Preparation method for matricial ultra-temperature ceramic composite material of zirconium boride-silicon carbide

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of composite materials and can solve problems such as low strength and fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

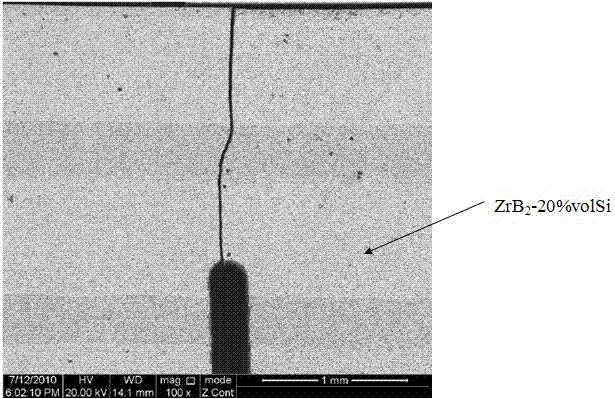

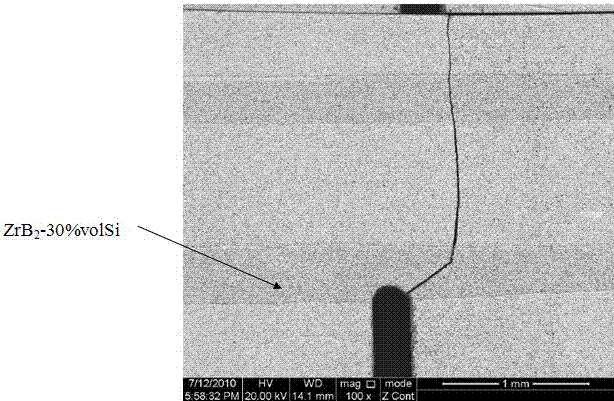

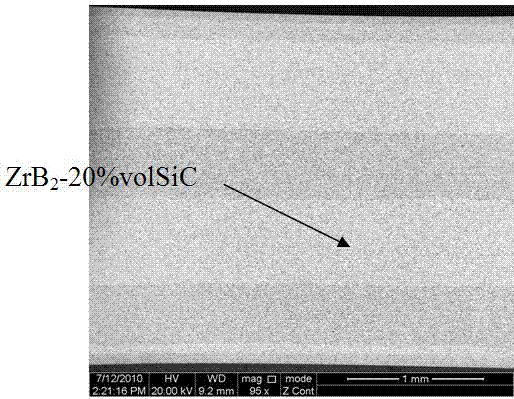

[0009] Specific embodiment one: the preparation method of the zirconium boride-silicon carbide layered ultra-high temperature ceramic composite material in this embodiment is as follows: 1. 20 parts by volume of α-SiC powder and 80 parts of ZrB 2 Mix powders, add absolute ethanol, the amount of absolute ethanol added is 70% to 75% of the volume percentage of the total amount of α-SiC powder, ZrB2 powder and absolute ethanol, and then perform constant temperature ball milling at 20 to 30°C for 10 to 15 hours Hours, then dry at 70-80°C, with a rotation speed of 30r / min-60r / min, and sieve to obtain ZrB with a particle size of 200-300 mesh 2 -20% volSiC powder; Two, 30 parts by volume of α-SiC powder and 70 parts of ZrB 2 Mix powders, add absolute ethanol, the amount of absolute ethanol added is 70% to 75% of the volume percentage of the total amount of α-SiC powder, ZrB2 powder and absolute ethanol, and then perform constant temperature ball milling at 20 to 30°C for 10 to 15 hou...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment is different from Embodiment 1 in that the release agent described in step 3 is boron nitride. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the addition of dehydrated alcohol in step 1 is 72% of the volume percentage of the total amount of α-SiC powder, ZrB2 powder and dehydrated ethanol. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com