint 20. Arm 15 and secondary conveying arm 19, rear conveying arm 15 and secondary conveying a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com